Ensuring Long-Term Reliability in Oil and Gas Equipment with CNC Machined Superalloy Components

Defying Extreme Downhole Conditions with Advanced Materials

Oil and gas operations demand components that withstand 20,000+ psi pressures, H₂S-rich environments, and abrasive sand erosion. Superalloys like Inconel and Hastelloy form 60% of critical downhole tools, offering 5x higher corrosion resistance than carbon steel. Precision CNC machining services create complex valve geometries and sealing surfaces that maintain integrity through 10⁷ operational cycles.

A North Sea case study on Hastelloy C276 choke valves processed via 5-axis milling showed zero failures after 5 years in 15% H₂S environments—a 300% lifespan improvement over duplex steel alternatives.

Material Selection: Engineered for Aggressive Media

Superalloy | Key Metrics | Oil & Gas Applications | Limitations |

|---|---|---|---|

830 MPa UTS @ 600°C, 40% Ni content | Subsea connectors, Christmas trees | Requires stress-relief annealing post-machining | |

0.005mm/yr corrosion rate in H₂S | Downhole valves, wellhead components | Machining necessitates low-speed high-feed strategies | |

1,100 MPa yield strength, seawater resistant | Marine riser joints, pump shafts | Limited to <400°C operating temps | |

950 MPa UTS, 50% weight savings vs steel | Deepwater drill collars | Requires anti-galling surface treatments |

Material Selection Protocol

Sour Service Environments

Rationale: Hastelloy C276’s 16% Mo content prevents chloride stress corrosion cracking. Combined with electropolishing, surface roughness reduces to Ra 0.1μm to minimize pitting initiation.

Validation: NACE TM0177 testing confirms 90-day exposure survival in 25% H₂S at 200°C.

High-Pressure Systems

Logic: Inconel 625’s niobium-stabilized matrix withstands 25,000 psi cyclic loads. CNC turning with ceramic inserts achieves API 6A/17D sealing surface requirements.

CNC Machining Process Optimization

Process | Technical Specifications | Applications | Advantages |

|---|---|---|---|

30:1 L/D ratio, ±0.02mm straightness | Hydraulic control line ports | Maintains concentricity in 1,500mm depths | |

±0.01mm profile accuracy, 12,000 RPM | Gate valve complex flow paths | Single-setup machining of 3D geometries | |

0.15mm kerf width, Ra 0.8μm | Blowout preventer (BOP) shear rams | Zero heat-affected zones in hardened alloys | |

0.08mm layer resolution, 99.5% density | Repairing eroded pump impellers | Restores original dimensions with matched material properties |

