Best Materials for CNC Milling: A Buyer’s Guide to Metals and Plastics

Choosing the right material is one of buyers' most crucial decisions when ordering CNC-milled parts. Material selection affects everything from part strength and corrosion resistance to surface finish, machinability, and overall cost. With countless options available, it's essential to understand which metals and plastics are best suited for CNC milling based on application requirements.

Choosing the right material is one of buyers' most crucial decisions when ordering CNC-milled parts. Material selection affects everything from part strength and corrosion resistance to surface finish, machinability, and overall cost. With countless options available, it's essential to understand which metals and plastics are best suited for CNC milling based on application requirements.

This guide explores the most commonly used materials in CNC milling—including aluminum, steel, copper, titanium, and engineering plastics—highlighting their benefits, challenges, and ideal use cases for buyers of custom parts.

Key Considerations When Choosing CNC Milling Materials

When selecting materials for CNC milling, buyers should evaluate several critical factors:

Machinability: Determines how easily a material can be cut and shaped, affecting tooling costs and cycle time

Mechanical Properties: Includes yield strength, tensile strength, and hardness

Thermal and Chemical Resistance: Vital for high-heat or corrosive environments

Surface Finish Requirements: Some materials respond better to polishing, anodizing, or coating

Application Environment: Different industries have varying demands such as biocompatibility or electrical insulation

Cost and Availability: Affects prototyping, production scalability, and lead time

Top Metals for CNC Milling

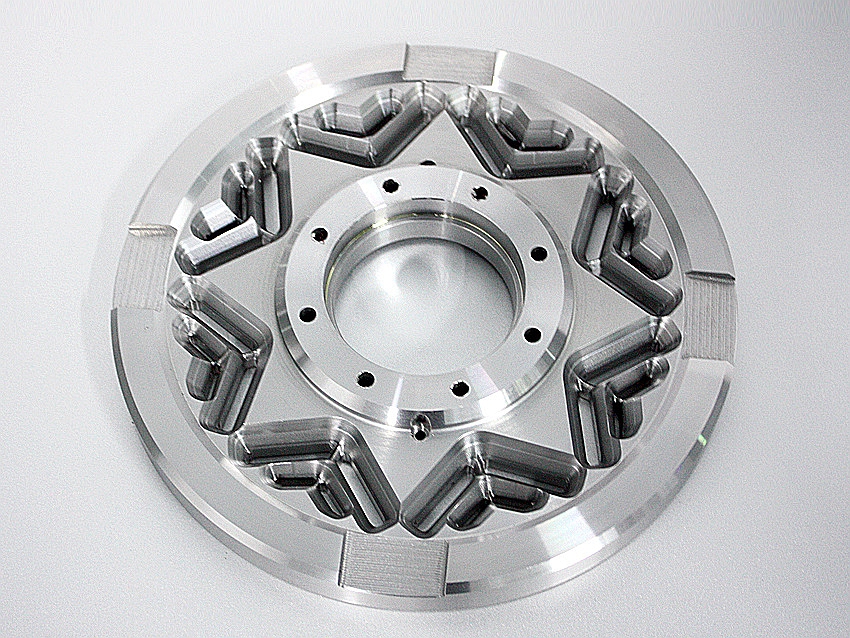

Aluminum Alloys

Aluminum is the most popular material for CNC milling due to its lightweight nature, machinability, and excellent thermal conductivity. It is non-magnetic, corrosion-resistant, and allows for high-speed machining.

Comparison of Common Aluminum Grades

Grade | Tensile Strength (MPa) | Machinability | Applications |

|---|---|---|---|

6061 | 290 | Excellent | Fixtures, enclosures, structural parts |

7075 | 570 | Good | Aerospace, motorsport, high-load components |

ADC12 (A380) | 310 | Good (cast) | Die-cast housings, consumer electronics |

Aluminum CNC machining allows for rapid prototyping and volume production due to high spindle speeds (up to 15,000 RPM) and chip clearance efficiency.

Stainless Steel

Stainless steels offer excellent mechanical strength, corrosion resistance, and high durability. They are more challenging to machine than aluminum due to work hardening and lower thermal conductivity.

Popular Stainless Steel Grades

Grade | Tensile Strength (MPa) | Corrosion Resistance | Machinability | Applications |

|---|---|---|---|---|

SUS303 | 520 | Moderate | Excellent | Machined fittings, shafts |

SUS304 | 520 | High | Moderate | Food, chemical, and marine parts |

SUS316 | 530 | Very High | Moderate | Medical, marine, chemical processing |

Stainless steel CNC machining suits environments requiring hygiene, pressure resistance, or saltwater durability.

