Tailored CNC Machining of Critical Parts for Industrial Equipment Longevity

Introduction to Tailored CNC Machining for Industrial Longevity

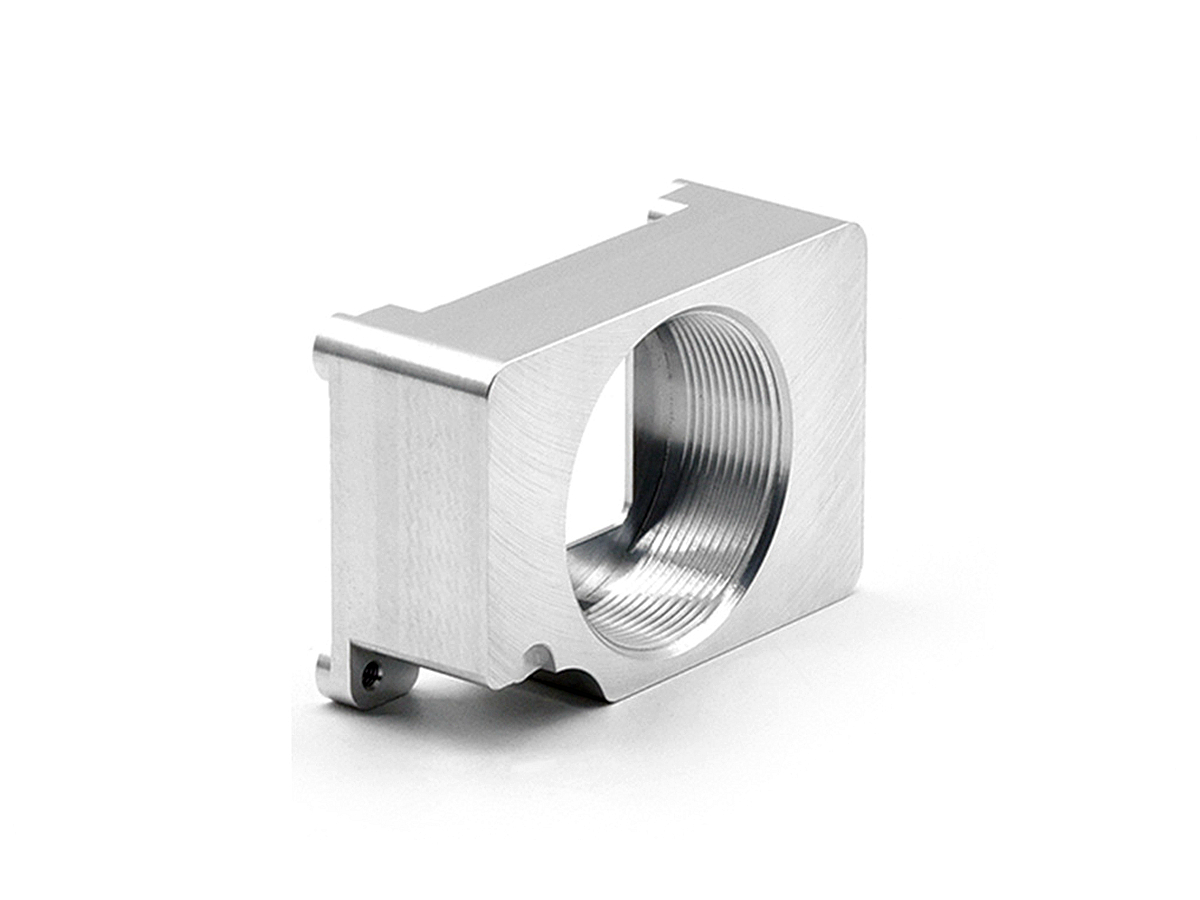

Ensuring industrial equipment longevity requires critical components manufactured to precise specifications and durability standards. Tailored CNC machining achieves strict dimensional accuracy (±0.005 mm) and refined surface finishes (Ra ≤0.8 µm), significantly enhancing the reliability and lifespan of equipment parts such as drive shafts, precision gears, bearing housings, and custom fittings. These high-quality machined components directly benefit sectors including industrial equipment, automation, and power generation.

Utilizing specialized CNC machining services, industries ensure component consistency, improve operational efficiency, and effectively minimize maintenance costs and downtime under severe operational conditions.

Material Comparison for Long-Lasting Industrial Components

Material Performance Comparison

Material | Tensile Strength (MPa) | Wear Resistance | Corrosion Resistance | Typical Applications | Advantage |

|---|---|---|---|---|---|

1080-1230 | Excellent | Good | Shafts, high-load gears | Superior fatigue strength, high toughness | |

1100-1310 | Excellent | Excellent | Bearing housings, precision valves | High corrosion resistance, exceptional strength | |

276-310 | Good | Excellent | Lightweight structural parts | High strength-to-weight ratio, corrosion resistance | |

360-400 | Good | Good | Precision fittings, connectors | Excellent machinability, dimensionally stable |

Material Selection Strategy for Critical Industrial Components

Choosing materials for tailored CNC machining of longevity-focused industrial parts involves evaluating tensile strength, fatigue resistance, machinability, and corrosion resistance:

4340 Alloy Steel is ideal for high-stress, cyclically-loaded components like shafts and gears, providing excellent tensile strength (up to 1230 MPa), fatigue resistance, and toughness.

