Custom Online Copper CNC Machining Service

Our Custom Online Copper CNC Machining Service offers precision machining for copper parts, ensuring high accuracy and quality. We handle complex designs with advanced CNC technology, providing fast turnaround times and custom solutions tailored to your project needs.

- Copper CNC Rapid Prototyping Service

- Low Volume Copper CNC Machining Service

- Copper CNC Machining Mass Production

- One Stop Copper Machining Service

Send us your designs and specifications for a free quotation

All uploaded files are secure and confidential

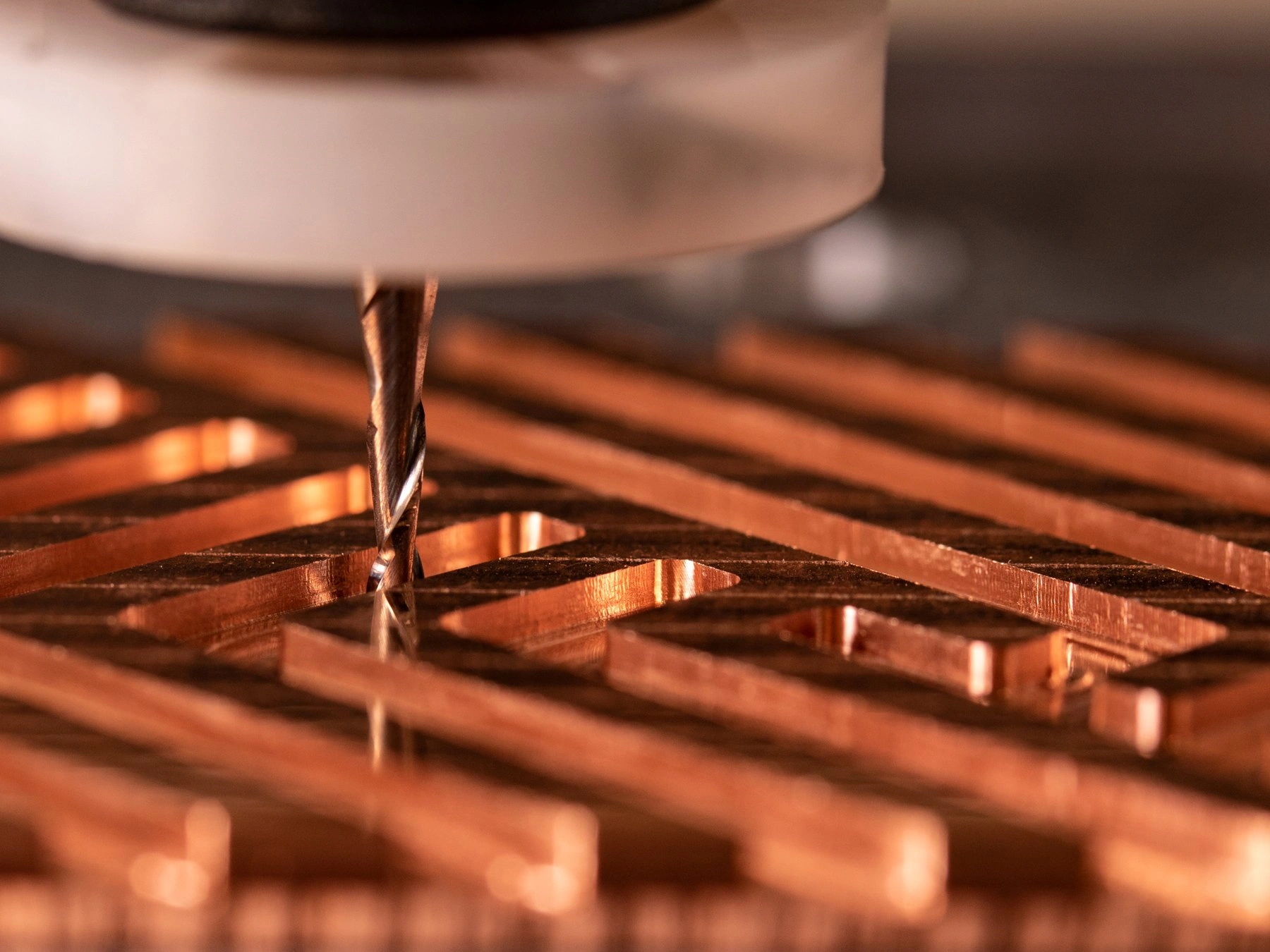

Know About Copper CNC Machining

Copper CNC machining involves precision cutting and shaping of copper materials using advanced CNC technology. It offers excellent conductivity and machinability, ideal for electrical and thermal applications. Proper machining parameters and tool selection are essential for achieving high-quality, precise copper parts.

Typical CNC Machining Copper Alloys

Typical CNC machining copper alloys include Copper C101, C110, Beryllium Copper, and Brass. These alloys are chosen for their excellent electrical conductivity, corrosion resistance, and machinability. Common applications include electrical connectors, heat exchangers, industrial machinery, and aerospace components.

