Engineering Ceramic CNC Machining: Custom Solutions for Advanced Industrial Applications

Introduction

Engineering ceramics possess superior mechanical strength, thermal stability, and excellent wear resistance, positioning them as essential materials for advanced industrial applications. Industries such as aerospace, electronics, and medical devices rely heavily on ceramic CNC machining to achieve precise tolerances (±0.005 mm), high-quality surface finishes, and exceptional dimensional stability.

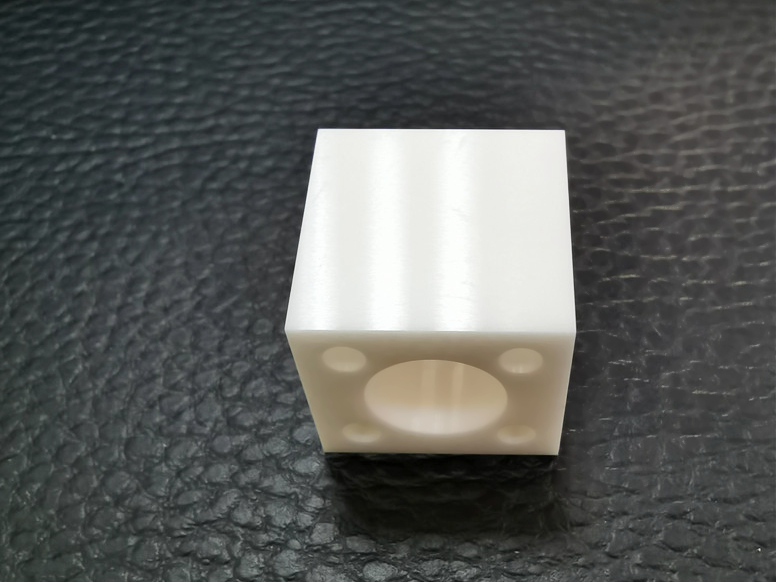

Advanced ceramic CNC machining services facilitate the custom manufacturing of critical components like insulators, bearings, valves, and structural parts, ensuring reliability, durability, and performance in demanding industrial environments.

Engineering Ceramics Material Properties

Material Performance Comparison Table

Material | Hardness (HV) | Fracture Toughness (MPa√m) | Max Operating Temp (°C) | Thermal Conductivity (W/m·K) | Typical Applications | Advantages |

|---|---|---|---|---|---|---|

1700-2100 | 4-5 | 1700 | 25-35 | Bearings, insulators, seals | High hardness, electrical insulation, wear resistance | |

1200-1400 | 5-10 | 1200 | 2-3 | Structural ceramics, implants, blades | High fracture toughness, mechanical strength | |

1500-1700 | 6-8 | 1400 | 15-25 | Bearings, engine parts, valves | High strength, thermal stability, good wear resistance | |

2500-2800 | 4-5 | 1650 | 120-150 | Seals, grinding components, nozzles | Extreme hardness, high thermal conductivity |

Engineering Ceramics Selection Strategy

Selecting the appropriate engineering ceramic for CNC machining involves analyzing key material characteristics tailored to specific applications:

Alumina (Al₂O₃) is ideal for electrical and thermal insulation components, combining high hardness (up to 2100 HV) with excellent temperature stability (up to 1700°C).

Zirconia (ZrO₂) offers superior toughness (fracture toughness 5-10 MPa√m), suitable for load-bearing and impact-resistant applications like structural ceramics and biomedical components.

Silicon Nitride (Si₃N₄) provides a balance of strength, thermal stability (up to 1400°C), and moderate thermal conductivity (15-25 W/m·K), making it suitable for precision bearings and engine components.

Silicon Carbide (SiC) stands out for applications requiring exceptional hardness (up to 2800 HV), wear resistance, and superior thermal conductivity (120-150 W/m·K).

