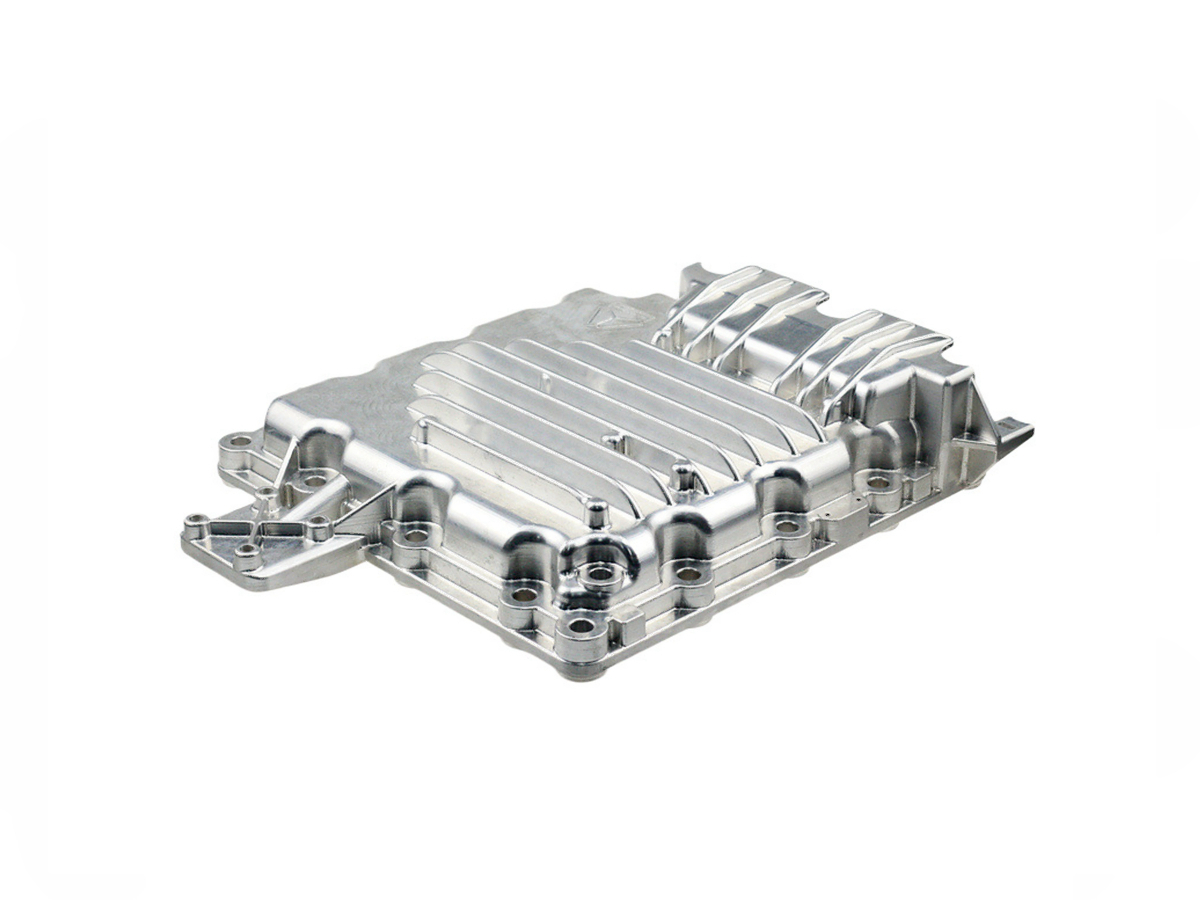

Custom CNC Machined Suspension Parts for Enhanced Vehicle Performance

Introduction to CNC Machined Suspension Components

Vehicle suspension systems are critical to automotive performance, directly influencing handling, stability, comfort, and overall safety. Custom CNC machining ensures suspension components—such as control arms, suspension brackets, sway bars, steering knuckles, and coil spring mounts—meet rigorous standards for precision, durability, and reliability. Common materials include aluminum alloys (6061, 7075), alloy steels (4130, 4340), stainless steels (SUS304, SUS630), and titanium alloys (Ti-6Al-4V), chosen specifically for their strength-to-weight ratios, corrosion resistance, and fatigue performance.

Advanced CNC machining services allow for high-precision manufacturing, delivering suspension components significantly enhancing vehicle responsiveness and road handling capabilities.

Material Performance Comparison for Suspension Parts

Material | Tensile Strength (MPa) | Density (g/cm³) | Fatigue Resistance | Typical Applications | Advantage |

|---|---|---|---|---|---|

540-570 | 2.80 | Excellent | Control arms, mounts | Lightweight, high-strength | |

560-670 | 7.85 | Outstanding | Sway bars, suspension links | High fatigue strength, good weldability | |

950-1100 | 4.43 | Exceptional | Steering knuckles, coil spring mounts | Exceptional strength-to-weight ratio | |

930-1200 | 7.78 | Outstanding | Precision mounts, fasteners | High strength, corrosion-resistant |

Material Selection Strategy for CNC Machined Suspension Parts

Selecting suitable materials for suspension components involves analyzing critical parameters including strength, fatigue resistance, weight considerations, and corrosion resistance:

Aluminum 7075-T6 provides an optimal strength-to-weight ratio with tensile strengths up to 570 MPa, ideal for lightweight control arms and suspension brackets that improve handling and reduce unsprung mass.

