What Determines the Cost of CNC Milled Parts? A Breakdown for Buyers

For buyers sourcing custom CNC-milled parts, understanding what drives cost is crucial for budgeting, comparing quotes, and optimizing designs. CNC milling offers unmatched precision and flexibility, but the final price of a component is influenced by many technical and operational factors.

This guide provides a clear breakdown of the elements determining CNC milling costs—from design complexity and material selection to tolerances, surface finish, and order volume—so you can make informed purchasing decisions.

Key Cost Drivers in CNC Milling

CNC milling costs can be grouped into five main categories:

Material cost

Machining time and complexity

Tolerances and surface finish

Setup and tooling

Quantity and batch size

Let’s explore each factor in detail.

1. Material Selection and Cost

The choice of material significantly impacts the cost of CNC milled parts—not only because of the raw material price, but also due to its machinability.

Material Cost Comparison

Material | Approx. Cost (USD/kg) | Machinability | Notes |

|---|---|---|---|

Aluminum 6061 | 4.00–6.00 | Excellent | Lightweight, easy to machine |

Stainless Steel 304 | 6.00–8.00 | Moderate | Strong, corrosion-resistant, work-hardens |

Titanium Ti-6Al-4V | 20.00–35.00 | Difficult | Low thermal conductivity, slow to machine |

Brass C360 | 6.00–8.00 | Excellent | Fast machining, minimal tool wear |

PEEK | 60.00–100.00 | Moderate | High-performance thermoplastic |

Acetal (POM) | 4.00–6.00 | Good | Good stability and wear resistance |

Materials that are hard, gummy, or have low thermal conductivity increase machining time, tool wear, and cooling requirements, resulting in higher costs. At Neway, our CNC milling services support all major engineering metals and plastics with optimized feeds and speeds.

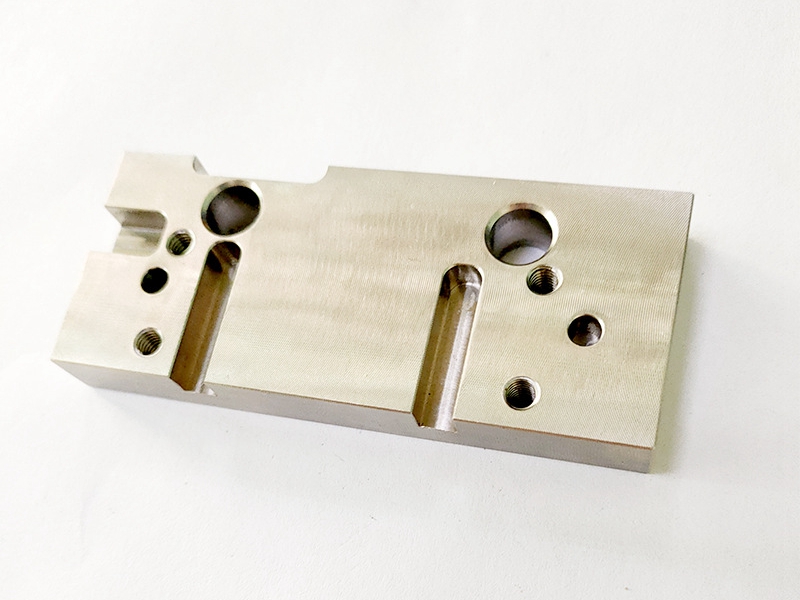

2. Machining Time and Geometric Complexity

Machining time is one of the largest cost contributors. The more complex the geometry, the longer the machine needs to cut, reposition, and finish the part.

Relationship Between Complexity and Time

Complexity Level | Typical Machining Time | CNC Setup |

|---|---|---|

Simple rectangular block | 10–20 minutes | 3-axis |

Multi-face bracket | 30–60 minutes | 4-axis |

Aerospace impeller | 1–4 hours | 5-axis |

Parts with deep pockets, tight internal radii, or intricate 3D contours require multiple toolpaths, slower finishing passes, and more advanced equipment such as multi-axis CNC machining. All of these extend machining time and increase cost.

3. Tolerances and Surface Finish Requirements

Tighter tolerances and specialized surface finishes increase both time and cost due to slower feeds, specialized tooling, and extended inspections.

Tolerance Range Impact

Tolerance Class | Range (mm) | Cost Impact | Typical Use |

|---|---|---|---|

Standard | ±0.1 | Baseline | Non-critical fits, brackets, general use |

Precision | ±0.05 | +30% | Functional parts, mating features |

High Precision | ±0.01 or better | +50–100% | Aerospace, medical, sealing surfaces |

