Efficient CNC Prototyping of Aluminum for Lightweight and Durable Designs

Introduction

Aluminum alloys are highly valued in advanced manufacturing due to their unique combination of low density, high strength-to-weight ratio, and excellent machinability. Industries such as aerospace, automotive, and consumer electronics increasingly rely on CNC prototyping services to rapidly develop lightweight yet durable components with tight tolerances (±0.005 mm).

By leveraging precision aluminum CNC machining methods, engineers can quickly validate designs and optimize performance characteristics, significantly reducing development timelines and ensuring superior final products.

Aluminum Alloy Material Properties

Material Performance Comparison Table

Material | Tensile Strength (MPa) | Yield Strength (MPa) | Density (g/cm³) | Elongation (%) | Typical Applications | Advantages |

|---|---|---|---|---|---|---|

310 | 276 | 2.70 | 12% | Structural parts, brackets | Excellent machinability, high strength-to-weight ratio | |

572 | 503 | 2.81 | 11% | Aerospace structures, automotive components | High strength, good fatigue resistance | |

310 | 260 | 2.70 | 10% | Automotive, mechanical parts | Strong corrosion resistance, easily weldable | |

320 | 160 | 2.76 | 3.5% | Complex castings, housings | Excellent casting properties, good mechanical strength |

Material Selection Strategy

Selecting an aluminum alloy for CNC prototyping depends on strength, machinability, and intended application:

Aluminum 6061-T6 is widely chosen for general-purpose prototyping due to its excellent machinability and balanced mechanical properties, making it suitable for structural components.

Aluminum 7075-T6 is preferred for high-strength applications, such as aerospace parts, requiring tensile strength up to 572 MPa and superior fatigue resistance.

Aluminum 6082 offers optimal weldability and corrosion resistance, suitable for automotive and mechanical components requiring frequent joining.

Aluminum ADC12 (A380) provides outstanding casting properties, ideal for prototypes of complex geometries or intricate housing designs.

CNC Machining Techniques for Aluminum Prototypes

CNC Machining Process Comparison

CNC Process | Accuracy (mm) | Surface Finish (Ra µm) | Applications | Advantages |

|---|---|---|---|---|

±0.01 | 0.4-0.8 | Structural prototypes, brackets | High-speed production, complex geometries | |

±0.005 | 0.4-1.2 | Shafts, cylindrical prototypes | Precise cylindrical shaping, excellent accuracy | |

±0.01 | 0.6-1.2 | Precision holes, fixtures | Accurate hole placement in prototypes | |

±0.005 | 0.2-0.4 | High-tolerance prototypes, mechanical fittings | Ultra-high precision, consistent repeatability |

CNC Process Selection Strategy

Choosing CNC machining methods for aluminum prototyping depends on the prototype's complexity, precision demands, and functional requirements:

CNC Milling excels in rapidly producing intricate designs and structural prototypes, efficiently handling complex geometries and detailed features.

CNC Turning delivers high accuracy (±0.005 mm) for cylindrical components such as shafts or spindles requiring tight dimensional control.

CNC Drilling provides precise placement of holes or features essential for fixtures and assemblies, ensuring alignment accuracy within ±0.01 mm.

Precision Machining is ideal for prototypes requiring exceptional accuracy and tight tolerances, ensuring critical mechanical fits and assembly reliability.

Surface Treatments for CNC Machined Aluminum Prototypes

Surface Treatment Comparison

Treatment Method | Hardness (HV) | Corrosion Resistance | Max Temp (°C) | Applications | Key Features |

|---|---|---|---|---|---|

200-600 | Excellent | 200°C | Aerospace, automotive | Enhanced corrosion resistance, improved durability | |

300-400 | Excellent | 180°C | Consumer products, automotive | Durable, aesthetic finishes, scratch resistance | |

Base Material | Excellent | 400°C | Electronics, medical devices | Surface purity, improved corrosion protection | |

Base Material | Excellent | 600°C | Precision components, medical devices | Ultra-smooth finish, corrosion resistance |

Surface Treatment Selection Strategy

Surface treatments significantly improve the performance and longevity of CNC machined aluminum prototypes:

Anodizing increases surface hardness up to 600 HV, dramatically enhancing corrosion resistance and wear protection, suitable for aerospace or automotive prototypes.

Powder Coating offers durable and visually appealing finishes with robust scratch resistance, ideal for consumer-facing products.

Passivation enhances surface cleanliness and corrosion resistance, especially beneficial in sensitive electronic and medical prototypes.

Electropolishing provides ultra-smooth surfaces (Ra ≤0.2 µm), improving aesthetic appearance and corrosion protection for precision aluminum components.

Typical Prototyping Methods

CNC Machining Prototyping: Provides highly accurate prototypes with tolerances up to ±0.005 mm, facilitating precise mechanical fit and function evaluation.

