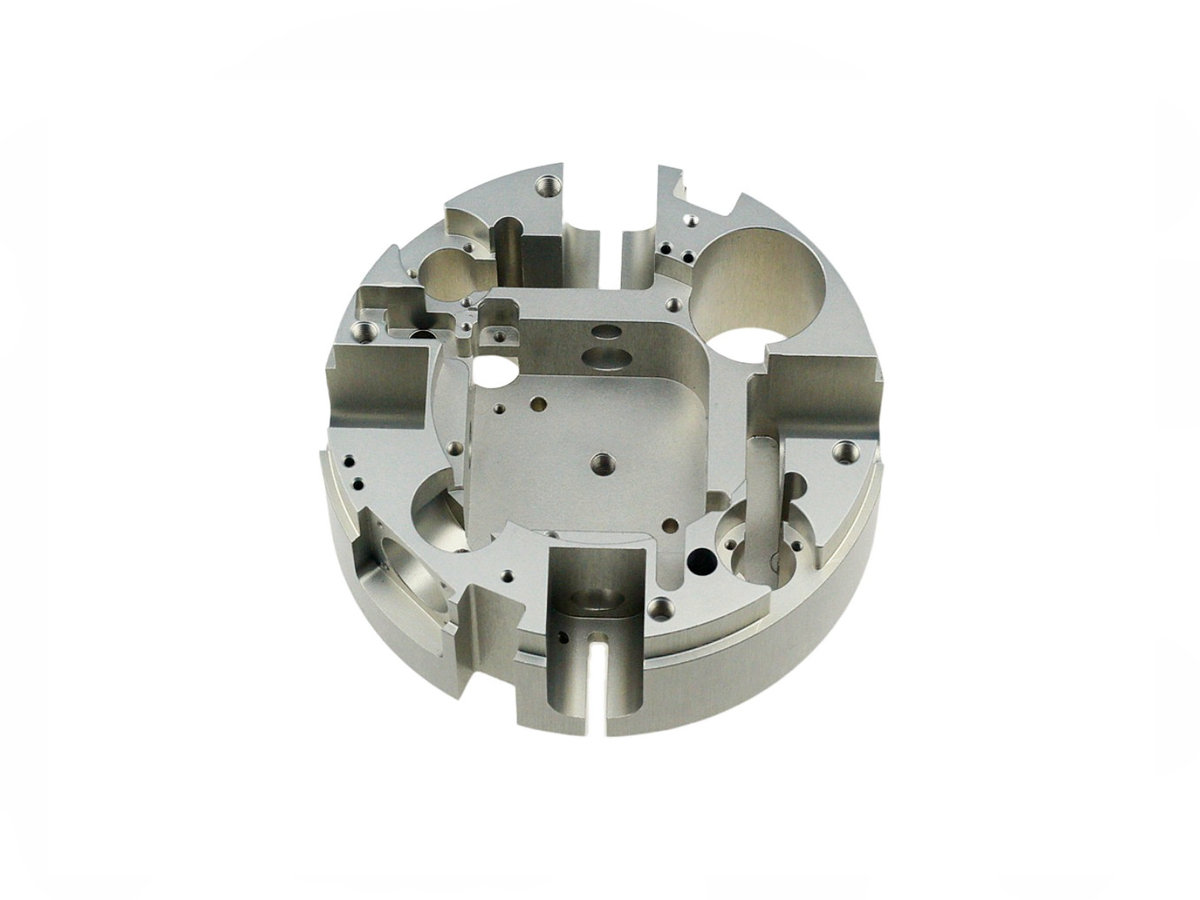

Engine Components CNC Machining for Agricultural Equipment Components

Introduction to CNC Machined Engine Components

Agricultural equipment engines demand precision-engineered components to withstand intense workloads, high temperatures, continuous vibration, and harsh environmental conditions. Custom CNC machining delivers critical engine components such as crankshafts, pistons, connecting rods, cylinder heads, valve components, and bearing housings. Engine parts are commonly machined from materials including alloy steels (4140, 4340), cast iron, stainless steels (SUS304, SUS316), aluminum alloys (7075-T6), and brass alloys (C360), each selected for strength, durability, heat resistance, and precise machinability.

Expert CNC machining services guarantee accurate tolerances, consistent quality, and enhanced engine performance and reliability in agricultural machinery applications.

Material Performance Comparison for Engine Components

Material | Tensile Strength (MPa) | Density (g/cm³) | Heat Resistance | Typical Applications | Advantages |

|---|---|---|---|---|---|

745-1080 | 7.85 | Excellent (≤500°C) | Crankshafts, connecting rods | High fatigue strength | |

200-400 | 7.03-7.20 | Excellent (≤600°C) | Cylinder heads, blocks | Excellent thermal stability | |

510-572 | 2.81 | Good (≤250°C) | Pistons, lightweight components | High strength-to-weight ratio | |

345-480 | 8.50 | Good (≤300°C) | Valve guides, fittings | Excellent machinability |

Material Selection Strategy for CNC Machined Engine Parts

Selecting suitable materials is essential for optimal engine performance and longevity:

Alloy Steel 4340 is ideal for high-strength, fatigue-resistant components such as crankshafts and connecting rods, offering superior tensile strength (up to 1080 MPa) and excellent resilience under heavy cyclic loads.

