Choosing the Right Coating: Anodizing vs Powder Coating for CNC Machined Aluminum Parts

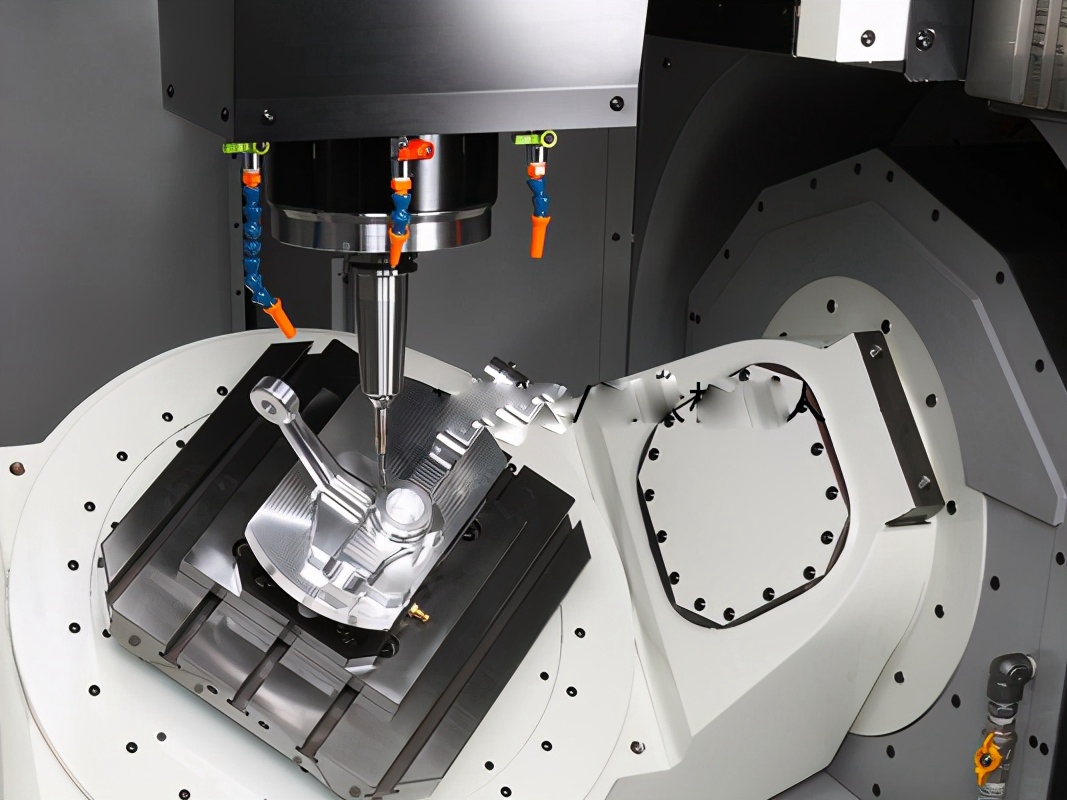

Aluminum is one of the most commonly used metals in CNC machining due to its lightweight properties, excellent strength-to-weight ratio, and high corrosion resistance. However, surface finishing is essential to maximize the durability, appearance, and functional performance of CNC-machined aluminum parts.

Aluminum is one of the most commonly used metals in CNC machining due to its lightweight properties, excellent strength-to-weight ratio, and high corrosion resistance. However, surface finishing is essential to maximize the durability, appearance, and functional performance of CNC-machined aluminum parts.

Two of the most widely used finishing options are anodizing and powder coating. Both processes enhance surface protection and aesthetics, but they differ significantly in appearance, durability, cost, and application. This guide helps buyers understand the differences between anodizing and powder coating to make the right decision for their aluminum components.

Why Aluminum Surface Finishing Matters

Aluminum naturally forms a passive oxide layer when exposed to air, which provides basic corrosion resistance. However, this oxide layer is thin (2–5 nm) and insufficient for demanding environments or decorative purposes.

Post-machining surface treatments are used to:

Improve corrosion and wear resistance

Enhance electrical insulation or conductivity

Provide color, texture, or gloss for aesthetic purposes

Protect parts during handling and service life

At Neway, we offer CNC aluminum machining services followed by a full suite of surface finishing processes including anodizing, powder coating, electropolishing, and more.

What is Anodizing?

Anodizing is an electrolytic process that thickens the natural aluminum oxide layer on the part's surface. The component is immersed in an acid electrolyte and an electrical current is passed through, creating a controlled oxidation layer that is both hard and porous.

Characteristics of anodized aluminum:

An inorganic finish that is integral to the part

The corrosion resistance of up to 1,000 hours in salt spray (ASTM B117, Type III)

Surface hardness up to 500 HV for hard anodizing

Electrical insulation properties (resistivity >10⁹ Ω·cm)

Dye-compatible porous layer for color finishing

Anodizing layers typically range from 10–25 µm for decorative applications (Type II) and 25–100 µm for hard coat anodizing (Type III), conforming to MIL-A-8625 and ISO 7599 standards.

What is Powder Coating?

