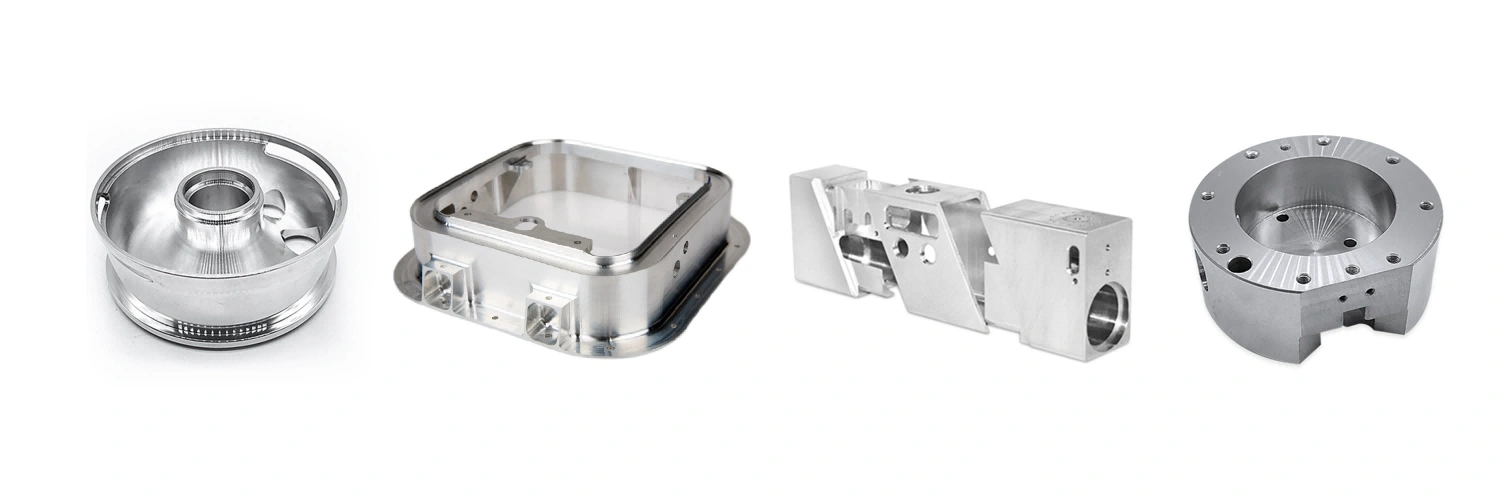

Custom Parts CNC Machining Mass Production Service

Custom CNC machining for mass production offers high precision, repeatability, and scalability. It reduces lead times, minimizes material waste, and ensures consistent quality. Ideal for complex geometries, it supports cost-effective manufacturing while maintaining tight tolerances for large volumes.

- CNC Machining Mass Production Service

- Rapid Molding Mass Production Service

- Mass Production Cost Optimization >>

Send us your designs and specifications for a free quotation

All uploaded files are secure and confidential

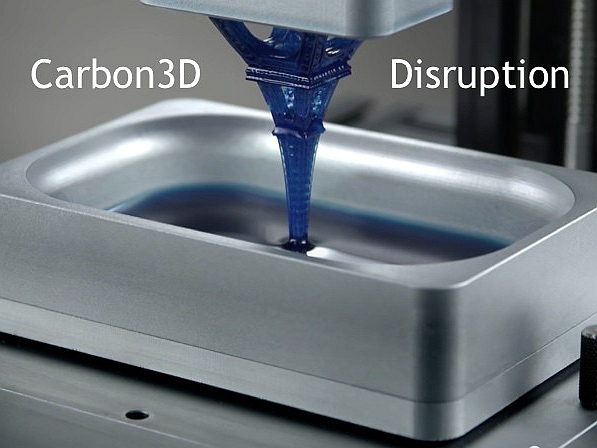

CNC Machining Mass Production Capabilities

CNC machining mass production offers versatile capabilities like CNC milling, turning, drilling, boring, grinding, and EDM. Multi-axis machining ensures complex shapes with high precision. These processes deliver consistent quality, tight tolerances, and fast production, reducing lead times and costs.

Material Selection In Mass Machining

Proper material selection in mass machining ensures optimal tool performance, reduces wear, and minimizes machining costs. It enhances part quality, improves cycle times, and reduces scrap rates. Choosing materials with suitable hardness and machinability boosts productivity and overall process efficiency.