3D Prototyping: Rapid validation of design concepts with an accuracy of around ±0.1 mm, enabling quick revisions and early-stage testing.

Rapid Molding Prototyping: Quickly produces prototype batches (±0.05 mm accuracy), essential for evaluating functional performance in realistic usage conditions.

Quality Assurance Procedures

CMM Inspection (ISO 10360-2): Ensuring dimensional accuracy to ±0.005 mm.

Surface Finish Testing (ISO 4287): Surface roughness assessment (Ra ≤0.2 µm).

Material Verification (ASTM E1251): Chemical composition analysis of aluminum alloys.

Mechanical Testing (ASTM E8/E8M): Tensile strength and yield testing to validate mechanical properties.

Corrosion Resistance Testing (ASTM B117): Salt spray tests for surface durability.

ISO 9001:2015 Certification: Strict adherence to quality management for consistency and traceability.

Key Industry Applications

Aerospace structural components

Automotive lightweight parts

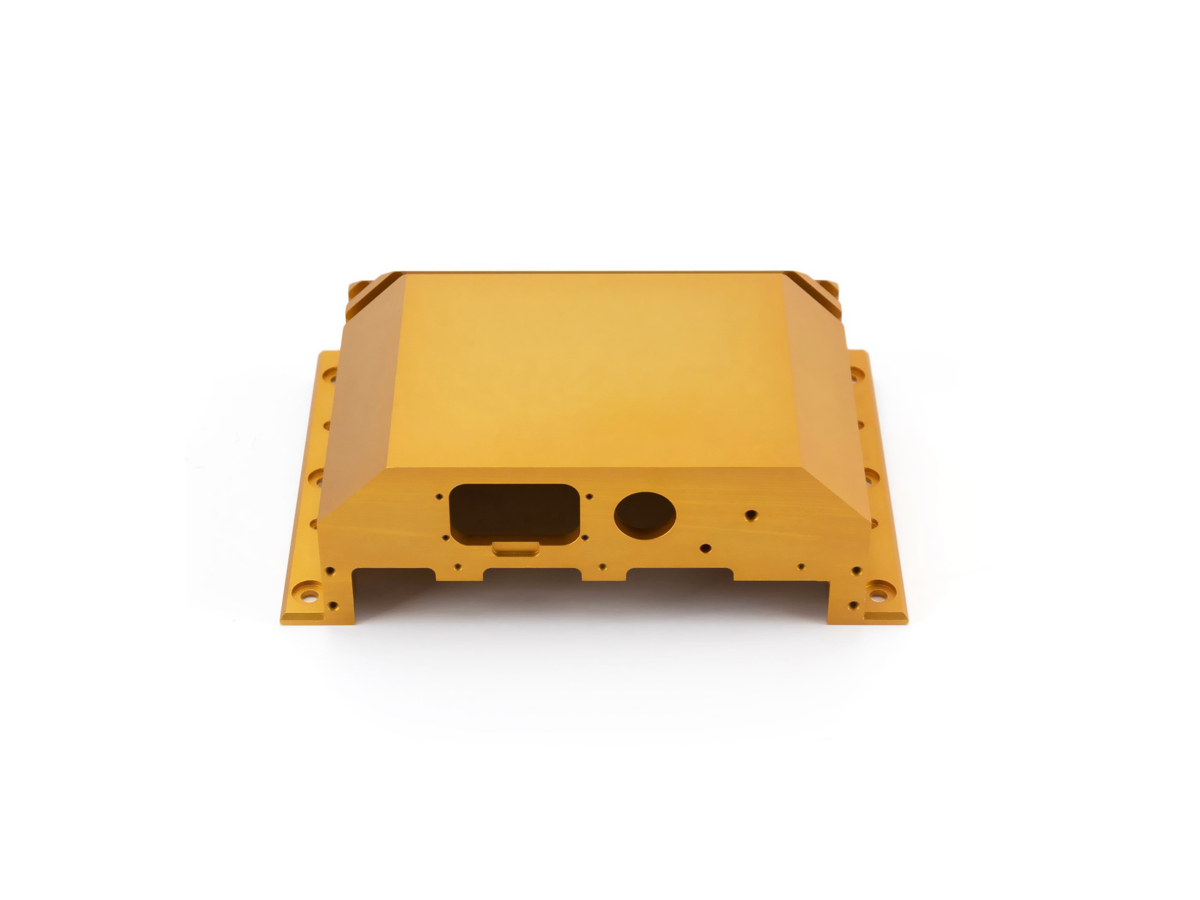

Consumer electronics housings

Industrial equipment fittings

Related FAQs:

What aluminum alloys are best for CNC prototyping?

Why is CNC machining ideal for aluminum components?

How do surface treatments enhance aluminum prototypes?

What quality controls ensure accuracy in aluminum CNC prototypes?

Which industries commonly use CNC machined aluminum prototypes?