Powder coating involves applying a dry, electrostatically charged polymer powder to the aluminum surface. The coated part is then baked at 160–200°C to fuse the particles into a continuous, hardened film.

Characteristics of powder-coated aluminum:

Organic coating with thicknesses typically between 60–120 µm

Excellent resistance to chipping, abrasion, and impact

Wide selection of RAL color matches, gloss levels, and textures

Chemical resistance depends on the resin system (epoxy, polyester, hybrid)

Low VOC, environmentally friendly process

Powder coatings are tested according to ISO 8130, ASTM D3359 (adhesion), and ASTM D3363 (hardness).

Anodizing vs Powder Coating: Side-by-Side Comparison

Feature | Anodizing | Powder Coating |

|---|---|---|

Coating Thickness | 10–100 µm (depending on Type) | 60–120 µm |

Surface Hardness | Up to 500 HV (Type III) | Typically 100–150 HV |

UV Resistance | High for clear and black finishes | Varies (polyester > epoxy) |

Corrosion Resistance | Excellent, especially Type III | Good in mild to moderate exposure |

Electrical Properties | Non-conductive, dielectric barrier | Insulating but less uniform |

Dimensional Impact | Low, uniform growth into surface | Higher; dimensional adjustments may be needed |

Aesthetic Options | Metallic finish, limited dyes | Wide color and texture range |

Thermal Resistance | Up to 350°C (hard anodizing) | Typically 200°C |

Cost | Moderate | Moderate to high depending on setup |

Suitable Alloys | 6061, 7075, 5052, 2024 | Most aluminum grades accepted |

When to Choose Anodizing

Anodizing is the preferred choice when:

Dimensional accuracy is critical (growth layer is ~50% penetration, 50% buildup)

High wear and abrasion resistance is required (e.g., valves, guides, rails)

Parts must retain a metallic appearance or need consistent surface texture

Enhanced adhesion for paints or adhesives is beneficial

UV and salt spray resistance is essential (Type III hardcoat >1,000 hrs per ASTM B117)

Typical applications include:

Aerospace brackets and housings

Optical and electronic enclosures

Medical instruments

Outdoor structural components

Neway offers Type II and Type III anodizing to meet MIL-A-8625, ISO 7599, and AMS 2471/2472 requirements.

