Optimizing Oil and Gas Equipment: CNC Grinding for High-Strength Superalloy Components

Introduction

The oil and gas industry demands materials capable of withstanding extreme operational environments, high pressures, corrosive substances, and elevated temperatures. Superalloys, recognized for their exceptional strength, corrosion resistance, and thermal stability, have become indispensable for critical components in oil and gas equipment such as valves, pumps, and drilling assemblies.

Advanced CNC grinding services ensure precision machining, excellent surface finish, and optimal dimensional accuracy of superalloy components. CNC grinding significantly enhances component reliability, operational performance, and lifespan, crucial factors in minimizing downtime and maintaining production efficiency in oil and gas operations.

Superalloy Materials

Material Performance Comparison

Superalloy | Tensile Strength (MPa) | Yield Strength (MPa) | Max Operating Temp (°C) | Typical Applications | Advantage |

|---|---|---|---|---|---|

1240-1450 | 1030-1240 | 700-750 | Valves, wellhead components | Outstanding fatigue and creep resistance, high strength | |

690-785 | 310-375 | 1030-1100 | Corrosion-resistant valves, piping | Exceptional corrosion resistance, especially to chloride-rich environments | |

965-1138 | 690-758 | 500-550 | Pump shafts, marine fittings | Superior corrosion resistance, high mechanical strength | |

1035-1175 | 620-720 | 800-900 | Valve seats, sealing surfaces | Excellent wear resistance, remarkable hardness at elevated temperatures |

Material Selection Strategy

Selecting suitable superalloys for oil and gas equipment involves critical evaluation based on operational conditions:

Components exposed to extreme mechanical stresses and high-temperature cycles: Inconel 718 provides optimal fatigue resistance and mechanical reliability.

Highly corrosive environments, particularly with chlorides and acids: Hastelloy C-276 ensures robust resistance against corrosion and chemical attacks.

Applications needing superior corrosion resistance and excellent mechanical properties: Monel K500 is ideal for pump shafts and marine applications in offshore settings.

High-wear, abrasion-prone components at elevated temperatures: Stellite 6 offers outstanding wear resistance and surface integrity.

CNC Grinding Processes

Process Performance Comparison

CNC Grinding Technology | Dimensional Accuracy (mm) | Surface Roughness (Ra μm) | Typical Applications | Key Advantages |

|---|---|---|---|---|

±0.002-0.008 | 0.2-0.8 | Valve flanges, sealing faces | Superior flatness, high-quality finishes | |

±0.002-0.01 | 0.4-1.0 | Pump shafts, precision rods | Precise concentricity, consistent diameter control | |

±0.001-0.005 | 0.2-1.0 | Valve stems, fittings, fasteners | High production rates, excellent diameter accuracy | |

±0.001-0.005 | 0.1-0.6 | Complex valve internals, intricate fittings | Exceptionally tight tolerances, optimal surface integrity |

Process Selection Strategy

Selecting CNC grinding processes for superalloy components in oil and gas depends on component complexity and precision requirements:

Flat surfaces demanding precise finishes: Surface Grinding delivers consistent flatness and surface quality crucial for sealing components.

Cylindrical components requiring precise rotational accuracy: Cylindrical Grinding maintains precise dimensions and uniform surface finish, vital for rotating shafts.

High-volume production of precision parts: Centerless Grinding ensures efficient throughput while maintaining consistent dimensional accuracy.

Intricate, high-precision internal components: Precision CNC Grinding guarantees tight tolerances, ensuring component reliability in critical oil and gas applications.

Surface Treatment

Surface Treatment Performance

Treatment Method | Corrosion Resistance | Wear Resistance | Temperature Stability (°C) | Typical Applications | Key Features |

|---|---|---|---|---|---|

Excellent (>1000 hours ASTM B117) | Very High (HV1000-1500) | Up to 1200 | Drilling equipment, valve parts | High-temperature protection, outstanding abrasion resistance | |

Excellent (700-900 hours ASTM B117) | Moderate | ≤400 | Precision valve components, pump internals | Superior surface smoothness, enhanced corrosion protection | |

Excellent (500-1000 hours ASTM B117) | High (HV800-1200) | Up to 550 | High-wear valve and pump components | Increased surface hardness, wear, and fatigue resistance | |

Exceptional (>1000 hours ASTM B117) | Very High (HV1500-2500) | Up to 600 | High-wear sealing and bearing surfaces | Superior mechanical durability, abrasion resistance |

Surface Treatment Selection

Surface treatments for superalloy components in oil and gas equipment should match operational requirements precisely:

Extreme high-temperature and abrasive conditions: Thermal Spray Coating provides robust thermal and abrasion protection.

High-precision components needing friction reduction and corrosion resistance: Electropolishing ensures smooth operation and corrosion mitigation.

Components experiencing intensive wear conditions: Nitriding significantly enhances surface hardness and wear performance.