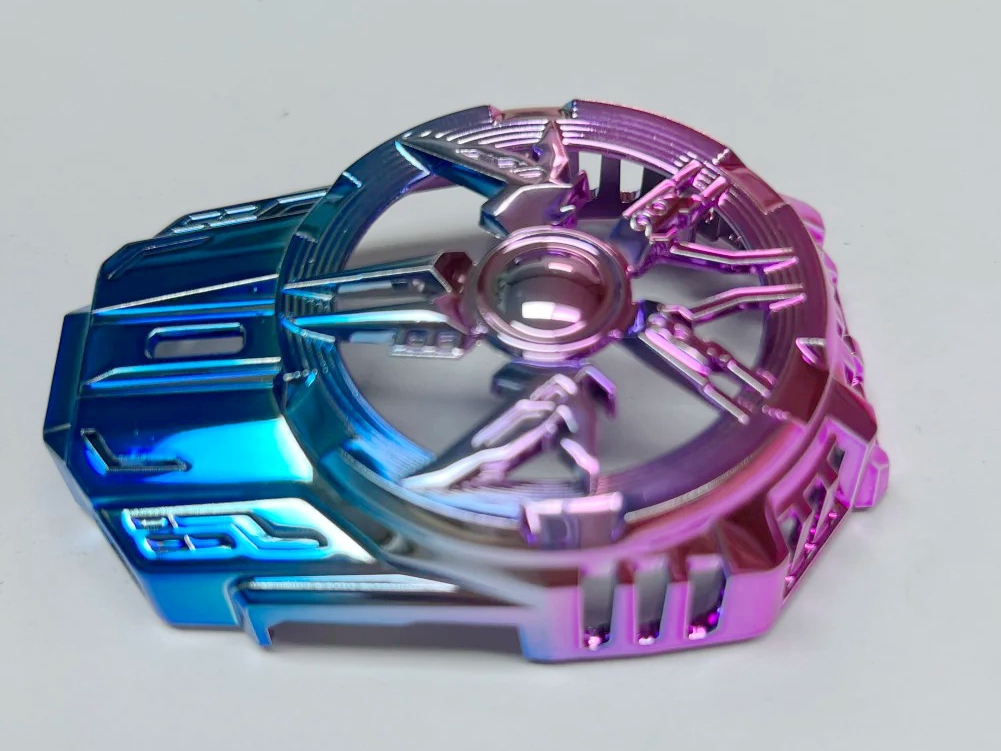

Surface Treatment For CNC Machined Copper Parts

Surface treatment for CNC machined copper parts includes processes like electroplating, anodizing, passivation, and polishing. These treatments enhance corrosion resistance, improve durability, and provide a smooth finish. They are commonly used in electronics, aerospace, and automotive applications to ensure optimal performance.

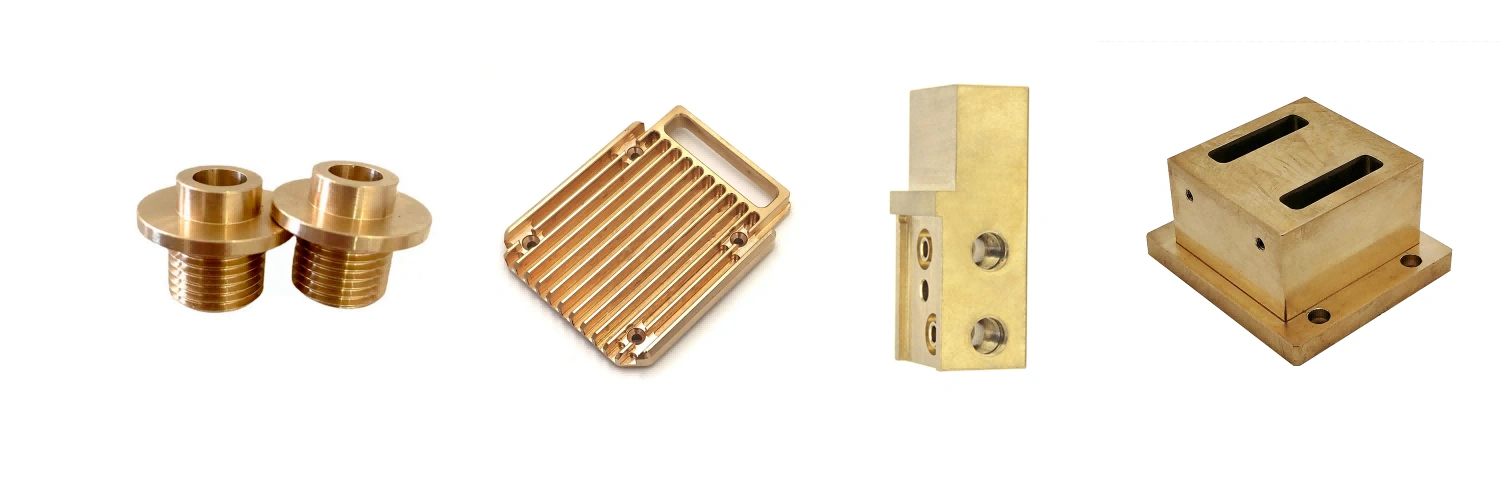

CNC Machined Copper Parts Gallery

Explore our CNC machined copper parts gallery, showcasing high-precision components made from top-grade copper alloys. From electrical connectors to aerospace parts, our gallery highlights the versatility and quality of our custom copper machining solutions for diverse industries.

Let's Start A New Project Today

Copper Alloy CNC Machining Parameter Suggestion

Copper alloy CNC machining requires optimized parameters for efficiency and quality. Key factors include spindle speed, cutting depth, feed rate, coolant type, and tool material. Proper adjustments ensure smooth machining, minimize tool wear, and achieve precise, high-quality copper components.

Tolerance Suggestions for Copper CNC Machining

Tolerance suggestions for copper CNC machining ensure precision and functionality in parts. General tolerances like ±0.1 mm are standard, while tighter precision tolerances, wall thickness, and part size considerations ensure quality. These guidelines optimize machining, reducing tool wear and enhancing product consistency.

Frequently Asked Questions

Explore Related Resources

Solutions

Copyright © 2025 Machining Precision Works Ltd.All Rights Reserved.