5 Axis CNC Milling: Revolutionizing High-Precision Manufacturing

Introduction

Introduction

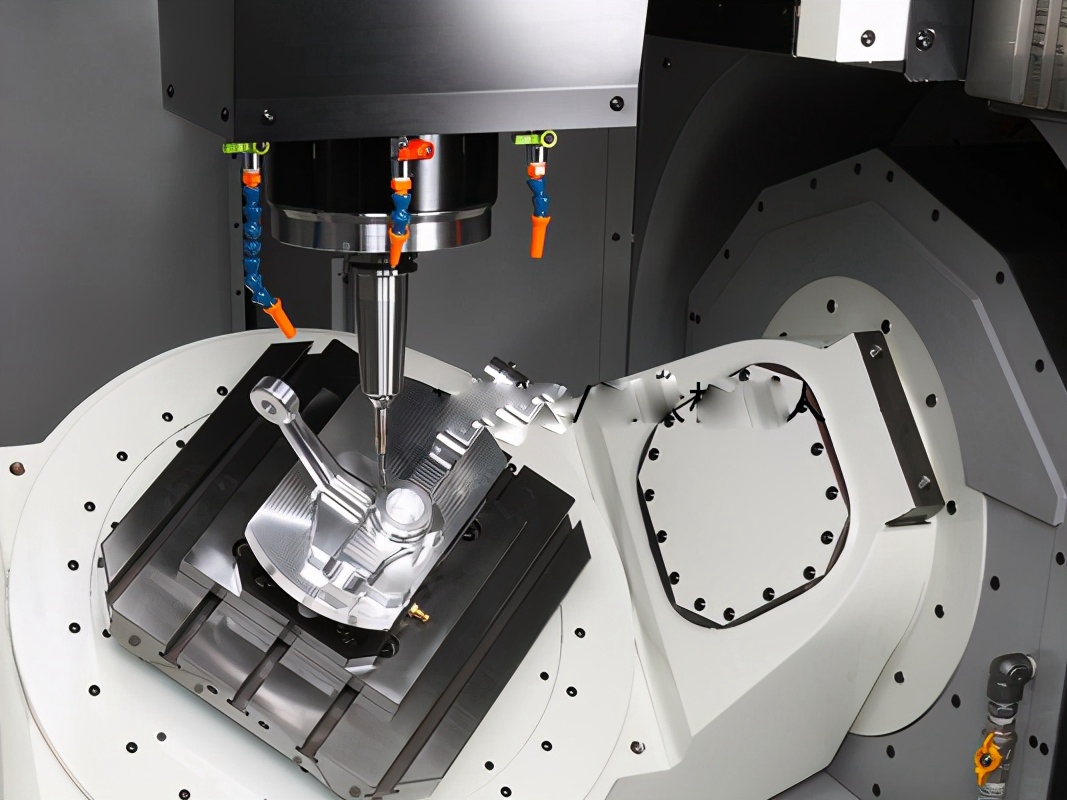

Computer Numerical Control (CNC milling) technology continuously evolves, driving precision manufacturing toward higher standards. Among the most transformative developments is 5 Axis CNC milling, significantly elevating accuracy, complexity, and production speed. This blog explores the fundamentals, advantages, and essential roles of 5 Axis CNC milling in contemporary precision manufacturing.

What is 5 Axis CNC Milling?

