Zirconia (ZrO2) CNC Machining for High-Performance Ceramic Parts and Components

Introduction

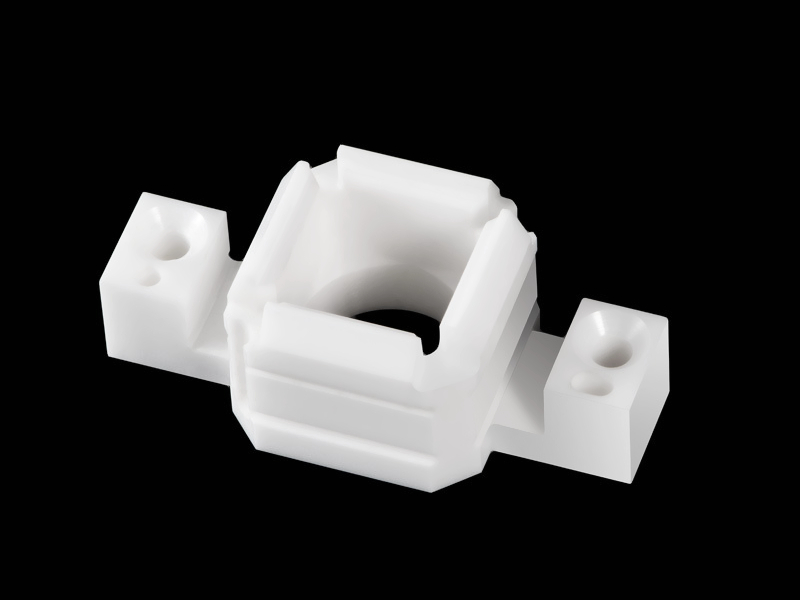

Zirconia (ZrO2), a high-performance ceramic, is widely used in applications requiring excellent wear resistance, high strength, and thermal stability. CNC machining of zirconia offers unparalleled precision (±0.01 mm) and exceptional surface finishes (Ra ≤0.8 µm), making it ideal for critical components in industries such as aerospace, medical devices, and industrial equipment. By leveraging advanced CNC machining services, manufacturers produce zirconia parts that deliver superior performance in demanding environments, including turbine blades, wear-resistant seals, and precision valves.

Zirconia's unique properties, including its high fracture toughness and resistance to high temperatures, make it an ideal material for high-performance applications that require reliability, durability, and consistent performance over time.

Zirconia Material Properties

Material Comparison Table

Material | Tensile Strength (MPa) | Hardness (HV) | Density (g/cm³) | Fracture Toughness (MPa√m) | Thermal Conductivity (W/m·K) | Typical Applications | Advantages |

|---|---|---|---|---|---|---|---|

800-1100 | 1200-1400 HV | 6.0-6.1 | 5-10 MPa√m | 2.5-3.0 | Aerospace turbine components, medical implants, wear-resistant parts | High strength, exceptional fracture toughness, excellent thermal stability | |

300-350 | 1700-2100 HV | 3.9 | 3-4 MPa√m | 20-30 | Electrical insulators, heat exchangers | High hardness, electrical insulation | |

200-400 | 2500-2800 HV | 3.2 | 4-5 MPa√m | 120-150 | Wear-resistant components, abrasives | Excellent wear resistance, high thermal conductivity |

Zirconia Selection Criteria

When selecting zirconia (ZrO2) for CNC machining, it’s crucial to consider its superior mechanical properties, such as high tensile strength (up to 1100 MPa) and fracture toughness (5-10 MPa√m), which make it ideal for demanding applications that require high reliability under stress.

Zirconia (ZrO2) stands out in high-performance applications due to its excellent mechanical properties, including high tensile strength and fracture toughness. It is especially suitable for aerospace turbine components, medical implants, and industrial components that operate under extreme conditions.

Alumina (Al2O3), while harder, lacks the fracture toughness of zirconia and is best suited for applications requiring electrical insulation and high hardness.

Silicon Carbide (SiC) is another high-performance ceramic material but excels in wear resistance rather than fracture toughness, making it ideal for abrasives and wear-resistant components.

