Ceramic CNC Machining for Extreme-Temperature Oil and Gas Applications

Introduction to Ceramic CNC Machining for Oil and Gas Applications

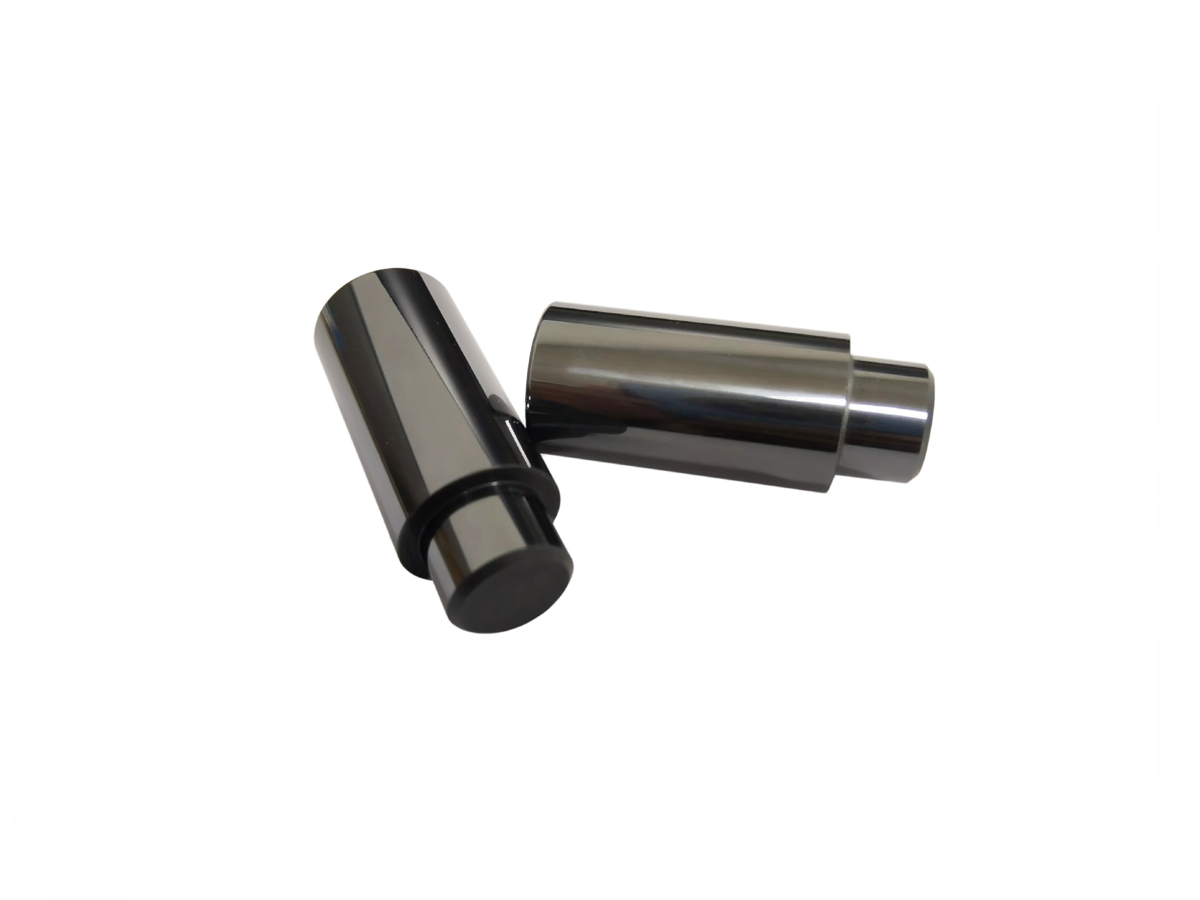

Components often face extreme temperatures, pressures, and corrosive environments in the demanding oil and gas industry. Ceramic materials have emerged as an essential solution, offering unparalleled strength, wear resistance, and thermal stability. Precision CNC machining services enable the production of ceramic parts with tight tolerances and superior surface finishes, iwhich are deal for critical applications in oil and gas exploration, drilling, and production. Ceramic CNC machining produces components such as seals, valve seats, insulators, and bearings that can withstand harsh conditions while maintaining performance.

Ceramic CNC machining is used to fabricate complex geometries from materials like alumina (Al₂O₃), zirconia (ZrO₂), and silicon carbide (SiC), which exhibit exceptional resistance to thermal expansion, high wear resistance, and chemical inertness—making them suitable for extreme-temperature and high-pressure applications in the oil and gas sector.

