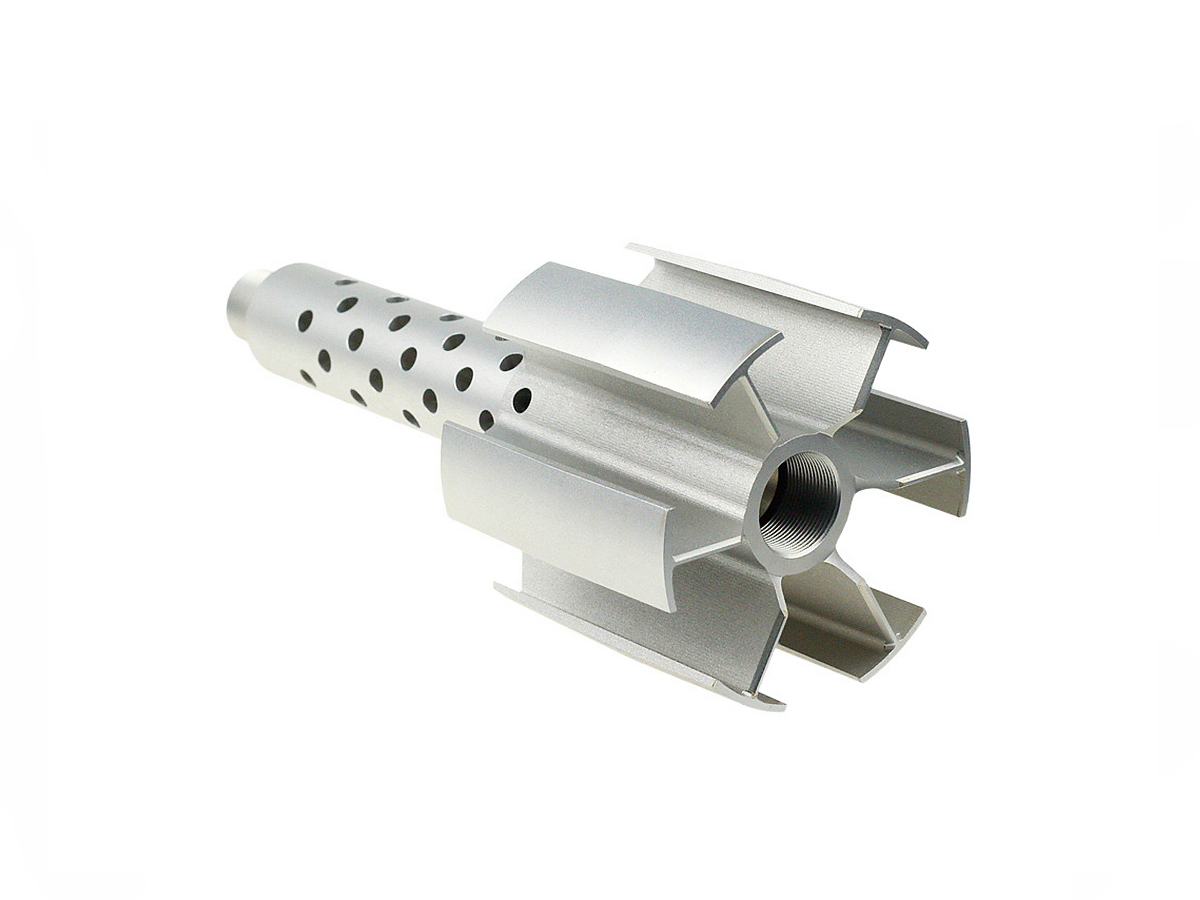

High-Quality CNC Machined Automotive Parts for Reliability and Safety

Introduction to CNC Machined Automotive Components

Reliability and safety are paramount in automotive manufacturing, requiring components engineered with exceptional precision and consistency. Advanced CNC machining technology meets these exacting demands by producing high-quality automotive components, including braking systems, steering assemblies, suspension parts, and critical drivetrain components. Materials commonly selected include aluminum alloys (6061, 7075), alloy steels (4140, 4340), stainless steels (SUS304, SUS316), and titanium alloys, each chosen for their superior mechanical properties, reliability, and durability.

Through specialized CNC machining services, automotive manufacturers ensure that every part achieves precise tolerances and consistent performance, significantly enhancing vehicle safety and reliability.

Material Performance Comparison for Automotive Safety Components

Material | Tensile Strength (MPa) | Density (g/cm³) | Fatigue Resistance | Typical Applications | Advantage |

|---|---|---|---|---|---|

310-345 | 2.70 | Excellent | Brake calipers, suspension brackets | Lightweight, corrosion-resistant | |

655-1000 | 7.85 | Outstanding | Steering shafts, axles | High toughness, fatigue-resistant | |

745-1080 | 7.85 | Exceptional | Suspension arms, drivetrain gears | Superior strength, durability | |

515-620 | 8.00 | Excellent | Fasteners, brake system components | High corrosion resistance, strength |

Material Selection Strategy for Reliable Automotive Parts

Selecting materials for automotive components with high safety and reliability standards involves evaluating strength, fatigue resistance, corrosion resistance, and weight efficiency:

Aluminum 6061-T6 is ideal for lightweight, corrosion-resistant parts such as braking systems and suspension components, offering good tensile strength (up to 345 MPa) and significantly reducing vehicle mass.

