Efficient Low-Volume CNC Machining of Aluminum for Lightweight, Precision Parts

Introduction

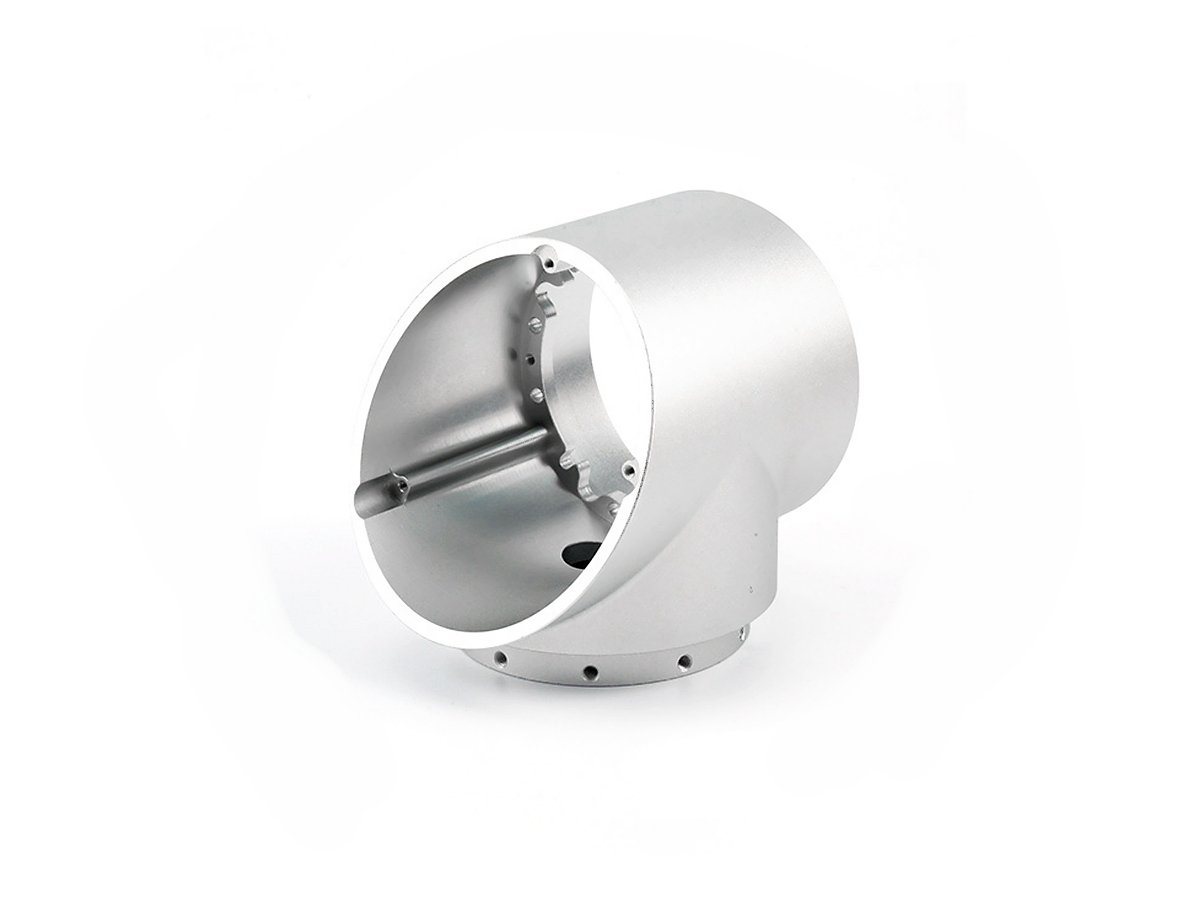

Efficient low-volume CNC machining of aluminum offers manufacturers a precise, cost-effective method for producing lightweight, high-performance parts. Aluminum alloys such as 6061, 7075, and 2024 are known for their excellent strength-to-weight ratio, corrosion resistance, and ease of machinability, making them ideal for applications across various industries. Industries such as aerospace, automotive, electronics, and consumer products increasingly rely on Aluminum CNC Machining to create low-volume, precision components with tight tolerances (±0.005 mm) for both prototype and production purposes.

Low-volume CNC machining is especially beneficial for rapid prototyping, allowing manufacturers to quickly iterate on designs and validate performance in real-world applications before scaling up for mass production. This low-volume CNC machining capability enables manufacturers to meet demanding lead times and reduce waste while ensuring that parts meet exact specifications.

Aluminum Material Properties

Material Performance Comparison Table

Aluminum Alloy | Tensile Strength (MPa) | Yield Strength (MPa) | Hardness (HB) | Density (g/cm³) | Applications | Advantages |

|---|---|---|---|---|---|---|

275–310 | 240–275 | 95–100 | 2.70 | Structural components, aerospace parts, marine hardware | Excellent corrosion resistance, good weldability | |

505–570 | 430–510 | 150–160 | 2.81 | Aircraft structures, high-performance components | High strength, fatigue resistance | |

470–500 | 380–430 | 120–130 | 2.78 | Aerospace, military applications, high-stress components | Excellent fatigue resistance, high strength-to-weight ratio | |

210–230 | 193–240 | 60–70 | 2.68 | Marine environments, pressure vessels | Excellent corrosion resistance, high weldability |

Selecting the Right Aluminum Alloy for Low-Volume CNC Machining

Choosing the right aluminum alloy depends on specific performance requirements, such as mechanical strength, weight, and environmental durability:

Aluminum 6061: Ideal for structural components, marine hardware, and aerospace applications, offering a balance of strength, corrosion resistance, and good machinability.

