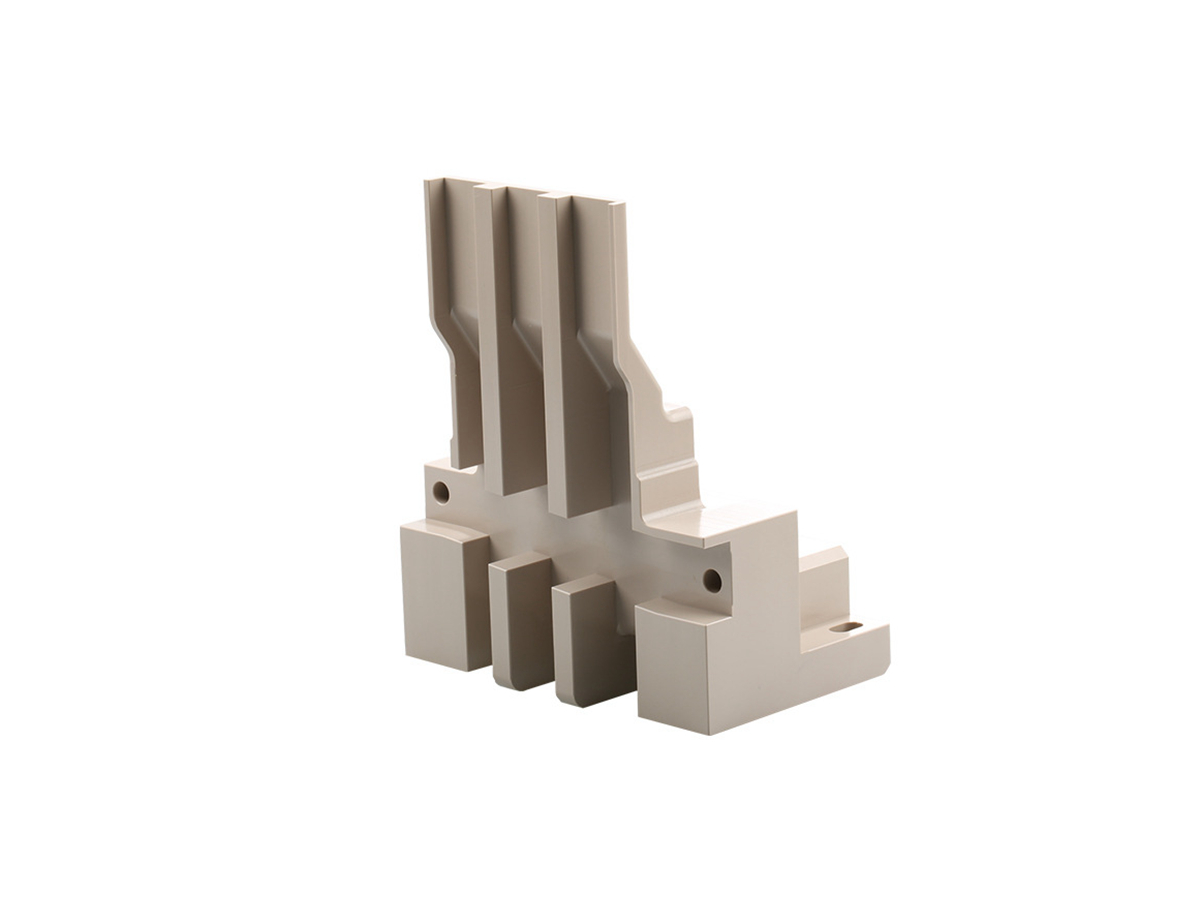

Custom CNC Machining of Acetal for High-Precision, Low-Friction Applications

Introduction to Custom CNC Machined Acetal Components for Precision and Low-Friction Performance

Industries such as medical devices, automation, and industrial equipment demand components featuring exceptional dimensional stability, low friction, and reliable mechanical performance. Acetal (Polyoxymethylene, POM) is a high-performance engineering thermoplastic renowned for its superior machinability, outstanding dimensional accuracy, and inherent low friction properties. Acetal is commonly chosen for precision gears, bushings, bearings, valve components, and medical equipment parts.

Leveraging advanced CNC machining, manufacturers can precisely craft custom Acetal components that meet tight dimensional tolerances, complex geometries, and smooth surface finishes, ensuring optimum performance in low-friction applications.

