Understanding 3-Axis, 4-Axis, and 5-Axis CNC Milling: Which Is Right for Your Project?

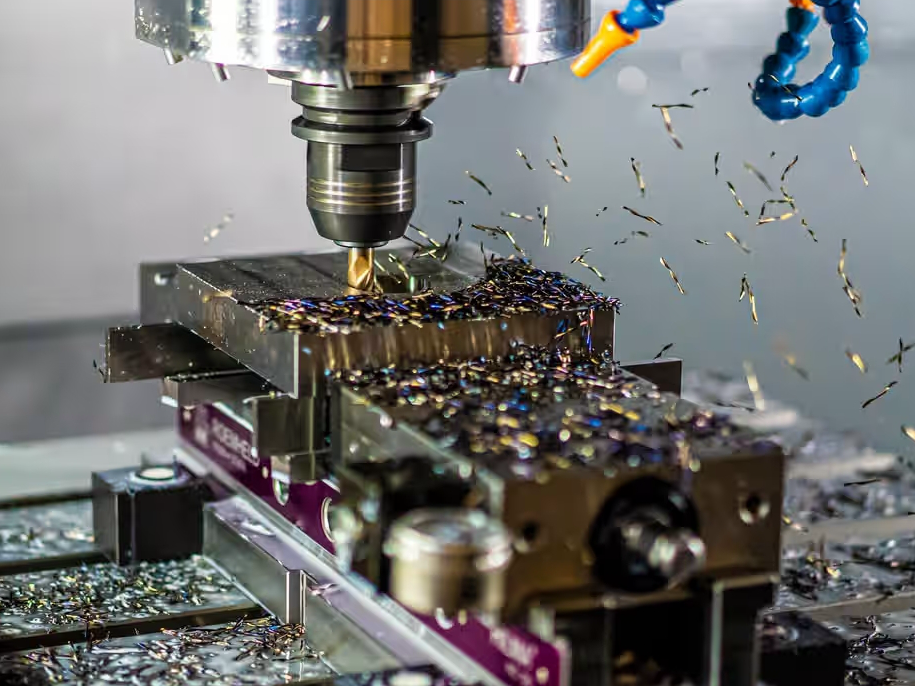

CNC milling is a cornerstone of modern precision manufacturing. From simple brackets to complex aerospace components, the capabilities of CNC milling machines play a critical role in determining part complexity, lead time, surface finish, and cost. One of the key factors buyers must understand when sourcing custom CNC machined parts is the difference between 3-axis, 4-axis, and 5-axis milling.

This guide breaks down what each configuration means, their advantages, and how to choose the right setup for your specific application.

What Is CNC Milling?

CNC (Computer Numerical Control) milling uses rotating cutting tools to remove material from a workpiece mounted on a machine bed. Movement along multiple axes enables precise control over the geometry of the final part.

At Neway, we offer a full range of CNC milling services, including 3-axis, 4-axis, and advanced multi-axis machining for high-complexity components.

Key Differences Between 3-Axis, 4-Axis, and 5-Axis CNC Milling

Configuration | Controlled Axes | Movement Description | Ideal For |

|---|---|---|---|

3-Axis | X, Y, Z | Basic vertical milling—tool moves in 3 directions | Flat surfaces, slots, holes |

4-Axis | X, Y, Z + A (rotary) | Adds rotation around X-axis for machining on multiple sides | Cylindrical parts, holes on side faces |

5-Axis | X, Y, Z + A and B (dual rotary) | Adds rotation around 2 axes—can approach any surface without re-clamp | Complex 3D shapes, undercuts, aerospace, and impellers |

Let’s explore each configuration in more detail.

3-Axis CNC Milling: Cost-Effective for Simpler Parts

3-axis CNC milling is the most common and affordable configuration. The cutting tool moves in three directions (X, Y, Z), while the workpiece remains stationary on the table. This setup is ideal for basic geometries and 2.5D parts.

Typical Capabilities:

Drilling, tapping, contouring, pocketing

Surface roughness: Ra 3.2–1.6 μm

Tolerance range: ±0.1 mm (can be improved with finishing passes)

Best For:

Flat parts with features on a single side

Plates, covers, and brackets

Low-cost prototyping

Limitations:

Requires multiple setups for multi-face machining

Not suitable for undercuts or complex 3D geometries

At Neway, we use high-speed vertical machining centers (VMCs) for efficient and affordable 3-axis milling.