Alloy Steel 4140 provides excellent toughness, high tensile strength (up to 1000 MPa), and fatigue resistance, which are essential for critical components such as steering shafts and drivetrain axles.

Alloy Steel 4340 is selected for high-stress suspension and drivetrain parts due to its exceptional strength (up to 1080 MPa), fatigue resistance, and overall durability, enhancing safety under demanding operational conditions.

Stainless Steel SUS304 offers high corrosion resistance and reliable strength (up to 620 MPa), making it suitable for brake systems and fasteners exposed to harsh environments.

CNC Machining Processes for Reliable Automotive Components

CNC Machining Process | Dimensional Accuracy (mm) | Surface Roughness (Ra μm) | Typical Applications | Key Advantages |

|---|---|---|---|---|

±0.005-0.02 | 0.4-1.6 | Brake calipers, suspension brackets | Versatile, consistent precision | |

±0.005-0.01 | 0.4-1.2 | Axles, steering components | Rotational accuracy | |

±0.005-0.01 | 0.2-0.8 | Complex suspension parts, steering knuckles | High accuracy, complex geometries | |

±0.002-0.005 | 0.1-0.4 | Drivetrain gears, precision bearings | Ultra-precision finishes |

CNC Process Selection Strategy for High-Quality Automotive Components

Optimal CNC machining processes ensure automotive components meet strict safety and reliability criteria:

Precision CNC Milling reliably produces components with consistent dimensional accuracy (±0.005-0.02 mm), essential for brake and suspension assemblies.

CNC Turning provides critical rotational accuracy (±0.005 mm) necessary for steering components, axles, and drivetrain shafts.

Multi-Axis CNC Machining excels at manufacturing complex parts with tight tolerances (±0.005 mm), improving accuracy for suspension and steering components.

CNC Grinding achieves ultra-high precision (±0.002-0.005 mm) and exceptional surface finishes critical for drivetrain gears and precision bearing components, ensuring optimal performance and longevity.

Surface Treatment Performance Comparison for Automotive Components

Treatment Method | Surface Roughness (Ra μm) | Wear Resistance | Corrosion Resistance | Surface Hardness | Typical Applications | Key Features |

|---|---|---|---|---|---|---|

0.4-1.0 | Excellent | Excellent (≥1000 hrs ASTM B117) | HV 400-600 | Aluminum brake parts | Enhanced corrosion protection | |

0.4-1.2 | Exceptional | Good | HRC 55-62 | Steel drivetrain components | Improved fatigue life, strength | |

0.8-1.6 | Moderate | Good (≥200 hrs ASTM B117) | Unchanged | Internal steel parts | Economical corrosion protection | |

0.8-1.6 | Moderate | Excellent (≥1000 hrs ASTM B117) | Unchanged | Stainless steel components | Superior corrosion resistance |

Surface Treatment Selection for Reliable Automotive Parts

Proper surface treatments significantly enhance the durability and operational reliability of automotive components:

Anodizing enhances aluminum components with superior corrosion resistance (≥1000 hrs ASTM B117) and improved surface hardness, essential for braking systems and chassis components.

Heat Treatment significantly increases mechanical properties (HRC 55-62), improving fatigue life and overall strength, critical for drivetrain and steering components.

Black Oxide Coating provides cost-effective corrosion resistance (≥200 hrs ASTM B117), suitable for internal steel components requiring basic corrosion protection.

Passivation ensures stainless steel parts maintain superior corrosion resistance (≥1000 hrs ASTM B117), essential for safety-critical braking and fastener components.

Typical Prototyping Methods for Automotive Components

CNC Machining Prototyping: Delivers precision prototypes with tolerances of ±0.005 mm, enabling accurate testing and validation of safety-critical components.

Rapid Molding Prototyping: Quickly produces functional prototypes for comprehensive mechanical and structural testing under realistic conditions.

Metal 3D Printing (Powder Bed Fusion): Efficiently creates complex prototypes (±0.05 mm accuracy), suitable for early validation of intricate component designs.

Quality Assurance Procedures

CMM Inspection (ISO 10360-2): Accurate dimensional verification within ±0.005 mm for precise assembly fitment.

Surface Roughness Verification (ISO 4287): Confirms compliance with surface quality standards (Ra ≤0.8 µm).

Mechanical Testing (ASTM E8/E466): Validates tensile strength, yield strength, and fatigue durability.

Non-Destructive Testing (ASTM E1444/E2375): Identifies internal defects, ensuring the reliability of safety-critical components.

Corrosion Testing (ASTM B117 Salt Spray): Ensures long-term corrosion resistance compliance.

Full ISO 9001 Traceability: Comprehensive documentation maintaining strict adherence to automotive industry standards.

Industry Applications

Automotive braking systems

Steering and suspension assemblies

Safety-critical drivetrain components

Related FAQs:

Which materials ensure reliability for automotive safety components?

How does CNC machining enhance automotive part safety?

What surface treatments increase component durability?

Why is prototyping essential for automotive safety parts?

What quality assurance methods ensure automotive component reliability?