Top 5 Most Cost-Effective Metals for Custom CNC Parts Without Compromising Performance

When selecting a metal for custom CNC machined parts, cost is a key consideration—but it should not come at the expense of mechanical performance, corrosion resistance, or precision. Several metal alloys balance affordability and functionality, making them ideal for a wide range of CNC applications.

This blog explores the top 5 most cost-effective metals used in CNC machining that deliver exceptional value without compromising quality. Whether you're prototyping or producing low-volume parts, these materials provide high machinability, strength, and consistency.

Why Material Selection Matters in CNC Machining

Material choice influences more than just the cost of raw stock. It directly affects:

Machinability: Determines cycle time, tool wear, and setup complexity

Tolerance Control: Influences achievable precision and dimensional stability

Surface Finish: Impacts cosmetic appearance and post-processing compatibility

Corrosion Resistance: Critical for components exposed to harsh environments

Structural Integrity: Affects strength, fatigue life, and safety factors

At Neway, we offer CNC machining services using a wide range of metals optimized for performance and cost efficiency. We support industries such as aerospace, automotive, energy, and electronics.

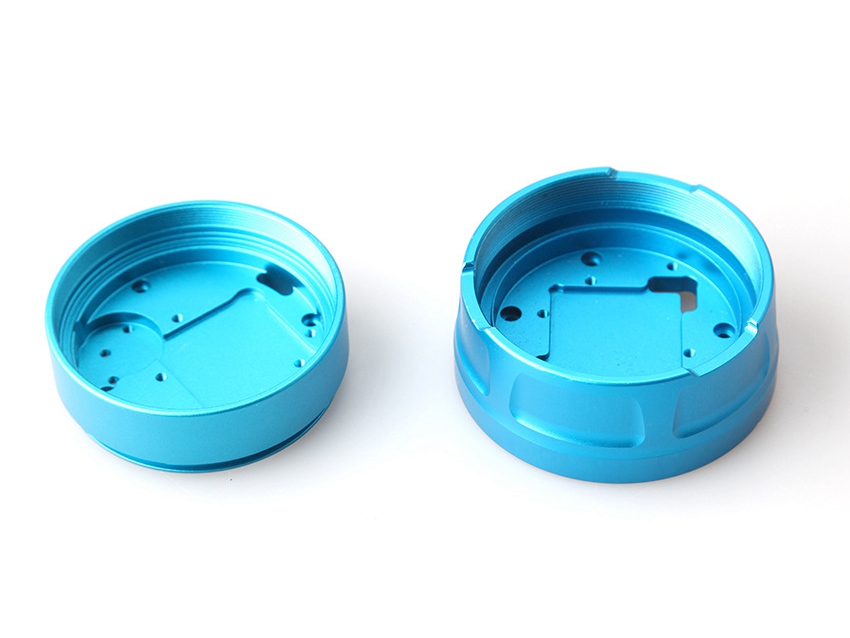

1. Aluminum 6061-T6

Machinability: 90% Tensile Strength: 310 MPa Yield Strength: 275 MPa Density: 2.70 g/cm³ Corrosion Resistance: Excellent Thermal Conductivity: 167 W/m·K Typical Cost: $3.00–$5.00/kg

Aluminum 6061-T6 is one of the most commonly used alloys in CNC machining thanks to its outstanding combination of mechanical strength, corrosion resistance, and ease of machining. Its excellent dimensional stability and low density make it suitable for lightweight structural applications. It responds well to anodizing, providing further corrosion and wear resistance.

Common Applications:

Aerospace brackets and airframes

Automotive parts and enclosures

Structural components in robotics and automation

Consumer electronics housings

See more about aluminum CNC machining to explore finish options and tolerances down to ±0.01 mm.

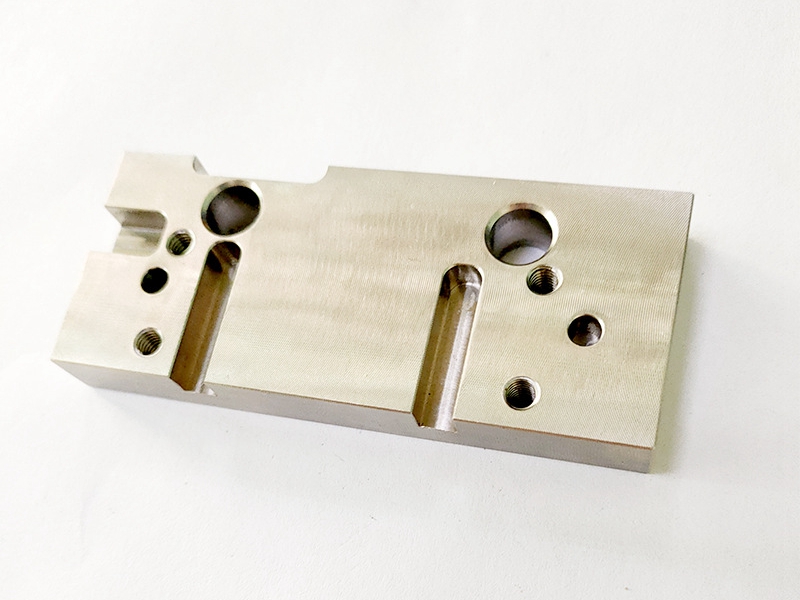

2. Mild Steel 1018

Machinability: 78% Tensile Strength: 440 MPa Yield Strength: 370 MPa Density: 7.87 g/cm³ Corrosion Resistance: Low (requires coating) Thermal Conductivity: 51.9 W/m·K Typical Cost: $1.50–$2.50/kg

1018 steel is a low-carbon, cold-rolled steel widely used in custom-machined components for its strength, uniformity, and affordability. Although it lacks natural corrosion resistance, it is easily finished with black oxide, powder coating, or galvanizing.

