Surface Perfection: How Sandblasting Transforms CNC Machined Parts

Introduction

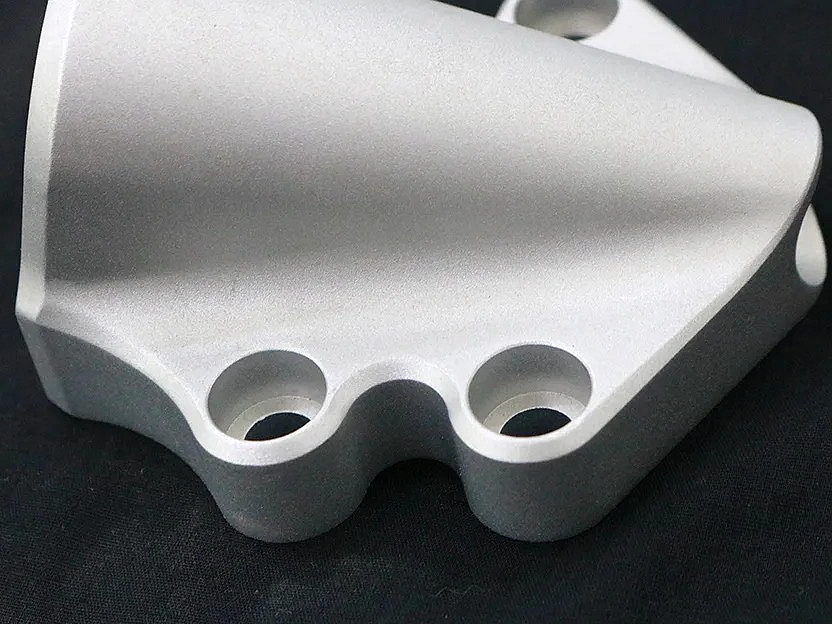

Sandblasting is a mechanical surface treatment applied to CNC machined components, utilizing abrasive media propelled by compressed air to refine surface texture after processes such as CNC machining. Typically achieving surface roughness between Ra 1.2–3.2 μm, sandblasting effectively removes machining marks, burrs, and minor defects. This treatment significantly enhances component aesthetics by creating uniform matte or satin finishes while also preparing surfaces for improved coating adhesion and corrosion resistance.

Widely adopted in automotive, aerospace, medical equipment, and consumer electronics industries, sandblasting efficiently treats diverse materials, including aluminum alloys, stainless steel, and engineering plastics. Capable of uniformly processing complex geometries and intricate features, it helps manufacturers produce visually appealing, high-quality components optimized for subsequent finishing treatments like painting, anodizing, or powder coating.

Surface Perfection: How Sandblasting Transforms CNC Machined Parts

Scientific Principles & Industrial Standards

Definition:

Sandblasting involves the controlled impact of abrasive media, typically aluminum oxide, glass beads, or steel grit, propelled by compressed air onto CNC machined surfaces. It creates uniform textures (Ra 1.2–3.2 μm), removes contaminants, and prepares surfaces for further finishing or protective treatments.

Governing Standards:

ASTM D4417: Standard methods for surface profile measurement

ISO 8501-1: Preparation of steel substrates before coating

SAE J444: Standard for sizing abrasive grains

Process Function and Cases

Performance Dimension | Technical Parameters | Application Cases |

|---|---|---|

Surface Uniformity | Consistent Ra 1.2–3.2 μm surface roughness | Medical device enclosures, precision aerospace components |

Aesthetic Enhancement | Matte or satin visual finishes | Consumer electronics, luxury automotive parts |

Surface Cleaning | Complete removal of oils, burrs, contaminants | Valve bodies, industrial equipment, semiconductor parts |

Coating Adhesion | Improved adhesion strength by >50% | Automotive coatings, anodized aerospace parts |

Surface Finish Classification

Technical Specification Matrix

Sandblasting Method | Key Parameters & Metrics | Advantages | Limitations |

|---|---|---|---|

Aluminum Oxide Blasting | Ra: 1.5–3.2 μm; Hardness: 9 Mohs | Effective deburring, excellent paint adhesion | Potential surface embedding |

Glass Bead Blasting | Ra: 1.2–2.5 μm; Hardness: 6 Mohs | Satin finish, no substrate damage | Less aggressive on heavy burrs |

