Comprehensive CNC Machining of Stainless Steel: From Design to Manufacturing

Introduction

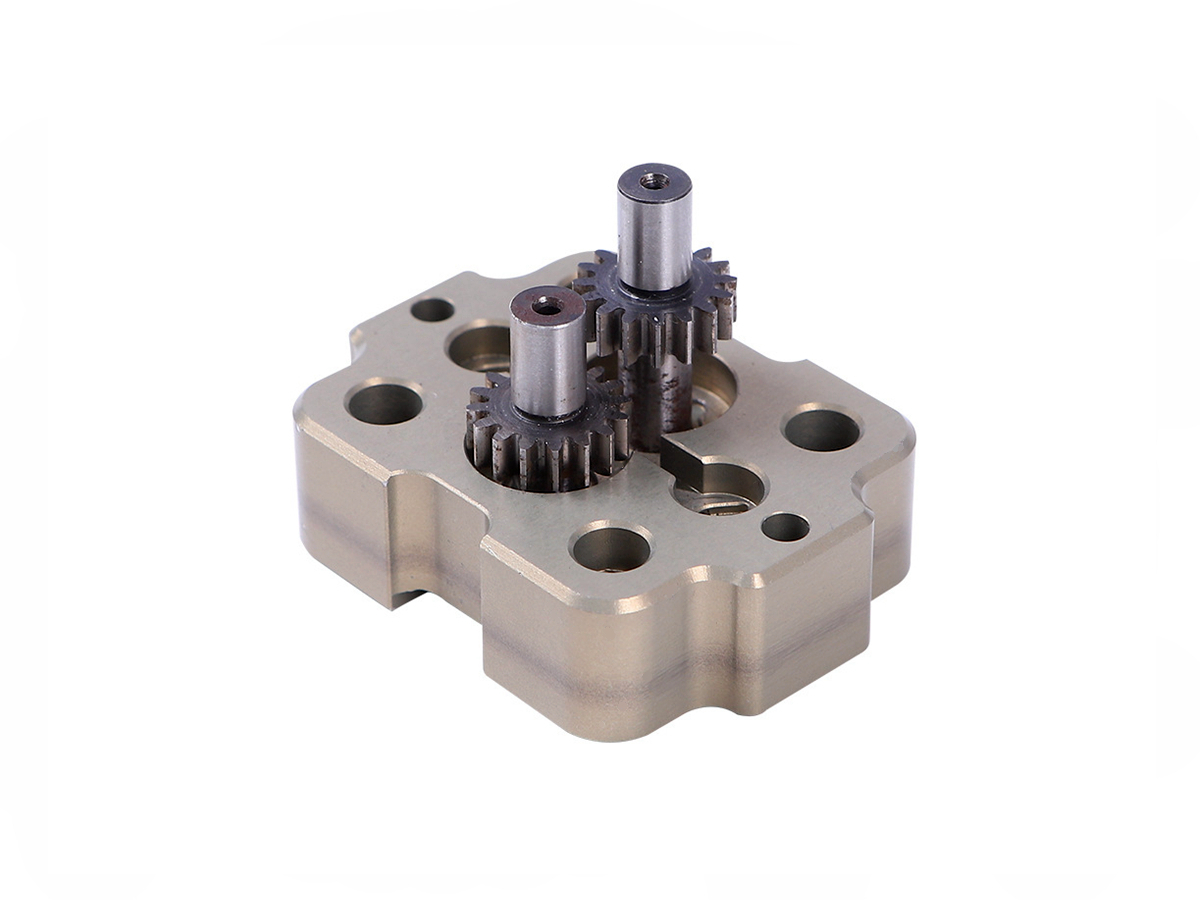

Comprehensive CNC stainless steel machining offers a complete, efficient solution for designing and manufacturing high-precision parts for aerospace, automotive, medical devices, and industrial equipment industries. Stainless steel alloys, including 304, 316, and 17-4PH, are known for their superior corrosion resistance, high strength, and excellent durability, making them the material of choice for components that must perform in demanding environments. By utilizing stainless steel CNC machining, manufacturers can produce components that meet exact performance and quality standards.

From initial design to final production, Mass Production CNC Machining ensures that stainless steel parts are produced with precision, speed, and cost-efficiency. This all-in-one solution offers rapid prototyping, tight tolerances, and high-quality finishes, enabling industries to meet the most stringent specifications and deliver durable, long-lasting components.

Stainless Steel Material Properties

Material Performance Comparison Table

Stainless Steel Alloy | Tensile Strength (MPa) | Yield Strength (MPa) | Hardness (HRC) | Density (g/cm³) | Applications | Advantages |

|---|---|---|---|---|---|---|

520–720 | 210–500 | 30–40 | 7.93 | Kitchenware, structural components | Excellent corrosion resistance, good formability | |

580–750 | 290–690 | 30–40 | 7.98 | Marine, chemical processing, medical devices | Superior corrosion resistance, high toughness | |

1000–1300 | 900–1100 | 30–35 | 7.75 | Aerospace, turbine parts | High strength, excellent fatigue resistance | |

510–740 | 200–500 | 30–40 | 7.90 | Food processing, medical parts | Excellent weldability, low carbon content |

Selecting the Right Stainless Steel Alloy for CNC Machining

Choosing the appropriate stainless steel alloy is crucial for ensuring the durability, strength, and corrosion resistance required for various applications:

304 Stainless Steel: Ideal for general-purpose applications such as kitchenware, structural components, and piping, offering excellent corrosion resistance and good formability.