Cast Iron provides outstanding thermal stability and vibration damping, making it suitable for engine blocks and cylinder heads subject to continuous heat cycles and mechanical stress.

Aluminum 7075-T6 offers an exceptional strength-to-weight ratio, suitable for lightweight, high-performance engine components such as pistons, reducing overall engine mass while maintaining strength.

Brass C360 excels in machinability and moderate heat resistance, making it ideal for precision components like valve guides and engine fittings requiring tight tolerances and durability.

CNC Machining Processes for Agricultural Engine Components

CNC Machining Process | Dimensional Accuracy (mm) | Surface Roughness (Ra μm) | Typical Applications | Key Advantages |

|---|---|---|---|---|

±0.005-0.01 | 0.4-1.2 | Crankshafts, pistons | Precision rotational accuracy | |

±0.01-0.02 | 0.8-1.6 | Cylinder heads, valve bodies | High versatility, complex geometry | |

±0.002-0.005 | 0.1-0.4 | Bearing surfaces, crankshaft journals | Exceptional surface finishes | |

±0.01-0.02 | 0.8-3.2 | Oil passages, mounting holes | Accurate and precise hole positioning |

CNC Process Selection Strategy for Agricultural Engine Components

Selecting appropriate CNC processes is essential to meet demanding accuracy and reliability requirements:

CNC Turning delivers critical dimensional accuracy (±0.005 mm) for rotational components such as crankshafts and pistons, ensuring balance, optimal performance, and durability.

CNC Milling provides versatile and precise shaping of complex engine parts such as cylinder heads and valve bodies, maintaining accurate geometry and tolerances (±0.01-0.02 mm).

CNC Grinding achieves ultra-high accuracy (±0.002-0.005 mm) and superior surface finishes, critical for bearing surfaces, crankshaft journals, and precision-engine components to reduce friction and wear.

CNC Drilling ensures accurate hole placement (±0.01-0.02 mm) essential for internal oil passages, cooling channels, and precise assembly points in engine blocks.

Surface Treatment Performance Comparison for Engine Components

Treatment Method | Surface Roughness (Ra μm) | Wear Resistance (ASTM G99) | Corrosion Resistance (ASTM B117) | Surface Hardness | Typical Applications | Key Features |

|---|---|---|---|---|---|---|

0.4-1.2 | Excellent (wear rate <0.1mm³/Nm) | Moderate (>500 hrs) | HRC 55-62 | Crankshafts, connecting rods | Enhanced fatigue life, increased strength | |

0.2-0.6 | Superior (wear rate <0.05mm³/Nm) | Good (>700 hrs) | HV 900-1200 | Valve guides, pistons | High hardness, improved wear and corrosion resistance | |

0.8-2.0 | Moderate (wear rate 0.2-0.3mm³/Nm) | Good (>600 hrs) | Moderate (~HV 300-500) | Gears, fasteners | Enhanced lubrication, moderate corrosion protection | |

0.4-1.0 | Good (wear rate 0.1-0.2mm³/Nm) | Excellent (>1000 hrs) | HV 400-600 | Aluminum pistons, components | Increased corrosion and wear resistance, decorative finish |

Surface Treatment Selection for CNC Machined Engine Components

Choosing suitable surface treatments significantly improves engine reliability and longevity:

Heat Treatment enhances fatigue strength and hardness (HRC 55-62) of critical engine parts such as crankshafts and connecting rods, vital for extended component lifespan under cyclic loading.

Nitriding significantly increases surface hardness (HV 900-1200) and wear resistance, suitable for precision components like valve guides, pistons, and other engine components exposed to friction.

Phosphating provides moderate corrosion resistance and friction reduction, beneficial for gears, fasteners, and internal moving engine parts.

Anodizing enhances aluminum component durability, providing improved corrosion (>1000 hrs ASTM B117) and wear resistance (HV 400-600), ideal for pistons and lightweight engine parts.

Typical Prototyping Methods for Engine Components

CNC Machining Prototyping: Produces precise prototypes (±0.005 mm) to validate mechanical and dimensional specifications accurately.

Rapid Molding Prototyping: Enables quick production of functional prototypes suitable for rigorous mechanical testing in realistic engine conditions.

Metal 3D Printing (Powder Bed Fusion): Rapidly creates metal engine component prototypes (±0.05 mm accuracy) for early-stage performance evaluation and iterative design improvements.

Quality Assurance Procedures

Coordinate Measuring Machine (CMM) Inspection (ISO 10360-2) ensures critical dimensional accuracy within ±0.005 mm.

Surface Roughness Measurement (ISO 4287) verifies required finishes (Ra ≤1.6 µm).

Mechanical and Fatigue Testing (ASTM E8/E466) ensures reliability under high-stress cyclic loads.

Non-Destructive Testing (ASTM E1444, ASTM E2375) detects internal and surface defects.

ISO 9001 Certified Documentation guarantees traceability, compliance, and consistent quality control.

Industry Applications

Tractor and harvester engines

Heavy-duty irrigation and pumping equipment

Agricultural machinery drivetrain systems

Related FAQs:

Which materials best suit agricultural engine components?

How does CNC machining enhance engine component reliability?

Which surface treatments extend the life of agricultural engine parts?

Why prototype agricultural machinery engine parts?

Which quality control processes ensure CNC engine component reliability?