Titanium CNC Prototyping: Custom Parts for Aerospace and Medical Applications

Introduction

Specialized ceramic materials excel due to their remarkable hardness, thermal stability, and outstanding chemical resistance, making them essential in industries demanding precision and durability, such as aerospace, medical devices, and electronics. Utilizing CNC machining processes ensures these advanced ceramics are manufactured to stringent tolerances (±0.005 mm), providing consistent reliability and superior component performance.

By leveraging advanced ceramic CNC machining services, companies can produce customized precision components like ceramic bearings, insulators, and structural parts tailored specifically to their application requirements.

Specialized Ceramic Material Properties

Material Performance Comparison Table

Material | Hardness (HV) | Max Temp (°C) | Thermal Conductivity (W/m·K) | Fracture Toughness (MPa√m) | Typical Applications | Advantages |

|---|---|---|---|---|---|---|

1700-2100 | 1700 | 25-35 | 4-5 | Insulators, pump seals | Excellent wear resistance, high electrical insulation | |

1200-1400 | 1200 | 2-3 | 5-10 | Medical implants, mechanical components | High strength and fracture toughness | |

2500-2800 | 1650 | 120-150 | 4-5 | Mechanical seals, high-wear parts | High hardness, superior thermal conductivity | |

500-700 | 2100 | 30-60 | 2-3 | High-temperature insulators | Excellent thermal shock resistance, high-temperature stability |

Material Selection Strategy

Selecting specialized ceramics for CNC machining involves careful consideration of mechanical, thermal, and chemical requirements:

Alumina offers high hardness (up to 2100 HV) and superior electrical insulation, making it ideal for wear-resistant insulators and sealing components operating up to 1700°C.

Zirconia is chosen for applications demanding high fracture toughness (up to 10 MPa√m), particularly in medical implants and load-bearing structural parts.

Silicon Carbide (SiC) is best for extremely hard and high-wear environments, combining high thermal conductivity (120-150 W/m·K) and exceptional hardness (up to 2800 HV).

Boron Nitride (BN) excels in high-temperature insulation applications, maintaining stability and thermal shock resistance up to 2100°C.

CNC Machining Processes for Specialized Ceramic Components

CNC Machining Process Comparison

CNC Process | Accuracy (mm) | Surface Finish (Ra µm) | Applications | Advantages |

|---|---|---|---|---|

±0.003 | 0.05-0.2 | Bearings, seals | Exceptional surface finish and precision | |

±0.01 | 0.4-0.8 | Complex structural parts, fixtures | Precision shaping of intricate geometries | |

±0.01 | 0.6-1.2 | Cooling channels, precision holes | Accurate hole placement in hard ceramics | |

±0.002 | 0.2-0.5 | Intricate features, fine details | Accurate machining without mechanical stress |

CNC Process Selection Strategy

The selection of CNC machining techniques for ceramics depends on component complexity, tolerance requirements, and surface finish quality:

CNC Grinding is the preferred method for achieving ultra-precise surfaces (Ra ≤0.2 µm), critical for bearings, seals, and precision parts.

CNC Milling allows efficient machining of complex geometries in ceramic structural components with consistent tolerances (±0.01 mm).

CNC Drilling ensures precise hole placements, essential for components requiring accurate fluid or airflow channels.

EDM Machining provides stress-free machining for intricate features or detailed internal structures, maintaining extremely tight tolerances (±0.002 mm).

Surface Treatments for CNC Machined Ceramic Components

Surface Treatment Comparison

Treatment Method | Hardness (HV) | Corrosion Resistance | Max Temp (°C) | Applications | Key Features |

|---|---|---|---|---|---|

Base Material | Excellent | 600°C | Precision components | Ultra-smooth surfaces | |

2200-2500 | Excellent | 1300°C | Aerospace, thermal management | High-temperature protection | |

Base Material | Excellent | 400°C | Electronic insulators | Improved corrosion resistance | |

600-700 | Excellent | 260°C | Chemical-resistant parts | Non-stick surface, chemical resistance |

Surface Treatment Selection Strategy

Surface treatments enhance the performance and longevity of ceramic components:

Electropolishing provides exceptionally smooth surfaces, which are crucial for precision mechanical and medical components requiring minimal friction.

Thermal Barrier Coatings (TBC) deliver superior thermal insulation for aerospace and high-temperature industrial components operating up to 1300°C.

Passivation ensures enhanced corrosion resistance and surface purity, critical for electronics and sensitive applications.

Teflon Coating achieves non-stick, chemical-resistant surfaces, which are ideal for chemical processing and low-friction applications.

Typical Prototyping Methods

Ceramic 3D Printing: Provides rapid prototyping with an accuracy of ±0.1 mm, ideal for validating intricate ceramic geometries.

CNC Machining Prototyping: Offers precise prototyping accuracy (±0.005 mm), validating dimensional accuracy and functional properties.

Powder Bed Fusion: Delivers highly accurate ceramic prototypes (±0.05 mm), enabling comprehensive testing before final production.

Quality Assurance Procedures

CMM Inspection (ISO 10360-2): Ensures component accuracy within ±0.005 mm tolerance.

Surface Roughness Measurement (ISO 4287): Verifies precise surface finishes (Ra ≤0.2 µm).

Thermal Stability Testing (ASTM C1525): Confirms operational stability at temperatures up to 1700°C.

Fracture Toughness Analysis (ASTM C1421): Validates up to 10 MPa√m of ceramic toughness.

Dielectric Strength Testing (ASTM D149): Confirms electrical insulation (≥30 kV/mm) for electronic components.

ISO 9001:2015 Certification: Ensures quality control, traceability, and consistency throughout production.

Key Industry Applications

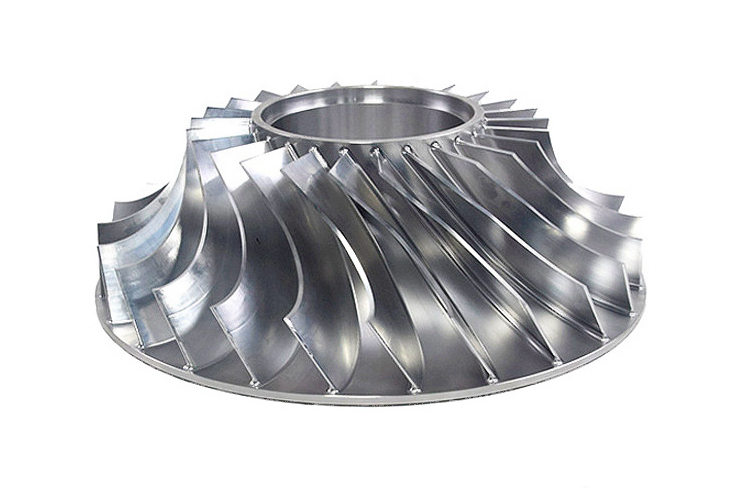

Aerospace structural ceramics

Medical implants and tools

Semiconductor insulators

Mechanical seals and bearings

Related FAQs:

What specialized ceramics are best suited for precision machining?

Why is CNC machining ideal for producing ceramic parts?

How do surface treatments enhance ceramic durability?

What industries benefit most from CNC machined ceramic components?

What quality assurance methods ensure precision in ceramic CNC machining?