Custom Parts Online Rapid Prototyping Service

Neway offers a Custom Parts Online Rapid Prototyping Service, providing fast, precise prototypes using CNC Machining, 3D Printing, and Rapid Molding. Our service ensures quick turnaround, high accuracy, and customized solutions for your unique part requirements.

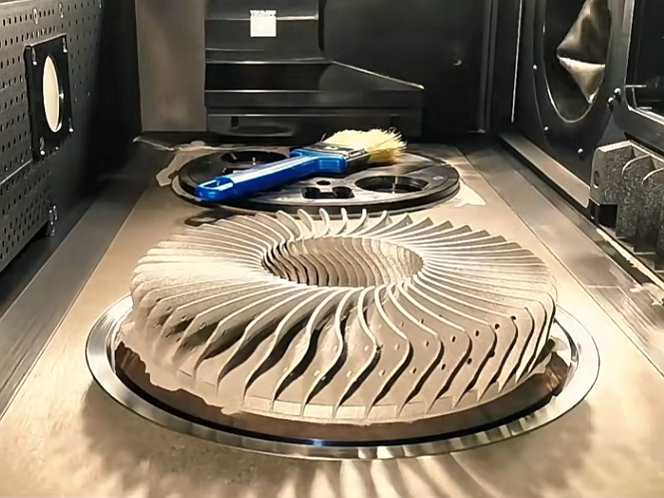

- CNC Machining Prototyping Service

- 3D Printing Prototyping Service

- Rapid Molding Prototyping Service

- Expedited Prototyping Service >>

Send us your designs and specifications for a free quotation

All uploaded files are secure and confidential

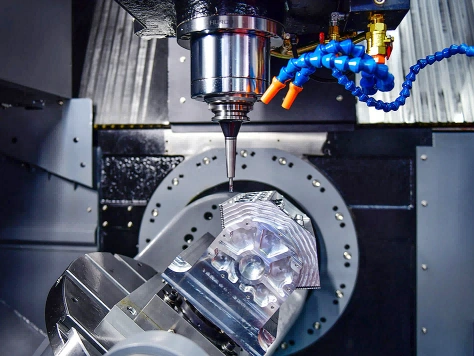

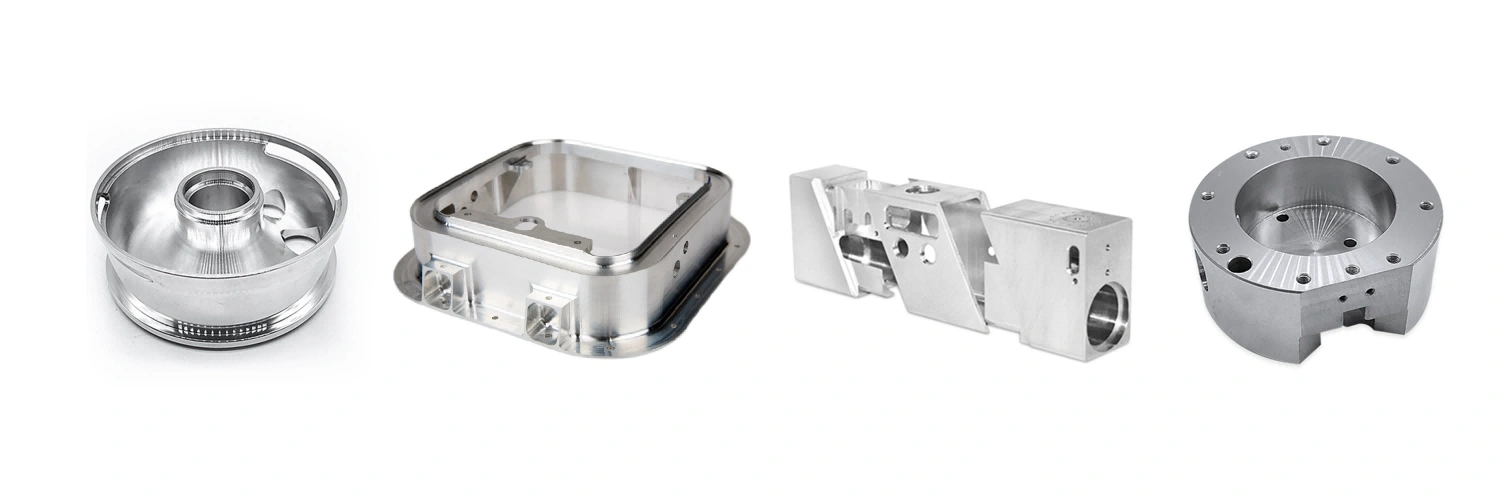

Machining Prototyping Capabilities

Neway's Machining Prototyping capabilities include CNC Machining, CNC Milling, CNC Turning, CNC Drilling, CNC Boring, CNC Grinding, Multi-Axis Machining, Precision Machining, and Electrical Discharge Machining (EDM). We deliver high-precision prototypes with exceptional accuracy and fast turnaround.