CNC Machining Techniques for Engineering Ceramics

CNC Machining Process Comparison

CNC Process | Accuracy (mm) | Surface Finish (Ra µm) | Typical Applications | Advantages |

|---|---|---|---|---|

±0.01 | 0.4-0.8 | Complex structural parts, insulators | Precise shaping of intricate geometries | |

±0.003 | 0.05-0.2 | Bearings, sealing surfaces | Ultra-precision and exceptional surface finish | |

±0.005 | 0.4-1.2 | Shafts, round ceramic components | Accurate dimensional control for cylindrical shapes | |

±0.002 | 0.2-0.5 | Intricate internal features, holes | Precise machining of hard ceramics without mechanical stress |

CNC Process Selection Strategy

The CNC machining process for engineering ceramics depends on the required accuracy, geometry complexity, and surface finish:

CNC Milling is best suited for shaping complex geometries and detailed structures in ceramics, such as custom insulators or fixtures.

CNC Grinding provides precise surface finishes (Ra ≤0.2 µm), crucial for high-precision ceramic components like bearings and sealing surfaces.

CNC Turning is ideal for creating high-precision cylindrical ceramic components, ensuring tight tolerances (±0.005 mm).

EDM Machining accurately produces intricate features and internal structures in extremely hard ceramics, maintaining tolerances within ±0.002 mm.

Surface Treatments for CNC Machined Ceramic Components

Surface Treatment Comparison

Treatment Method | Hardness (HV) | Corrosion Resistance | Max Operating Temp (°C) | Applications | Key Features |

|---|---|---|---|---|---|

Base Material | Excellent | 600°C | Medical implants, precision surfaces | Smooth finishes, reduced friction | |

2200-2500 | Excellent | 1300°C | Aerospace components, thermal protection | Exceptional insulation and heat protection | |

Base Material | Excellent | 400°C | Electronic ceramics, insulators | Enhanced surface purity and corrosion resistance | |

600-700 | Excellent | 260°C | Chemical handling ceramics | Non-stick, chemical resistance |

Surface Treatment Selection Strategy

Surface treatments significantly enhance the functionality of ceramic CNC machined components:

Electropolishing ensures superior surface smoothness, essential for medical implants and precision ceramic parts.

Thermal Barrier Coatings (TBC) provide high-temperature insulation (up to 1300°C), vital for aerospace or industrial applications with extreme thermal exposure.

Passivation improves corrosion resistance and purity for ceramic components used in sensitive electronic applications.

Teflon Coating offers low friction and chemical resistance, valuable for ceramic components used in chemical processing.

Typical Prototyping Methods

Ceramic 3D Printing: Rapid prototyping with precision up to ±0.1 mm, beneficial for complex ceramic geometries validation.

CNC Machining Prototyping: High-precision prototyping (±0.005 mm), providing reliable, functional tests before production.

Powder Bed Fusion: Suitable for creating prototypes with an accuracy of ±0.05 mm, allowing detailed evaluation of ceramic component designs.

Quality Assurance Procedures

CMM Inspection (ISO 10360-2): Ensures dimensional tolerances within ±0.005 mm.

Surface Finish Analysis (ISO 4287): Validates roughness criteria (Ra ≤0.2 µm).

Fracture Toughness Testing (ASTM C1421): Confirms structural integrity and toughness (up to 10 MPa√m).

Non-Destructive Testing (Ultrasonic, ASTM E2375): Detects internal defects or structural issues.

Thermal Stability Tests (ASTM C1525): Validates performance under operating temperatures up to 1700°C.

ISO 9001:2015 Quality Management: Maintains traceability and consistency throughout ceramic machining processes.

Key Industry Applications

Aerospace structural ceramics

Electronic insulators and substrates

Medical implants

Precision mechanical components

Related FAQs:

Why choose CNC machining for engineering ceramics?

Which ceramics are most suited to advanced industrial applications?

How do surface treatments benefit ceramic components?

What quality standards apply to ceramic CNC machining?

Which industries rely heavily on CNC machined ceramics?