High-Performance 3D Printing Prototyping with Superalloys for Complex Aerospace Components

Introduction

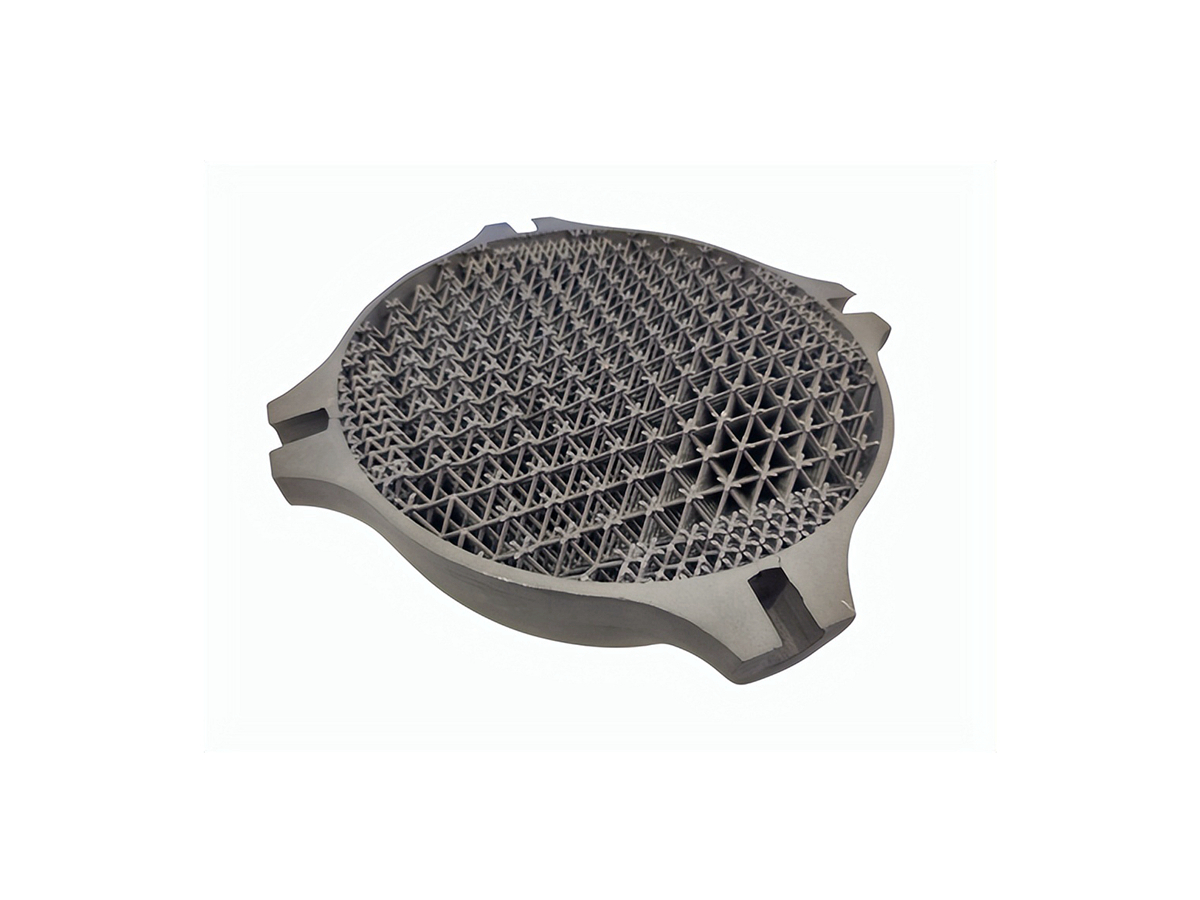

Superalloys offer exceptional mechanical strength, corrosion resistance, and thermal stability, making them ideal for complex aerospace components' additive manufacturing (3D printing) prototyping. Industries such as aerospace, power generation, and aviation engines rely on superalloy prototypes created via Powder Bed Fusion, achieving intricate geometries with high dimensional accuracy (±0.1 mm).

Advanced superalloy 3D printing accelerates prototyping cycles, enhances performance testing, and ensures component reliability, reducing overall development time for high-performance aerospace applications.

Superalloy Material Properties

Material Performance Comparison Table

Superalloy | Tensile Strength (MPa) | Yield Strength (MPa) | Density (g/cm³) | Max Operating Temp (°C) | Applications | Advantages |

|---|---|---|---|---|---|---|

1375-1450 | 1030-1200 | 8.19 | 700 | Turbine discs, engine blades | Excellent tensile strength, corrosion resistance | |

880-970 | 490-580 | 8.44 | 980 | Exhaust components, combustors | High oxidation resistance, fatigue strength | |

790-860 | 350-380 | 8.22 | 1200 | Afterburners, flame holders | Excellent oxidation resistance, weldability | |

1000-1100 | 600-700 | 8.36 | 850 | Gas turbines, combustion chambers | Good creep strength, thermal stability |

Material Selection Strategy

Selecting a suitable superalloy for 3D printing prototyping in aerospace requires careful evaluation based on temperature performance, mechanical properties, and environmental resilience:

Inconel 718: Ideal for high-stress turbine components needing excellent tensile (1450 MPa) and yield strengths (1200 MPa), combined with superior corrosion resistance up to 700°C.