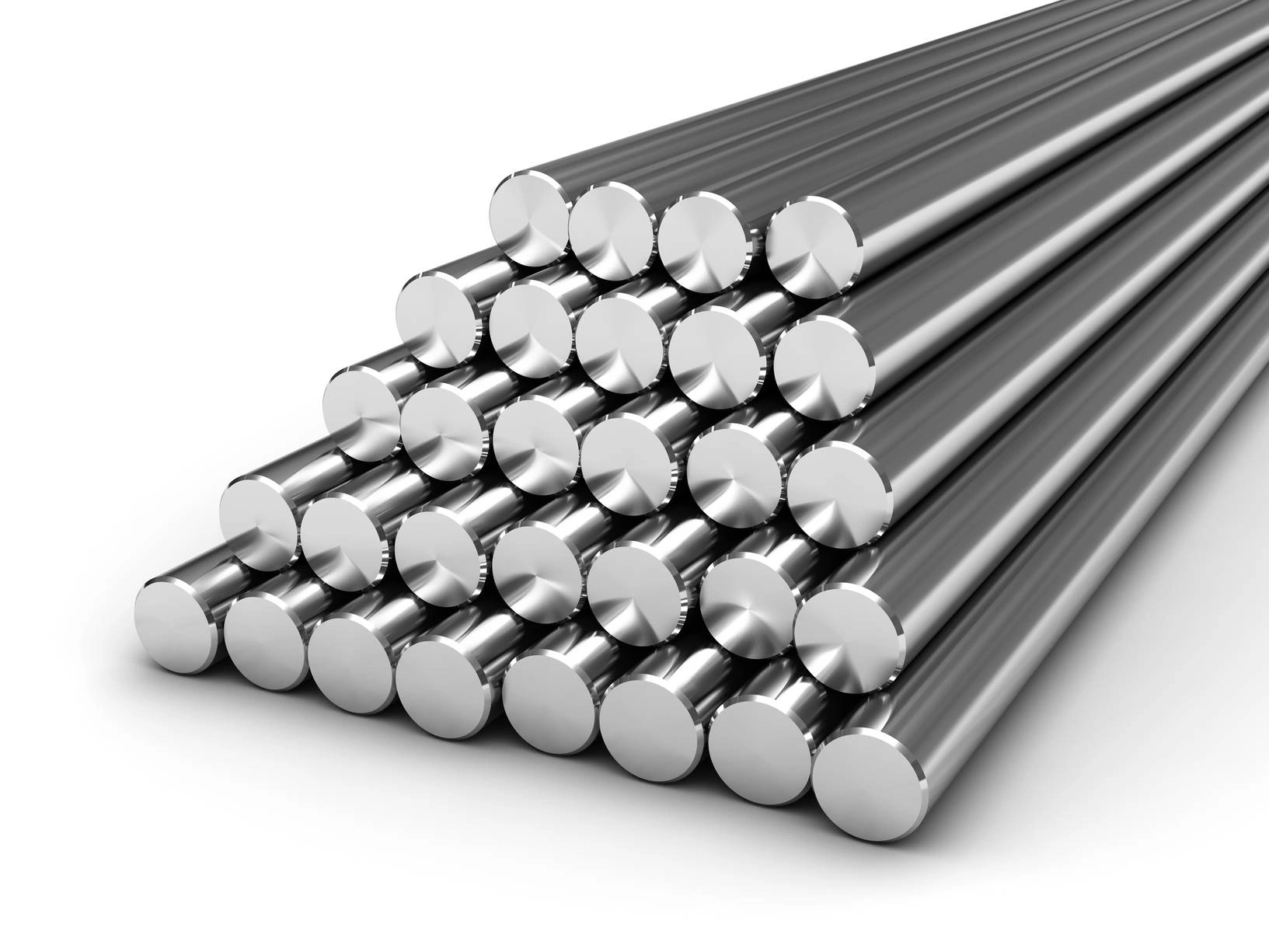

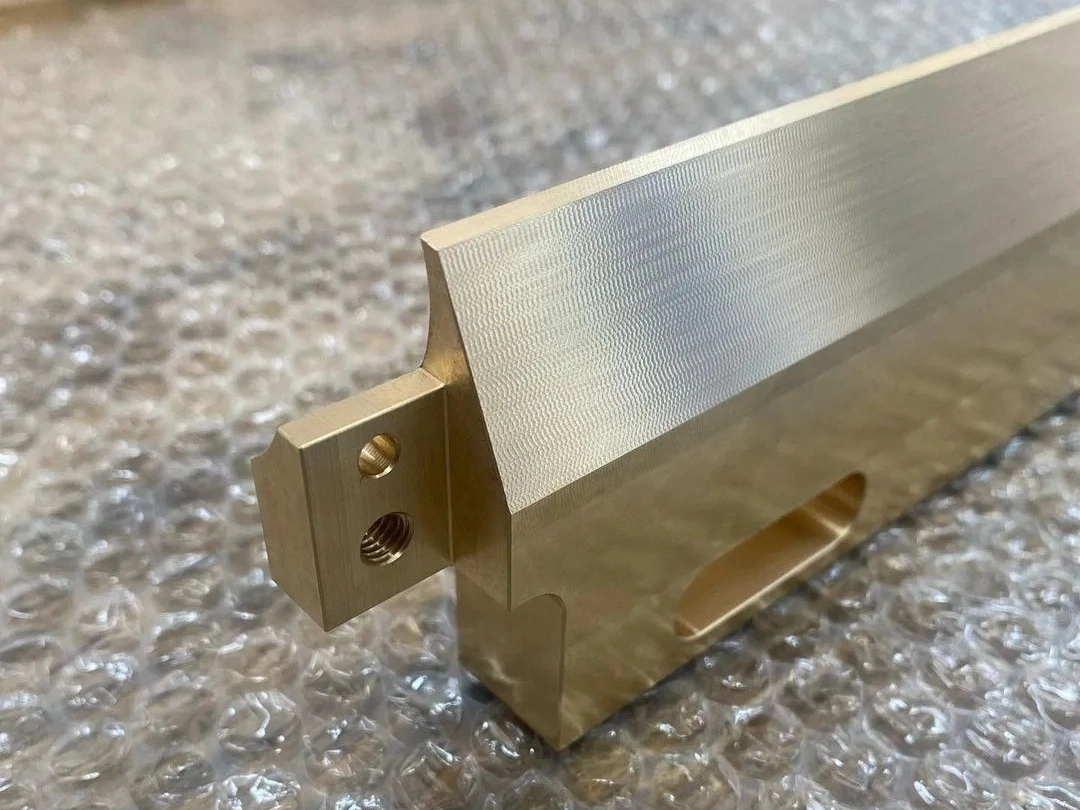

Machining Prototyping Materials Solution

Neway’s Machining Prototyping Materials Solution offers a wide range of materials, including Superalloy, Titanium, Aluminum, Copper, Brass, Bronze, Carbon Steel, Stainless Steel, Plastic, and Ceramic, ensuring high-performance prototypes with superior quality, precision, and material-specific properties.