CNC Machining Techniques for Zirconia

CNC Process Comparison

CNC Machining Technology | Dimensional Accuracy (mm) | Surface Roughness (Ra µm) | Typical Applications | Key Advantages |

|---|---|---|---|---|

±0.01 | 0.4-1.0 | Complex geometries, custom parts | Precision, versatility, high detail | |

±0.01 | 0.5-1.2 | Cylindrical components | Consistent accuracy, efficient production | |

±0.005-0.01 | 0.05-0.2 | Fine finishing for tight tolerances | Ultra-fine surface finishes, high precision | |

±0.005-0.01 | 0.2-0.8 | Highly detailed parts with intricate features | Complex geometries, maximum flexibility |

CNC Process Selection Strategy

Each CNC machining process contributes to the accuracy, efficiency, and surface quality of zirconia parts:

CNC Milling is highly effective for machining complex zirconia components such as turbine blades or intricate structural parts with tight dimensional tolerances and superior surface finishes.

CNC Turning is ideal for manufacturing cylindrical zirconia parts such as valves and shafts, ensuring consistent accuracy and smooth finishes.

CNC Grinding achieves ultra-fine finishes (Ra ≤0.2 µm), essential for high-precision applications such as sealing surfaces and tight-fitting components.

Multi-Axis CNC Machining is best suited for producing detailed zirconia components with complex geometries, enabling efficient multi-angle machining for parts like aerospace turbine blades and medical components.

Surface Treatments for CNC Zirconia Parts

Surface Treatment Comparison

Treatment Method | Wear Resistance (HV) | Corrosion Resistance | Max Operating Temp (°C) | Typical Applications | Key Features |

|---|---|---|---|---|---|

2000-2500 HV | Excellent | 1300°C | Turbine blades, combustion chamber liners | Superior thermal insulation, high durability | |

1200-1400 HV | Excellent | 1200°C | Medical implants, precision components | Extremely smooth surface, improved corrosion resistance | |

1400-1600 HV | Excellent | 1000°C | High-wear mechanical parts, cutting tools | High hardness, enhanced wear protection | |

2200-2600 HV | High | 1000°C | Wear-resistant seals, valve components | Extreme wear resistance, extended service life |

Surface Treatment Selection Strategy

The right surface treatment enhances zirconia's mechanical performance and extends the lifespan of critical components:

Thermal Barrier Coating (TBC) significantly improves thermal insulation and wear resistance (up to 2500 HV), ideal for zirconia parts operating in high-temperature environments such as turbine blades.

Electropolishing provides ultra-smooth surfaces and improved corrosion resistance, optimal for medical implants and precision zirconia components.

PVD Coatings offer additional hardness (up to 1600 HV) and superior wear resistance, suitable for parts experiencing severe friction and mechanical stress.

Ceramic Coating provides outstanding wear protection (up to 2600 HV) and durability, excellent for wear-resistant components such as seals and valve parts.

Quality Assurance for Zirconia Machined Parts

Quality assurance is critical to ensure that zirconia CNC machined components meet high standards of precision and durability:

CMM Inspection: Dimensional accuracy verification within ±0.01 mm using advanced Coordinate Measuring Machines to ensure precise tolerances.

Surface Finish Testing: Profilometer analysis to guarantee surface roughness meets the specified Ra ≤0.8 µm for smoothness and reliability.

Mechanical Testing: Tensile strength, fracture toughness, and hardness tests per ASTM and ISO standards to confirm material performance under stress.

Non-Destructive Testing (NDT): Ultrasonic or radiographic testing to detect internal defects or inconsistencies, ensuring part integrity.

Corrosion Resistance Testing: Salt spray testing (ASTM B117) to evaluate resistance to environmental factors and confirm part longevity.

ISO 9001 Compliance: Documentation of manufacturing processes to maintain traceability and ensure consistent quality.

Key Industry Applications

Aerospace turbine components

Medical implants and prosthetics

Wear-resistant seals and bushings

Industrial equipment and tooling

Related FAQs:

Why choose zirconia for CNC machining in high-performance applications?

How does CNC machining enhance the precision of zirconia components?

What are the most common applications for zirconia CNC machined parts?

Which surface treatments improve the durability of zirconia components?

What quality assurance measures ensure optimal performance of zirconia CNC machined parts?