Custom Parts Manufacturing Solutions

Automotive Components Manufacturing Service

Neway provides Automotive Components Manufacturing, offering CNC Machining, 3D Printing, Vacuum Casting, Die Casting, and Injection Molding. We deliver high-quality, precision-engineered parts to meet the rigorous standards of the automotive industry.

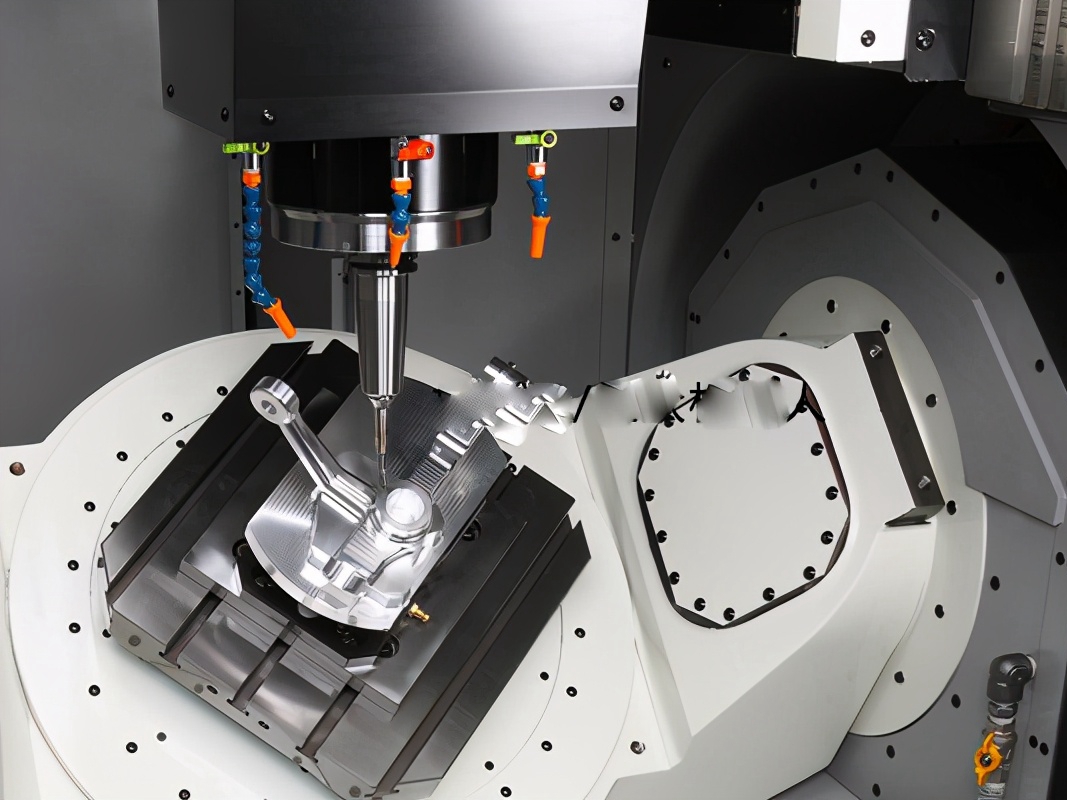

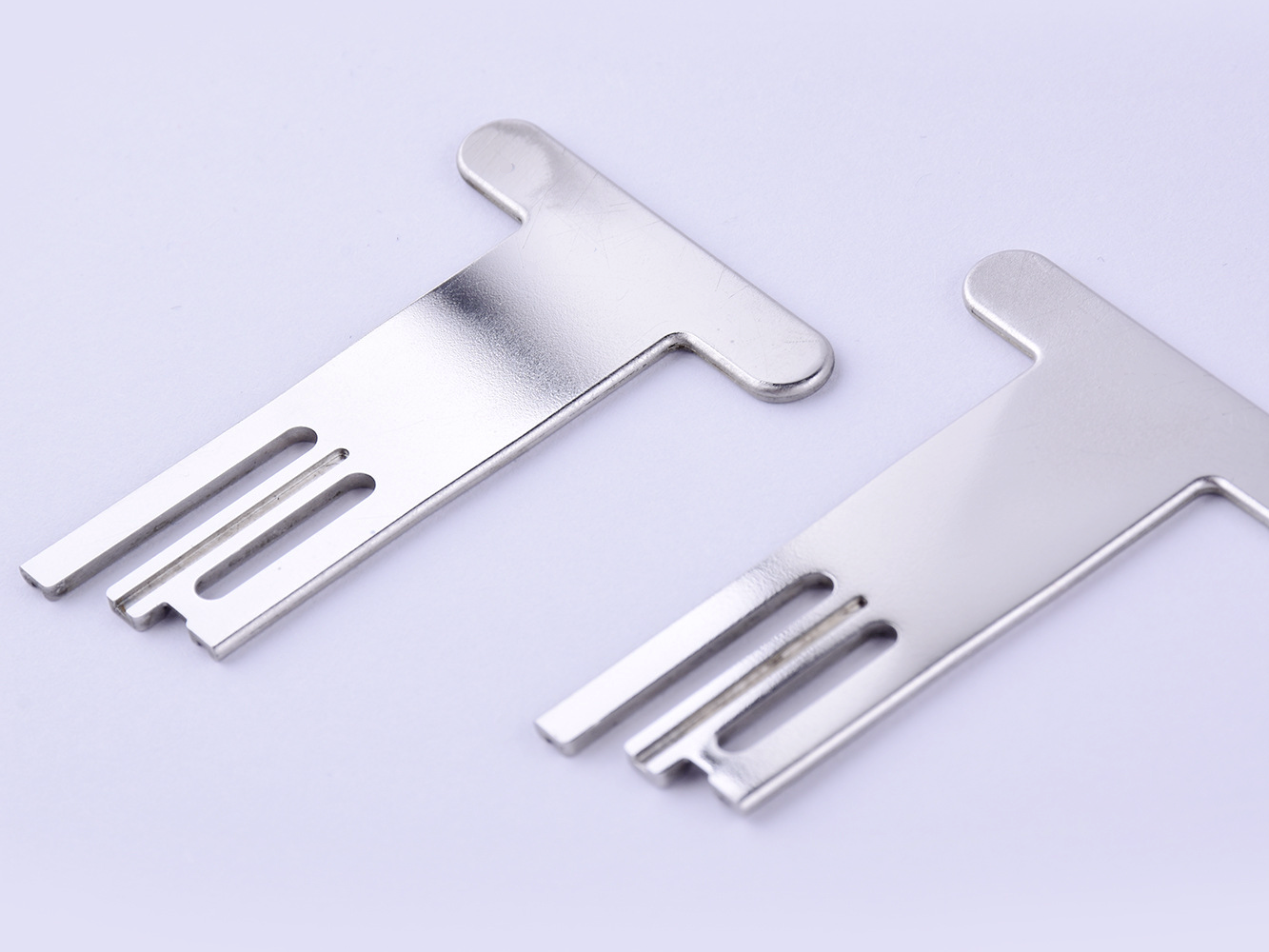

Custom Automotive Parts Machining

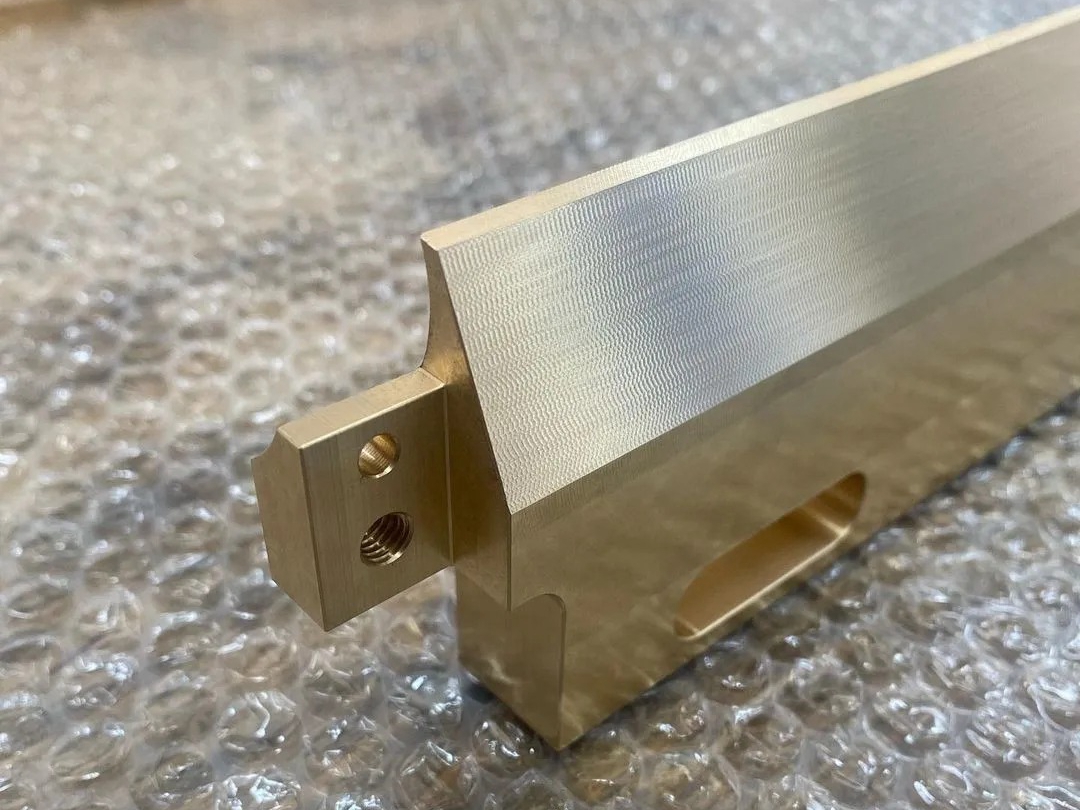

Custom automotive parts machining involves precision CNC processes like milling, turning, drilling, and grinding to create high-quality components for the automotive industry. With techniques such as multi-axis machining and EDM, parts are produced to meet exact specifications, ensuring optimal performance, durability, and fit. This service covers a wide range of automotive applications, from prototypes to production runs.

Automotive Material Selection

Materials such as superalloy, titanium, aluminum, copper, brass, bronze, carbon steel, stainless steel, plastic, and ceramic are chosen for automotive parts for their strength, lightweight properties, durability, corrosion resistance, and heat resistance, ensuring high performance and safety in automotive applications.