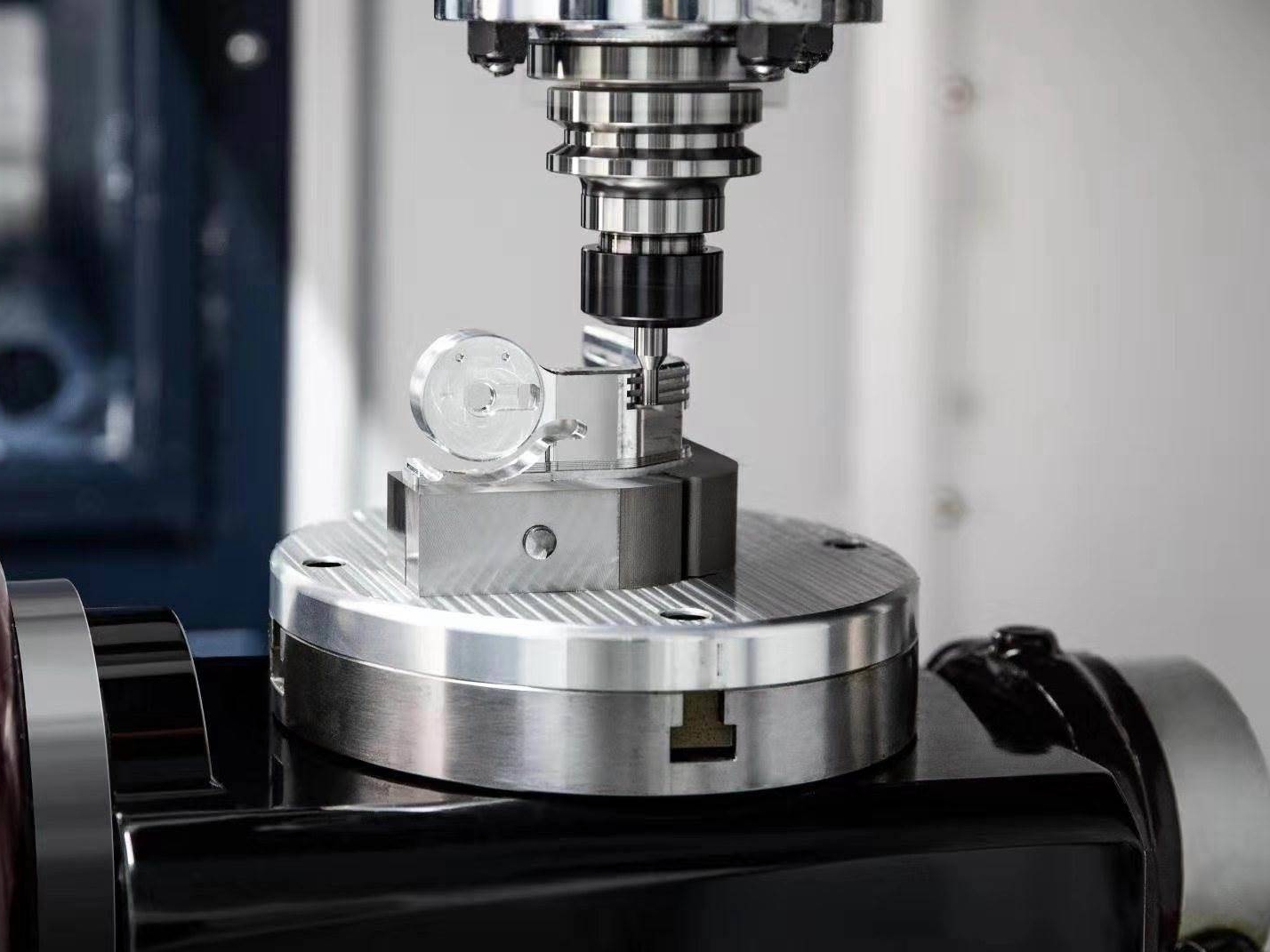

5 Axis CNC milling is a sophisticated machining technique that enables simultaneous cutting tool movements along the standard linear X, Y, and Z axes, plus two rotational axes (A-axis and either B or C-axis). This multidirectional motion allows precise machining of intricate geometries that were previously difficult or impossible using traditional methods.

Key Advantages of Additional Axes

The additional rotational axes greatly enhance machining flexibility. Manufacturers can achieve superior precision, fewer production steps, and reduced setup times, enabling efficient manufacturing of highly complex components.

Benefits of 5 Axis CNC Milling

Exceptional Accuracy and Precision

5 Axis CNC milling provides unparalleled precision by continuously adjusting workpiece orientation, eliminating repositioning errors and significantly reducing tolerance stack-ups.

Reduced Machining Time and Increased Productivity

Simultaneous 5-axis movements minimize manual repositioning and multiple setups, dramatically reducing machining time. This results in rapid turnaround and higher productivity, making it ideal for high-volume production.

Ability to Machine Highly Complex Geometries

The rotational axes facilitate the machining of intricate components like aerospace turbine blades, complex molds, and precise medical instruments in fewer operations.

Minimized Setups and Improved Consistency

Fewer setups are needed, substantially enhancing consistency and reducing production variability. Components are produced faster, with fewer errors, ensuring uniform quality.

Applications Across Various Industries

Aerospace Industry

Aerospace heavily relies on 5 Axis CNC milling for precision-critical components such as engine turbine blades, structural elements, and aerodynamic parts, significantly reducing machining time while improving component accuracy.

Automotive Industry

Automotive manufacturers use 5 Axis CNC milling for intricate components such as transmission parts, engine blocks, and suspension systems. This streamlines production, ensuring consistent quality critical to vehicle performance.

Medical Industry

Medical device manufacturing leverages 5 Axis CNC milling to produce surgical instruments, implants, dental devices, and prosthetics, ensuring extreme precision essential for patient safety and treatment effectiveness.

Custom Complex Prototypes

Industries involved in rapid prototyping depend on 5 Axis CNC milling to swiftly produce complex designs for testing and validation, shortening development cycles significantly.