Common Applications:

Gears, shafts, and pins

Structural supports and machinery bases

Fixtures and jigs

Low-cost industrial parts

Explore carbon steel CNC machining for both prototyping and volume production with optional coatings.

3. Brass C360

Machinability: 100% Tensile Strength: 345 MPa Yield Strength: 100 MPa Density: 8.44 g/cm³ Corrosion Resistance: Good in dry conditions Thermal Conductivity: 125 W/m·K Typical Cost: $5.00–$9.00/kg

Brass C360 (free-machining brass) is the standard for machinability. It produces minimal tool wear, requires no lubrication in many cases, and allows for high-speed operations with excellent surface finishes (Ra ≤ 0.8 µm). Despite its higher raw material cost, it offers cost savings due to faster cycle times and lower tool maintenance.

Common Applications:

Plumbing fittings and valves

Electrical components and terminals

Decorative hardware

Precision instrumentation parts

Visit brass CNC machining services to see how we achieve tight tolerances and apply finishes like PVD coating.

4. Aluminum 5052

Machinability: 65% Tensile Strength: 230 MPa Yield Strength: 193 MPa Density: 2.68 g/cm³ Corrosion Resistance: Excellent, especially in saltwater Thermal Conductivity: 138 W/m·K Typical Cost: $4.00–$6.00/kg

Aluminum 5052 is highly corrosion-resistant and ideal for marine and chemical environments. While it is less machinable than 6061, it excels in applications requiring superior formability and corrosion performance. It can be welded easily and is frequently used in sheet metal designs and structural panels.

Common Applications:

Marine equipment

Battery enclosures

Structural sheet parts

Welded chassis and brackets

Neway machines 5052 with careful parameter control to prevent work hardening and to maintain excellent flatness in precision parts.

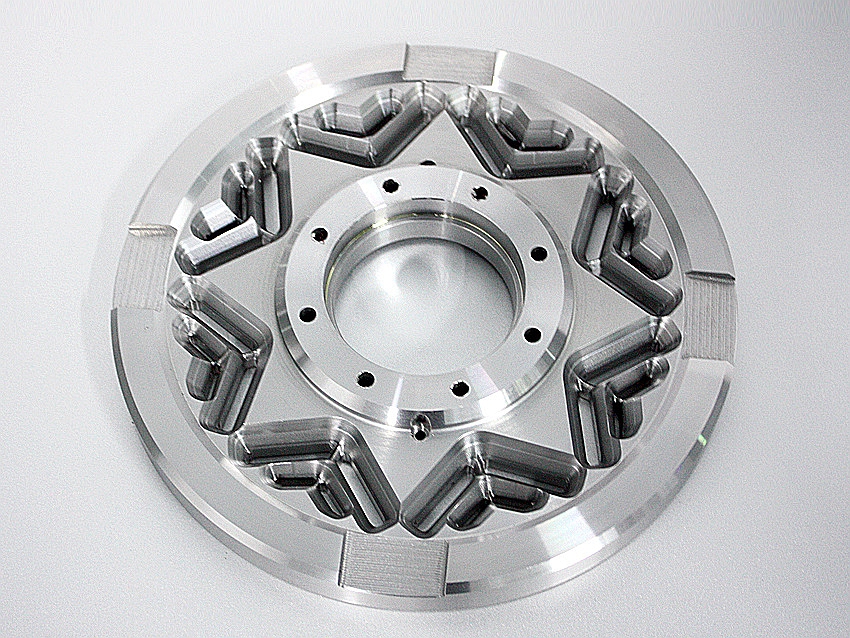

5. Stainless Steel 304

Machinability: 45–50% Tensile Strength: 505 MPa Yield Strength: 215 MPa Density: 8.00 g/cm³ Corrosion Resistance: Very high Thermal Conductivity: 16.2 W/m·K Typical Cost: $5.00–$7.50/kg

Stainless Steel 304 is a widely used austenitic alloy known for its excellent corrosion resistance, strength, and workability. Though it is more difficult to machine than aluminum or brass, it is cost-effective for applications requiring chemical resistance and long-term durability.

Common Applications:

Food-grade and pharmaceutical equipment

Marine components

Structural hardware

Custom fittings and fasteners

We offer stainless steel machining services with post-processing options like electropolishing, passivation, and bead blasting.

Honorable Mentions

Aluminum 7075-T6: High strength (tensile strength ~570 MPa), used in aerospace but more expensive

Cold-Rolled Steel (CRS): Economical alternative for high-stiffness parts

Copper C101 (T2): Superior conductivity, but higher material and tooling cost

Bronze C905: Used in high-load bushings and wear-resistant components

Conclusion

The top five metals—Aluminum 6061, Mild Steel 1018, Brass C360, Aluminum 5052, and Stainless Steel 304—offer an excellent combination of performance, machinability, and affordability. Selecting the right material is essential for balancing mechanical requirements with cost constraints.

At Neway, our engineering team helps customers choose the optimal material based on mechanical performance, corrosion resistance, thermal properties, and budget. From prototyping to production, we ensure every CNC machined part meets its specifications without inflating manufacturing costs.

Frequently Asked Questions (FAQs)

Which metal provides the best machinability and cost savings for CNC?

How do aluminum alloys compare to stainless steel in terms of strength and price?

Can brass be used for high-precision CNC parts in mechanical assemblies?

What’s the most affordable corrosion-resistant metal for outdoor parts?

How do I select the right metal for both machining speed and durability?