316 Stainless Steel: Best for components exposed to harsh environments, such as marine, chemical processing, and medical devices, due to its superior resistance to corrosion and pitting.

17-4PH Stainless Steel: Suitable for aerospace and turbine parts, where high strength, fatigue resistance, and the ability to perform in extreme conditions are essential.

304L Stainless Steel: Preferred for parts requiring good weldability and resistance to sensitization, such as food processing equipment and medical devices.

CNC Machining Processes for Stainless Steel Parts

CNC Process Comparison Table

CNC Machining Process | Accuracy (mm) | Surface Finish (Ra µm) | Typical Uses | Advantages |

|---|---|---|---|---|

±0.005 | 0.4–1.6 | Aerospace, automotive parts | High precision for complex geometries | |

±0.005 | 0.4–1.0 | Shafts, pins, cylindrical parts | Consistent surface finishes, high accuracy | |

±0.01 | 0.8–3.2 | Holes, threaded components | Fast, precise hole-making | |

±0.003 | 0.2–1.0 | Complex stainless steel parts | High precision, multi-directional machining |

CNC Process Selection Strategy

The choice of CNC machining process depends on the complexity of the stainless steel parts, required precision, and material properties:

CNC Milling: Perfect for machining intricate stainless steel parts such as turbine blades, engine components, and structural frameworks, providing high precision (±0.005 mm) for complex shapes.

CNC Turning: Ideal for cylindrical stainless steel components such as shafts, pins, and bushings, ensuring high consistency and accuracy (±0.005 mm) and smooth surface finishes (Ra ≤1.0 µm).

CNC Drilling: Best for creating precise holes, threads, and fastener holes in stainless steel parts, with fast hole-making and high precision (±0.01 mm).

Multi-Axis Machining: Suitable for machining complex, multi-directional stainless steel parts, offering superior precision (±0.003 mm) and reducing production steps for intricate geometries.

Surface Treatments for Stainless Steel Parts

Surface Treatment Comparison Table

Treatment Method | Surface Roughness (Ra µm) | Corrosion Resistance | Max Temp (°C) | Applications | Key Features |

|---|---|---|---|---|---|

≤0.4 | Excellent | 250 | Aerospace, medical devices | Smooth surface, enhanced corrosion resistance | |

≤1.0 | Excellent | 250 | Food processing, medical devices | Improved corrosion resistance, extended lifespan | |

≤1.0 | Excellent | 450 | Aerospace, high-performance parts | Increased hardness, wear resistance | |

≤2.0 | Excellent | 200 | Industrial machinery, automotive parts | Durable, weather-resistant, aesthetic finishes |

Surface Treatment Selection Strategy

Surface treatments for stainless steel parts are essential for enhancing their corrosion resistance, durability, and overall performance in harsh environments:

Electropolishing: Best for stainless steel parts exposed to harsh conditions, such as aerospace and medical components, where smooth surfaces and enhanced corrosion resistance are crucial.

Passivation: Ideal for food processing and medical devices, passivation improves corrosion resistance, ensuring that parts remain durable and hygienic over time.

PVD Coating: Recommended for high-performance aerospace parts, PVD coating increases hardness and wear resistance, protecting parts from oxidation and wear.

Powder Coating: Suitable for industrial and automotive parts, powder coating offers durable, weather-resistant finishes, making it ideal for parts exposed to the elements.

Typical Stainless Steel Rapid Prototyping Methods

Effective prototyping methods for stainless steel parts include:

CNC Machining Prototyping: Fast, high-precision production of stainless steel parts for small batches and testing, ideal for aerospace, medical, and industrial applications.

Stainless Steel 3D Printing: Ideal for rapid prototyping of complex stainless steel components, enabling quick design iterations before full-scale production.

Rapid Molding Prototyping: Cost-effective for creating moderately complex stainless steel parts before transitioning to high-volume production.

Quality Assurance Procedures

Dimensional Inspection: ±0.002 mm accuracy (ISO 10360-2).

Material Verification: ASTM A276, ASTM A312 standards for stainless steel alloys.

Surface Finish Assessment: ISO 4287.

Mechanical Testing: ASTM E8 for tensile and yield strength.

Visual Inspection: ISO 2768 standards.

ISO 9001 Quality Management System: Ensuring consistent quality and performance.

Key Applications

Aerospace: Turbine blades, structural components, heat exchangers.

Medical Devices: Surgical instruments, implants, diagnostic equipment.

Automotive: Engine parts, exhaust systems, body components.

Industrial Equipment: Pumps, valves, machinery parts.

Related FAQs:

Why is CNC machining ideal for stainless steel aerospace components?

What stainless steel alloys best suit CNC machining in automotive and medical applications?

How do surface treatments improve the performance of stainless steel parts?

What are the advantages of CNC machining for stainless steel parts in high-performance industries?

How does low-volume CNC machining support prototyping for stainless steel components?