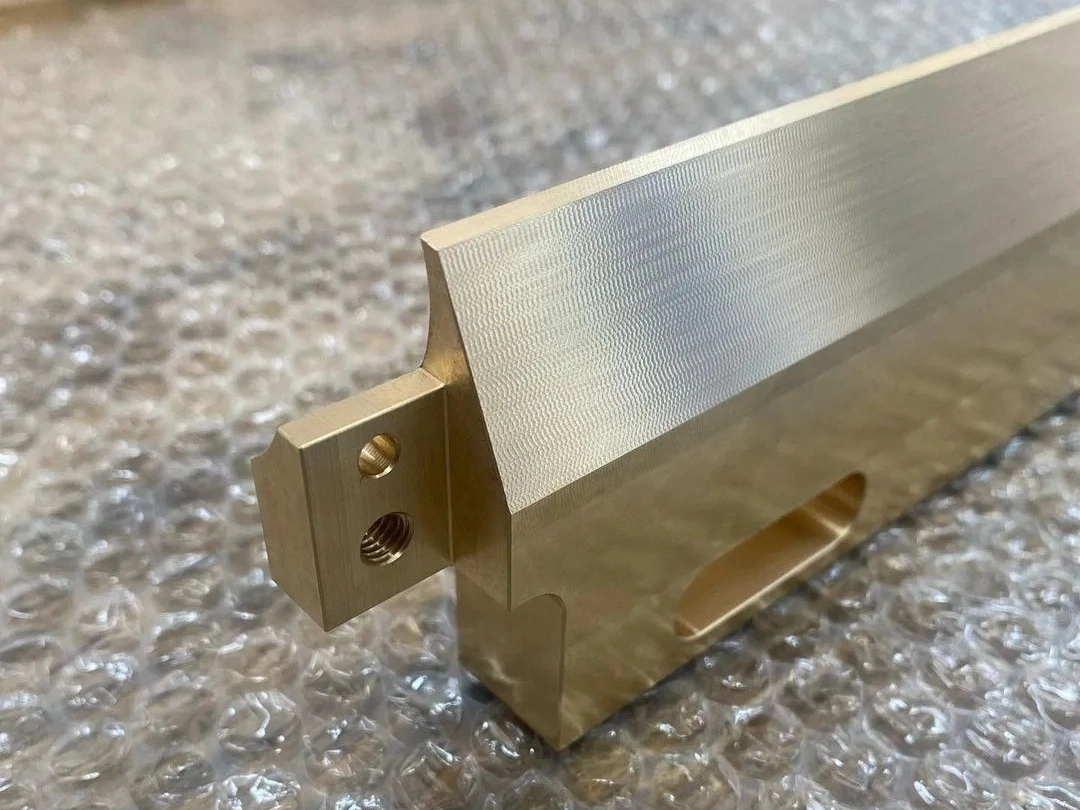

Surface Treatment for CNC Machined Parts

Surface treatment for CNC machined parts enhances performance, durability, and aesthetics. Common processes include polishing, which smooths surfaces for a shiny finish; anodizing, which increases corrosion resistance, especially for aluminum; and powder coating, providing a durable, decorative layer. Electropolishing improves smoothness and corrosion resistance, while passivation creates a protective oxide layer on stainless steel. PVD and electroplating offer decorative and functional coatings, such as gold or chrome. Other treatments like sandblasting, brushing, and black oxide improve surface texture, while heat treatment strengthens the material. These treatments optimize parts for specific industrial applications.