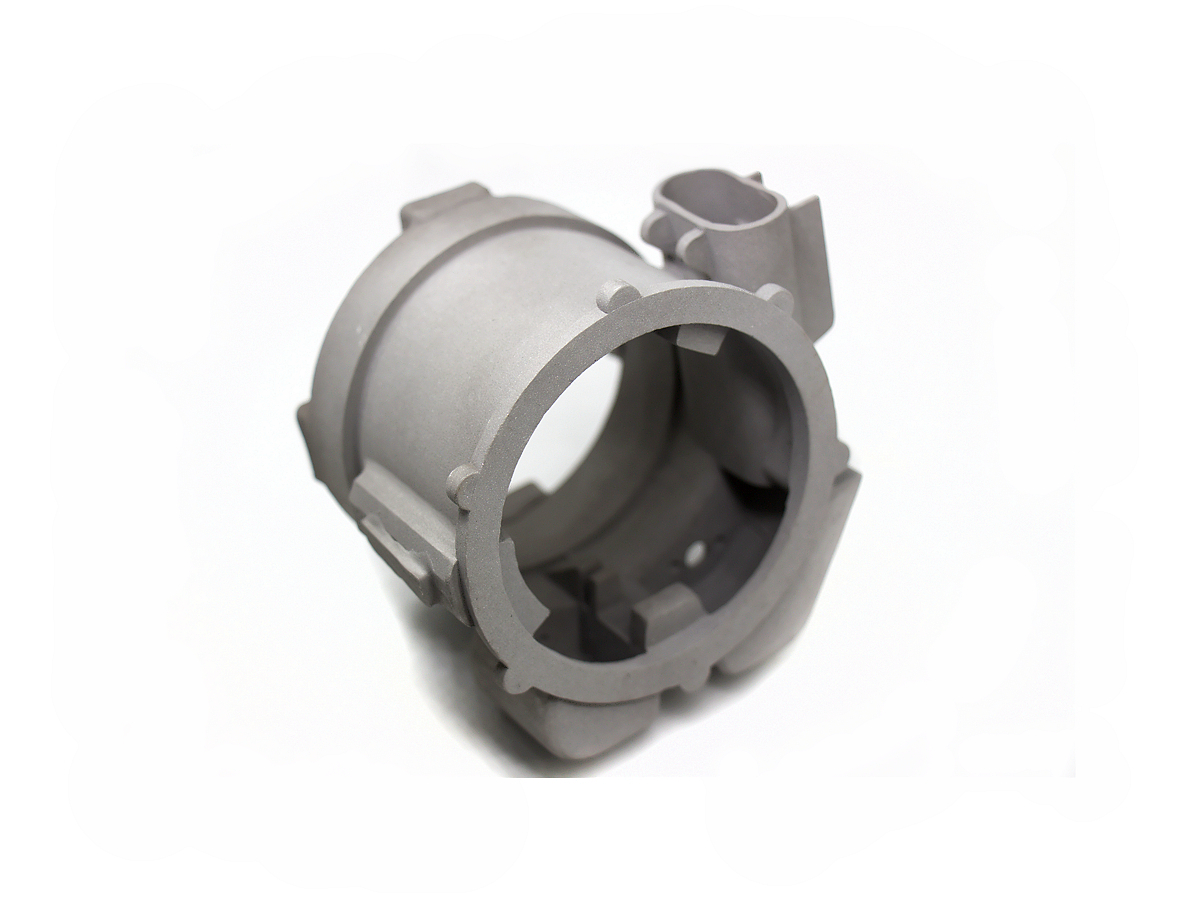

Manufacturing Strategy for Subsea Connectors

Precision Forging

Closed-die forging enhances Inconel 625’s grain flow for 20% higher fatigue resistance.

Stress-Relief Machining

4-axis roughing removes 70% of material with 0.3mm chip loads to minimize residual stresses.

Critical Surface Finishing

5-axis contouring achieves API 17D-compliant Ra 0.4μm sealing surfaces using diamond-coated tools.

Surface Engineering: Combatting Harsh Environments

Treatment | Technical Parameters | Oil & Gas Benefits | Standards |

|---|---|---|---|

50μm thickness, 0.08 friction coefficient | Wear resistance for valve stems | ASTM B733 Class 4 | |

0.3mm case depth, >1,100 HV | Sand erosion protection in drill bits | AMS 2759/5 | |

300μm thickness, 1,200 HV hardness | Abrasion resistance for pump components | ISO 14923 |

Coating Selection Logic

Sour Gas Valves

Electroless Ni-PTFE reduces friction by 60% while withstanding 15% H₂S exposure per NACE MR0175.

Directional Drilling Tools

Plasma nitrided surfaces on Monel K500 drill collars achieve a 500-hour lifespan in abrasive formations—3x longer than uncoated tools.

Quality Control: Meeting Industry Standards

Stage | Critical Parameters | Methodology | Equipment | Standards |

|---|---|---|---|---|

Corrosion Testing | 90-day exposure in 25% H₂S/CO₂ | Autoclave chambers | Cortest Vessel Systems | NACE TM0177 |

Pressure Cycling | 25,000 psi @ 10⁴ cycles | Hyperbaric test rigs | Schlumberger Phoenix HPC | API 6A/17D |

Metallurgical Analysis | Grain size ASTM 5-6, <0.2% porosity | SEM/EDS cross-section analysis | Thermo Fisher Scios 2 | ASTM E3/E407 |

Certifications:

API Q1-compliant manufacturing

NORSOK M-650 approved coatings

Industry Applications

BOP Shear Rams: Wire EDM-cut Hastelloy C276 (meets API 16A shear force specs)

Subsea Manifolds: 5-axis milled Inconel 625 (30-year design life in 3,000m depth)

Downhole Pumps: Plasma-nitrided Monel K500 (1,200-hour MTBF in abrasive wells)

Conclusion

Precision superalloy CNC machining ensures 99.95% reliability in critical oilfield components. Our oil & gas solutions deliver API/NORSOK-certified parts with auditable material traceability.

FAQ

Why choose Inconel 625 over duplex steel for subsea equipment?

How does electroless Ni-PTFE enhance valve performance?

Best coating for sand erosion resistance in drill tools?

How to validate H₂S resistance per NACE standards?

What CNC parameters prevent work hardening in Monel K500?