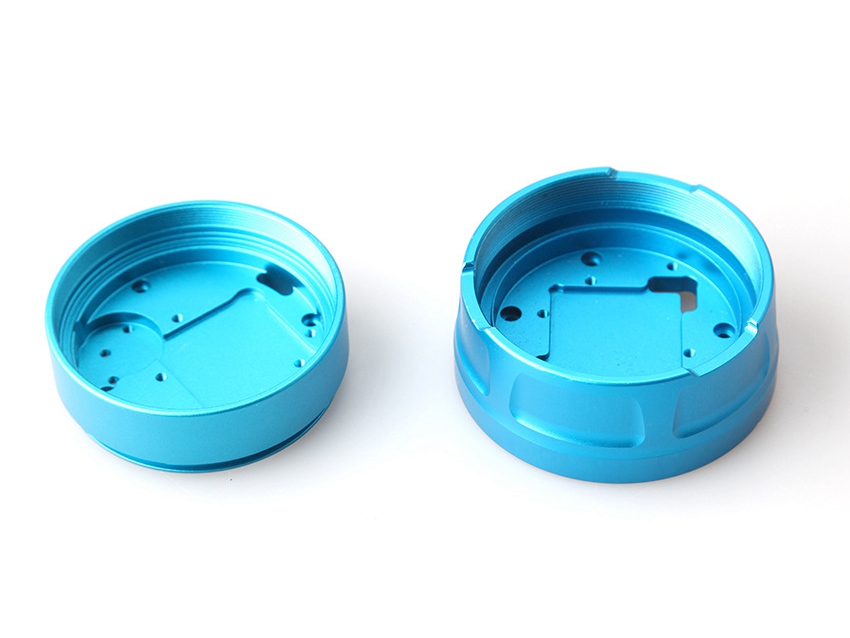

Surface Finish Options

Finish Type | Roughness (Ra, µm) | Added Cost | Suitable For |

|---|---|---|---|

As-machined | 3.2–1.6 | None | Internal parts, prototypes |

Anodized (Type II) | N/A | Medium | Corrosion-resistant aluminum components |

Electropolished | ≤0.4 | High | Stainless steel for hygiene or aesthetics |

Powder Coated | N/A | Medium | Aesthetic protection for steel and aluminum |

Polished | ≤0.8 | Medium–High | Visible parts, optical clarity |

At Neway, we offer finishing solutions that comply with MIL-A-8625, ISO 1302, and other industry standards.

4. Setup and Tooling Requirements

Each new part requires unique CAM programming, tool setup, and fixturing before cutting begins. Setup cost is amortized over the order quantity and becomes significant for low-volume production.

Setup Time Estimates

Activity | Duration (minutes) | Notes |

|---|---|---|

CAM Programming | 30–90 | Depends on part geometry and toolpaths |

Fixture Design and Setup | 20–60 | May be reused for repeat orders |

First Article Inspection | 15–45 | Required for tight-tolerance components |

Depending on complexity, setup costs typically range from USD 100–300 per part. Reducing setup through design consolidation, standardization, or repeat ordering lowers total unit cost.

5. Quantity and Batch Size

Unit cost is heavily influenced by production volume. As order size increases, setup, programming, and tool change costs are spread across more parts.

Cost per Unit vs. Quantity (Aluminum 6061, 100 × 60 × 25 mm)

Quantity | Approx. Cost per Unit (USD) |

|---|---|

1 | 140–180 |

10 | 45–60 |

100 | 18–25 |

1000 | 10–15 |

Low-volume manufacturing is suitable for pre-production and bridge tooling, while mass production drives per-unit cost down substantially for consistent long-term orders.

Other Cost Considerations

Threading (tapped holes, helicoils) may require manual operations

Custom inserts, pins, or dowels add cost for secondary assembly

Post-machining processes like heat treatment or hard anodizing increase both time and cost

Dimensional inspection reports, material certifications, and RoHS/REACH compliance may be billable depending on buyer requirements

Shipping and packaging costs can vary based on destination, part weight, and handling needs

Neway provides full transparency in our quotes to help you understand all factors driving price.

How to Reduce CNC Milling Costs Without Compromising Quality

Buyers can take several steps to reduce CNC part costs:

Relax tolerances where they’re not functionally necessary

Minimize unnecessary surface finishes

Avoid deep pockets (high aspect ratio) which increase tool deflection

Design parts to be machined in fewer setups

Use common material stock sizes and grades

Increase batch size to amortize setup

We provide DFM (Design for Manufacturability) feedback to help buyers refine geometry for optimal production without compromising part function or quality.

Conclusion: Pricing Transparency and Optimization Lead to Value

Understanding what determines the cost of CNC milled parts gives buyers the advantage when sourcing high-quality components. Each factor influences final pricing and delivery, from materials and tolerances to batch size and finish.

Neway offers precision CNC milling backed by professional quoting, high-capability equipment, and in-house finishing. Whether you're building a prototype or scaling to full production, we’re committed to delivering value through quality, efficiency, and expert support.

Frequently Asked Questions (FAQs)

How can I reduce the cost of CNC milling for complex parts?

What’s the cost difference between 3-axis and 5-axis CNC machining?

How much does surface finishing like anodizing or polishing add to the price?

Why do tight tolerances increase CNC machining costs?

What’s the best material for low-cost prototyping with CNC milling?