Electroplating: The Secret to Stronger and More Attractive CNC Parts

Introduction

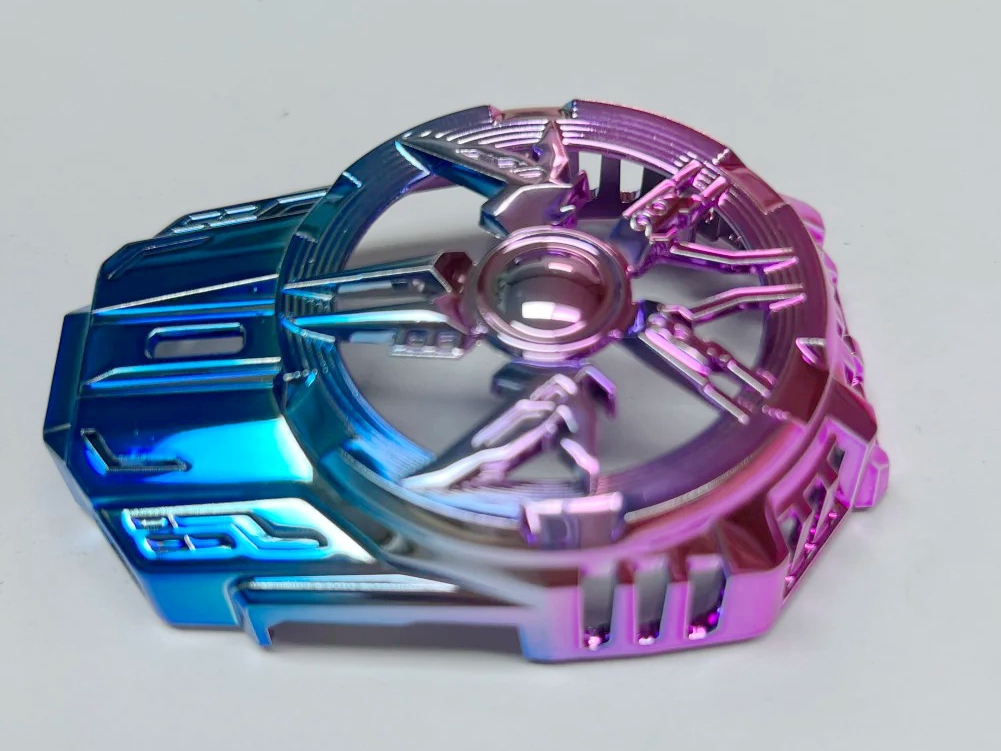

Electroplating is an advanced surface treatment involving the electrodeposition of metallic layers onto CNC machined components, typically following CNC machining. This controlled electrolytic process deposits uniform layers ranging from 5–50 µm, significantly enhancing surface hardness, corrosion resistance, wear durability, and aesthetics. Electroplating also provides attractive metallic finishes such as chrome, nickel, or gold, which are essential for applications demanding visual appeal and improved mechanical performance.

Commonly utilized in industries like automotive, aerospace, electronics, and medical devices, electroplating effectively treats materials such as aluminum alloys, steel, brass, and copper. The process uniformly coats intricate CNC geometries, including deep cavities, fine threads, and complex profiles. Consequently, manufacturers rely on electroplating to deliver robust, attractive, and optimized components for demanding industrial applications.

Electroplating: The Secret to Stronger and More Attractive CNC Parts

Scientific Principles & Industrial Standards

Definition:

Electroplating involves depositing metallic layers onto CNC-machined surfaces through an electrolytic bath, where the component acts as a cathode. Achieving layer thicknesses typically between 5–50 µm, electroplating enhances durability, improves corrosion resistance, and significantly upgrades the visual aesthetics of the parts.

Governing Standards:

ASTM B456: Standard specification for electroplated coatings on metals

ISO 2081: Metallic coatings—Electroplated coatings of zinc

ASTM B117: Salt spray corrosion resistance testing standard

Process Function and Cases

Performance Dimension | Technical Parameters | Application Cases |

|---|---|---|

Corrosion Resistance | 1000–3000 hr salt spray resistance (ASTM B117) | Automotive fasteners, marine hardware, aerospace components |

Wear Resistance | Surface hardness up to HV 900 (Hard chrome) | Hydraulic pistons, injection mold cores, industrial gears |

Decorative Appeal | Uniform, bright metallic finishes | Luxury consumer electronics, jewelry, automotive trims |

Conductivity Improvement | Electrical resistivity <2.5 µΩ·cm (Copper plating) | Electrical connectors, PCB components, RF components |

