4 Axis CNC Milling: Unlocking Precision for Complex Parts

Introduction

Computer Numerical Control (CNC milling) has revolutionized manufacturing, offering unmatched precision in producing complex parts. Among advanced CNC technologies, 4 Axis CNC milling excels by handling intricate geometries efficiently. Its unique capability to rotate components along four axes enhances precision and versatility, making it crucial across various manufacturing sectors.

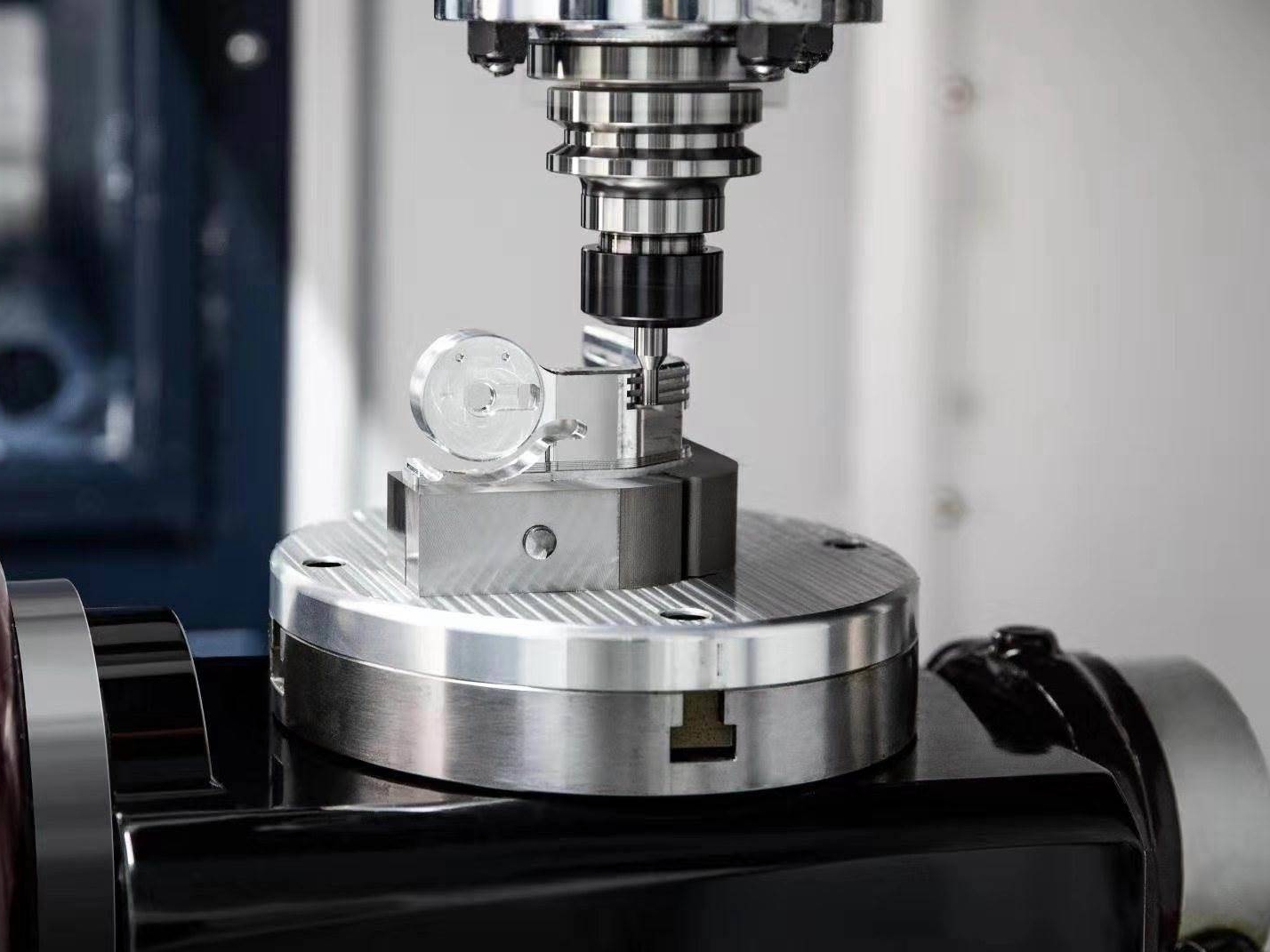

What is 4 Axis CNC Milling?