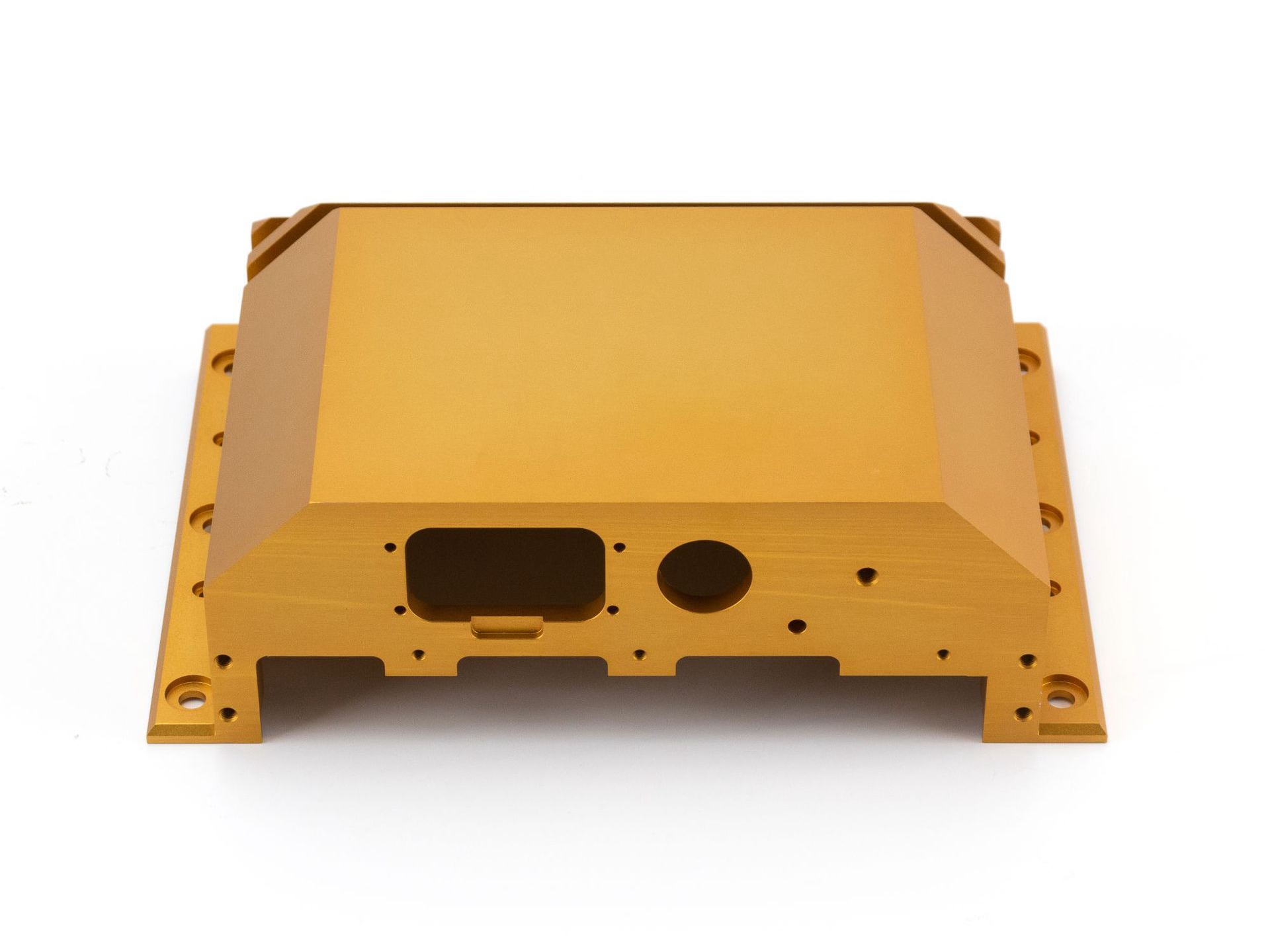

When to Choose Powder Coating

Powder coating is ideal for:

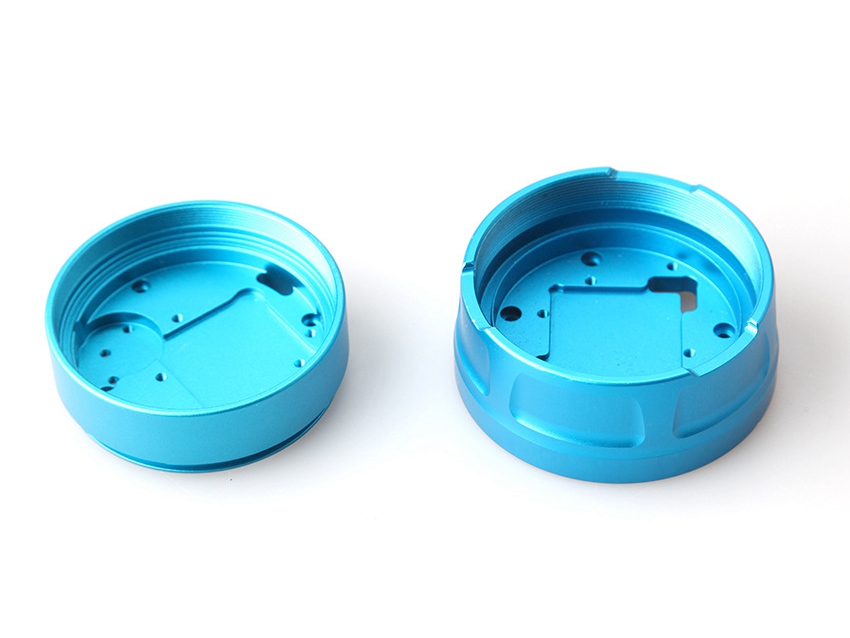

Decorative parts requiring vibrant colors or special textures (e.g., sand, matte, gloss)

Consumer-facing products where aesthetics matter

Parts subject to impact, chemical splash, or abrasion

Assemblies where surface uniformity masks machining or casting marks

Projects where batch coating of many parts is economically favorable

Applications include:

Industrial equipment covers

Enclosures and panels

Consumer electronics housings

Outdoor furniture and signage

Neway’s powder coating services include polyester, epoxy, and hybrid systems with batch sizes from small prototype lots to volume production.

Design Considerations for CNC Machined Parts

Dimensional Tolerances:

Anodizing grows into the material (typically 50% into the surface, 50% buildup), allowing close tolerances to be maintained without significant distortion

Powder coating adds thickness uniformly on all exposed surfaces (60–120 µm), which can affect sliding fits or thread engagement

Part Geometry:

Sharp edges should be broken (R > 0.25 mm) to promote uniform coating

Blind holes or complex internal cavities may not coat evenly in powder coating

Material Compatibility:

6000-series aluminum (6061, 6082) responds well to both finishes

2000- and 7000-series (2024, 7075) may require pretreatment for consistent anodizing results

Castings should be fully degassed prior to powder coating to prevent outgassing defects

Conclusion

Anodizing and powder coating both offer effective ways to enhance the durability and appearance of CNC-machined aluminum parts, but each method suits different applications and performance demands.

Choose to anodize when precision, UV resistance, or hard-wear surfaces are required. Opt for powder coating when bold color, impact protection, or surface masking is the priority.

At Neway, we deliver both anodizing and powder coating as part of our integrated CNC aluminum machining services, ensuring your parts meet technical, environmental, and aesthetic requirements with professional-grade consistency.

Frequently Asked Questions (FAQs)

How much thickness does anodizing add to aluminum parts?

Can powder coating be applied over anodized aluminum?

Which finish lasts longer in outdoor environments: anodizing or powder coating?

Is powder coating suitable for tight-tolerance CNC machined components?

What aluminum alloys are best suited for anodizing?