Alodine Coating: Essential Corrosion Protection for Aluminum CNC Parts

Introduction

Alodine coating, also known as chem film or chromate conversion coating, is a crucial chemical surface treatment widely applied to CNC-machined aluminum parts. This process involves immersing aluminum components in a chemical bath to produce a thin (0.5–2 µm), corrosion-resistant film that significantly enhances surface durability, electrical conductivity, and paint adhesion without altering component dimensions.

Ideal for industries such as aerospace, automotive, electronics, and military applications. Alodine coating effectively treats intricate geometries, tight tolerances, fine threads, and complex CNC-machined aluminum parts, delivering consistent corrosion resistance and reliable performance in demanding environments.

Alodine Coating Technology: Enhanced Corrosion Resistance for CNC Components

Scientific Principles & Industrial Standards

Definition: Alodine coating is a chemical conversion coating produced through immersion or spraying aluminum parts with chromate-based or non-chromate chemical solutions, forming a thin, protective layer that enhances corrosion resistance, electrical conductivity, and paint bonding.

Governing Standards:

MIL-DTL-5541: Military standard for chemical conversion coatings on aluminum

ASTM B449: Specification for chromate conversion coatings

AMS 2473: Aerospace Material Specification for chemical conversion coatings on aluminum alloys

Process Function and Cases

Performance Dimension | Technical Parameters | Application Cases |

|---|---|---|

Corrosion Protection | - Salt spray resistance: 168–336 hrs (ASTM B117) - Coating thickness: 0.5–2 µm | Aerospace brackets, Military electronic enclosures, Automotive engine components |

Electrical Conductivity | - Surface resistance: <0.5 milliohms/cm² - Ideal for grounding applications | Electronics housings, RF connectors, Communication devices |

Paint Adhesion Enhancement | - Adhesion rating: 5B (ASTM D3359) - Superior primer and paint bonding | Aircraft fuselage components, Automotive trim parts, Marine hardware |

Dimensional Accuracy | - Negligible dimensional change: ≤0.1 µm | Precision machined fittings, Aerospace connectors, Optical instrument housings |

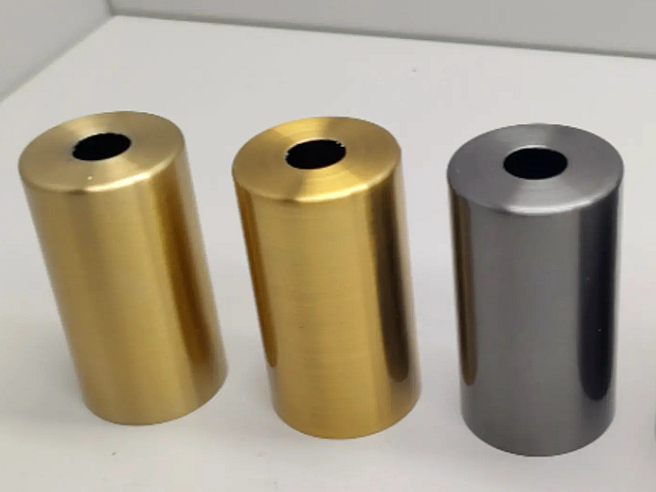

Alodine Coating Process Classification

Technical Specification Matrix

Alodine Coating Type | Key Parameters & Metrics | Advantages | Limitations |

|---|---|---|---|

Chromate Conversion Coating | - Process time: 2–10 min - Thickness: 0.5–2 µm - Color: Gold to tan | - Excellent corrosion resistance - Superior electrical conductivity | - Environmental restrictions (hexavalent chromium) |

Trivalent Chromate Coating | - Process time: 2–15 min - Thickness: 0.5–2 µm - Color: Clear to light blue | - Environmentally safer alternative - Good corrosion resistance | - Slightly lower corrosion resistance compared to hexavalent coatings |

Non-Chromate Conversion Coating | - Process time: 3–10 min - Thickness: 0.5–2 µm - Clear appearance | - Environmentally friendly - Compliance with RoHS and REACH | - Moderate corrosion resistance |

Selection Criteria & Optimization Guidelines

Chromate Conversion Coating (Hexavalent)

Selection Criteria: Ideal for aerospace, military, and high-performance applications demanding maximum corrosion resistance and electrical conductivity.

Optimization Guidelines:

Maintain precise chemical bath parameters and immersion timing

Ensure rigorous post-rinsing to eliminate residues

Regular bath testing to monitor hexavalent chromium levels

Trivalent Chromate Conversion Coating

Selection Criteria: Preferred in applications requiring good corrosion protection combined with environmentally compliant processing.

Optimization Guidelines:

Control chemical bath composition and temperature precisely

Optimize immersion times to achieve a uniform coating

Frequent validation of coating thickness and conductivity

Non-Chromate Conversion Coating

Selection Criteria: Best suited for consumer electronics, automotive, and general industrial applications demanding moderate corrosion protection and strict environmental compliance.

Optimization Guidelines:

Maintain strict control of process conditions (temperature, time, pH)

Post-process sealing is recommended for enhanced protection

Regular coating performance testing (ASTM B117 salt spray test)

Material-Coating Compatibility Chart

Substrate | Recommended Alodine Type | Performance Gain | Industrial Validation Data |

|---|---|---|---|

Hexavalent Chromate Coating | Superior corrosion resistance | Aerospace certified, 336-hour salt spray (ASTM B117) | |

Trivalent Chromate Coating | Excellent environmental compliance | Military-grade performance validation | |

Non-Chromate Conversion Coating | Effective corrosion protection & eco-compliance | Automotive components passed 168-hour salt spray | |

Hexavalent Chromate Coating | Maximum conductivity & adhesion | Aerospace electrical components validated | |

Trivalent Chromate Coating | Optimal combination of protection & compliance | Marine fittings validated for harsh environments |

Alodine Coating Process Control: Critical Steps & Standards

Pre-Treatment Essentials

Surface Cleaning: Alkaline cleaning solution immersion (50–60°C) Validation: Water-break test (ASTM F22)

Surface Etching: Acidic etching (optional) for improved coating adherence Validation: Surface roughness verification (Ra 0.2–0.8 µm)

Alodine Process Controls

Chemical Bath Monitoring: Regular testing of chemical composition and pH Validation: Titration and spectrophotometric analysis

Temperature & Time Control: Accurate thermostatic controls ±2°C Validation: Digital process logging and verification

Post-Coating Enhancement

Rinse & Drying: Thorough rinsing with DI water, controlled drying Validation: Surface residue testing (ASTM F22)

Quality Inspection: Coating thickness and adhesion verification Validation: Adhesion cross-hatch test (ASTM D3359)

FAQs

How does Alodine coating compare to anodizing in corrosion protection?

What are the environmental considerations with hexavalent chromate coatings?

Does Alodine coating significantly impact dimensional tolerances?

Is Alodine coating electrically conductive?

Can Alodine coatings enhance paint adhesion on aluminum CNC parts?