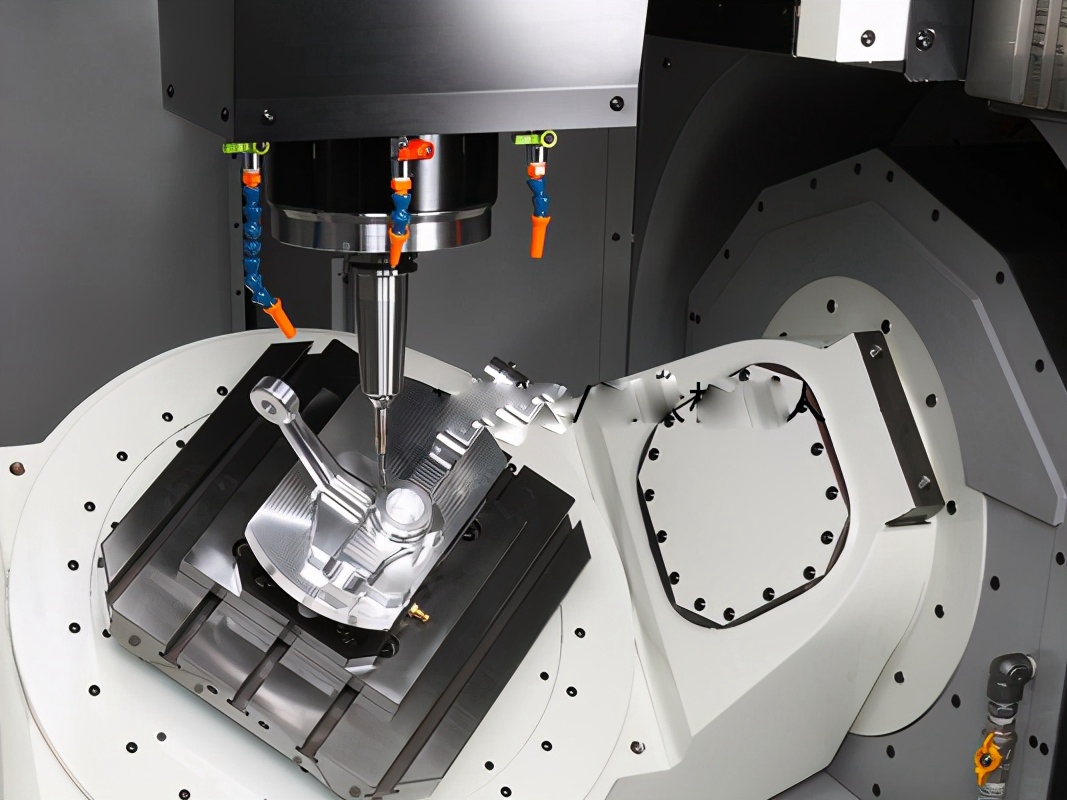

4 Axis CNC milling involves simultaneous machining along four axes. Unlike traditional 3 Axis CNC machines, which move only along X, Y, and Z axes, the 4 Axis CNC incorporates an additional rotational axis (A-axis). This added rotation allows the machining tool to access parts from multiple angles without manual repositioning, significantly boosting machining speed and accuracy.

How It Differs from 3 Axis CNC Milling

In standard 3 Axis CNC milling, the cutting tool travels along linear X, Y, and Z paths, suitable for simpler parts but less efficient for complex geometries. Conversely, the 4 Axis CNC milling approach, through its automated rotational axis, eliminates frequent manual repositioning, ensuring superior precision and quicker production times for complex components.

Types of 4 Axis CNC Milling Machines

There are two main types of 4 Axis machines:

Vertical 4 Axis Machines: Feature vertical spindle movement with rotational capabilities around the X-axis, ideal for versatile machining tasks.

Horizontal 4 Axis Machines: Feature horizontal spindle movements with rotational table capabilities around the Y-axis, suitable for large, elongated components.

