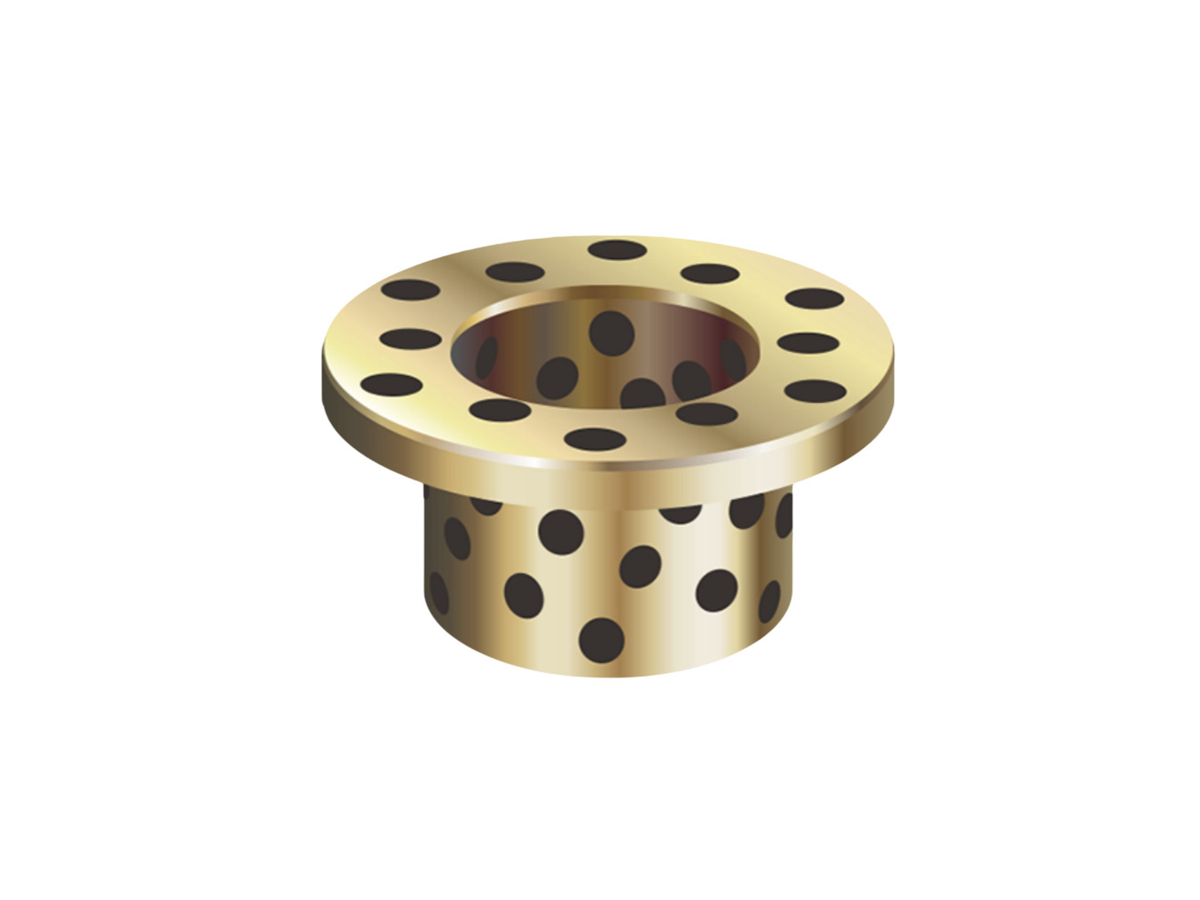

Brass C377 CNC Machining Components for Durable Plumbing and Automotive Components

Engineering Excellence in Corrosion-Resistant Systems

Modern plumbing and automotive systems demand components that withstand high-pressure fluids, dezincification, and cyclic thermal stresses. Brass C377 (CuZn39Pb3) has emerged as the gold standard, offering 500 MPa tensile strength and 35% zinc content for optimal machinability. Precision CNC machining services produce leak-proof valve bodies and fuel system parts with ±0.02mm tolerances—critical for ISO 4038 hydraulic compliance.

A 2023 industry study on C377 brass fittings processed via multi-axis turning showed zero failures after 50,000 pressure cycles in 90°C coolant environments.

