How to Select the Right Metal for Custom CNC Machined Parts: A Buyer's Guide

Choosing the right metal for your CNC machined part is one of the most critical decisions in any custom manufacturing project. The material you select will impact performance, durability, machinability, surface finish, cost, and lead time. From lightweight aluminum to high-strength steel and corrosion-resistant titanium, each metal offers distinct advantages—and trade-offs.

This buyer’s guide outlines key criteria for selecting the best metal for your application and provides practical comparisons based on industry standards and machining considerations.

Why Metal Selection Matters in CNC Machining

CNC machining is a subtractive manufacturing process where materials are shaped with extreme precision. The selected metal affects:

Dimensional stability during machining

Achievable tolerances and surface finishes

Cutting tool wear and machine runtime

Post-processing and surface treatment compatibility

Total manufacturing cost and lead time

At Neway, we offer CNC machining services across a wide range of metal alloys, with expert guidance on matching material properties to your functional and commercial goals.

Key Factors to Consider When Choosing Metal

Mechanical Properties

Evaluate the mechanical requirements of your component, including:

Tensile Strength (MPa): resistance to pulling forces

Yield Strength (MPa): resistance to plastic deformation

Hardness (HB/HRC): resistance to surface indentation and wear

Fatigue Strength: endurance under cyclic loading

Elongation (%): ductility or ability to stretch before breaking

For example, 7075-T6 aluminum has a tensile strength of approximately 570 MPa, yield strength of 505 MPa, and elongation of 11%. In contrast, 304 stainless steel offers 505 MPa tensile strength but far superior corrosion resistance and higher elongation around 40%.

Corrosion Resistance

Corrosion behavior is essential for components exposed to moisture, chemicals, saltwater, or sterilization environments.

Use 304 or 316 stainless steel for marine, food-grade, or medical parts

Select 5052 or 6061 aluminum for outdoor components

Choose Grade 5 titanium for biocompatibility and chemical stability

Learn more about stainless steel machining and titanium CNC machining to evaluate application-specific options.

Machinability

Machinability ratings indicate how easily a metal can be cut, shaped, and finished. These ratings are compared to 1212 free-machining steel, which is assigned a reference value of 100%.

Aluminum 6061: 90% machinability

Brass C360: 100%, excellent for tight tolerances

Carbon Steel 1018: around 78%

Stainless Steel 304: 45–50%, moderate difficulty

Titanium Grade 5: 20–30%, challenging due to low thermal conductivity

Machinable materials reduce production costs, extend tool life, and allow shorter lead times—ideal for CNC prototyping and low-volume production.

Surface Finish Requirements

Certain metals offer better as-machined finishes or are more receptive to post-processing.

Aluminum alloys can achieve Ra 0.8–1.6 μm easily and anodize well

Brass provides a bright, decorative finish ideal for consumer components

Stainless steel may require electropolishing or passivation

Titanium is best coated with PVD or nitriding for wear resistance

More information is available on our surface treatment page.

Cost and Availability

Material cost is a significant factor in large-batch production or budget-sensitive applications. The following table summarizes typical raw material prices:

Material | Estimated Price (USD/kg) | Characteristics |

|---|---|---|

Aluminum 6061 | $3.0–$5.0 | Widely available, low density |

Stainless Steel 304 | $5.0–$7.5 | Corrosion-resistant, moderately machinable |

Brass C360 | $6.0–$9.0 | Excellent machinability, decorative use |

Copper C101 (T2) | $10.0–$15.0 | High conductivity, soft metal |

Titanium Grade 5 | $20.0–$40.0 | High strength-to-weight, corrosion resistant |

At Neway, we source traceable raw materials globally and ensure material compliance with ASTM, GB, and DIN standards.