Materials Compatible with 5 Axis CNC Milling

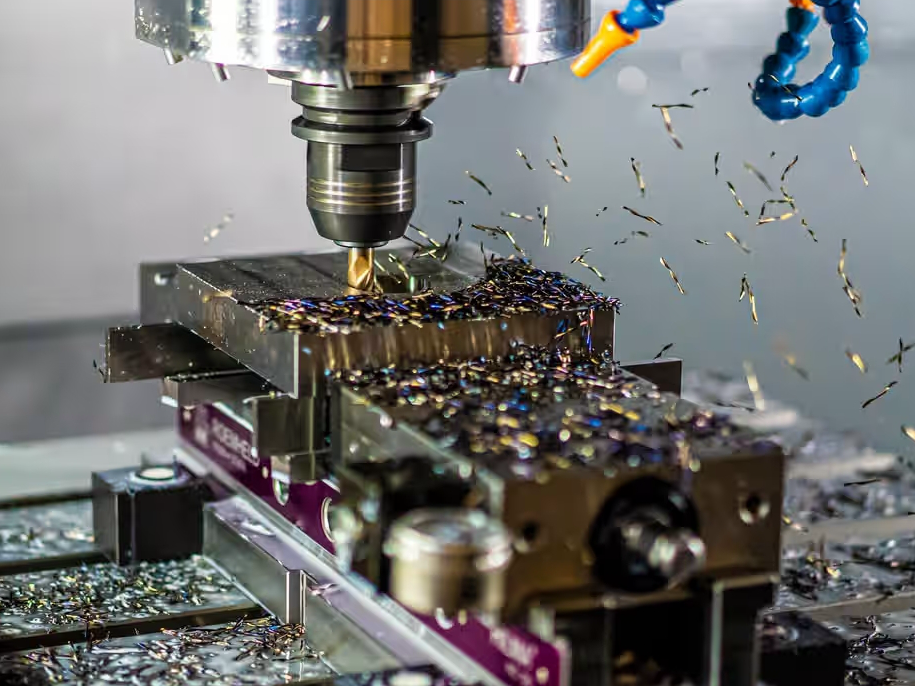

Metals and Alloys

5 Axis CNC milling accommodates a range of metals, including Aluminum alloys, Titanium, Stainless Steel, and high-performance superalloys like Inconel, Hastelloy, and Nimonic.

Plastics and Composites

Engineering plastics and composites such as PEEK, ABS, polycarbonates, and Nylon are highly precise machined, suitable for sectors requiring lightweight and durable materials.

Ceramics

Technical ceramics like Zirconia and Alumina, used in aerospace, medical, and electronic applications, benefit from precise and effective 5 Axis CNC milling.

Surface Treatments to Enhance 5 Axis Machined Parts

Electroplating

Electroplating enhances strength, corrosion resistance, and aesthetics, with coatings like chrome, zinc, and nickel.

Powder Coating

Powder coating provides durable environmental protection and improved appearance, widely utilized in automotive and consumer goods.

Anodizing

Anodizing significantly improves corrosion resistance and hardness, primarily for aluminum components.

Heat Treatments

Heat treatments, including annealing and hardening, enhance mechanical properties, strength, and durability, particularly in metal alloys.

Polishing and Surface Finishing

Advanced polishing methods deliver visually appealing surfaces and precise dimensions, crucial for medical devices and consumer products demanding fine detail.

Selecting the Right 5 Axis CNC Milling Service Provider

Technical Capabilities and Expertise

Providers should have advanced equipment, skilled machinists, and modern software capabilities to ensure maximum precision and consistency.

Machine Precision and Software Technology

Evaluate providers based on the quality of CNC equipment and their investment in CAD/CAM software, critical for achieving consistent and precise outcomes.

Quality Assurance Practices

Prioritize providers with comprehensive quality processes, ISO certifications, and thorough inspections, ensuring consistently high-quality production.

Cost-effectiveness and Project Timelines

Choose providers offering competitive pricing, reliable delivery schedules, and scalability to match project requirements without compromising quality.

Tips for Optimizing Your Design for 5 Axis CNC Milling

Effective CAD Modeling

Ensure your CAD designs maximize the capabilities of 5 Axis milling, clearly detailing requirements for smooth production.

Material Selection Considerations

Select materials that balance machinability, cost, and end-use performance, aligning effectively with 5 Axis machining advantages.

Minimizing Complexity to Save Costs and Time

Design simplifications without compromising function can significantly reduce complexity and production expenses.

Planning for Surface Finishes and Tolerances

Explicitly specify surface finishes and dimensional tolerances, streamlining the machining process and post-machining activities.

Conclusion

5 Axis CNC milling technology transforms precision manufacturing by enabling unprecedented complexity, superior precision, and faster production cycles. Selecting proficient providers and optimizing designs for 5 Axis capabilities ensures high-quality, productive, and cost-effective outcomes.

FAQs

What makes 5 Axis CNC Milling ideal for complex part production?

How does 5 Axis CNC Milling benefit aerospace and automotive manufacturing industries?

What materials are commonly machined using 5 Axis CNC Milling?

How does 5 Axis CNC Milling technology enhance precision and reduce machining errors?

What should businesses consider when choosing a 5 Axis CNC Milling service provider?