From Prototype to Production: Optimizing Low-Volume CNC Machining for Custom Applications

Low-volume CNC machining bridges the gap between rapid prototyping and full-scale production. For industries that require high-precision, on-demand custom components—such as aerospace, medical, robotics, and consumer electronics—this flexible manufacturing strategy delivers cost efficiency, design validation, and speed to market without compromising quality.

This blog explores how buyers can leverage low-volume CNC machining to accelerate product development cycles, reduce tooling costs, and bring customized parts to production-ready status faster and more efficiently.

What Is Low-Volume CNC Machining?

Low-volume CNC machining typically refers to the manufacturing of 10 to 1,000 parts per batch. Unlike mass production, which often relies on expensive tooling, molds, or casting setups, CNC machines can create precision parts directly from CAD models without requiring dedicated dies or jigs.

This makes low-volume machining ideal for:

Engineering prototypes

Pilot runs and pre-launch testing

Custom or limited-edition product lines

Spare parts for high-mix, low-demand components

At Neway, our low-volume manufacturing services deliver consistent dimensional accuracy, functional performance, and surface finishes that match production-grade quality—across metals, plastics, ceramics, and composite materials.

Benefits of Low-Volume CNC Machining

Faster Time to Market

Without the need for time-consuming tooling or mold preparation, CNC machining enables rapid production of functional parts within days. This speed is critical for iterative design validation, especially when multiple revisions are expected.

Typical lead time for low-volume CNC batches:

Aluminum, steel, plastic prototypes: 5–7 working days

Complex multi-axis titanium or ceramic parts: 10–14 working days

Cost-Effective for Custom Applications

Low-volume machining minimizes upfront investment. There is no mold fabrication or die setup cost, making it the most economical method for small series, custom-fit, or one-off parts.

For example:

A CNC-machined 6061 aluminum enclosure prototype may cost $120–250 per unit with zero tooling cost

The same part produced via die casting would require an initial mold investment of $4,000–12,000

This approach is ideal for startups, R&D teams, and OEMs seeking flexibility without committing to high-volume expenditures.

Precision and Repeatability

CNC machining provides tolerance control down to ±0.005 mm, ensuring functional accuracy even at low volumes. Unlike 3D printing or metal casting, CNC processes produce parts with consistent geometry, stable material properties, and tight fit tolerances.

Common tolerances achieved at Neway:

Standard: ±0.10 mm

Precision: ±0.05 mm

High precision: ±0.01 mm or better with precision CNC machining

Surface finishes range from Ra 3.2 μm (as-machined) to Ra 0.4 μm (polished), and post-processing such as anodizing or powder coating can be added as required.

Common Materials and Applications

Neway’s CNC machining services cover a full range of engineering materials to support diverse low-volume applications.

Metals

Aluminum (6061, 7075, 5052): Lightweight and corrosion-resistant, used in aerospace and consumer products

Stainless Steel (304, 316, 17-4PH): Excellent corrosion resistance, ideal for food-grade, marine, and surgical components

Titanium (Grade 5, Grade 23): High strength-to-weight ratio, critical for aerospace and medical implants

Brass, Bronze, Copper: High conductivity and machinability, used in electrical and precision instrumentation

Plastics

POM (Delrin), Nylon (PA6), ABS, PC: Tough, low-friction materials suitable for mechanical and enclosures

PTFE, PEEK: Chemically resistant and heat-resistant plastics for aerospace, energy, and medical use

Ceramics

Zirconia, Alumina, Silicon Nitride: Suitable for wear-resistant, insulating, or biocompatible applications requiring high hardness and thermal stability

Process Optimization from Prototype to Production

Design for Manufacturability (DFM)

Low-volume machining benefits from early design collaboration to prevent costly reworks and ensure smooth manufacturability. At Neway, our engineers offer full DFM support to evaluate:

Machinability of features like thin walls, deep pockets, undercuts, and tight corner radii

Tolerances and fits (e.g., H7/g6) to balance cost and functionality

Material substitution opportunities for faster procurement or improved performance

Batch Strategy and Fixturing

Efficient batch processing of 10–500 units involves fixture design optimization, modular setups, and standardized tool paths. This ensures part-to-part consistency with minimal repositioning.

