Understanding Machining Tolerances: What Buyers Must Know Before Ordering CNC Parts

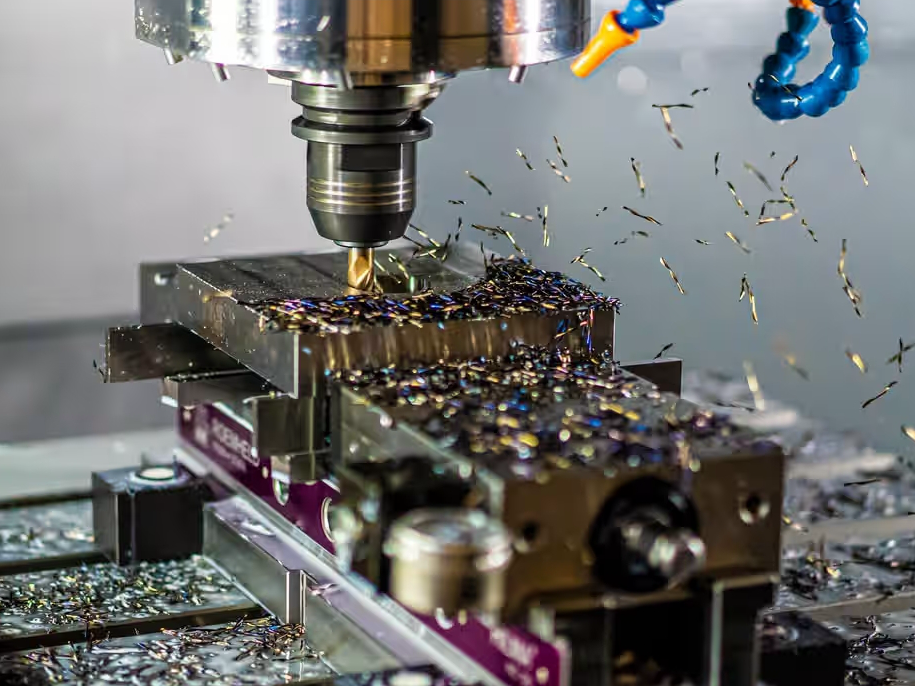

When ordering custom CNC machined parts, understanding machining tolerances is crucial. Tolerances directly impact part fit, performance, cost, and lead time—especially in aerospace, medical, and automotive industries where precision is non-negotiable. This guide explains machining tolerances, their definition, and what buyers should consider when specifying them for CNC manufacturing.

When ordering custom CNC machined parts, understanding machining tolerances is crucial. Tolerances directly impact part fit, performance, cost, and lead time—especially in aerospace, medical, and automotive industries where precision is non-negotiable. This guide explains machining tolerances, their definition, and what buyers should consider when specifying them for CNC manufacturing.

What Are Machining Tolerances?

In CNC machining, a tolerance is the permissible variation in a part’s dimension from its nominal (or ideal) value. Because no manufacturing process can produce perfectly exact dimensions every time, tolerances set acceptable upper and lower limits for size and geometry.

For instance, a shaft with a specified diameter of Ø10.00 mm ±0.02 mm permits actual measurements between 9.98 mm and 10.02 mm. This tolerance range ensures the shaft fits securely into its mating bore without excessive looseness or tightness.

Tolerances are critical to ensuring components' interchangeability, functionality, and repeatability, especially when multiple parts are manufactured separately and later assembled.

Common Types of CNC Machining Tolerances

Machining tolerances are generally categorized into dimensional and geometric tolerances. Buyers should understand both when designing and specifying precision parts.

Dimensional tolerances:

Linear tolerances apply to length, width, and thickness features.

Diameter tolerances are common for shafts, pins, and holes.

Angular tolerances specify permissible deviation from specified angles.

Geometric Dimensioning & Tolerancing (GD&T):

Flatness controls surface straightness without reference to a datum.

Parallelism ensures two surfaces are equidistant across their lengths.

Cylindricity ensures uniform roundness and straightness of a cylindrical part.

True position defines allowable location variation for features like holes or slots.

Concentricity and runout manage rotational alignment for shafts or bores.

Neway supports full GD&T-compliant manufacturing with advanced inspection through precision CNC machining services for tight-tolerance applications in aerospace, robotics, and medical fields.

Standard Tolerance Grades in CNC Machining

Machining tolerances are often based on international standards such as ISO 2768 and ASME Y14.5. These standards define general tolerance classes for dimensions not explicitly toleranced in drawings.