Learn More

Thermal Coating

Learn More

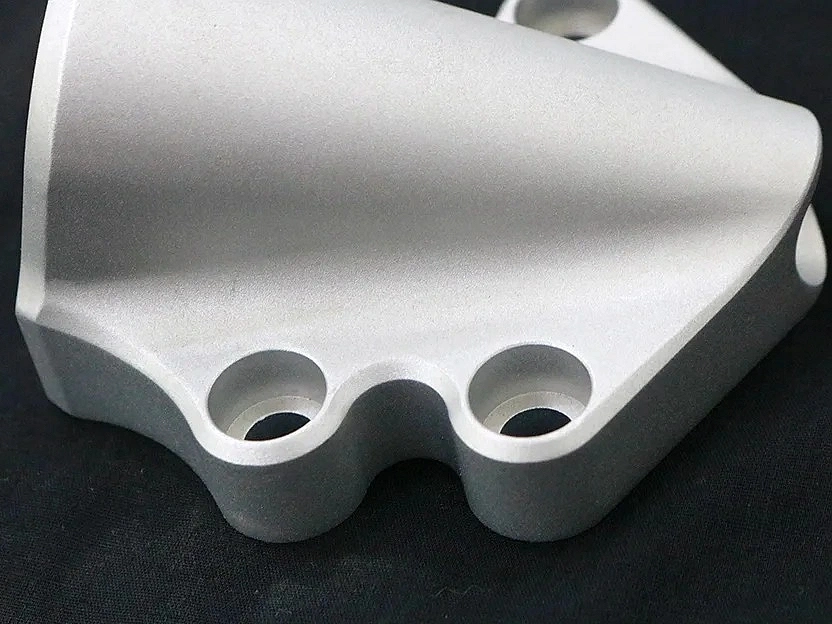

As Machined

Learn More

Painting

Learn More

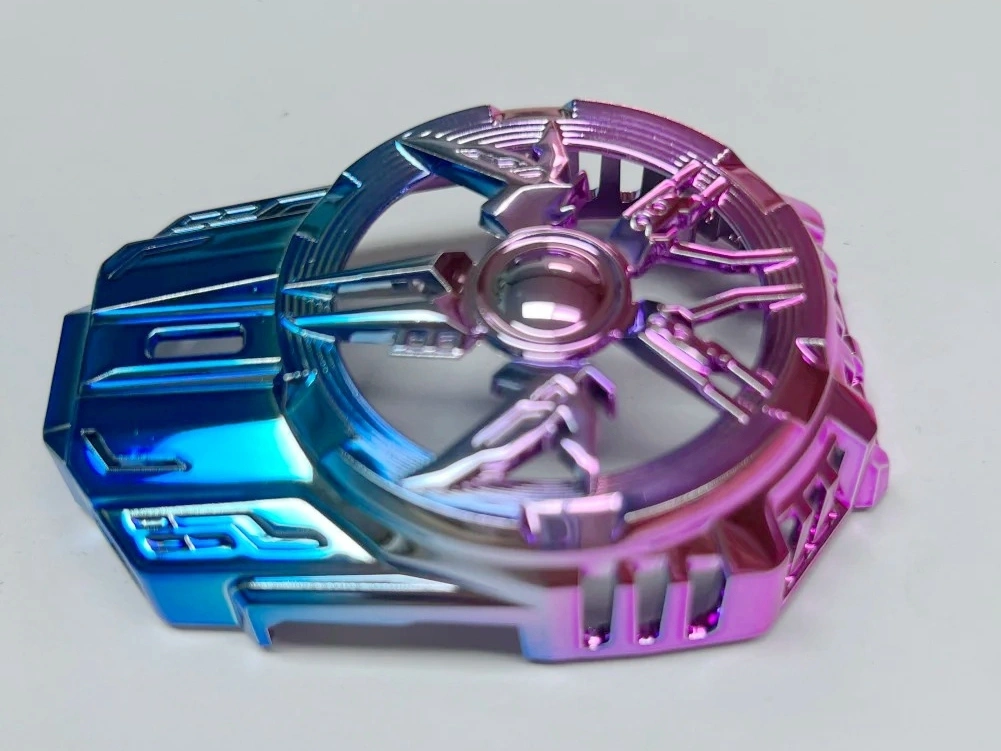

PVD (Physical Vapor Deposition)