Stainless Steel SUS630 (17-4PH) offers superior corrosion resistance and exceptional tensile strength (up to 1310 MPa), making it suitable for bearing housings and precision valves in aggressive industrial environments.

Aluminum 6061-T6 is preferred when lightweight structural integrity and high corrosion resistance are necessary, and it is ideal for precision brackets and structural supports.

Brass C360 is excellent for detailed precision fittings and connectors due to its exceptional machinability and stability in dimensional tolerances (±0.005 mm).

CNC Machining Process Analysis for Industrial Longevity Components

CNC Machining Processes Performance Comparison

CNC Machining Technology | Dimensional Accuracy (mm) | Surface Roughness (Ra µm) | Typical Applications | Key Advantages |

|---|---|---|---|---|

±0.005-0.01 | 0.4-1.0 | Complex housings, gearboxes | Precise complex geometries | |

±0.005-0.01 | 0.6-1.2 | Shafts, spindles, bearings | Efficient precision production | |

±0.002-0.005 | 0.05-0.2 | Precision mating surfaces | Ultra-fine surface finishes | |

±0.003-0.008 | 0.2-0.8 | Complex assemblies, intricate parts | Advanced accuracy, flexibility |

CNC Machining Process Selection Strategy for Longevity Components

Correct selection of CNC processes ensures critical parts maintain exact tolerances and high-performance attributes over their lifespan:

CNC Milling effectively handles intricate geometries and complex shapes, suitable for gearboxes and detailed housing components, providing dimensional accuracy within ±0.005 mm.

CNC Turning provides high-efficiency production for rotational components such as shafts, bearings, and spindles, ensuring consistent dimensional accuracy (±0.005-0.01 mm).

CNC Grinding achieves exceptionally tight tolerances (±0.002-0.005 mm) and ultra-smooth finishes (Ra ≤0.2 µm), essential for precision mating surfaces in bearings and sealing components.

Multi-axis CNC Machining is optimal for producing highly intricate, detailed parts and assemblies, offering exceptional flexibility, reduced setups, and high accuracy down to ±0.003 mm.

Surface Treatment Solutions for CNC Machined Longevity Parts

Surface Treatment Performance Comparison

Treatment Method | Wear Resistance | Corrosion Resistance | Max Operating Temp (°C) | Typical Applications | Key Features |

|---|---|---|---|---|---|

Excellent (up to HV 1100) | Excellent (~1200 hrs ASTM B117) | 550 | Shafts, gears, bearings | High hardness, fatigue strength | |

Excellent | Exceptional (~1000 hrs ASTM B117) | 400 | Valve components, fittings | Consistent thickness, corrosion resistance | |

Good | Outstanding (~1500 hrs ASTM B117) | 300 | Aluminum structures, brackets | Durable surface, excellent protection | |

Excellent | Outstanding (~1200 hrs ASTM B117) | 450 | Bearing surfaces, fittings | Superior hardness, friction reduction |

Surface Treatment Selection Strategy for Longevity Components

Appropriate surface treatments significantly increase durability, corrosion resistance, and operational lifespan:

Nitriding improves hardness (HV 1100), wear resistance, and fatigue strength, ideal for critical shafts, gears, and bearing surfaces exposed to high mechanical stresses.

Electroless Nickel Plating provides uniform coating and corrosion protection, beneficial for valves and connectors exposed to harsh environmental conditions.

Anodizing offers superior corrosion resistance and enhanced durability for aluminum parts, significantly prolonging service life in corrosive environments.

Chrome Plating enhances surface hardness and friction resistance, optimal for high-precision bearing surfaces and fittings, reducing wear and extending component longevity.

Typical Prototyping Method

CNC Machining Prototyping: Delivers high-precision prototypes (±0.005 mm tolerance, Ra ≤0.8 µm surface finish), enabling accurate performance and durability evaluations.

Powder Bed Fusion: Allows the creation of metal prototypes with complex geometries, tolerances around ±0.1 mm, excellent for functional testing and validation.

Material Jetting: Offers prototypes with fine details and layer resolutions between 16-32 microns, ideal for assessing intricate designs and interactions early in development.

Quality Control Standards for Tailored CNC Machined Parts

Precision dimensional inspections using Coordinate Measuring Machines (CMM).

Surface roughness assessments with precision profilometers.

Non-destructive testing (ultrasonic, magnetic particle inspections) for structural integrity.

Mechanical property evaluations are compliant with ASTM and ISO standards.

Corrosion resistance testing via ASTM B117 salt spray standards.

Full documentation and traceability complying with ISO 9001 quality management.

Industry Applications of Tailored CNC Machined Components

Critical drive systems and gear assemblies.

High-load bearings and shaft components.

Precision hydraulic and pneumatic components.

Custom brackets and housing for automation and robotics.

Related FAQs:

Why is tailored CNC machining crucial for industrial equipment longevity?

What materials ensure maximum durability for industrial components?

Which CNC machining processes best enhance component reliability?

How do surface treatments extend the lifespan of critical industrial parts?

What quality standards ensure CNC machined component reliability?