Surface Finish Classification

Technical Specification Matrix

Electroplating Method | Key Parameters & Metrics | Advantages | Limitations |

|---|---|---|---|

Chrome Plating | Thickness: 10–50 µm; Hardness: HV 700–900 | Excellent wear resistance, bright finish | Potential environmental regulations |

Nickel Plating | Thickness: 10–40 µm; Hardness: HV 500–600 | Good corrosion protection, uniform finish | Potential allergic reactions (nickel) |

Gold Plating | Thickness: 0.5–5 µm; Conductivity: excellent | Superior electrical conductivity, aesthetics | High cost, lower wear resistance |

Zinc Plating | Thickness: 5–25 µm; Corrosion resistance: >2000 hr | Cost-effective, good corrosion protection | Less suitable for severe wear |

Copper Plating | Thickness: 10–30 µm; Resistivity: <2.5 µΩ·cm | Excellent electrical conductivity | Lower corrosion resistance |

Selection Criteria & Optimization Guidelines

Chrome Plating

Selection Criteria: Preferred for high-wear applications needing exceptional hardness and aesthetic brilliance.

Optimization Guidelines: Maintain bath temperature (45–55°C), adjust current density (20–30 A/dm²), and ensure thorough pre-plating surface preparation for best results.

Nickel Plating

Selection Criteria: Ideal for consistent corrosion resistance, decorative purposes, and as an underlayer for subsequent coatings.

Optimization Guidelines: Control plating bath chemistry (pH 3.5–4.5), regulate bath temperature (50–60°C), and maintain stable current densities (5–10 A/dm²).

Gold Plating

Selection Criteria: Essential for electronics and luxury items where superior conductivity and premium appearance are critical.

Optimization Guidelines: Precisely manage gold solution concentrations, maintain low plating temperatures (40–50°C), and use agitation to achieve uniform coating thickness.

Zinc Plating

Selection Criteria: Suitable for cost-effective corrosion protection of steel components in moderately aggressive environments.

Optimization Guidelines: Control electrolyte zinc content (8–12 g/L), maintain bath pH (4.8–5.5), and operate at temperatures between 20–30°C for uniform deposits.

Copper Plating

Selection Criteria: Used predominantly for enhancing electrical conductivity and as a preparatory coating for other plating processes.

Optimization Guidelines: Optimize bath current density (2–5 A/dm²), maintain bath pH (0.8–1.5), and carefully monitor bath cleanliness to prevent surface defects.

Material-Finish Compatibility Chart

Substrate Category | Recommended Electroplating Method | Performance Gain | Industrial Validation Data |

|---|---|---|---|

Nickel Plating | Enhanced corrosion resistance (>2000 hr ASTM B117) | Automotive and aerospace components per ASTM B456 | |

Gold Plating | Excellent conductivity; corrosion resistance | Medical devices compliant with ISO 10993 | |

Chrome Plating | Surface hardness HV 850–900; improved wear resistance | Hydraulic fittings tested per ISO 2081 | |

Zinc Plating | Cost-effective corrosion protection; improved lifespan | Automotive hardware verified per ASTM B117 salt spray | |

Copper Plating | Improved electrical conductivity and EMI shielding | Electronic enclosures validated per ASTM B734 |

Electroplating Process Control: Critical Steps & Standards

Pre-Plating Essentials

Surface Cleaning: Alkaline and acid cleaning to achieve contaminant-free surfaces (ASTM B322 compliance).

Surface Activation: Etching or activation baths (sulfuric/hydrochloric acid solutions) to ensure excellent adhesion (ISO 4527).

Masking and Fixture Setup: Precision masking and jigging to ensure selective coating deposition.

Plating Process Controls

Current Density Control: Maintain specified current densities (±5% tolerance) for uniform deposition.

Bath Chemistry Management: Regularly monitor and adjust electrolyte concentration, pH, and temperature (±2°C accuracy).

Agitation and Circulation: Maintain proper solution agitation for uniform coating thickness and reduced defect rates.

Post-Plating Checks

Coating Thickness Verification: Eddy current or X-ray fluorescence (XRF) testing per ASTM B568 standards.

Adhesion Testing: Tape and bend testing to validate coating adhesion (ASTM B571).

Corrosion Resistance Testing: Salt spray exposure testing in compliance with ASTM B117 standards.

FAQs

What key advantages does electroplating offer compared to anodizing or powder-coating CNC components?

How uniform are electroplated layers on complex CNC geometries?

Can electroplating significantly enhance corrosion resistance for industrial CNC parts?

Which electroplating methods provide the best hardness and wear resistance for mechanical components?

Are there specific material compatibility considerations when choosing electroplating for CNC machined parts?