Tumbling: The Best Way to Deburr and Polish CNC Machining Parts

Introduction

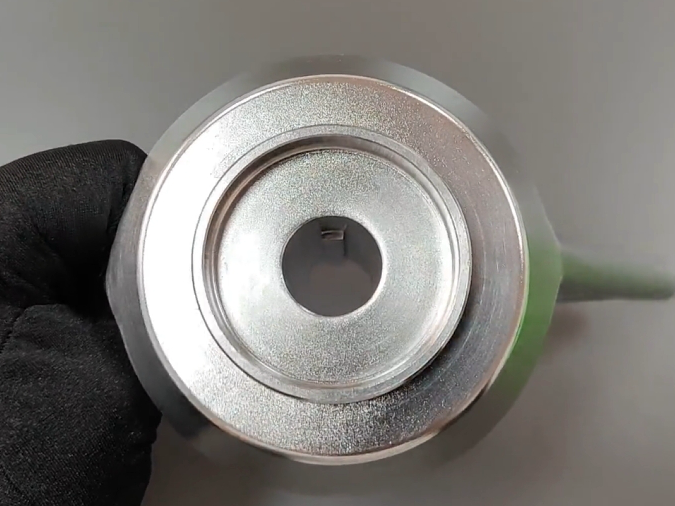

Tumbling, also known as vibratory finishing or barrel finishing, is a highly effective post-processing method extensively used to deburr, smooth, and polish CNC machined parts. It employs mechanical action through abrasive media within rotating barrels or vibratory bowls, efficiently removing burrs, reducing sharp edges, and enhancing surface finish quality. This process significantly improves aesthetics, ensures safe handling, and extends the service life of precision components.

Ideal for industries such as automotive, medical devices, consumer electronics, and aerospace, tumbling effectively treats intricate CNC geometries, internal features, and complex surface structures, preserving dimensional accuracy and ensuring consistent, uniform finishes.

Tumbling Technology: Efficient Deburring and Polishing for CNC Parts

Scientific Principles & Industrial Standards

Definition: Tumbling is a mechanical finishing process utilizing abrasive media and controlled agitation in rotary barrels or vibratory bowls to deburr, polish, and enhance surface finishes. It gently removes material irregularities and surface imperfections, providing a consistent, visually appealing result.

Governing Standards:

ISO 6103: Specification for abrasive products for surface finishing

ASTM B600: Standard guide for descaling and cleaning titanium alloys

ISO 4287: Surface texture profile measurement method

Process Function and Cases

Performance Dimension | Technical Parameters | Application Cases |

|---|---|---|

Deburring Efficiency | - Effective burr removal: >95% removal - Edge radius consistency: ±0.05 mm | Medical instruments, Automotive fasteners, Electronics housings |

Surface Smoothness | - Surface roughness improvement: Ra ≤0.1–0.4 µm achievable - Uniformity across batches | Aerospace fittings, Consumer electronics casings, Precision valves |

Polishing and Aesthetics | - Reflectivity enhancement: ≥80% increase - Visually consistent finish | Automotive trim components, Luxury consumer products, Surgical tools |

Dimensional Integrity | - Minimal dimensional impact: ≤0.02 mm tolerance maintained | Precision gears, Threaded connectors, Complex aerospace parts |

Tumbling Process Classification

Technical Specification Matrix

Tumbling Method | Key Parameters & Metrics | Advantages | Limitations |

|---|---|---|---|

Rotary Barrel Tumbling | - Speed: 20–40 RPM - Media: ceramic, plastic, steel - Processing time: 1–6 hrs | - Economical for high-volume parts - Efficient deburring & edge rounding | - Longer cycle times - Possible dimensional variation |

Vibratory Tumbling | - Frequency: 900–3000 cycles/min - Media Variety: ceramic, plastic, porcelain | - Shorter cycle times - Uniform surface finishes - Minimal dimensional change | - Higher equipment investment |

Centrifugal Disc Finishing | - RPM: 50–300 RPM - Aggressive finishing action | - Rapid deburring and polishing - Efficient for small components | - Limited to smaller parts - Risk of excessive material removal |

Centrifugal Barrel Finishing | - High-speed rotation: 100–250 RPM - Media variety: ceramic, plastic, porcelain | - Precise dimensional control - Ideal for high-precision components | - Complex machinery setup - Higher operational costs |

Selection Criteria & Optimization Guidelines

Rotary Barrel Tumbling

Selection Criteria: Best suited for high-volume parts requiring cost-effective deburring, smoothing, and general finishing operations.

Optimization Guidelines:

Maintain consistent barrel rotation (20–40 RPM)

Regularly inspect and replenish media

Control cycle duration to minimize dimensional impacts

Vibratory Tumbling

Selection Criteria: Ideal for delicate CNC parts demanding uniform finishing, minimal dimensional change, and efficient processing times.

Optimization Guidelines:

Precisely control frequency (900–3000 cycles/min)

Choose appropriate abrasive media types (ceramic, plastic)

Monitor processing times closely for optimal surface results

Centrifugal Disc Finishing

Selection Criteria: Recommended for small CNC machined components requiring aggressive and rapid deburring and polishing.

Optimization Guidelines:

Adjust disc speed carefully (50–300 RPM)

Select media based on component hardness and finishing requirements

Short, controlled cycles to prevent excessive material removal

Centrifugal Barrel Finishing

Selection Criteria: Preferred for precision CNC components needing fine surface finishes, tight dimensional control, and minimal material loss.

Optimization Guidelines:

Regulate high-speed rotation settings (100–250 RPM)

Utilize carefully selected media for surface optimization

Regular inspection to ensure dimensional tolerances

Material-Coating Compatibility Chart

Substrate | Recommended Tumbling Method | Performance Gain | Industrial Validation Data |

|---|---|---|---|

Vibratory Tumbling | Superior surface finish, minimal dimensional changes | Validated surface roughness Ra ≤0.2 µm | |

Rotary Barrel Tumbling | Excellent deburring & edge rounding | Automotive parts passed stringent edge inspection criteria | |

Centrifugal Barrel Finishing | Precise dimensional control & polishing | Medical implants validated for strict FDA requirements | |

Vibratory Tumbling | Enhanced aesthetic appearance | Consumer electronics components meeting aesthetic standards | |

Centrifugal Disc Finishing | Rapid & effective deburring | Machinery parts validated for minimal burr presence |

Tumbling Process Control: Critical Steps & Standards

Pre-Treatment Essentials

Cleaning & Degreasing: Ultrasonic or alkaline baths Validation: Water-break test (ASTM F22)

Media Selection: Appropriate abrasive selection Validation: ISO 6103 compliance

Tumbling Process Controls

Cycle Time Management: Strictly monitor and control processing durations Validation: Visual inspection & surface roughness measurement (ISO 4287)

Media Condition: Routine inspection and replacement Validation: Consistency checks to maintain finishing uniformity

Post-Process Enhancement

Surface Finish Inspection: Surface roughness and visual quality checks Validation: ISO 4287 surface measurement standards

Dimensional Accuracy Verification: Precise dimensional inspection Validation: ISO 2768 tolerance compliance

FAQs

How does tumbling compare to manual deburring and polishing?

Can tumbling effectively process internal threads or intricate CNC features?

What media types are best suited for polishing CNC machined aluminum components?

Is tumbling suitable for high-precision medical device components?

What is the typical processing time for vibratory finishing CNC parts?