Learn More

Sandblasting

Learn More

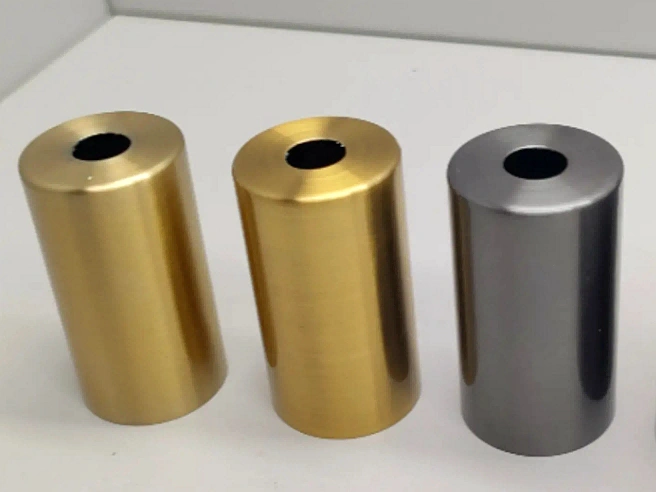

Electroplating

Learn More

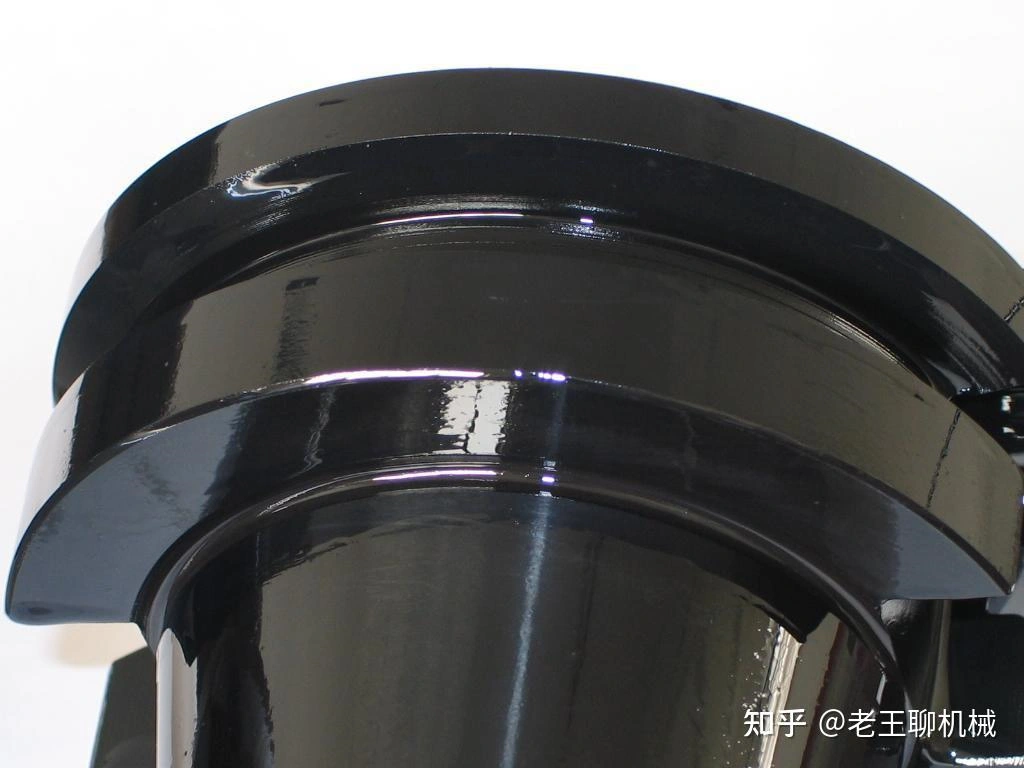

Polishing

Learn More

Anodizing

Learn More

Powder Coating

Learn More

Electropolishing

Learn More

Passivation

Learn More

Brushing

Learn More

Black Oxide

Learn More

Heat Treatment

Learn More

Thermal Barrier Coating (TBC)

Learn More

Tumbling

Learn More

Alodine

Learn More

Chrome Plating

Learn More

Phosphating

Learn More

Nitriding

Learn More

Galvanizing

Learn More

UV Coating

Learn More

Lacquer Coating

Learn More

Teflon Coating

CNC Machining Mass Production Case Study

In a recent CNC machining mass production case study, we optimized production efficiency for a client in aerospace. By leveraging multi-axis machining and precision turning, we reduced lead times by 30%, ensured consistent quality, and improved part accuracy for high-volume manufacturing.

Let's Start A New Project Today

Suggestions for Mass Machining

For efficient mass machining, consider using multi-axis CNC machines for complex geometries, optimizing tool paths to reduce cycle time, and implementing automated quality control systems. Additionally, selecting the right material and precise machining techniques ensures consistency and minimizes production costs.

Frequently Asked Questions

Explore Related Resources

Solutions

Copyright © 2026 Machining Precision Works Ltd.All Rights Reserved.