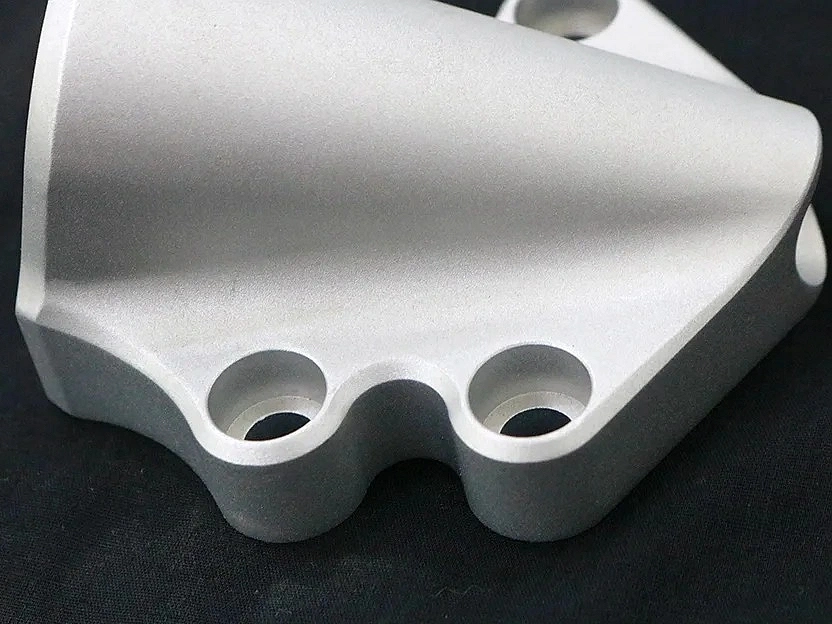

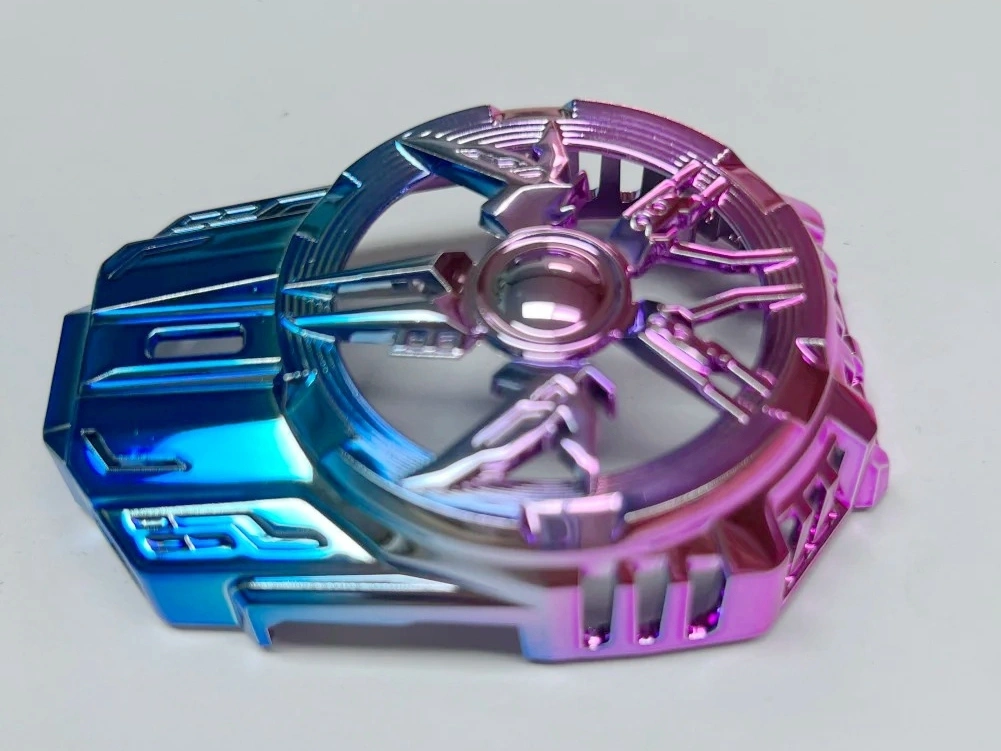

Surface Treatment for Prototyping Parts

Neway’s Surface Treatment for Prototyping Parts includes processes like anodizing, coating, polishing, plating, and heat treatment. These treatments enhance material properties, improve durability, corrosion resistance, and surface finish, ensuring high-quality, functional prototypes suited for demanding applications.

