Electropolishing: A Process That Improves CNC Part Smoothness and Durability

Introduction

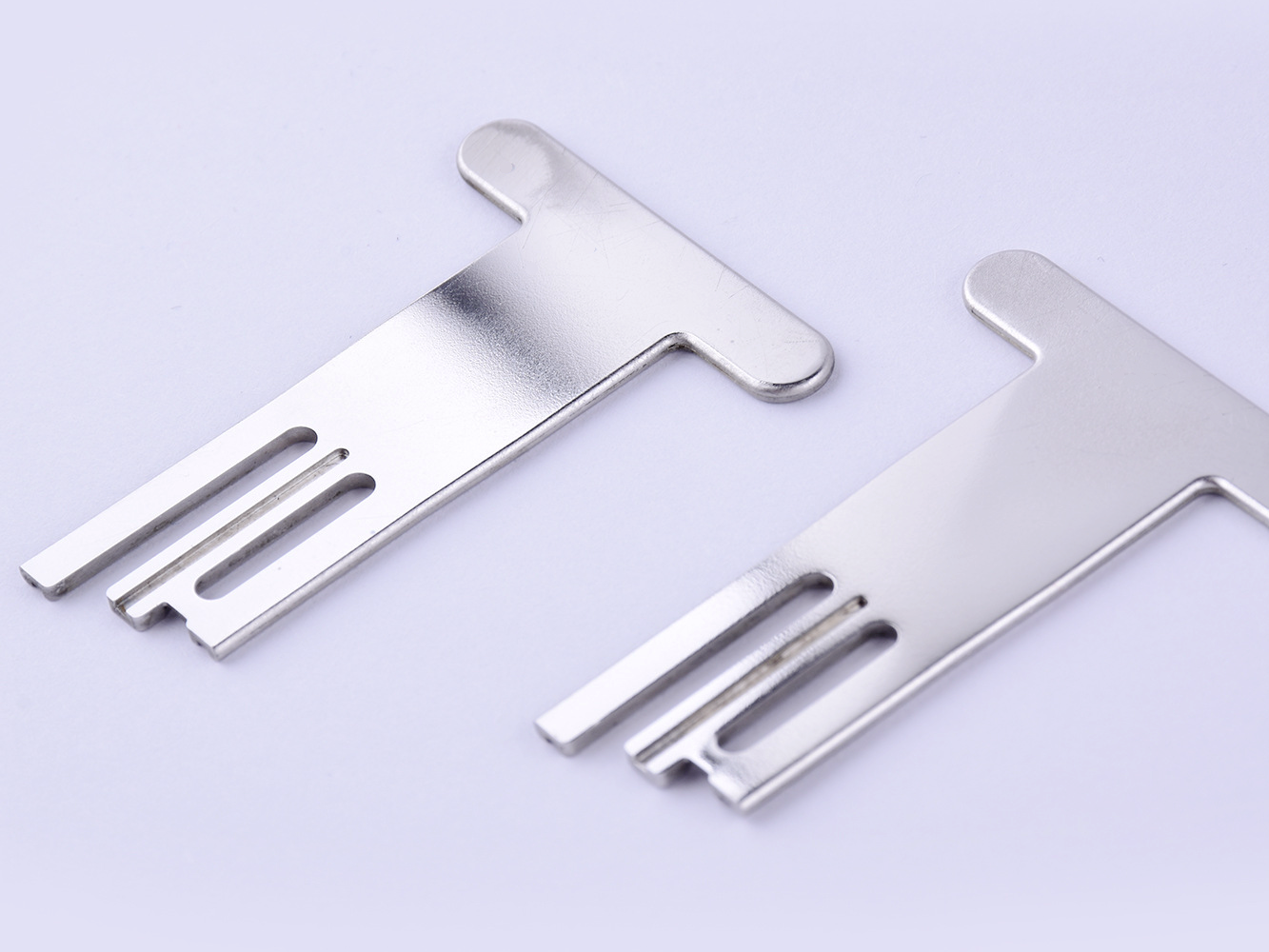

Electropolishing is an advanced electrochemical finishing technique extensively utilized to improve the surface smoothness and durability of CNC machined components. This process produces a highly reflective, ultra-smooth finish typically ranging from 5–40 µm material removal by selectively dissolving microscopic peaks from metal surfaces through controlled electrolysis. It significantly enhances corrosion resistance, mechanical performance, and cleanliness.

Ideal for critical industries such as medical devices, aerospace, and semiconductor manufacturing, electropolishing effectively treats intricate CNC geometries, including thin-walled structures, microchannels, and precision threads, delivering superior surface quality and reliability.

Electropolishing Technology: Advanced Surface Refinement for Enhanced Performance

Scientific Principles & Industrial Standards

Definition: Electropolishing is an electrochemical finishing method where metal surfaces undergo controlled anodic dissolution in an electrolytic bath, resulting in a highly smooth, bright, and corrosion-resistant surface. Typical metal removal is precisely controlled, usually between 5–40 µm.