Aluminum 7075: Best suited for high-performance components in aerospace and military applications due to its superior strength and fatigue resistance.

Aluminum 2024: Perfect for aerospace and military parts requiring high strength and excellent fatigue resistance, particularly in high-stress environments.

Aluminum 5052: Optimal for marine applications and pressure vessels due to its excellent corrosion resistance and ease of welding.

CNC Machining Processes for Aluminum Parts

CNC Process Comparison Table

CNC Machining Process | Accuracy (mm) | Surface Finish (Ra µm) | Typical Uses | Advantages |

|---|---|---|---|---|

±0.005 | 0.4–1.2 | Complex parts, precision aerospace components | High versatility, excellent for intricate designs | |

±0.005 | 0.4–1.0 | Rotational components, bushings, shafts | Precision for cylindrical parts, consistent results | |

±0.01 | 0.8–3.2 | Holes, threaded components | Fast, precise hole-making | |

±0.003 | 0.2–1.0 | Aerospace components, complex geometries | Superior precision, reduced production cycles |

CNC Process Selection Strategy

Selecting the appropriate CNC machining process for aluminum parts is essential to meet the needs of the part's complexity, tolerances, and application:

CNC Milling: Best for creating intricate and complex parts with fine details in aluminum, ideal for aerospace, automotive, and consumer product applications.

CNC Turning: Ideal for rotational components such as bushings and shafts, ensuring consistent accuracy (±0.005 mm) and surface finishes as fine as Ra 0.4 µm.

CNC Drilling: Perfect for creating precise holes and threads in aluminum components, crucial for parts that require accurate mechanical fastening.

Multi-Axis Machining: Essential for high-precision parts requiring complex geometries, offering superior dimensional accuracy (±0.003 mm) and reducing the need for multiple setups.

Surface Treatments for Aluminum Parts

Surface Treatment Comparison Table

Treatment Method | Surface Roughness (Ra µm) | Wear Resistance | Max Temp (°C) | Applications | Key Features |

|---|---|---|---|---|---|

≤0.8 | 1500 V (ASTM B117 Salt Spray Test) | 400 | Aerospace, marine parts, automotive components | Corrosion resistance, enhanced hardness | |

≤0.4 | Excellent | 250 | Medical devices, precision tools | Smooth surface, reduced friction, improved durability | |

≤1.0 | 2–5 times higher than uncoated aluminum (ASTM G99) | 450–600 | Cutting tools, automotive components | Increased hardness, enhanced wear resistance | |

≤2.0 | Excellent (ASTM D3359) | 200 | Consumer products, furniture, industrial equipment | Durable finish, wide range of colors, protective barrier |

Surface Treatment Selection Strategy

Surface treatments for aluminum components are essential for enhancing performance, durability, and resistance to wear and corrosion:

Anodizing: Perfect for aluminum parts used in aerospace and marine environments, providing excellent corrosion resistance and improving surface hardness. This process enhances wear resistance, with tested values exceeding 1500 hours in ASTM B117 Salt Spray tests.

Electropolishing: Ideal for medical devices and precision tools, achieving ultra-smooth surfaces (Ra ≤0.4 µm), reducing friction, and enhancing durability.

PVD Coating: Recommended for increasing aluminum components' hardness and wear resistance, ideal for automotive and cutting tool applications. PVD coatings significantly enhance wear resistance, with results up to 5 times better than uncoated aluminum based on ASTM G99 testing.

Powder Coating: Best suited for consumer products and industrial equipment, providing a durable, aesthetically pleasing finish with excellent protection against corrosion, following ASTM D3359 standards for adhesion.

Typical Low-Volume CNC Prototyping Methods

Effective prototyping methods for aluminum components include:

CNC Machining Prototyping: Provides rapid prototyping with high precision and low volume production of aluminum parts.

Aluminum 3D Printing: Ideal for creating complex, lightweight components with rapid turnaround times.

Rapid Molding Prototyping: Cost-effective production of moderate complexity aluminum parts for quick validation.

Quality Assurance Procedures

Dimensional Inspection: ±0.002 mm accuracy (ISO 10360-2).

Material Verification: ASTM B221 standards for aluminum alloys.

Surface Finish Assessment: ISO 4287.

Mechanical Testing: ASTM B557 for tensile and yield strength.

Visual Inspection: ISO 2768 standards.

ISO 9001 Quality Management compliance.

Key Applications

Aerospace: Aircraft components, structural parts, landing gear.

Automotive: Engine parts, lightweight structural components, heat exchangers.

Consumer Products: Lightweight housings, enclosures, and electronics.

Industrial Equipment: Machinery parts, precision tools, and fasteners.

Related FAQs:

Why is low-volume CNC machining ideal for aluminum parts?

What aluminum alloys are most commonly used in low-volume CNC machining?

How do surface treatments improve aluminum parts in aerospace applications?

What industries benefit the most from aluminum CNC machining?

How does low-volume CNC machining support rapid prototyping of aluminum components?