Advantages of 4 Axis CNC Milling

Enhanced Precision and Accuracy

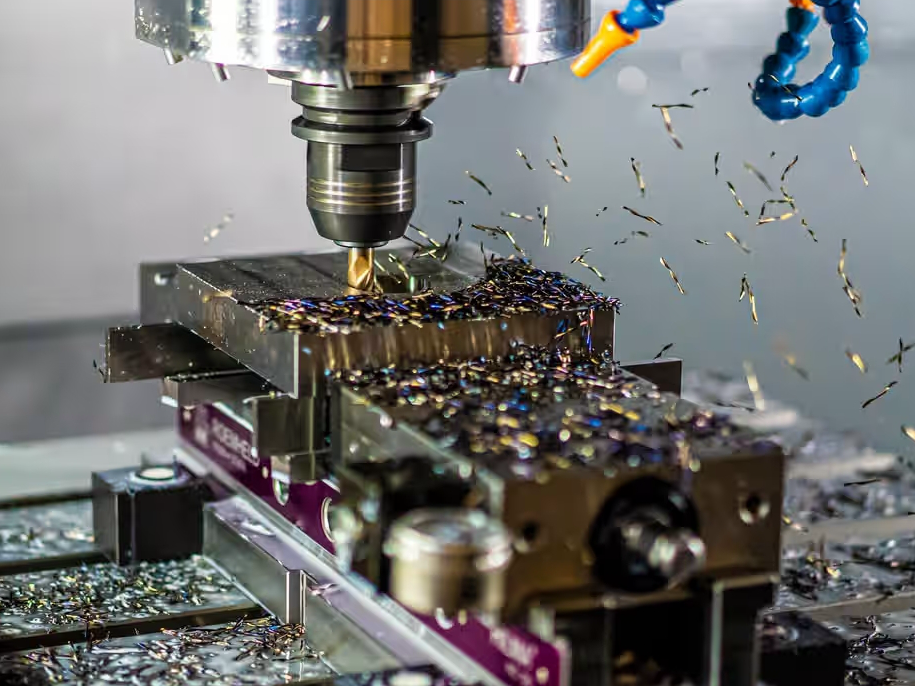

The fourth axis enables seamless machining of intricate geometries without repositioning, leading to exceptional precision. Components are accurately produced within tighter tolerances, fulfilling stringent industry standards.

Ability to Machine Complex Geometries

Industries needing complex geometries—like aerospace turbine blades, automotive components, or detailed medical devices—benefit immensely from 4 Axis CNC milling's multi-angle machining capability.

Reduction in Machining Time

Eliminating manual part adjustments during machining minimizes production downtime, accelerating overall production cycles and enhancing productivity.

Increased Efficiency in Production Runs

Manufacturing batches of complex parts become more streamlined and consistent, significantly decreasing errors and boosting overall output.

Common Applications and Industries

Aerospace Components

The aerospace sector extensively utilizes 4 Axis CNC milling to fabricate components such as turbine blades, airframe structures, and high-tolerance engine parts.

Automotive Parts

Automotive manufacturers benefit from 4 Axis milling for producing critical components like gearbox casings, transmission parts, and precise engine components.

Medical Equipment

Medical devices, including surgical tools, implants, and prosthetics, require the precise and complex machining capabilities of 4 Axis CNC milling.

Custom Complex Prototypes

Prototyping sectors in electronics, robotics, and consumer product design leverage 4 Axis CNC milling for fast, precise prototyping.

Materials Compatible with 4 Axis CNC Milling

Metals and Alloys

Materials such as aluminum alloys, titanium, stainless steel, carbon steel, and superalloys like Inconel and Hastelloy are effectively machined using 4 Axis technology.

Plastics

Engineering-grade plastics including ABS, Nylon, PEEK, Delrin, and Polycarbonate can be precision-machined on 4 Axis CNC mills.

Ceramics

Advanced ceramics, such as Zirconia and Alumina, are efficiently machined with 4 Axis technology, ideal for high-performance applications.

Essential Surface Treatments after 4 Axis Milling

Post-machining treatments enhance both functionality and appearance:

Anodizing: Offers corrosion resistance and durability for aluminum parts.

Electroplating: Enhances corrosion resistance, durability, and aesthetic appeal.

Polishing: Provides smooth, visually appealing finishes essential in medical and consumer industries.

Powder Coating: Combines environmental protection with aesthetic improvements.

Heat Treatments: Strengthen parts, improving mechanical characteristics like hardness and wear resistance.

Factors to Consider When Choosing a 4 Axis CNC Milling Service Provider

Technical Capabilities and Expertise

Providers should have advanced 4 Axis equipment, skilled machinists, and engineering expertise to manage complex machining tasks.

Machine Precision and Software Technology

Choose providers utilizing modern CNC technology and integrated CAD/CAM software for consistent, repeatable, and precise outcomes.

Quality Assurance Practices

Opt for providers that adhere to stringent quality standards, such as ISO certification and detailed inspection processes, ensuring reliable and high-quality results.

Cost-effectiveness and Project Timelines

Assess providers based on competitive pricing structures, efficient turnaround times, and scalability to match your production requirements.

Tips for Optimizing Your Design for 4 Axis CNC Milling

Effective CAD Modeling

Utilize robust CAD software to design parts specifically optimized for 4 Axis machining capabilities.

Material Selection Considerations

Select materials that balance machinability, performance characteristics, and cost-effectiveness, aligning with your product’s final application.

Minimizing Complexity to Save Costs and Time

Design simpler features wherever possible to significantly reduce machining complexity, saving production time and costs.

Planning for Surface Finishes and Tolerances

Clearly indicate required surface finishes and dimensional tolerances in designs, aiding accurate quotations and efficient machining processes.

Conclusion

4 Axis CNC milling significantly enhances precision and efficiency in manufacturing complex parts. Leveraging its advanced capabilities, industries like aerospace, automotive, and medical benefit through improvements in quality, speed, and overall cost-effectiveness. Selecting a suitable machining partner and thoughtfully optimizing your designs will ensure your components consistently meet demanding performance and precision standards.

FAQs

What makes 4 Axis CNC Milling ideal for complex part manufacturing?

Which industries benefit the most from 4 Axis CNC Milling?

What materials can be machined effectively using 4 Axis CNC Milling?

How does 4 Axis CNC Milling improve accuracy and reduce machining time?

What factors should I consider when selecting a 4 Axis CNC Milling provider?