Critical moving parts demanding maximum wear resistance: PVD Coating delivers superior durability and reliability.

Quality Control

Quality Control Procedures

Dimensional verification using Coordinate Measuring Machines (CMM) and precision optical comparators.

Surface roughness assessment with advanced profilometers.

Mechanical property testing, including tensile, yield strength, and hardness evaluations (ASTM standards).

Non-destructive testing (NDT), such as ultrasonic and radiographic inspections, to detect internal defects.

Corrosion resistance validation via ASTM B117 (Salt Spray Testing).

Comprehensive documentation complying with ISO 9001, API Spec Q1, and ASME standards relevant to oil and gas.

Industry Applications

Superalloy Component Applications

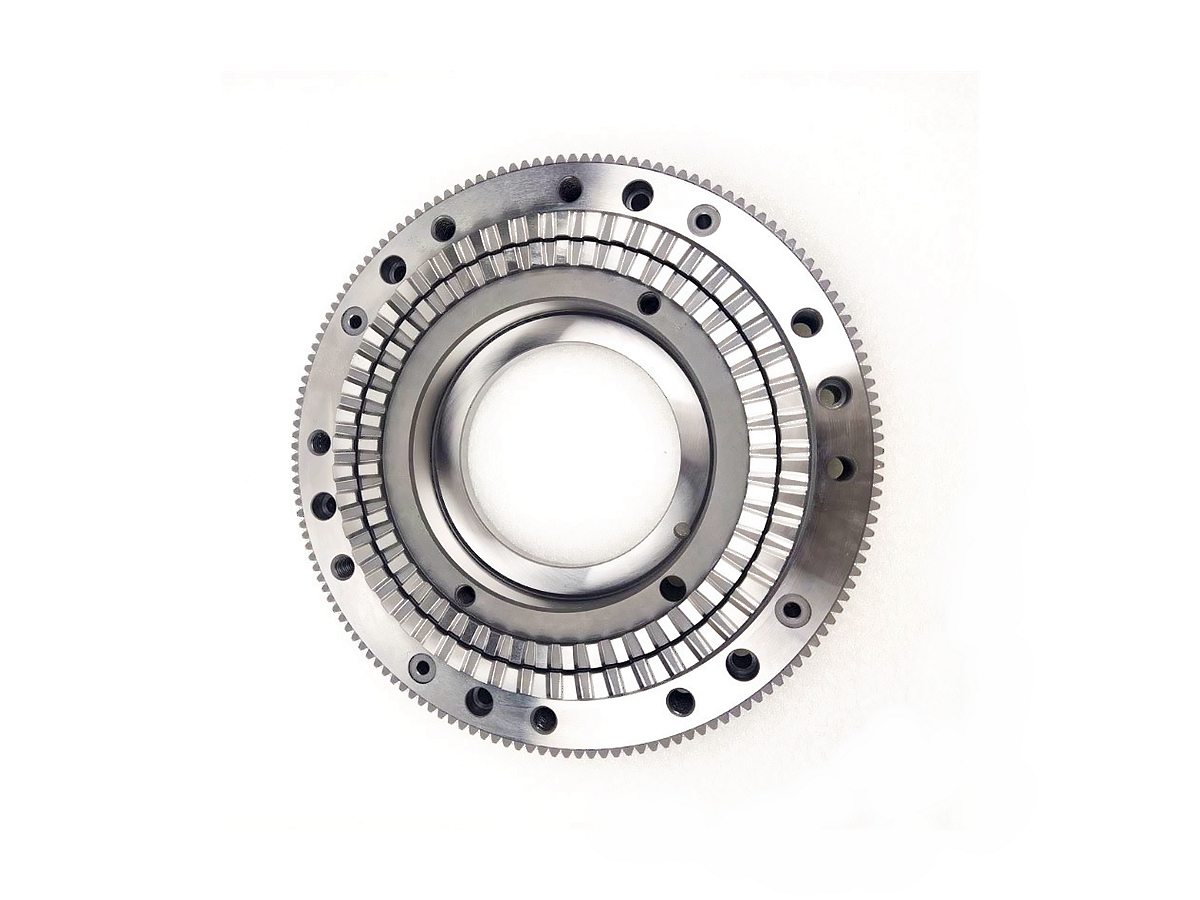

High-pressure valves, valve seats, and fittings for offshore and onshore operations.

Drilling and completion equipment, including mud pumps and downhole tools.

Precision pump components and mechanical seals are subjected to severe service conditions.

Specialized pipeline components and structural connectors for harsh environments.

Related FAQs:

Why are superalloys critical for oil and gas equipment?

How does CNC grinding enhance the performance of oil and gas components?

Which surface treatments best protect superalloy parts in harsh environments?

What standards regulate the quality of CNC-ground superalloy components in oil and gas?

How to choose the right superalloy for specific oil and gas applications?