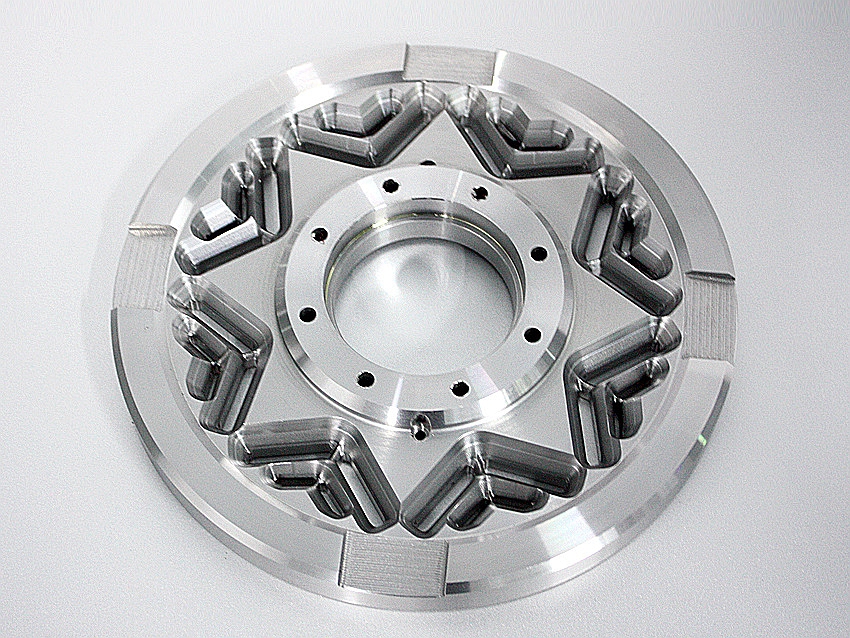

Commonly Used Metals and Their Applications

Aluminum Alloys

6061-T6: General-purpose alloy with good strength, corrosion resistance, and weldability

7075-T6: Aerospace-grade aluminum, tensile strength up to 570 MPa

5052: Excellent corrosion resistance, used in marine applications

2024: High fatigue resistance for aircraft components

See our aluminum CNC machining services for more details.

Stainless Steels

304: General corrosion-resistant grade, good formability and weldability

316: Marine-grade with molybdenum for improved chemical resistance

17-4PH (SUS630): Precipitation-hardened steel with tensile strength above 900 MPa

440C: High hardness, ideal for tooling and bearings

Carbon and Alloy Steels

1018 / 1020: Low-carbon steels with good machinability and moderate strength

4140 / 4340: High-strength alloy steels for load-bearing parts

A36: Low-cost structural steel commonly used in frames and supports

More information at carbon steel CNC machining.

Copper, Brass, and Bronze

Brass C360: Free-machining brass used in fittings, valves, and fasteners

Copper C101: 99.99% conductivity, ideal for electrical connectors

Bronze C630 / C905: High strength and corrosion resistance in bearings and gears

Explore copper CNC machining for specific use cases.

Titanium Alloys

Grade 5 (Ti-6Al-4V): 900 MPa tensile strength, excellent biocompatibility

Grade 23 (Ti-6Al-4V ELI): Enhanced fracture toughness for implants and critical aerospace parts

More details available on titanium machining services.

Material Substitution and Design Tips

If your preferred metal is unavailable or outside budget constraints, consider the following engineering alternatives:

Replace 7075 with 6061 for less critical aerospace parts at 40% lower cost

Use 316L instead of 304 for enhanced corrosion performance in saline or acidic environments

Substitute copper with brass where high conductivity is not essential

Switch titanium to aluminum when biocompatibility is not a factor

Neway’s engineering team supports material consulting based on international equivalents (e.g., ASTM to DIN or GB), ensuring functionally and economically optimized results.

Conclusion

Choosing the right metal for CNC machining involves balancing performance, durability, machinability, aesthetics, and cost. With a clear understanding of mechanical and material properties, you can confidently select the alloy best suited for your project.

At Neway, we provide expert guidance, full material traceability, and precision machining across the entire spectrum of metals—from cost-effective aluminum to high-performance titanium. Whether you're producing aerospace housings, electrical contacts, or custom mechanical parts, we help ensure your parts meet all functional, regulatory, and commercial requirements.

Frequently Asked Questions (FAQs)

What is the best metal for CNC machining high-strength, lightweight parts?

Which metals offer the best corrosion resistance for marine or medical parts?

How do I balance cost and performance when selecting a CNC metal?

Can Neway help with material certification and traceability?

What’s the most machinable metal for short lead time and tight tolerances?