Governing Standards:

ASTM B912: Standard specification for electropolishing stainless steel alloys

ISO 15730: Metallic and other inorganic coatings – Electropolishing

ASTM E1558: Standard guide for electropolishing titanium and alloys

Process Function and Cases

Performance Dimension | Technical Parameters | Application Cases |

|---|---|---|

Surface Smoothness | - Surface roughness: Ra ≤ 0.1 µm achievable - Uniformity across complex shapes | Medical implants, Semiconductor wafer chambers, Pharmaceutical valves |

Corrosion Resistance | - Salt spray resistance: ≥1,500 hours (ASTM B117) - Passive oxide layer enhancement | Surgical instruments, Marine fittings, Aerospace fasteners |

Cleanability & Sterility | - Surface cleanliness: ISO Class 1 particle-free - Reduced bacterial adhesion | Food processing equipment, Cleanroom fittings, Biopharmaceutical equipment |

Mechanical & Fatigue Performance | - Reduced surface stress concentrations - Fatigue life improvement: up to 30% | Aerospace turbine blades, Automotive suspension components, High-performance gears |

Electropolishing Process Classification

Technical Specification Matrix

Electropolishing Method | Key Parameters & Metrics | Advantages | Limitations |

|---|---|---|---|

Standard Electropolishing (Bath Method) | - Voltage: 6–18 V DC - Temperature: 40–70°C - Removal rate: 5–20 µm/min | - Excellent surface finish - Superior corrosion resistance - Efficient bulk processing | - Bath maintenance required - Limited depth control |

Pulse Electropolishing | - Voltage Pulses: 5–20 V, duty cycle 20–80% - Removal rate: 1–15 µm/min | - Precise surface control - Uniform finish on micro-features - Reduced electrolyte consumption | - Higher equipment complexity |

Localized Electropolishing | - Voltage: 5–15 V DC - Spot treatment capability | - High precision on specific areas - Ideal for repair and targeted polishing | - Slower processing speed |

Dry Electropolishing (Environmentally Friendly) | - Voltage: 10–20 V - Electrolyte-free polishing | - Minimal environmental impact - Lower maintenance - Suitable for sensitive applications | - Limited to specialized applications - High initial investment |

Selection Criteria & Optimization Guidelines

Standard Electropolishing (Bath Method)

Selection Criteria: Optimal for CNC parts requiring uniform finish, corrosion resistance, and batch processing efficiency (medical, food, and semiconductor industries).

Optimization Guidelines:

Maintain electrolyte temperature at 50–60°C

Regular bath composition monitoring to maintain optimal polishing quality

Consistent electrical parameters (current density: 5–50 A/dm²) to ensure even metal removal

Pulse Electropolishing

Selection Criteria: Preferred for intricate CNC parts requiring precise dimensional control and minimal feature distortion (aerospace, precision micro-components).

Optimization Guidelines:

Adjust pulse frequencies and duty cycles to refine surface features

Maintain tight voltage control ±0.5 V accuracy

Ensure high electrolyte purity to enhance finish uniformity

Localized Electropolishing

Selection Criteria: Ideal for high-value CNC components needing targeted polishing, spot repairs, or fine detailing (aerospace repairs, precision molds).

Optimization Guidelines:

Utilize precision electrode positioning

Maintain low voltage for minimal heat generation

Perform detailed inspection post-process

Dry Electropolishing (Environmentally Friendly)

Selection Criteria: Ideal for eco-sensitive applications demanding minimal environmental impact and high cleanliness standards (electronics, medical implants).

Optimization Guidelines:

Ensure consistent electrode gap

Maintain strict voltage control

Implement real-time monitoring to optimize finish quality

Material-Coating Compatibility Chart

Substrate | Recommended Electropolishing Method | Performance Gain | Industrial Validation Data |

|---|---|---|---|

Standard Electropolishing | Improved corrosion resistance | Passed 2,000-hour salt spray (medical device validation) | |

Pulse Electropolishing | Enhanced biocompatibility | FDA-certified orthopedic implants | |

Localized Electropolishing | High precision surface finishing | Aerospace component dimensional accuracy verification | |

Standard Electropolishing | Enhanced conductivity & aesthetics | Semiconductor cooling systems validated for thermal performance | |

Pulse Electropolishing | Reduced surface stress concentrations | Aerospace turbine blades validated with extended fatigue life |

Electropolishing Process Control: Critical Steps & Standards

Pre-Treatment Essentials

Chemical Cleaning: Degreasing with alkaline solution, ultrasonic agitation at 50°C Validation: Water-break test (ASTM F22)

Electrolyte Composition Control: Regular monitoring and replenishment Validation: Electrolyte density/conductivity testing

Electropolishing Process Controls

Voltage and Current Regulation: DC rectifiers with ±1% accuracy Validation: Real-time digital monitoring

Temperature Control: Thermostatically controlled baths within ±2°C Validation: Continuous digital data logging

Post-Coating Enhancement

Rinsing and Drying: Ultra-pure water rinse followed by controlled drying Validation: Surface residue testing (ASTM F22)

Surface Finish Inspection: Precision surface roughness measurement (Ra ≤ 0.1 µm) Validation: ISO 25178 standards compliance

FAQs

How does electropolishing compare with mechanical polishing in terms of surface quality?

What metals and alloys are best suited for electropolishing?

Can electropolishing process intricate features like threads or thin walls effectively?

Is electropolishing suitable for CNC parts in the medical and food industry?

How does electropolishing impact the fatigue life of CNC machined components?