Online Rapid Molding Prototyping Service

Our Online Rapid Molding Prototyping Service offers fast and cost-effective solutions with rapid vacuum casting, plastic injection molding, metal injection molding, and ceramic injection molding. We provide high-quality prototypes for various industries, ensuring quick turnaround times and precision.

- Rapid Molding Prototyping Service

- Low Volume Molding Manufacturing Service

- Mass Molding Production Service

- One Stop Molding Service

Send us your designs and specifications for a free quotation

All uploaded files are secure and confidential

Rapid Molding Service Range

Our Rapid Molding Service Range includes rapid vacuum casting, plastic injection molding, metal injection molding, and ceramic injection molding. We deliver quick, accurate prototypes and production parts, ensuring high-quality results for a wide range of industries and applications.

Typical 3D Printing Materials

Common aluminum alloys used in CNC machining include 6061, 7075, 2024, and 5052, offering a range of properties like high strength, corrosion resistance, and machinability. These alloys are used in aerospace, automotive, marine, and structural applications.

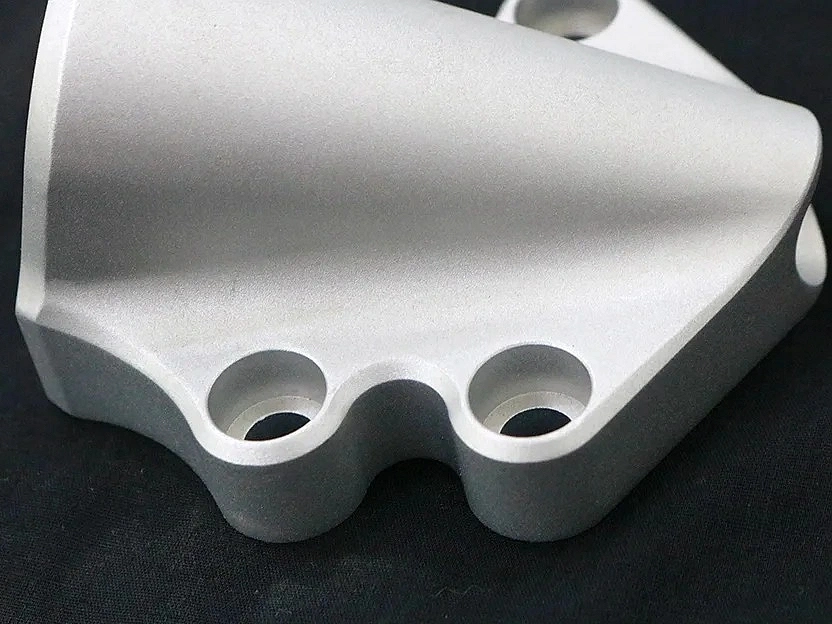

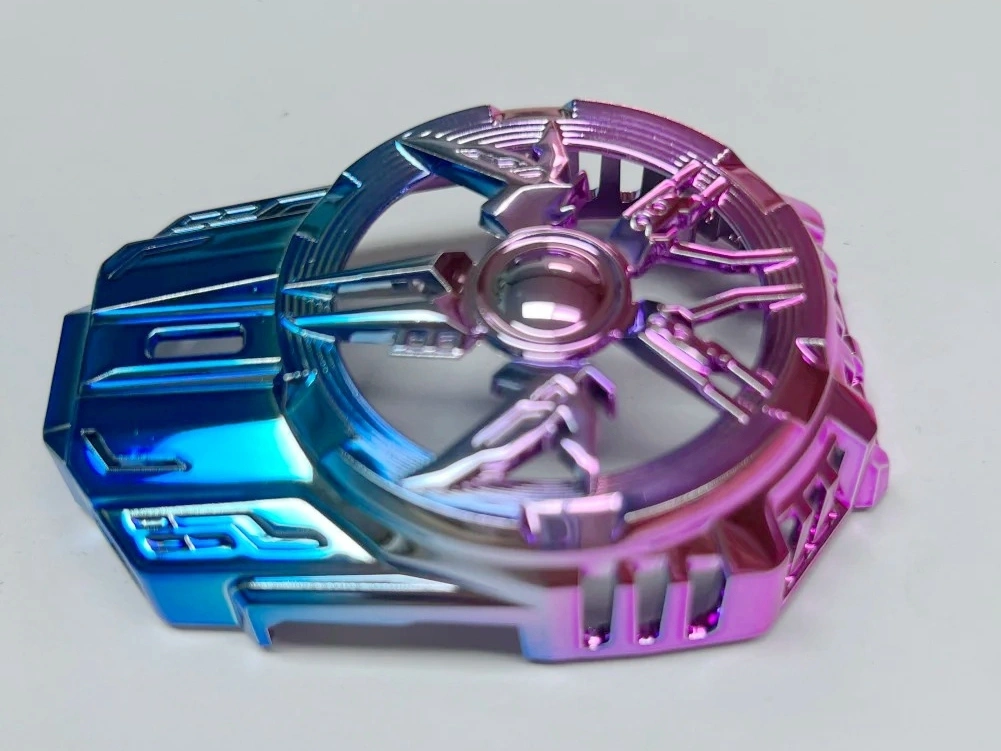

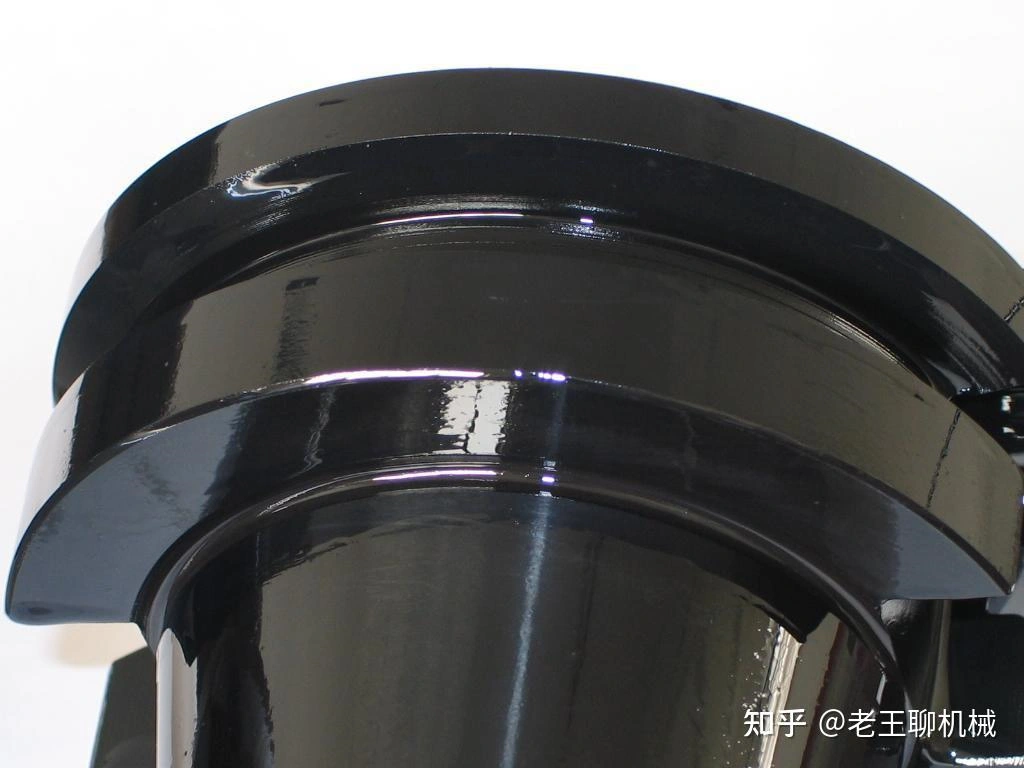

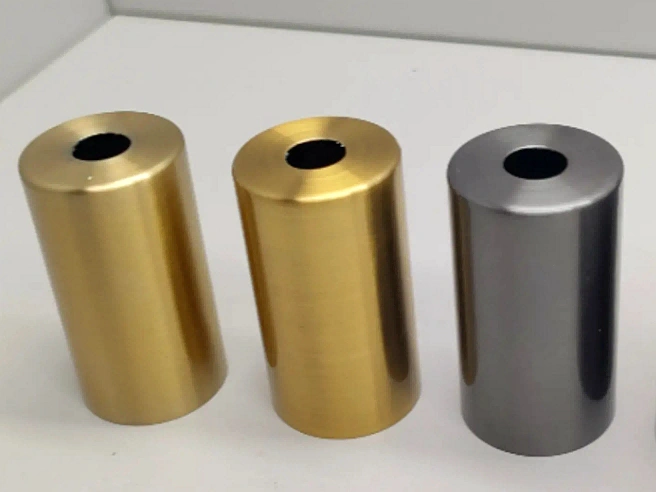

Surface Treatment for Rapid Molding Parts

Neway offers advanced surface treatment for rapid molding parts, including rapid vacuum casting, plastic injection molding, metal injection molding, and ceramic injection molding. Our services enhance durability, finish quality, and performance, ensuring precision and reliability for diverse applications.

Learn More

Thermal Coating

Learn More

As Machined

Learn More

Painting

Learn More

PVD (Physical Vapor Deposition)

Learn More

Sandblasting

Learn More

Electroplating

Learn More

Polishing

Learn More

Anodizing

Learn More

Powder Coating

Learn More

Electropolishing

Learn More

Passivation

Learn More

Brushing

Learn More

Black Oxide

Learn More

Heat Treatment

Learn More

Thermal Barrier Coating (TBC)