Material Performance Comparison for Ceramic Parts in Oil and Gas

Material | Compressive Strength (MPa) | Thermal Conductivity (W/m·K) | Hardness (Mohs Scale) | Wear Resistance | Typical Applications | Advantages |

|---|---|---|---|---|---|---|

2500 | 30 | 9 | Excellent | Valve seats, pumps, seals | High wear resistance, cost-effective | |

2200 | 2.5 | 8 | Good | Insulators, bearings, nozzles | Excellent fracture toughness, thermal stability | |

4000 | 120 | 9.5 | Exceptional | Seals, bearings, liners | Superior hardness, thermal conductivity | |

2000 | 30 | 4 | Moderate | Lubricating components, thermal insulators | High thermal stability, low friction |

Material Selection Strategy for Ceramic Parts in Oil and Gas Applications

Alumina (Al₂O₃) provides a cost-effective solution for many oil and gas components such as valve seats and pumps. Its high compressive strength (2500 MPa) and excellent wear resistance make it ideal for applications subject to mechanical stress and wear.

Zirconia (ZrO₂), with excellent fracture toughness and thermal stability, is suitable for components like bearings and insulators, especially in environments where impact resistance and thermal cycling are critical. It also offers resistance to thermal shock, which is important in extreme-temperature applications.

Silicon Carbide (SiC), known for its superior hardness (Mohs 9.5), thermal conductivity (120 W/m·K), and wear resistance, is ideal for high-performance components in demanding oil and gas applications, such as seals, bearings, and liners.

Boron Nitride (BN), while offering lower wear resistance, is a great choice for lubricating components and thermal insulators. It excels in high-temperature environments and provides excellent thermal stability, making it ideal for oil and gas applications involving extreme heat.

CNC Machining Processes for Ceramic Parts

CNC Machining Process | Dimensional Accuracy (mm) | Surface Roughness (Ra μm) | Typical Applications | Key Advantages |

|---|---|---|---|---|

±0.005 | 0.2-0.8 | Complex ceramic parts, seals, valve seats | High precision, intricate geometries | |

±0.005-0.01 | 0.4-1.2 | Cylindrical ceramic components, bushings | Excellent rotational symmetry | |

±0.01-0.02 | 0.8-1.6 | Precision holes in ceramic components | Accurate hole placement | |

±0.002-0.005 | 0.1-0.4 | Surface finishing of ceramic parts | Superior surface smoothness |

CNC Process Selection Strategy for Ceramic Parts

5-Axis CNC Milling is recommended for intricate, high-precision ceramic parts such as valve seats and seals, enabling the machining of complex geometries with tight tolerances (±0.005 mm) and superior surface finishes (Ra ≤ 0.8 µm).

Precision CNC Turning ensures high rotational accuracy (±0.005 mm), ideal for cylindrical components like bushings, bearings, and other oil and gas components requiring smooth, uniform rotational features.

CNC Drilling is used for creating precise and repeatable holes (±0.01 mm) in ceramic parts, which are necessary for mounting and assembly in critical applications like thermal insulators and valves.

CNC Grinding delivers exceptionally fine surface finishes (Ra ≤ 0.4 µm), ensuring smoothness and optimal surface quality for ceramic parts requiring a high finish level, such as seals and nozzles.

Surface Treatment Performance for Ceramic Parts in Oil and Gas Applications

Treatment Method | Surface Roughness (Ra μm) | Corrosion Resistance | Hardness (HV) | Applications |

|---|---|---|---|---|

0.4-1.0 | Excellent (>1000 hrs ASTM B117) | 400-600 | Alumina valve seats, pumps | |

0.1-0.4 | Superior (>1000 hrs ASTM B117) | N/A | Zirconia components, bearings | |

0.6-1.2 | Excellent (>800 hrs ASTM B117) | 300-400 | SiC components, seals | |

0.8-1.6 | Good (>500 hrs ASTM B117) | Moderate | BN insulating components |

Typical Prototyping Methods

CNC Machining Prototyping: Precision prototypes (±0.005 mm) are ideal for testing complex ceramic parts in extreme environments.

Rapid Molding Prototyping: Fast production of prototypes for ceramic components like seals and valve seats, allowing for rapid testing and adjustments.

3D Printing Prototyping: Cost-effective iterative prototyping (±0.1 mm accuracy), suitable for early-stage design validation of ceramic parts.

Quality Inspection Procedures

CMM Inspection (ISO 10360-2): Dimensional verification of ceramic components with tight tolerances.

Surface Roughness Test (ISO 4287): Ensures ceramic surfaces meet required smoothness standards.

Salt Spray Test (ASTM B117): Verifies the corrosion resistance of ceramic parts in harsh conditions.

Visual Inspection (ISO 2859-1, AQL 1.0): Ensures visual and functional quality of ceramic parts.

ISO 9001:2015 Documentation: Ensures full traceability and compliance with industry standards.

Industry Applications

Oil and Gas: Ceramic seals, valve seats, pump components, bearings.

Aerospace: Insulating components, wear-resistant parts, engine components.

Power Generation: High-temperature insulators, turbine components, protective coatings.

FAQs:

What are the key advantages of using ceramics for oil and gas applications?

How does CNC machining enhance the precision of ceramic components?

Which ceramic materials are best suited for extreme-temperature environments in the oil and gas industry?

What are the most effective surface treatments for ceramic parts used in oil and gas applications?

What prototyping methods are best for developing ceramic components for the oil and gas industry?