Comprehensive Analysis of Acetal (POM) for High-Precision, Low-Friction Components

Material Performance Comparison for Acetal Components

Material | Tensile Strength (MPa) | Coefficient of Friction | Dimensional Stability | Typical Applications | Advantage |

|---|---|---|---|---|---|

60-70 | 0.15-0.2 | Excellent | Precision gears, bearings | High stiffness, low friction | |

60-80 | 0.2-0.3 | Good | Gears, rollers | Good wear resistance, self-lubricating | |

35-45 | 0.1-0.2 | Good | Conveyor guides, wear strips | Superior abrasion resistance | |

20-35 | 0.05-0.1 | Moderate | Seals, sliding parts | Very low friction, chemical resistance |

Material Selection Strategy for CNC Machined Acetal Components

Choosing Acetal for CNC machining of high-precision, low-friction components involves evaluating dimensional accuracy, frictional performance, and mechanical stability:

Precision gears, bearings, and sliding components benefit significantly from Acetal due to its high stiffness (60-70 MPa tensile strength), low friction coefficient (0.15-0.2), and superior dimensional stability.

Applications requiring slightly higher impact resistance or self-lubrication may utilize Nylon (PA).

For extreme abrasion resistance applications such as conveyors, UHMW-PE is a suitable alternative.

Parts demanding exceptionally low friction or chemical resistance typically select PTFE (Teflon).

CNC Machining Processes for Precision Acetal Components

CNC Machining Process Performance Overview

CNC Machining Process | Dimensional Accuracy (mm) | Surface Roughness (Ra μm) | Typical Applications | Key Advantages |

|---|---|---|---|---|

±0.02-0.05 | 0.8-3.2 | Custom gears, precision fixtures | High accuracy, detailed machining | |

±0.02-0.05 | 0.4-1.6 | Bearings, valve components | Accurate rotational symmetry | |

±0.01-0.03 | 0.4-1.2 | Complex medical components, intricate gears | Complex geometries, excellent precision | |

±0.05-0.1 | 1.6-3.2 | Assembly components, precision holes | Accurate positioning |

Process Selection Strategy for CNC Machined Acetal Components

Selecting the optimal CNC machining methods for Acetal involves assessing complexity, precision requirements, and desired finishes:

Custom gears, precision fixtures, and components requiring detailed accuracy within ±0.02 mm benefit from CNC Milling Service.

Bearings, bushings, and cylindrical valve components needing high rotational accuracy (±0.02 mm) are best produced using CNC Turning Service.

Complex medical device parts and intricate gears requiring extremely tight tolerances (±0.01 mm) and high-quality finishes achieve optimal results with Precision Multi-Axis CNC Machining.

Assembly components and fittings needing accurately placed holes (±0.05 mm) commonly utilize CNC Drilling Service.

Surface Treatments to Optimize Acetal Component Performance

Surface Treatment Performance Comparison

Treatment Method | Wear Resistance | Friction Reduction | Industrial Suitability | Typical Applications | Key Features |

|---|---|---|---|---|---|

Excellent | Outstanding | Excellent | Low-friction bearings, sliding surfaces | Superior friction reduction | |

Moderate | Good | Excellent | Precision gears, medical parts | Exceptional surface smoothness | |

Good | Moderate | Excellent | Visible components, protective covers | Durable, aesthetic finish | |

Moderate | Moderate | Good | Textured surfaces, matte finishes | Uniform surface texture |

Surface Treatment Selection for CNC Machined Acetal Components

Choosing suitable surface treatments for Acetal components involves balancing friction reduction, wear performance, and visual quality:

Low-friction components, such as precision bearings and sliding surfaces, greatly benefit from PTFE coating for enhanced friction reduction and wear resistance.

Precision gears and medical device parts requiring a superior, glossy finish and reduced friction utilize Vapor Polishing.

Acetal components with aesthetic requirements, such as visible equipment covers, use UV Coating for enhanced durability and visual appeal.

Components requiring matte or uniform textures, such as instrument handles or non-slip surfaces, typically undergo Sandblasting.

Typical Prototyping Methods for Acetal Components

CNC Machining Prototyping: Ideal for quickly creating precise, functional prototypes from Acetal, allowing accurate performance testing and validation before full-scale production.

Plastic 3D Printing: Provides rapid and economical prototyping for initial design validation, particularly useful for testing complex geometries and mechanical properties.

Quality Assurance for CNC Machined Acetal Components

Quality Control Procedures

Dimensional Inspection: Conducted using Coordinate Measuring Machines (CMM) for tight tolerances.

Surface Roughness Testing: Profilometers ensure surface finishes meet specified requirements.

Mechanical Property Testing: Tensile strength and wear testing performed per ASTM standards.

Visual Inspection: Assessment of surface quality and defect detection.

Non-Destructive Testing: Ultrasonic inspections to ensure internal integrity.

Documentation: Complete ISO 9001-compliant traceability and detailed quality assurance reports.

Industry Applications of CNC Machined Acetal Components

Precision gears and bearings.

Medical device components.

Valve and fluid handling components.

Low-friction sliding and rotating parts.

Related FAQs:

Why choose Acetal for high-precision, low-friction CNC machined parts?

Which CNC processes deliver optimal accuracy for Acetal components?

How do surface treatments enhance Acetal performance?

What quality control practices ensure precision CNC machining of Acetal?

Which industries benefit most from CNC machined Acetal components?