According to ISO 2768-1, the following general tolerances apply to features between 0.5 mm and 30 mm:

Tolerance Class | Typical Linear Tolerance | Suitable Applications |

|---|---|---|

ISO 2768-f (Fine) | ±0.05 mm | Aerospace, optical devices |

ISO 2768-m (Medium) | ±0.10 mm | Automotive, mechanical assemblies |

ISO 2768-c (Coarse) | ±0.20 mm | Structural or non-critical parts |

Neway typically offers ±0.10 mm or better as a standard tolerance across most CNC machining services. We can achieve tolerances down to ±0.005 mm for ultra-precision applications with CMM-verified inspections.

How Tolerances Impact Cost and Lead Time

Tighter tolerances require more specialized tooling, reduced cutting speeds, and advanced inspection—all of which increase production time and cost. As tolerance tightens, the risk of part rejection also increases due to reduced margin for error.

For example:

A tolerance of ±0.10 mm may require basic tool paths and minimal inspection.

±0.05 mm necessitates precision machining and partial CMM checks.

±0.01 mm or tighter involves climate-controlled environments, high-end metrology, and specialized cutting tools.

Cost implications:

Machining ±0.10 mm features may cost 1.0× baseline

Machining ±0.05 mm features can cost 1.5–2.0×

Machining ±0.01 mm features often costs 3.0× or more

At Neway, our engineering team provides DFM consultation to help you select tolerances that align with both performance and budget goals.

When to Use Tight or Loose Tolerances

Tolerances should be based on the functional role of each dimension. Over-tolerancing leads to unnecessarily high manufacturing costs, while under-tolerancing may compromise assembly or performance.

Use tight tolerances (±0.01–0.03 mm) for:

Press-fit shafts and bearing bores

Sealing surfaces for hydraulic systems

Medical instruments and surgical components

Aerospace brackets requiring precise alignment

Use standard or loose tolerances (±0.05–0.20 mm) for:

Cover plates or housings

Mounting flanges

Cosmetic components or non-mating features

Neway offers DFM support to review your drawings and recommend optimal tolerances based on intended use, mating components, and industry practices.

Inspection and Quality Control of Toleranced Features

Tight tolerances demand accurate and repeatable measurement techniques. Quality control at Neway includes the following equipment and methods:

Coordinate Measuring Machine (CMM): Accurate to ±2 µm for verifying GD&T and tight dimensions

Optical comparators: Project magnified part profiles for visual tolerance verification

Digital calipers and micrometers: Accurate to ±0.01 mm for routine inspection

Pin gauges and bore gauges: Used to check holes and internal features

Go/No-Go gauges: Cost-effective validation of critical limits

Neway supports full documentation, including material certification, inspection reports, and First Article Inspection (FAI) as required by customers in regulated industries.

How to Specify Tolerances on Your Drawings

To avoid ambiguity and rework, clearly communicating tolerance requirements on part drawings is essential. Here are recommended practices:

Specify general tolerance class (e.g., ISO 2768-m) in the title block

Add specific tolerances for critical dimensions directly next to the feature

Use proper GD&T symbols and datums for features requiring geometric control

Include surface finish requirements, especially for sealing or optical components

If you are submitting a STEP or IGES model without a 2D drawing, include a separate PDF with tolerance annotations or a general note such as “Unless specified: ±0.10 mm.”

Neway’s quoting team will contact you during the RFQ process if any tolerance conflicts or ambiguities are found, helping avoid costly delays.

How Neway Helps Optimize Tolerances

At Neway, we deliver custom CNC machining solutions across aluminum, stainless steel, titanium, copper, plastic, and ceramic materials. Our facilities have high-precision multi-axis machining, EDM machining, and in-house CMM inspection.

We help clients:

Review 2D/3D files to identify over-constrained tolerances

Suggest alternate fits (e.g., H7/g6) or general tolerance classes

Balance performance and cost for high- or low-volume production

Meet the strictest quality requirements with traceable documentation

Our experience across industries such as aerospace, medical, automation, and consumer electronics ensures that your tolerances align with your real-world application.

Conclusion

Understanding machining tolerances is key to successful part performance and cost efficiency. Buyers should define tolerances that match function, apply industry standards such as ISO 2768 and ASME Y14.5, and consult with their CNC partner for design optimization.

With Neway’s advanced machining capabilities, materials expertise, and precision inspection, we ensure your parts are manufactured to the exact specifications needed—no more, no less.

To get started, explore our CNC machining services or contact our engineering team for a free tolerance review today.

Frequently Asked Questions (FAQs)

What is the tightest machining tolerance Neway can achieve on custom CNC parts?

How do I know which dimensions on my part require tight tolerances?

Will tighter tolerances significantly increase the lead time for my project?

Can I request a tolerance review or optimization during the quoting process?

What inspection reports are included with precision CNC machined components?