Material Selection: Optimizing for Performance and Cost

Material | Key Metrics | Applications | Limitations |

|---|---|---|---|

500 MPa UTS, 35% Zn, 3% Pb | Hydraulic fittings, fuel injector bodies | Limited to <200°C continuous operation | |

750 MPa UTS, 16% Cr content | Marine plumbing systems | Requires slower machining speeds | |

310 MPa UTS, 2.7g/cm³ density | Lightweight automotive brackets | Poor wear resistance in abrasive media | |

90 MPa UTS, 260°C thermal stability | Chemical-resistant valves | 5x higher cost than brass |

Material Selection Protocol

High-Pressure Fluid Systems

Rationale: C377's lead content enables 50% faster machining vs. lead-free brass, reducing production costs by 30%. Combined with electroless nickel plating, corrosion resistance meets ASTM B633 Class 2 requirements.

Cost-Sensitive Mass Production

Logic: C377's 85% machinability rating (vs. 100% for free-cutting brass) balances tool life and part cost. Swiss turning achieves <0.01mm runout for high-volume fittings.

CNC Machining Process Optimization

Process | Technical Specifications | Applications | Advantages |

|---|---|---|---|

0.005mm roundness, 3,000 RPM spindle | Fuel rail connectors | Single-setup machining of complex ports | |

20xD aspect ratio, 0.02mm straightness | Hydraulic valve bodies | Maintains ±0.5° angular accuracy | |

M5-M30 threads, 400% fatigue life improvement | Pipe fittings | Cold-worked surfaces resist galling | |

50 m/min feed rate, 0.1mm stepover | Custom flange faces | Achieves Ra 0.8μm sealing surfaces |

Production Strategy for Hydraulic Fittings

Precision Blank Preparation

Cold-forged C377 billets improve grain flow for 25% higher pressure ratings.

Adaptive Machining

6-axis CNC combines drilling and threading operations, reducing cycle times by 40%.

Surface Enhancement

Micro-bead blasting creates 2-3μm Ra finish for optimal O-ring sealing.

Surface Engineering: Extending Service Life

Treatment | Technical Parameters | Technical Benefits | Standards |

|---|---|---|---|

25μm thickness, 550 HV hardness | Salt spray resistance >1,000 hours | ASTM B733 Class 2 | |

0.1μm CrO₃ layer, <0.5μg/cm² lead leaching | Drinking water system compliance | NSF/ANSI 61 | |

0.2mm depth, permanent identification | Traceability for automotive components | ISO 9001:2015 |

Coating Selection Logic

Marine Plumbing

Electroless nickel with 0.3% phosphorus withstands 5% NaCl spray per ASTM B117 for 2,000+ hours.

Potable Water Systems

Passivated surfaces reduce lead leaching to <0.25μg/L, exceeding NSF/ANSI 61 requirements.

Quality Control: Industry-Compliant Validation

Stage | Critical Parameters | Methodology | Equipment | Standards |

|---|---|---|---|---|

Material Certification | Cu 58-60%, Pb 2.5-3.5% | XRF spectroscopy | Olympus Vanta Element | ASTM E1251 |

Pressure Testing | 25 MPa @ 10⁴ cycles | Hydraulic burst test rigs | Pressure Technology IST-10K | SAE J2044 |

Corrosion Resistance | 240h neutral salt spray | Cyclic corrosion chambers | Q-Fog CRH2200 | ASTM B117 |

Certifications:

ISO 9001:2015 compliant manufacturing

ASME B16.34 valve standards

Industry Applications

Fuel Injection Systems: CNC-turned C377 nozzles (0.1mm orifice precision)

HVAC Valves: Laser-marked C377 bodies (50-year lifespan in chlorinated water)

Brake Line Fittings: Thread-rolled C377 connectors (1,500+ N·m torque capacity)

Conclusion

Precision Brass C377 CNC machining delivers components outperforming stainless steel in cost/performance ratio. Our automotive manufacturing solutions ensure ASME-compliant parts with full PPAP documentation.

FAQ

Why choose C377 over lead-free brass for plumbing?

How does thread rolling improve fatigue resistance?

Best surface treatment for drinking water systems?

How to validate C377 composition compliance?

What CNC parameters prevent brass chip welding?