7 Ways to Reduce CNC Machining Costs Without Sacrificing Quality

CNC machining offers unmatched precision and versatility across various industries, from aerospace to consumer electronics. However, as design complexity increases and tolerances tighten, so can the cost. Fortunately, buyers can significantly reduce CNC machining expenses without compromising on part quality—if they understand what drives those costs.

This guide explores 7 proven ways to minimize CNC machining costs through smarter design, material selection, process optimization, and supplier collaboration.

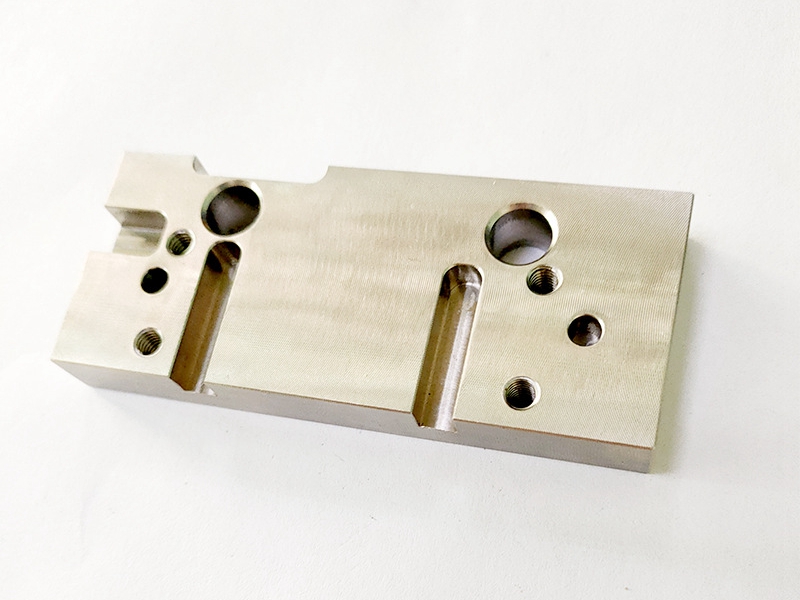

1. Optimize Part Design for Machinability

Designing with manufacturability in mind is the single most effective way to reduce CNC machining costs. Complex geometries, deep cavities, thin walls, and tight internal corners increase machining time, tool wear, and the number of setups required.

Recommended guidelines:

Maintain a minimum internal corner radius of 2 mm to accommodate standard end mills

Limit cavity depth to no more than 4× the tool diameter to avoid chatter and tool deflection

Avoid undercuts and sharp transitions unless essential

Standardize hole sizes to preferred drill diameters (e.g., Ø4 mm, Ø6 mm, Ø8 mm)

Eliminate features requiring 5-axis machining unless functionally necessary

At Neway, we offer DFM (Design for Manufacturability) feedback with every quote to help buyers simplify designs and reduce unnecessary complexity.

2. Choose Materials That Are Easier to Machine

Material type directly influences cycle time, tool wear, and part cost. Harder or more thermally resistant materials require slower feed rates and specialized tooling.

Recommended materials by machinability rating:

Aluminum 6061-T6: 90% machinability, tensile strength 310 MPa

Brass C360: 100% machinability, ideal for connectors and decorative components

Mild steel 1018: ~78% machinability, tensile strength ~440 MPa

POM (Delrin): Excellent for functional prototypes with low friction

Avoid difficult-to-machine alloys like Inconel 718 or hardened steel unless required by the application. Learn more about aluminum machining and stainless steel machining to compare materials.

3. Relax Tolerances Where Possible

Tight tolerances demand precision tooling, increased inspection time, and slower machining—leading to higher costs. For most CNC applications, only critical dimensions require tight tolerances.

Tolerance impact on cost:

±0.10 mm: Standard tolerance, low cost, suitable for most applications

±0.05 mm: Requires higher precision, adds 15–30% to machining cost

±0.01 mm or tighter: Demands specialized processes, potentially doubles cost

Use ISO 2768-m or ISO 2768-f for general tolerances. Neway also supports GD&T per ASME Y14.5 and offers precision machining services for applications with stringent requirements.

4. Limit the Number of Setups and Tool Changes

Each additional setup introduces alignment risk, downtime, and labor. Although multi-axis CNC machines can reduce repositioning, they have higher operational costs.