Inconel 625: Suited for exhaust and combustion prototypes demanding exceptional oxidation resistance at elevated temperatures up to 980°C and good fatigue resistance.

Hastelloy X: Best for high-temperature afterburner and flame holder prototypes operating up to 1200°C, providing remarkable oxidation resistance and reliable weldability.

Nimonic 263: Preferred for combustion chambers and turbine blades requiring good creep strength (1100 MPa tensile strength) and sustained performance at temperatures up to 850°C.

Additive Manufacturing Processes for Superalloy Prototypes

3D Printing Process Comparison

3D Printing Process | Accuracy (mm) | Surface Finish (Ra µm) | Typical Uses | Advantages |

|---|---|---|---|---|

±0.1 | 8-20 | Complex aerospace parts, turbine blades | Complex geometries, high density (≥99.8%) | |

±0.25 | 15-30 | Repair and large aerospace structures | High deposition rate, multi-material capability | |

±0.2 | 10-25 | Prototype tooling, rapid models | Cost-effective, good scalability |

3D Printing Process Selection Strategy

Selecting the right additive manufacturing process for superalloy prototyping involves a detailed analysis of geometric complexity, required precision, and intended use:

Powder Bed Fusion (ASTM F3055): Ideal for intricate aerospace prototypes like turbine blades, delivering high dimensional precision (±0.1 mm accuracy) and near-net-shape parts with ≥99.8% material density.

Directed Energy Deposition (ISO/ASTM 52926): Suitable for large aerospace prototypes or component repairs, featuring rapid deposition rates (up to 10 kg/hr) and acceptable accuracy (±0.25 mm).

Binder Jetting (ISO/ASTM 52900): Appropriate for rapid conceptual modeling and cost-effective production of complex geometries, achieving moderate precision (±0.2 mm accuracy) with faster build speeds.

Surface Treatments for Superalloy Aerospace Prototypes

Surface Treatment Comparison

Treatment Method | Surface Roughness (Ra µm) | Oxidation Resistance | Max Temp (°C) | Applications | Key Features |

|---|---|---|---|---|---|

0.5-2.0 | Excellent | 1300 | Turbine blades, combustors | Enhanced thermal protection, extended life | |

≤0.4 | Good | 600 | Engine components, precision parts | Improved fatigue life, reduced surface defects | |

2-6 | Good | Material Limit | Turbine discs, rotating parts | Enhanced fatigue resistance, surface strengthening | |

0.6-1.5 | Superior | 500 | Corrosion-sensitive aerospace parts | Improved corrosion resistance, surface purity |

Surface Treatment Selection Strategy

Surface treatments significantly enhance aerospace prototype performance and reliability:

Thermal Barrier Coatings (TBC): Essential for prototypes operating at high temperatures (up to 1300°C), providing thermal protection for turbine blades and combustion chambers.

Electropolishing: Achieves smooth finishes (Ra ≤0.4 µm), ideal for improving fatigue resistance and reducing surface imperfections critical in aerospace engine components.

Shot Peening: Enhances fatigue life and surface hardness, effectively extending the durability of rotating superalloy prototypes like turbine discs.

Passivation: Ensures corrosion resistance and surface cleanliness, which are vital for sensitive aerospace parts requiring stable long-term performance.

Typical Prototyping Methods

Superalloy 3D Printing: Produces complex prototypes rapidly (±0.1 mm accuracy) with exceptional mechanical properties for performance validation.

CNC Machining Prototyping: Offers high-precision secondary finishing or prototype refinement within tolerances of ±0.005 mm.

Rapid Molding Prototyping: Efficiently creates functional prototypes in limited runs (±0.05 mm accuracy) for realistic operational tests.

Quality Assurance Procedures

Dimensional Verification (ISO 10360-2): Validates prototype accuracy with CMM inspections within ±0.1 mm tolerance.

Microstructure Analysis (ASTM E112): Ensures optimal grain structure and density (≥99.8%) to guarantee high strength and durability.

Tensile and Yield Strength Testing (ASTM E8): Confirms mechanical properties, verifying compliance with aerospace material specifications.

Thermal Cycling Tests (ASTM F3316): Evaluates prototype resilience under repeated thermal stresses up to 1200°C.

Non-Destructive Testing (ASTM E1417, ASTM E1742): Identifies internal flaws ensuring reliability and structural integrity.

ISO 9001 and AS9100 Certification: Adheres to stringent aerospace quality management standards.

Key Industry Applications

Turbine blades and vanes

Combustion chamber components

Structural aerospace fittings

High-performance jet engine parts

Related FAQs:

Why use superalloys in aerospace prototyping?

Which 3D printing methods are best for aerospace superalloys?

How do surface treatments improve superalloy prototypes?

What quality standards apply to aerospace prototypes?

What aerospace applications benefit most from 3D printed superalloys?