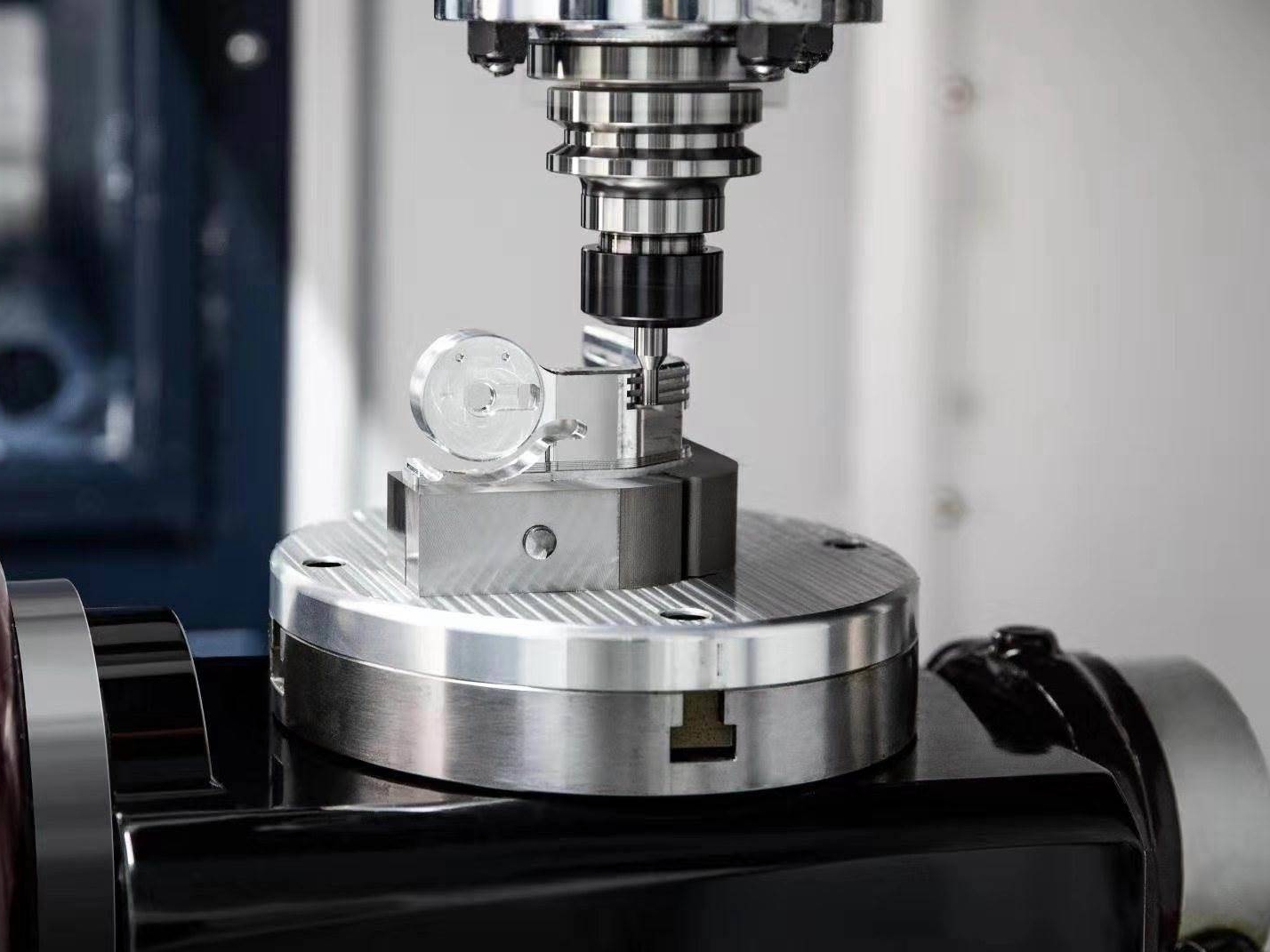

Neway applies advanced multi-axis CNC machining to handle complex geometries in a single setup. CNC turning ensures concentricity and surface finish within tight tolerance bands for rotational components.

Integrated Surface Treatments

Post-machining surface treatments help replicate production-quality parts. Neway provides full in-house and outsourced finishing options including:

Anodizing: Enhances corrosion resistance and wear on aluminum parts

Electropolishing: Improves smoothness and passivation of stainless steel surfaces

Powder coating: Provides decorative and abrasion-resistant finishes

Tumbling: Deburrs sharp edges for enhanced safety and assembly fit

Scaling to Mass Production

Low-volume CNC machining is often the final validation stage before scaling to mass production. It allows for:

Functional testing under actual load and environmental conditions

Real-world performance data collection for regulatory or durability assessment

Feedback-driven design iterations before investing in tooling

Once validated, Neway can transition to mass production via high-speed CNC machining, die casting with secondary machining, or other scalable manufacturing approaches—all while maintaining design integrity and material consistency.

Why Choose Neway for Low-Volume CNC Machining

Neway offers end-to-end manufacturing support from CNC prototyping to low-volume production and beyond. Our capabilities include:

3-axis to 5-axis CNC milling and turning for complex geometries

EDM machining for intricate internal features

Full material selection including superalloys, plastics, ceramics, and composites

CMM and in-process inspection with ISO-aligned quality management

Rapid turnaround and global shipping

We serve industries such as aerospace, medical, automation, and energy, delivering high-quality CNC parts at low volumes with speed and precision.

Conclusion

Low-volume CNC machining is the cornerstone of modern product development. It enables companies to move quickly from idea to market validation with minimal risk and maximum flexibility. Whether you're developing a medical prototype or testing an aerospace subcomponent, this process provides production-grade quality without the overhead of tooling or long setup times.

Neway helps you navigate every stage of this journey—optimizing your designs, accelerating your timelines, and ensuring each custom part exceeds expectations.

Frequently Asked Questions (FAQs)

What is the typical lead time for a low-volume CNC machining project?

How does low-volume CNC machining compare to 3D printing or casting?

Can I use the same material in prototype and production batches?

What is the minimum order quantity for low-volume CNC parts at Neway?

How do I ensure my part design is optimized for CNC manufacturability?