Steel Shot Blasting | Ra: 2.5–5.0 μm; Hardness: 40–50 HRC | High-intensity cleaning, stress-relief effect | Not suitable for delicate components |

Plastic Media Blasting | Ra: 1.0–2.0 μm; Low hardness (3–4 Mohs) | Gentle cleaning, ideal for delicate parts | Limited durability of media |

Silicon Carbide Blasting | Ra: 2.0–4.0 μm; Hardness: 9.5 Mohs | Aggressive cleaning, rapid surface etching | High material removal rate |

Selection Criteria & Optimization Guidelines

Aluminum Oxide Blasting

Selection Criteria: Preferred for general-purpose surface finishing, effective deburring, and excellent coating preparation.

Optimization Guidelines: Control pressure (4–6 bar), select grain size (#80–120 mesh), and ensure even nozzle movement for uniformity.

Glass Bead Blasting

Selection Criteria: Ideal for achieving smooth, satin-like finishes on precision components with minimal dimensional impact.

Optimization Guidelines: Use fine glass beads (#100–200 mesh), maintain moderate pressures (2–4 bar), and ensure uniform blasting distance (15–25 cm).

Steel Shot Blasting

Selection Criteria: Suitable for robust parts requiring intensive cleaning and stress relief, especially steel and cast components.

Optimization Guidelines: Employ coarse steel shot (S170–S330), carefully manage pressures (5–7 bar), and regularly monitor surface integrity to prevent damage.

Plastic Media Blasting

Selection Criteria: Recommended for delicate materials and lightweight components, ensuring minimal surface alteration.

Optimization Guidelines: Apply low pressures (1–3 bar), select suitable plastic media types (acrylic or melamine-based), and regularly replenish media to maintain consistency.

Silicon Carbide Blasting

Selection Criteria: Used for aggressive surface treatments and quick removal of machining marks on hard materials.

Optimization Guidelines: Set blasting pressures (4–6 bar), use medium-sized abrasive grains (#60–100 mesh), and closely monitor the process to prevent excessive surface erosion.

Material-Finish Compatibility Chart

Substrate Category | Recommended Sandblasting Method | Performance Gain | Industrial Validation Data |

|---|---|---|---|

Glass Bead Blasting | Uniform satin finish; improved paint adhesion | Aerospace components per ASTM D4417 standard | |

Aluminum Oxide Blasting | Effective deburring; enhanced corrosion resistance | Medical devices compliant with ISO 8501-1 | |

Plastic Media Blasting | Gentle cleaning without surface contamination | Aerospace implants tested per SAE AMS2430 | |

Plastic Media Blasting | Delicate surface treatment; low roughness (Ra <2 μm) | Electronic device enclosures validated per ASTM D7127 | |

Steel Shot Blasting | Stress-relieved surfaces; improved fatigue resistance | Industrial tooling verified per ASTM E466 |

Sandblasting Process Control: Critical Steps & Standards

Pre-Blasting Essentials

Surface Degreasing: Removal of oils and contaminants via alkaline washing or solvent cleaning (ISO 8501-1).

Masking and Protection: Precision masking of critical dimensions and threaded areas (ASTM D6123 compliance).

Media Selection: Verified grain size and hardness according to SAE J444 standards.

Blasting Process Controls

Pressure Monitoring: Maintain consistent blasting pressures (±0.2 bar accuracy).

Distance Control: Constant nozzle-to-workpiece distance (15–25 cm) ensures uniform finish.

Media Quality Assurance: Regularly inspect and refresh blasting media to maintain consistent abrasive quality.

Post-Blasting Checks

Surface Roughness Measurement: Validate using profilometers according to ASTM D4417.

Cleanliness Inspection: Ensure contaminant-free surfaces through visual and microscopic evaluation (ISO 8501-1).

Adhesion Test Preparation: Confirm enhanced coating adhesion through standardized tests (ASTM D3359).

FAQs

What are the key advantages of sandblasting CNC machined parts compared to other surface finishing methods?

Can sandblasting damage or distort precision CNC-machined parts?

Which abrasive media is best suited for delicate CNC components?

How does sandblasting improve the adhesion of subsequent coatings like paint or anodizing?

Is sandblasting suitable for all types of CNC materials, including plastics and non-metallic parts?