4-Axis CNC Milling: Enhanced Flexibility with Rotary Motion

4-axis CNC milling introduces a rotary axis (typically called the A-axis) that allows the part to rotate around the X-axis. This enables machining on the sides of a workpiece without repositioning.

Typical Capabilities:

Drilling/milling holes on cylindrical surfaces

Machining multiple faces in one setup

Improved part consistency and shorter cycle times

Performance Metrics:

Tolerance range: ±0.05 mm

Rotary axis positioning accuracy: ±15 arc-seconds

Best For:

Shafts, gears, spindles, and cams

Parts with holes or features on multiple sides

Medium complexity components requiring faster turnaround

Advantages:

Reduces setup time and error

Improves repeatability for small batch production

Neway’s 4-axis milling services combine accuracy with production efficiency for medium-complexity parts.

5-Axis CNC Milling: Ultimate Precision for Complex 3D Parts

5-axis CNC milling provides the highest flexibility and precision. In addition to the X, Y, and Z axes, the cutting tool or part rotates along two additional axes (A and B or C). This allows simultaneous multi-angle cutting and the ability to approach nearly any surface without re-fixturing.

Typical Capabilities:

Complex 3D contours and curved surfaces

Machining parts in one setup (“done-in-one”)

Surface roughness: Ra 0.8–1.6 μm

Tight tolerances: ±0.01 mm or better

Best For:

Aerospace and defense components

Impellers, turbine blades, bone implants

High-value, geometrically complex parts

Advantages:

Shortens lead times by reducing setups

Eliminates positioning errors

Enables cutting from difficult angles

Neway's 5-axis milling services support industries like medical, energy, and aerospace with ultra-precise machining.

Comparison Table: Which Axis Configuration Is Right for You?

Factor | 3-Axis | 4-Axis | 5-Axis |

|---|---|---|---|

Setup Time | Medium | Low | Very Low (1-setup) |

Tolerance Range | ±0.1 mm | ±0.05 mm | ±0.01 mm or tighter |

Surface Finish (Ra) | 3.2–1.6 μm | 1.6–1.0 μm | 1.6–0.8 μm |

Machining Time | Medium | Faster | Fastest (optimized tool paths) |

Complexity Level | Simple/Moderate | Moderate | High/Very High |

Cost per Unit | Lowest | Moderate | Higher (offset by fewer setups) |

Industry-Specific Use Cases

Industry | Recommended Axis | Application Example |

|---|---|---|

Aerospace | 5-Axis | Turbine blades, structural brackets |

Medical | 5-Axis | Orthopedic implants, surgical tools |

Automotive | 4-Axis | Cylinder heads, gear housings |

Consumer Goods | 3-Axis | Housings, mounts, connectors |

Robotics | 4/5-Axis | Multi-plane linkages, enclosures, and tool arms |

If you're unsure which axis configuration is ideal, our team at Neway will help evaluate your part geometry and suggest the most cost-effective and precise machining strategy.

How to Choose the Right Configuration

To determine the right CNC milling setup for your project, consider the following:

Geometry: If your part requires multi-surface machining or features at compound angles, 4- or 5-axis is preferred.

Tolerance Requirements: Higher tolerances (±0.01 mm or better) are best achieved with 5-axis systems.

Batch Size and Repeatability: For repeatable machining of parts with features on multiple sides, 4-axis strikes a balance between flexibility and cost.

Budget: 3-axis is the most affordable and sufficient for simple components. However, with fewer setups and faster cycle times, 5-axis machining may be more economical in the long run for complex jobs.

At Neway, we analyze your CAD files and technical drawings to recommend the optimal axis configuration—ensuring high-quality results and competitive pricing.

Conclusion: Matching Milling Complexity to Part Requirements

Choosing between 3-axis, 4-axis, and 5-axis CNC milling is a strategic decision that impacts part accuracy, surface finish, delivery time, and cost. Simpler designs may only require 3-axis, while high-performance industries such as aerospace, defense, and medical manufacturing benefit from the advanced capabilities of 5-axis machining.

With a full suite of multi-axis CNC milling services, Neway is equipped to handle everything from prototypes to mass production—across all complexity levels and material types.

Frequently Asked Questions (FAQs)

What is the cost difference between 3-axis and 5-axis CNC milling for the same part?

When should I choose 5-axis milling over 4-axis for a complex geometry?

How do tolerances vary between 3-axis and 5-axis milling machines?

Can I combine multiple axis configurations in one production workflow?

What industries require 5-axis CNC milling as a standard?