Titanium Alloys

Titanium is a high-strength, lightweight, and biocompatible material with excellent corrosion resistance. Due to its poor thermal conductivity and reactivity with cutting tools, it requires lower cutting speeds and specialized tool coatings.

Key Titanium Grade

Grade | Tensile Strength (MPa) | Density (g/cm³) | Machinability | Applications |

|---|---|---|---|---|

Ti-6Al-4V | 900 | 4.43 | Low | Aerospace brackets, implants, heat shields |

Ti-6Al-4V machining is commonly used for aerospace and medical industries where weight savings and corrosion resistance are vital.

Copper and Brass

Copper and brass alloys offer excellent electrical and thermal conductivity. They also exhibit good machinability, especially for intricate or threaded parts.

Copper and Brass Grades Overview

Material | Tensile Strength (MPa) | Conductivity (% IACS) | Machinability | Applications |

|---|---|---|---|---|

Copper C101 | 220 | >101 | Moderate | Busbars, contacts, heat exchangers |

Brass C360 | 345 | 28 | Excellent | Valves, fittings, precision gears |

Copper machining is essential in power transmission, while brass machining supports decorative and mechanical assemblies.

Carbon Steel

Carbon steels are widely used in structural and mechanical applications due to their high strength and affordability. However, they typically require surface treatment to prevent corrosion.

Common Carbon Steel Grades

Grade | Tensile Strength (MPa) | Surface Treatment Required | Applications |

|---|---|---|---|

1018 | 440 | Yes | Shafts, fasteners, supports |

4140 | 655 | Yes (Quench & Temper) | Tooling, gears, industrial parts |

Carbon steel machining is ideal for load-bearing structures, drive shafts, and precision tools.

Top Plastics for CNC Milling

Acetal (POM / Delrin)

Acetal is a high-stiffness, low-friction engineering plastic with excellent wear resistance and dimensional stability.

Property | Value |

|---|---|

Tensile Strength | ~70 MPa |

Water Absorption | <0.2% |

Best Use | Bushings, gears, valve bodies |

Acetal CNC machining is perfect for mechanical parts requiring low wear and low moisture absorption.

PEEK (Polyether Ether Ketone)

PEEK is a high-performance thermoplastic capable of withstanding continuous temperatures up to 250°C and is resistant to chemicals, radiation, and wear.

Property | Value |

|---|---|

Tensile Strength | ~100 MPa |

Temp Resistance | 250°C |

Best Use | Aerospace, implants, energy systems |

PEEK machining is common in aerospace, medical, and semiconductor applications.

PTFE (Teflon)

PTFE offers excellent chemical resistance, low friction (0.04), and wide temperature stability. It is difficult to machine due to its softness and deformation.

Property | Value |

|---|---|

Melting Point | 327°C |

Coefficient of Friction | 0.04 |

Best Use | Seals, gaskets, chemical tank liners |

PTFE machining is best for non-stick or chemically aggressive environments.

Nylon (Polyamide)

Nylon is a cost-effective plastic with good impact resistance and low friction. However, it absorbs moisture and can swell.

Property | Value |

|---|---|

Tensile Strength | ~75 MPa |

Moisture Absorption | 1.5–3% |

Best Use | Rollers, spacers, wear plates |

Nylon CNC machining is recommended for mechanical parts in dry environments.

PMMA (Acrylic)

PMMA is a lightweight, transparent plastic with good UV resistance and surface finish. It is brittle compared to other plastics.

Property | Value |

|---|---|

Transparency | ~92% light transmittance |

Tensile Strength | ~70 MPa |

Best Use | Optical housings, panels, displays |

Acrylic CNC machining provides clear, polished components for display and medical use.

Final Thoughts: Match Material to Application

Selecting the best material for CNC milling depends on balancing mechanical performance, machining cost, thermal and chemical resistance, and surface finishing options. Each project has unique requirements, and material choice plays a direct role in success.

At Neway, our team collaborates with buyers during design and quoting to recommend materials tailored to performance and cost targets. Whether you're prototyping or scaling to production, we offer full support across metals and plastics, all backed by precision milling and comprehensive surface treatments.

Frequently Asked Questions (FAQs)

What is the most cost-effective material for CNC milling prototypes?

How does material hardness affect CNC milling speed and tool life?

Can I use the same material for prototyping and final production?

What surface finishes are compatible with aluminum vs stainless steel?

How do I choose between plastic and metal for CNC milled parts?