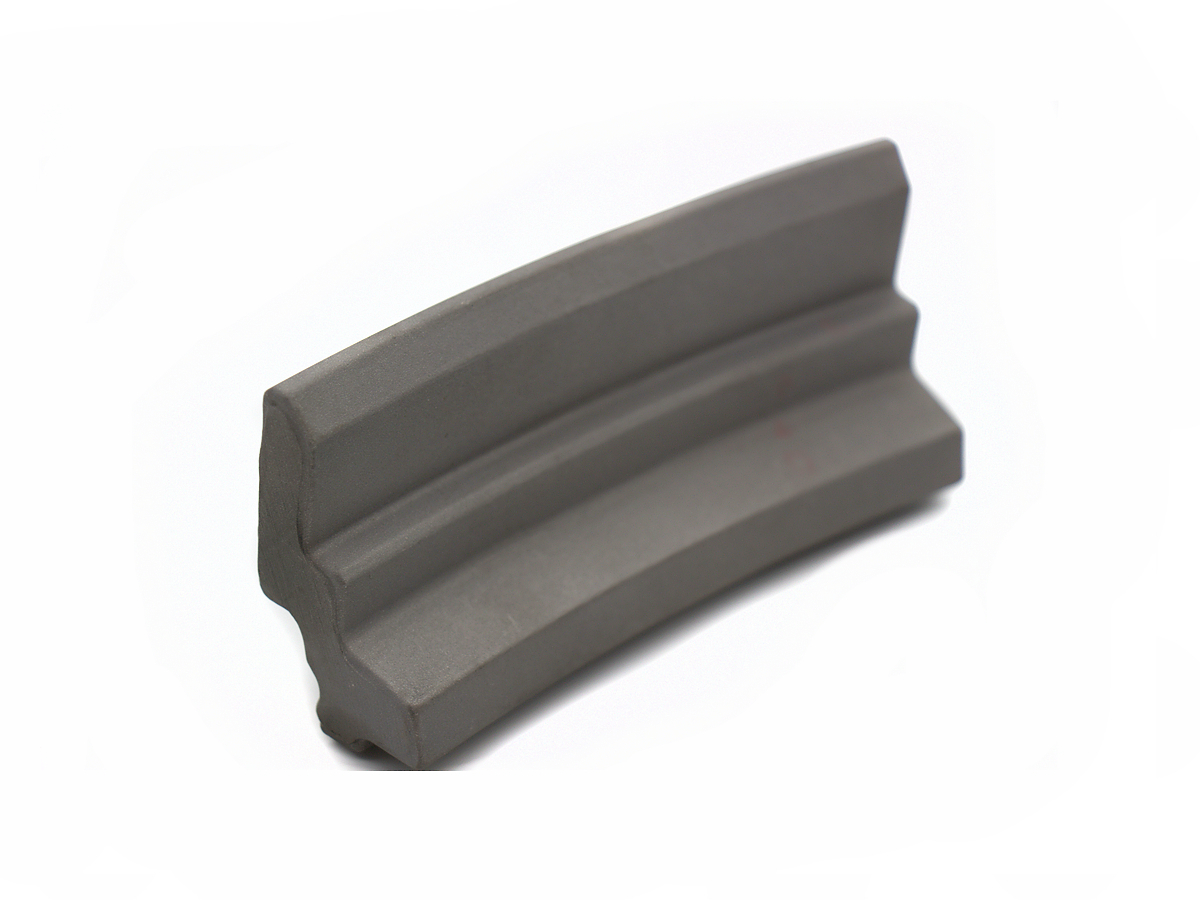

Custom CNC Machined Parts for Nuclear Power Plant Shielding Systems

Introduction to CNC Machining for Nuclear Shielding

In nuclear power plants, shielding systems are essential for radiation protection, ensuring safety for personnel, equipment, and the environment. Custom CNC machined parts for shielding systems must offer exceptional precision (±0.005 mm), structural integrity, and durability under prolonged exposure to radiation, extreme temperatures (up to 700°C), and corrosive conditions. CNC machining is crucial for producing precise radiation barriers, structural shielding components, neutron absorbers, and specialized fittings within the nuclear, power generation, and industrial equipment industries.

By leveraging state-of-the-art CNC machining, manufacturers ensure shielding systems meet strict nuclear regulatory standards, significantly enhancing plant safety, reliability, and long-term performance.

Material Comparison for CNC Machined Nuclear Shielding Components

Material Performance Comparison

Material | Density (g/cm³) | Radiation Shielding Capability | Corrosion Resistance | Typical Applications | Advantage |

|---|---|---|---|---|---|

11.34 | Excellent (Gamma/X-ray) | Moderate | Radiation barriers, containment shields | High density, excellent shielding | |

7.93 | Excellent (Neutron absorption) | Excellent | Neutron shielding panels, structural components | Superior neutron absorption | |

17.5-18.5 | Outstanding (Gamma radiation) | Good | Precision radiation shielding | Highest density, compact shielding | |

2.4 | Good (Gamma/neutron shielding) | Good | Structural shielding, containment | Cost-effective, versatile shielding |

Material Selection Strategy for Nuclear Shielding Components

Selecting materials for nuclear shielding applications involves balancing density, radiation shielding capability, structural integrity, and environmental stability:

Gamma and X-ray shielding components requiring high density and effective radiation attenuation commonly utilize Lead Alloy, providing excellent protection for containment areas and shielding barriers.