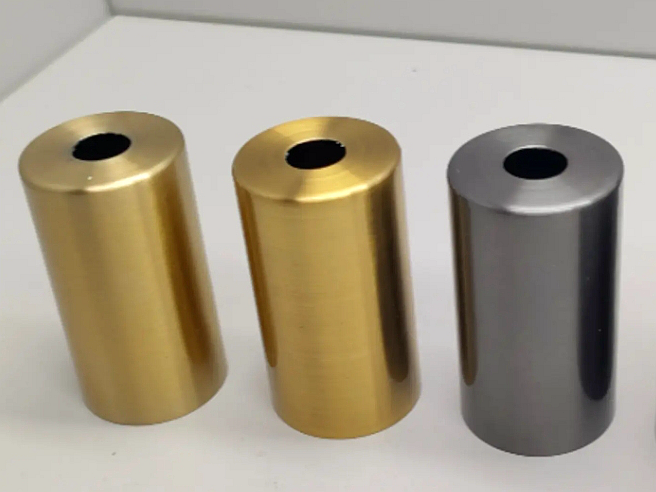

Typical Surface Treatment for Automotive Parts

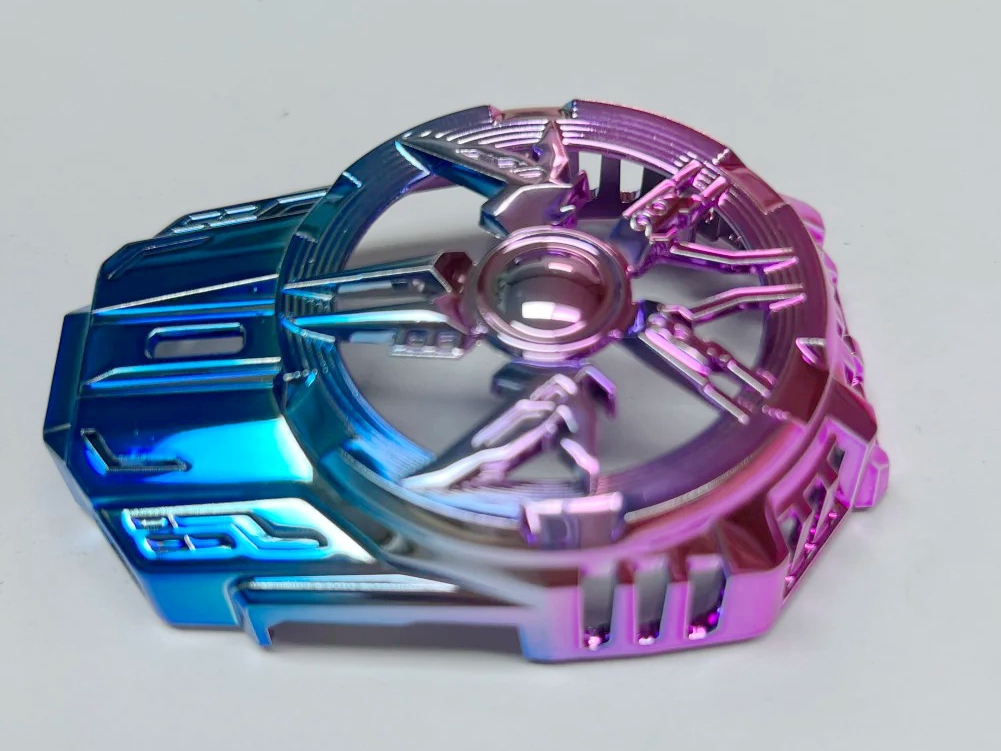

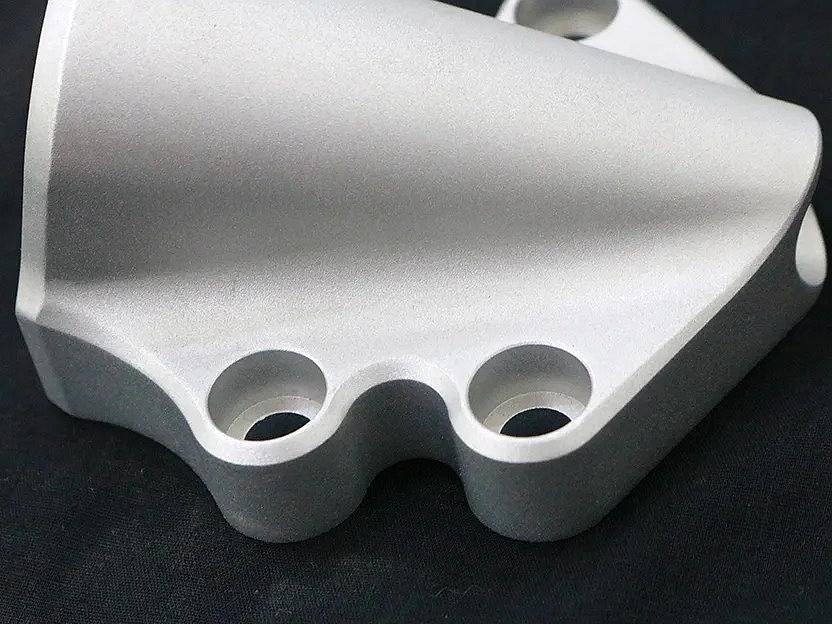

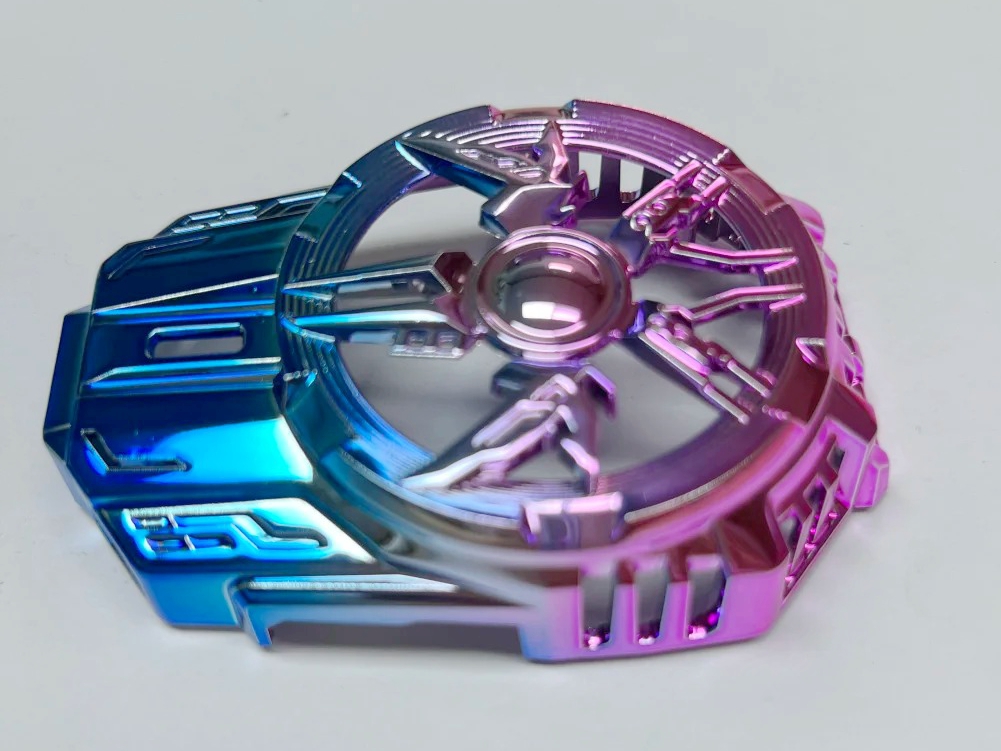

Typical surface treatments for automotive parts include methods like anodizing, electroplating, powder coating, and PVD to enhance durability, corrosion resistance, and aesthetic appeal. Other treatments like heat treatment, black oxide, and sandblasting improve strength and performance, while finishes such as polishing, tumbling, and lacquering provide a smooth, visually appealing surface. These treatments ensure parts meet demanding automotive standards.

learn more

Thermal Coating

learn more

As Machined

learn more

Painting

learn more

PVD (Physical Vapor Deposition)

learn more

Sandblasting

learn more

Electroplating

learn more

Polishing

learn more

Anodizing

learn more

Powder Coating

learn more

Electropolishing

learn more

Passivation

learn more

Brushing

learn more

Black Oxide

learn more

Heat Treatment

learn more

Thermal Barrier Coating (TBC)