Learn More

Tumbling

Learn More

Alodine

Learn More

Chrome Plating

Learn More

Phosphating

Learn More

Nitriding

Learn More

Galvanizing

Learn More

UV Coating

Learn More

Lacquer Coating

Learn More

Teflon Coating

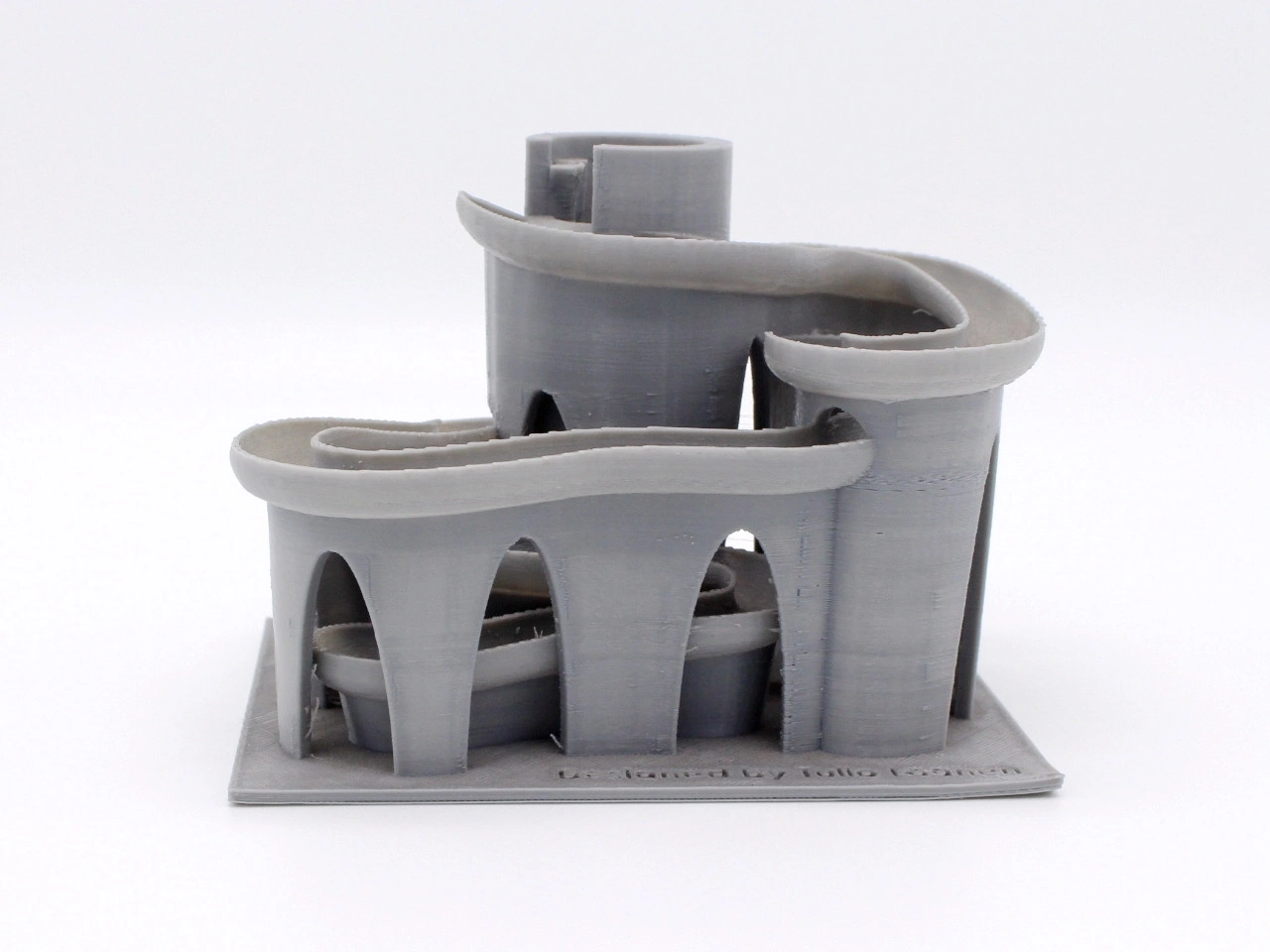

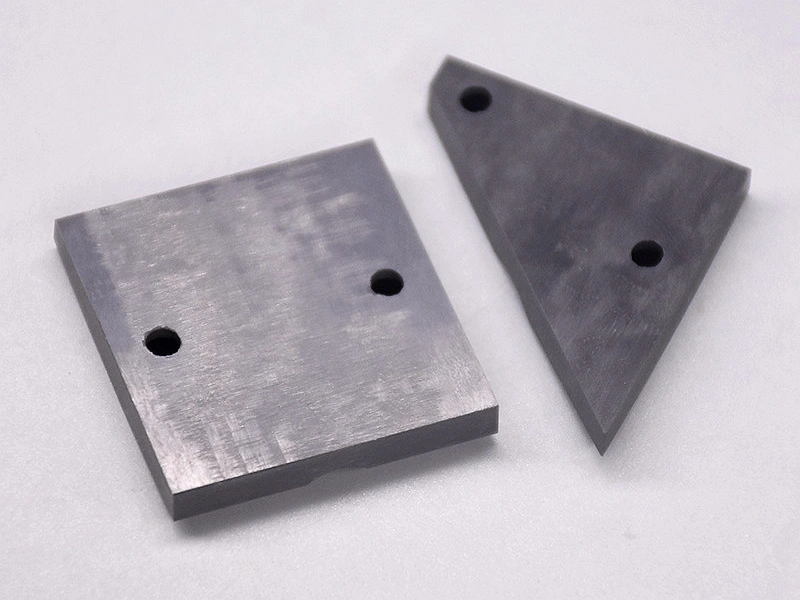

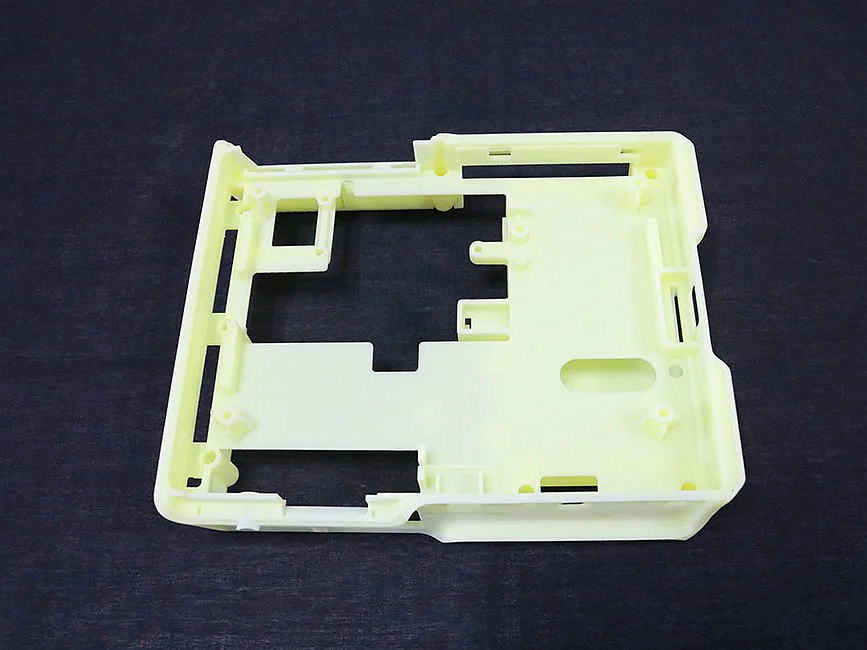

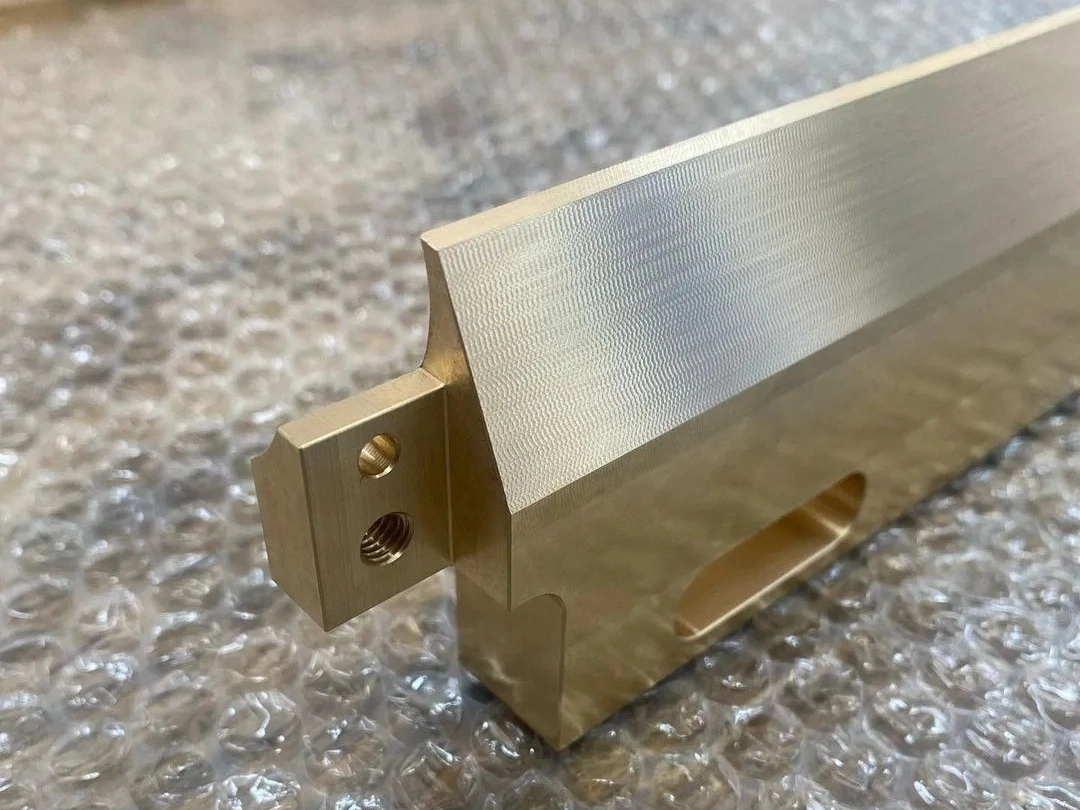

Custom Rapid Molding Parts Case Study

Our custom rapid molding parts case study showcases successful applications using rapid vacuum casting, plastic injection molding, metal injection molding, and ceramic injection molding. We deliver precise, high-quality parts tailored to client needs, optimizing production speed and cost efficiency.

Let's Start A New Project Today

Suggestions for Rapid Molding Parts

For optimal rapid molding parts, consider factors such as a 1-3° draft angle for easy ejection, minimum hole sizes of 0.8mm, tight tolerance control (±0.1mm), uniform wall thickness, proper radii, and material selection based on part performance and application needs.

Frequently Asked Questions

Explore Related Resources

Solutions

Copyright © 2025 Machining Precision Works Ltd.All Rights Reserved.