Neutron shielding panels and critical structural components requiring superior neutron absorption often use Boronated Stainless Steel, combining excellent corrosion resistance with effective neutron attenuation.

Applications requiring the highest density shielding with compact dimensions, such as precise radiation barriers, benefit significantly from Tungsten Alloy, ensuring maximum protection in limited spaces.

Structural shielding for large-scale containment and general shielding structures frequently utilize Concrete Composites due to their cost-effectiveness, moderate density, and versatile application capability.

CNC Machining Process Analysis for Nuclear Shielding Components

CNC Machining Processes Performance Comparison

CNC Machining Technology | Dimensional Accuracy (mm) | Surface Roughness (Ra μm) | Typical Applications | Key Advantages |

|---|---|---|---|---|

±0.005-0.01 | 0.4-1.2 | Complex shielding panels, structural parts | Precise geometries, efficient production | |

±0.005-0.02 | 0.8-1.6 | Cylindrical shielding elements, rods | High efficiency, dimensional accuracy | |

±0.01-0.03 | 1.6-3.2 | Mounting holes, fittings, fasteners | Fast processing, reliable accuracy | |

±0.002-0.005 | 0.1-0.4 | Precision mating surfaces, sealing areas | Ultra-high precision, exceptional surface finish |

CNC Machining Process Selection Strategy for Nuclear Shielding Components

Choosing suitable CNC machining processes for nuclear shielding components involves evaluating component complexity, dimensional requirements, surface finish, and operational demands:

Complex shielding panels, structural elements, and intricate geometries requiring precise tolerances (±0.005-0.01 mm) benefit greatly from Multi-Axis CNC Milling, achieving consistent accuracy and complex shaping.

Cylindrical shielding elements, neutron absorber rods, and similar components needing moderate dimensional precision (±0.005-0.02 mm) efficiently utilize CNC Turning, providing accurate and economical fabrication.

Mounting holes, fittings, and connectors requiring reliable accuracy (±0.01-0.03 mm) efficiently employ CNC Drilling, ensuring precision placement and quick turnaround.

Precision mating surfaces, sealing areas, and critical interfaces demanding ultra-high accuracy (±0.002-0.005 mm) and excellent surface finishes utilize CNC Grinding, significantly enhancing performance reliability.

Surface Treatment Solutions for CNC Machined Nuclear Shielding Components

Surface Treatment Performance Comparison

Treatment Method | Radiation Stability | Corrosion Resistance | Max Operating Temp (°C) | Typical Applications | Key Features |

|---|---|---|---|---|---|

Excellent | Excellent (~1200 hrs ASTM B117) | 350 | Stainless steel shielding panels | Reduced contamination, smooth finish | |

Good | Excellent (~1000 hrs ASTM B117) | 300 | Boronated stainless components | Enhanced corrosion protection | |

Excellent | Excellent (~1500 hrs ASTM B117) | 1200 | High-temperature shielding elements | Superior thermal insulation and oxidation resistance | |

Good | Very Good (~800 hrs ASTM B117) | 200 | General shielding, containment structures | Cost-effective corrosion resistance |

Surface Treatment Selection Strategy for CNC Machined Shielding Parts

Choosing appropriate surface treatments for nuclear shielding components significantly enhances corrosion resistance, radiation stability, and durability:

Stainless steel shielding panels and precision surfaces benefit from Electropolishing, achieving smooth, contamination-resistant finishes essential for nuclear environments.

Boronated stainless components and neutron shielding elements utilize Passivation, significantly improving corrosion protection and enhancing longevity.

High-temperature shielding components exposed to elevated temperatures (up to 1200°C) utilize Thermal Barrier Coatings (TBC), providing superior thermal insulation, oxidation resistance, and durability under harsh conditions.

General shielding components and containment structures benefit from Powder Coating, offering a cost-effective solution for good corrosion resistance and extended service life.

Quality Control Standards for CNC Machined Nuclear Shielding Components

Quality Control Procedures

Dimensional inspections with Coordinate Measuring Machines (CMM) and optical comparators.

Surface roughness verification using precision profilometers.

Density and material composition analysis to confirm radiation shielding effectiveness.

Corrosion and radiation resistance testing per ASTM and ASME standards.

Non-destructive testing (ultrasonic, radiographic, eddy-current) to ensure structural integrity.

Comprehensive documentation and traceability compliant with ISO 9001, ASME NQA-1, and nuclear industry standards.

Industry Applications of CNC Machined Nuclear Shielding Components

Typical Applications

Reactor containment shielding and barriers.

Neutron absorber components and structural panels.

Precision radiation shielding elements and fittings.

Structural shielding supports and fasteners.

Related FAQs:

Why is CNC machining essential for nuclear shielding systems?

What materials offer optimal shielding performance in nuclear applications?

Which CNC machining processes ensure precision for nuclear shielding parts?

How do surface treatments enhance the durability of nuclear shielding components?

What quality standards must CNC machined shielding parts in nuclear plants meet?