Surface Finishing Overview

Surface Finishings For Custom CNC Machined Parts

We offer a wide range of surface finishing options for custom CNC machined parts to enhance performance, aesthetics, and durability. Our services include anodizing, plating, polishing, coating, and sandblasting. These finishes provide improved corrosion resistance, smoother surfaces, better wear properties, and enhanced appearance, tailored to your specific requirements.

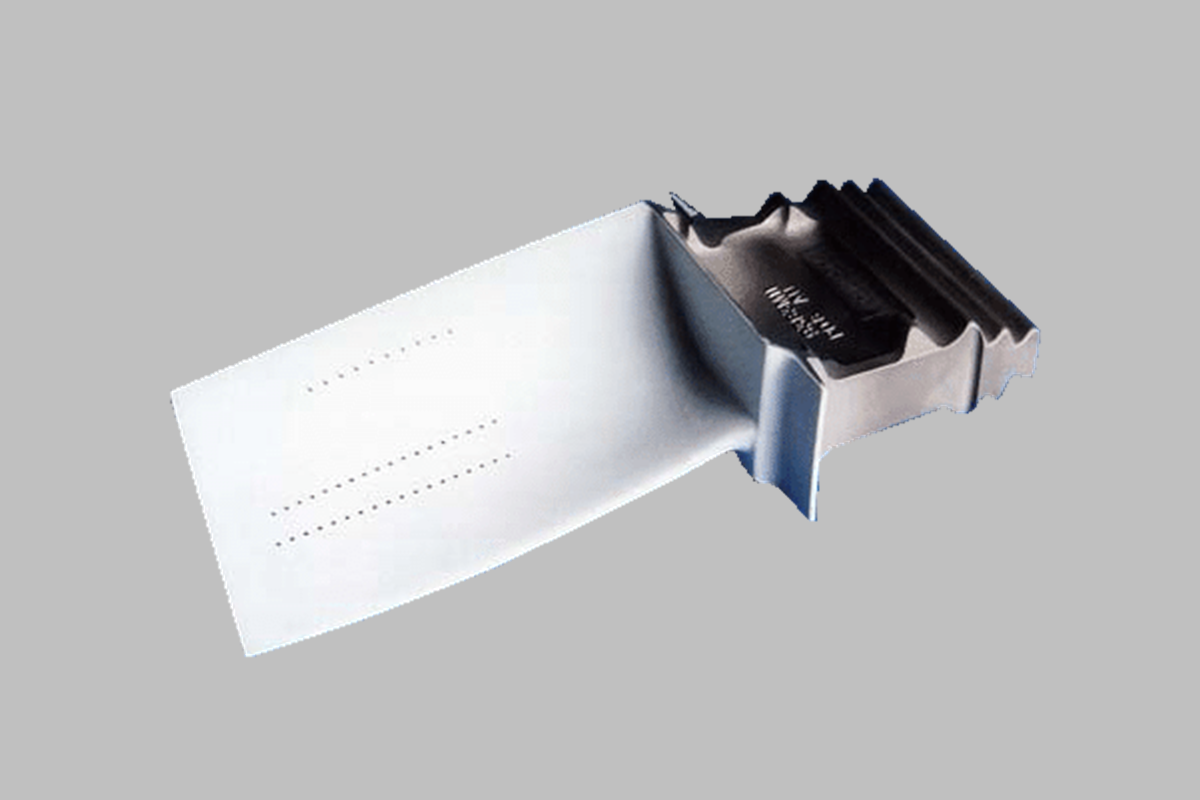

Aluminum Anodizing

Aluminum anodizing is an electrochemical process that enhances the surface of aluminum parts, providing improved corrosion resistance, wear resistance, and aesthetic finish. This process increases hardness, durability, and offers a range of colors, ideal for both functional and decorative applications.

Let's Start A New Project Today