Alloy Steel 4130 is well-suited for sway bars and suspension links due to its excellent fatigue resistance, tensile strength (up to 670 MPa), and good weldability, ensuring durability under continuous dynamic stress.

Titanium Ti-6Al-4V offers exceptional tensile strength (up to 1100 MPa) combined with a low density, perfect for critical components like steering knuckles, significantly enhancing vehicle responsiveness without compromising strength.

Stainless Steel SUS630 (17-4PH) is selected for high-strength precision mounts and corrosion-resistant fasteners, providing tensile strength up to 1200 MPa, critical for long-term reliability in harsh operating environments.

CNC Machining Processes for Suspension Components

CNC Machining Process | Dimensional Accuracy (mm) | Surface Roughness (Ra μm) | Typical Applications | Key Advantages |

|---|---|---|---|---|

±0.005-0.02 | 0.4-1.6 | Suspension mounts, brackets | Versatile, precise geometries | |

±0.005-0.01 | 0.4-1.2 | Suspension bushings, shafts | Accurate rotational components | |

±0.005-0.01 | 0.2-0.8 | Steering knuckles, control arms | Complex geometries, fewer setups | |

±0.01-0.02 | 0.8-3.2 | Mounting points, bolt holes | Accurate hole positioning |

CNC Process Selection Strategy for Custom Suspension Parts

Choosing the right CNC machining processes ensures suspension components meet exacting standards of performance and safety:

Precision CNC Milling reliably produces components like mounts and brackets with accuracy (±0.005-0.02 mm), critical for consistent suspension geometry.

CNC Turning is ideal for precise rotational suspension elements, such as shafts and bushings, ensuring exact tolerances (±0.005 mm) for stable handling.

5 Axis CNC Machining excels at fabricating complex shapes like steering knuckles and advanced control arms, significantly enhancing precision and efficiency with tolerances as tight as ±0.005 mm.

CNC Drilling provides consistent accuracy (±0.01-0.02 mm) for critical hole placement in suspension systems, ensuring reliable assembly and performance.

Surface Treatment Performance Comparison for Suspension Parts

Treatment Method | Surface Roughness (Ra μm) | Wear Resistance | Corrosion Resistance | Surface Hardness | Typical Applications | Key Features |

|---|---|---|---|---|---|---|

0.4-1.0 | Excellent | Excellent (≥1000 hrs ASTM B117) | HV 400-600 | Aluminum control arms | Superior corrosion protection | |

0.4-1.2 | Exceptional | Good | HRC 55-62 | Steel suspension links | Enhanced strength, durability | |

0.6-1.2 | Excellent | Excellent (≥1000 hrs ASTM B117) | Variable | Steel brackets, mounts | Durable, corrosion-resistant coating | |

0.8-1.6 | Moderate | Excellent (≥1000 hrs ASTM B117) | Unchanged | Stainless steel suspension parts | Excellent corrosion resistance |

Surface Treatment Selection for CNC Machined Suspension Parts

Proper surface treatments enhance the longevity and performance of suspension components:

Anodizing provides excellent corrosion resistance (≥1000 hrs ASTM B117) and improved surface hardness (HV 400-600) for aluminum control arms and brackets.

Heat Treatment significantly increases mechanical strength (HRC 55-62), ensuring durability and extended service life of steel suspension links and sway bars.

Powder Coating offers robust corrosion resistance (≥1000 hrs ASTM B117), durability, and attractive finishes for steel mounts and visible chassis components.

Passivation ensures stainless steel suspension components maintain excellent corrosion resistance (≥1000 hrs ASTM B117), ideal for long-term reliability.

Typical Prototyping Methods for Suspension Components

CNC Machining Prototyping: Provides highly precise prototypes (±0.005 mm accuracy), essential for verifying suspension performance and handling characteristics.

Rapid Molding Prototyping: Quickly produces functional prototypes for thorough mechanical testing under realistic suspension conditions.

Metal 3D Printing (Powder Bed Fusion): Efficiently creates complex suspension prototypes (±0.05 mm accuracy), enabling early-stage validation of component geometry and stress analysis.

Quality Assurance Procedures

CMM Inspection (ISO 10360-2): Precision verification (±0.005 mm) for accurate suspension geometry.

Surface Roughness Testing (ISO 4287): Ensures compliance with surface standards (Ra ≤0.8 µm).

Fatigue Testing (ASTM E466): Validates long-term reliability of suspension components.

Non-Destructive Testing (ASTM E1444, ASTM E2375): Ensures component integrity.

ISO 9001 Traceability: Comprehensive documentation for strict quality compliance.

Industry Applications

Performance automotive suspension

Racing and motorsports components

Luxury vehicle suspension upgrades

Related FAQs:

What materials are ideal for CNC machined suspension components?

How does CNC machining improve suspension performance?

Which surface treatments enhance suspension durability?

Why prototype automotive suspension components?

What quality procedures guarantee reliability of CNC suspension parts?