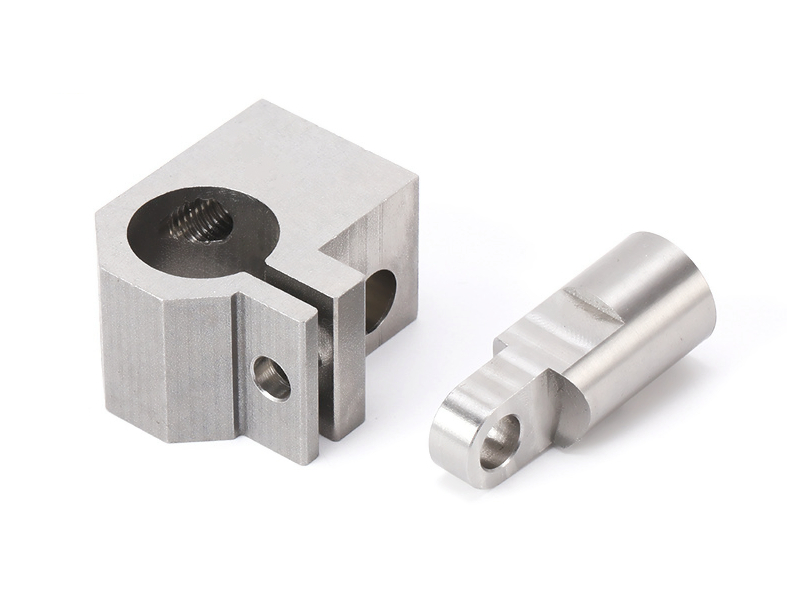

Precision Titanium Ti-6Al-4V CNC Milling for Aerospace Structural Components

Introduction

Aerospace manufacturing demands the highest precision, reliability, and strength standards in structural components. Titanium Ti-6Al-4V (Grade 5), known for its superior strength-to-weight ratio, corrosion resistance, and exceptional durability, has become a preferred material for aerospace structural components. This case study highlights our expertise in precision CNC Milling Service of Titanium Ti-6Al-4V, emphasizing manufacturing processes, material properties, essential surface treatments, aerospace applications, and inherent advantages and limitations.

Manufacturing Process

Our precision machining processes for Titanium Ti-6Al-4V involve advanced techniques essential for aerospace:

3-Axis CNC Milling: Suitable for simpler geometries and cost-effective production.

4-Axis CNC Milling: Enhances precision, enabling intricate component designs.

5-Axis CNC Milling: Crucial for complex aerospace structural components, offering superior dimensional accuracy.

High-Speed Machining (HSM): Optimizes surface finish quality, reducing stress and enhancing fatigue resistance.

Precision Drilling and Boring: Ensures accurate hole alignments and assemblies essential in aerospace.

These processes optimize performance, precision, and efficiency, making them indispensable in aerospace manufacturing.

Material: Titanium Ti-6Al-4V

Titanium Ti-6Al-4V, known as TC4 or Grade 5 titanium, offers unmatched qualities crucial for aerospace:

Exceptional strength-to-weight ratio: Ideal for weight-sensitive aerospace designs.

Superior corrosion resistance: Vital for durability in aggressive aerospace environments.

High fracture toughness and fatigue strength: Ensuring reliability under cyclic stresses.

Good weldability: Compatible with various aerospace design standards.

These attributes position Titanium Ti-6Al-4V as a preferred material in aerospace applications.

Surface Treatments for Optimal Performance

To enhance the durability and reliability of titanium aerospace components, specialized surface treatments are employed:

Anodizing: Improves corrosion resistance, extends lifespan, and provides easy color-coding identification.

Shot Peening: Enhances fatigue resistance, critical for components experiencing repeated stress.

Passivation: Forms a protective oxide layer, significantly improving corrosion resistance.

PVD Coatings: Adds wear resistance and aesthetic value and reduces frictional losses.

These treatments are strategically selected based on aerospace component requirements, ensuring maximum performance.

Industry Application

Precision CNC-milled Titanium Ti-6Al-4V components are widely utilized across aerospace structural applications:

Airframe Structures: Lightweight, high-strength brackets, beams, and structural supports essential for aircraft performance.

Landing Gear Components: Robust parts offering exceptional fatigue and corrosion resistance.

Engine Mounts and Fittings: High-strength, reliable components handling extreme conditions and stresses.

Fasteners and Connectors: Precision-manufactured hardware capable of enduring severe operational conditions.

These applications depend heavily on precision manufacturing and material excellence, underscoring the importance of CNC machining expertise.

Advantages and Limitations

Advantages:

Superior Strength-to-Weight Ratio: Vital for aerospace structures requiring lightweight strength.

Exceptional Corrosion Resistance: Reduces maintenance and extends service life.

Excellent Thermal Stability: Suitable for high-stress aerospace environments.

High Machinability: Allows for precise, intricate aerospace component designs.

Limitations:

High Production Costs: Due to raw material costs and specialized machining processes.

Machining Complexity: Requires advanced CNC machinery and precision tooling.

Significant Tool Wear: Results in higher machining and production expenses.

Despite these challenges, Titanium Ti-6Al-4V’s advantages overwhelmingly justify its application in aerospace structures.

Importance of Precision in Aerospace CNC Machining

Precision CNC machining in aerospace is non-negotiable, as even minor deviations can compromise safety and performance. Utilizing state-of-the-art Multi-Axis Machining, we achieve unparalleled accuracy, ensuring components consistently meet stringent aerospace specifications.

Sustainability Considerations

Sustainable manufacturing is increasingly critical in aerospace, and Titanium Ti-6Al-4V aligns with this goal by reducing aircraft weight, improving fuel efficiency, and decreasing environmental impacts. Precision CNC machining further minimizes waste, enhancing sustainability.

Ensuring Quality and Compliance

Quality assurance in aerospace manufacturing is stringent. Our CNC machining processes for Titanium Ti-6Al-4V adhere strictly to industry certifications and compliance standards. Rigorous quality control ensures that every aerospace component performs reliably under the most demanding conditions.

Emerging Trends in Aerospace CNC Machining

Continuous innovation drives aerospace CNC machining. Trends such as advanced CAD/CAM integration, digital twin technologies, and automation enhance machining efficiency and accuracy, improving overall aerospace component performance and production timelines.

Conclusion

Precision CNC milling of Titanium Ti-6Al-4V structural components significantly impacts aerospace safety, efficiency, and performance. Utilizing advanced machining processes, specialized surface treatments, and meticulous quality assurance, we deliver components that consistently meet and exceed aerospace industry standards.

FAQs

Why is Titanium Ti-6Al-4V commonly used in aerospace structural components? Titanium Ti-6Al-4V offers an unmatched strength-to-weight ratio, exceptional corrosion resistance, and high durability essential for aerospace.

What CNC milling methods are best suited for titanium aerospace components? Advanced 4-Axis and 5-Axis CNC milling methods are most suitable due to their ability to handle complex geometries and precision demands.

How do surface treatments enhance the performance of aerospace titanium components? Surface treatments improve corrosion resistance, fatigue life, wear resistance, and component durability.

What machining challenges are associated with Titanium Ti-6Al-4V? Machining challenges include significant tool wear, higher machining complexity, and increased production costs.

How does precision CNC milling impact the reliability of aerospace structures? Precision milling ensures accuracy and consistency, enhancing reliability, safety, and structural integrity.