Best practices:

Design parts for machining in one or two orientations

Group features requiring the same tool types

Avoid complex geometries that demand 5-axis machining unless justified by performance

For example, machining a complex bracket with tight side features may require three-axis machining with repositioning. A redesign allowing top-down machining with a standard tool can cut cycle time by 20–30%.

5. Consolidate Parts Where Feasible

Reducing the number of assembled components can result in fewer fixtures, fewer fasteners, and less overall machining time.

Advantages of part consolidation:

Reduces tolerance stack-up across mating parts

Simplifies inventory and assembly

Cuts setup and material handling time

This strategy is ideal for housings, enclosures, and structural brackets. During the prototyping phase, Neway can provide feedback on which subassemblies can be machined as single parts.

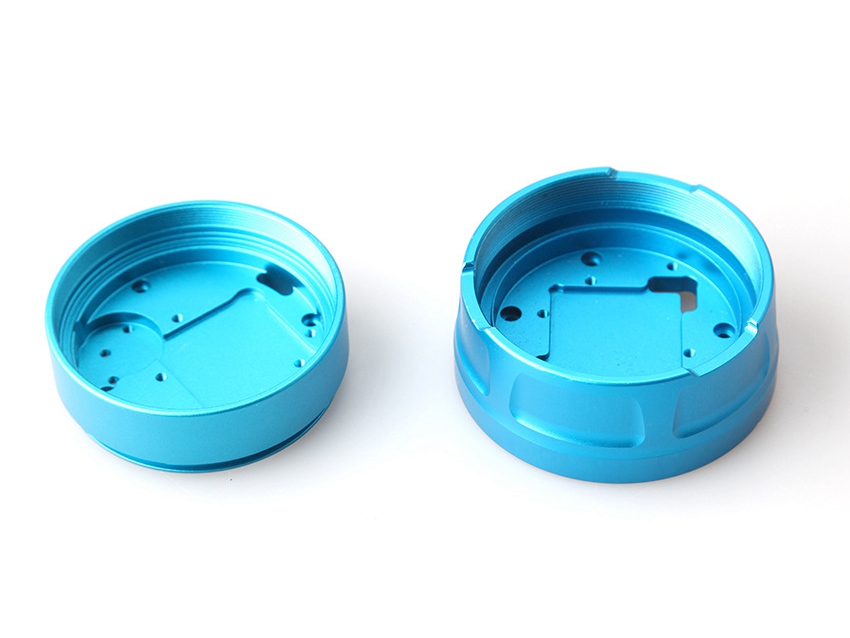

6. Use Standard Surface Finishes

Surface finishes beyond "as-machined" add cost through polishing, bead blasting, or chemical processes. While sometimes necessary, a smoother surface rarely improves mechanical performance.

Common CNC surface finishes:

As-machined: Ra 3.2–6.3 µm, standard and most economical

Bead blasted: Uniform matte finish, adds $1–$3 per part

Polished: Ra ≤ 0.8 µm, labor-intensive, adds 15–25% to cost

Anodizing or powder coating: Improves corrosion resistance, $2–$5 per part depending on color and batch size

For reference, Ra 3.2 µm meets many industrial functional requirements. Neway provides anodizing, powder coating, and electropolishing for applications needing enhanced appearance or corrosion resistance.

7. Order in Low-Volume Batches Strategically

Single prototypes are often expensive due to NRE (non-recurring engineering) costs, while high volumes may lock you into a design too early. Strategic low-volume batches strike a balance between unit cost and flexibility.

Tips for smart ordering:

Order 10–100 pieces to amortize setup costs

Combine multiple parts into one quote to share machine time

Match quantities to standard stock sizes (e.g., 6061 aluminum plate thicknesses)

Neway offers low-volume CNC manufacturing with rapid lead times and competitive pricing for bridge production or engineering validation lots.

Conclusion

CNC machining does not have to be prohibitively expensive. Buyers can significantly reduce costs without compromising performance or quality by designing for manufacturability, choosing the right materials, relaxing unnecessary tolerances, and streamlining machining steps.

At Neway, we specialize in high-precision, cost-efficient CNC solutions with engineering support at every stage—from prototyping to mass production. Our capabilities cover multi-axis machining, EDM, tight-tolerance parts, and full finishing services tailored to your project's technical and commercial goals.

Frequently Asked Questions (FAQs)

How do tighter tolerances impact CNC machining costs?

Which materials are cheapest and easiest to machine?

Can Neway help reduce cost during the design phase?

What’s the typical price difference between 3-axis and 5-axis machining?

How many parts should I order to get a lower per-unit price?