Learn More

Thermal Coating

Learn More

As Machined

Learn More

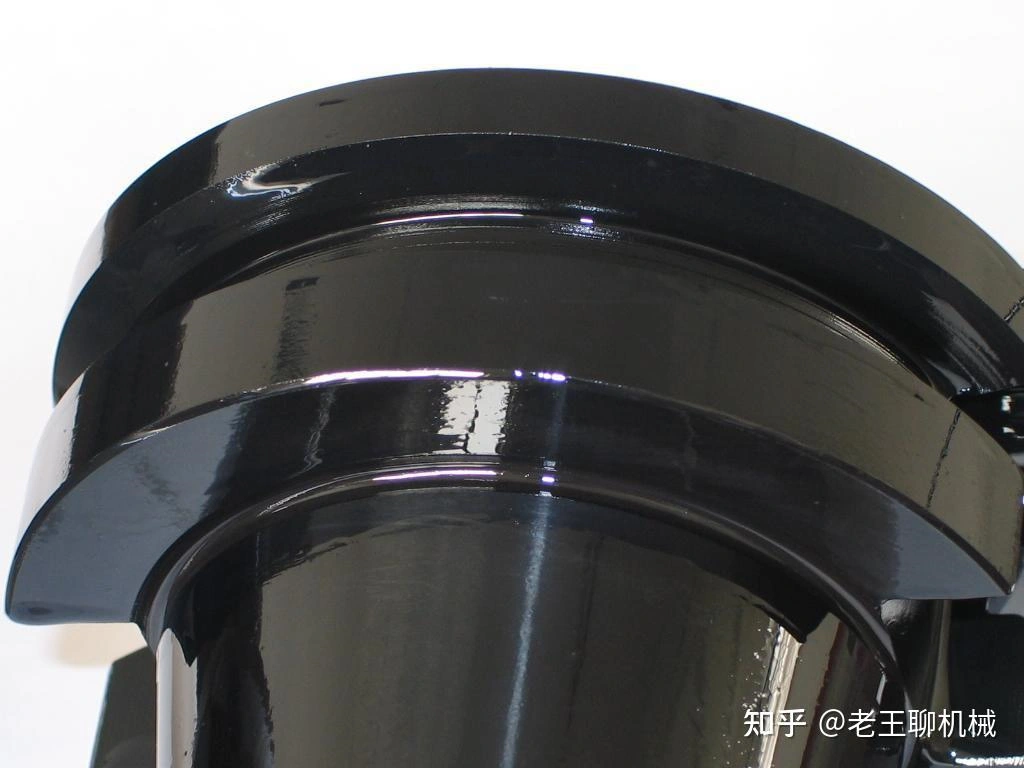

Painting

Learn More

PVD (Physical Vapor Deposition)

Learn More

Sandblasting

Learn More

Electroplating

Learn More

Polishing

Learn More

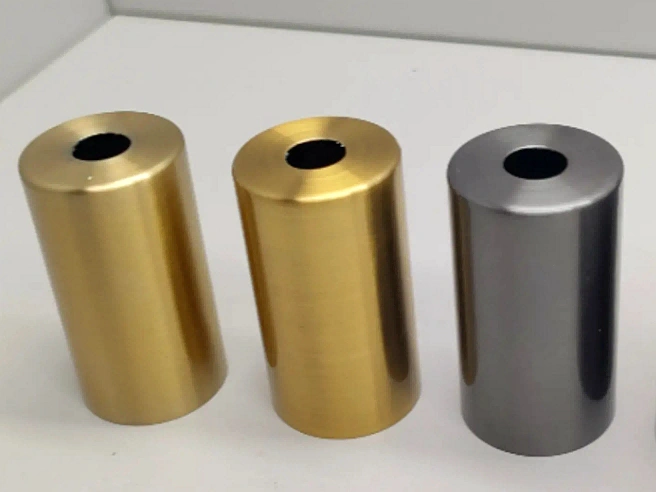

Anodizing

Learn More

Powder Coating

Learn More

Electropolishing

Learn More

Passivation

Learn More

Brushing

Learn More

Black Oxide

Learn More

Heat Treatment

Learn More

Thermal Barrier Coating (TBC)

Learn More

Tumbling

Learn More

Alodine

Learn More

Chrome Plating

Learn More

Phosphating

Learn More

Nitriding

Learn More

Galvanizing

Learn More

UV Coating

Learn More

Lacquer Coating

Learn More

Teflon Coating

Machining Prototyping Case Study

Neway's Machining Prototyping Case Study demonstrates successful use of Superalloy, Titanium, Aluminum, Copper, Brass, Bronze, Carbon Steel, Stainless Steel, Plastic, and Ceramic materials. We delivered precise, high-performance prototypes across diverse industries, meeting client specifications with exceptional quality and efficiency.

Let's Start A New Project Today

Suggestions for CNC Prototyping

CNC prototype design guidelines emphasize material selection, uniform wall thickness, achievable tolerances, and accessible features. Key principles include avoiding sharp corners, minimizing material removal, and ensuring proper hole design and symmetry to optimize machining efficiency, cost, and part quality.

Frequently Asked Questions

Explore Related Resources

Solutions

Copyright © 2026 Machining Precision Works Ltd.All Rights Reserved.