learn more

Tumbling

learn more

Alodine

learn more

Chrome Plating

learn more

Phosphating

learn more

Nitriding

learn more

Galvanizing

learn more

UV Coating

learn more

Lacquer Coating

learn more

Teflon Coating

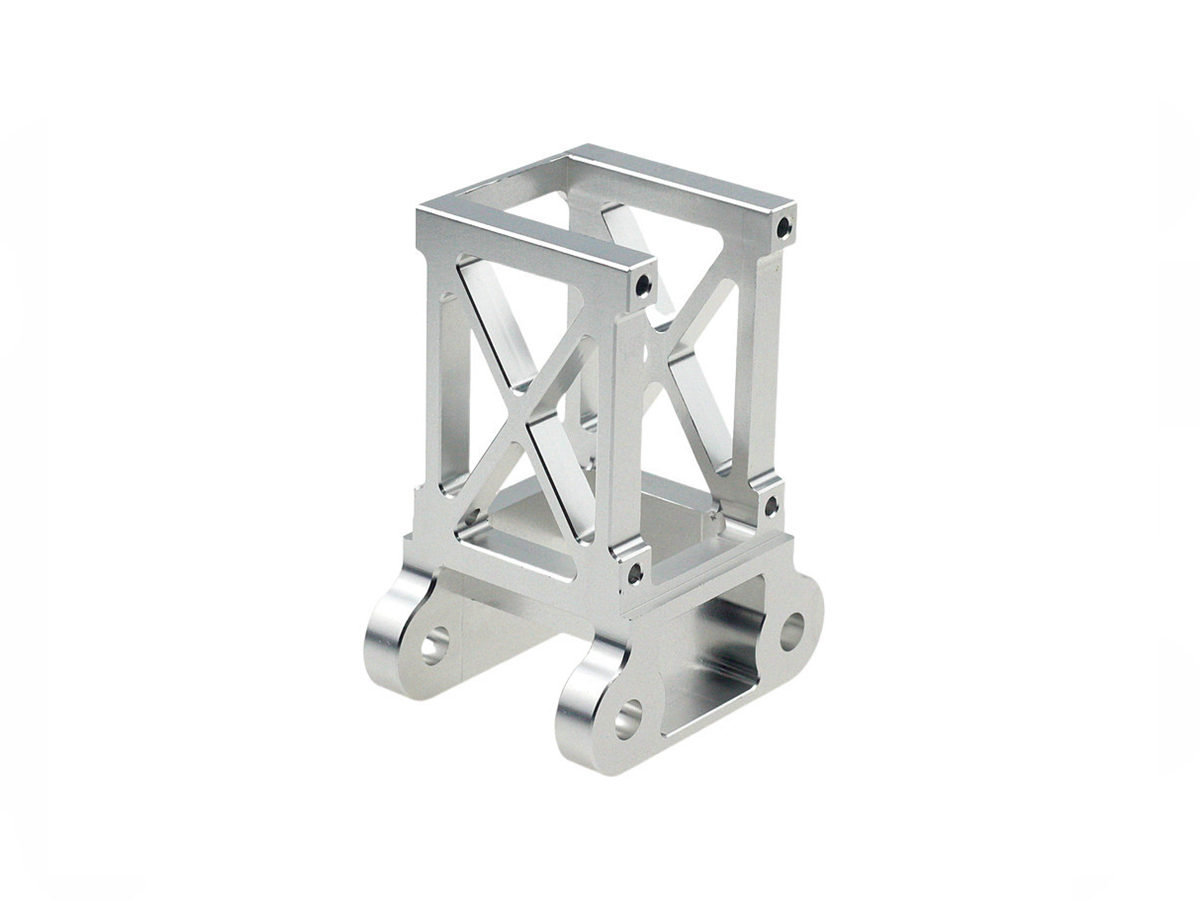

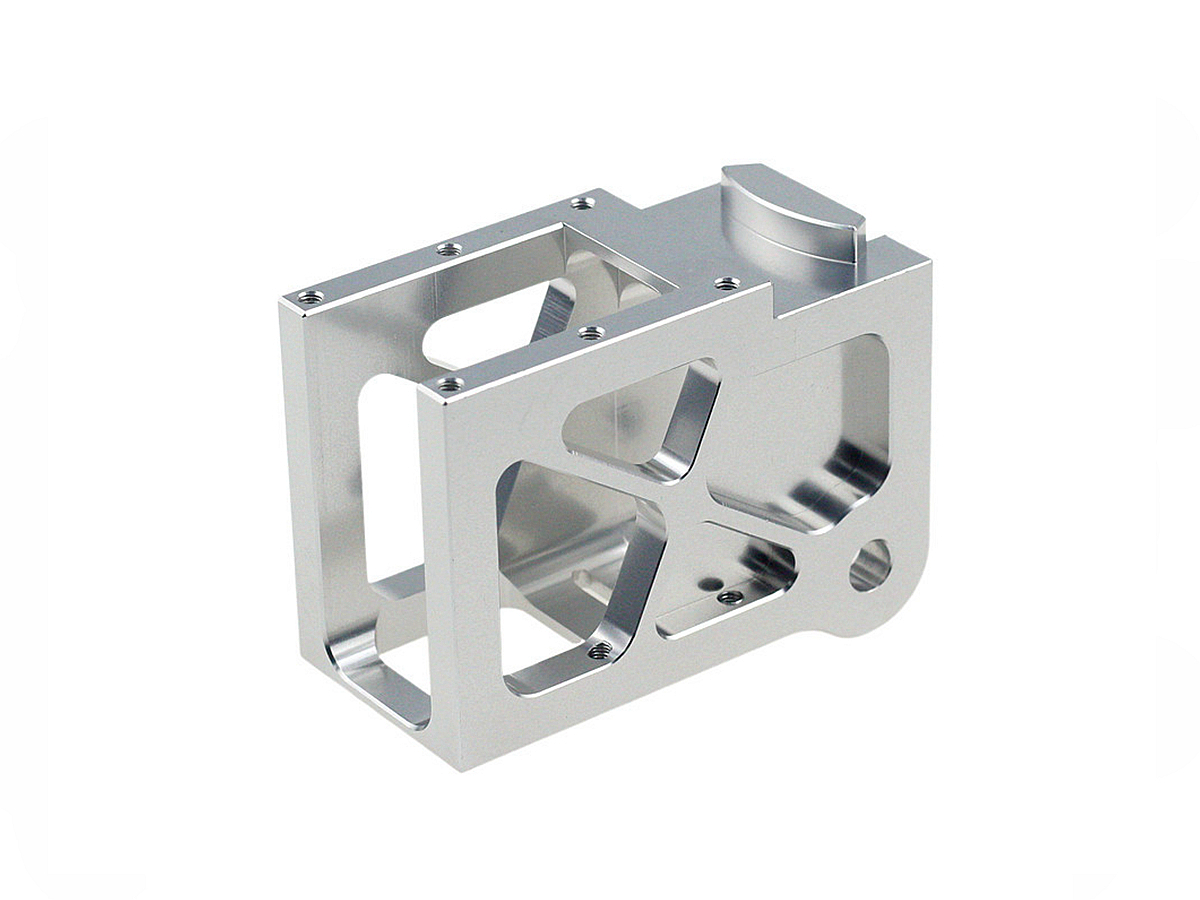

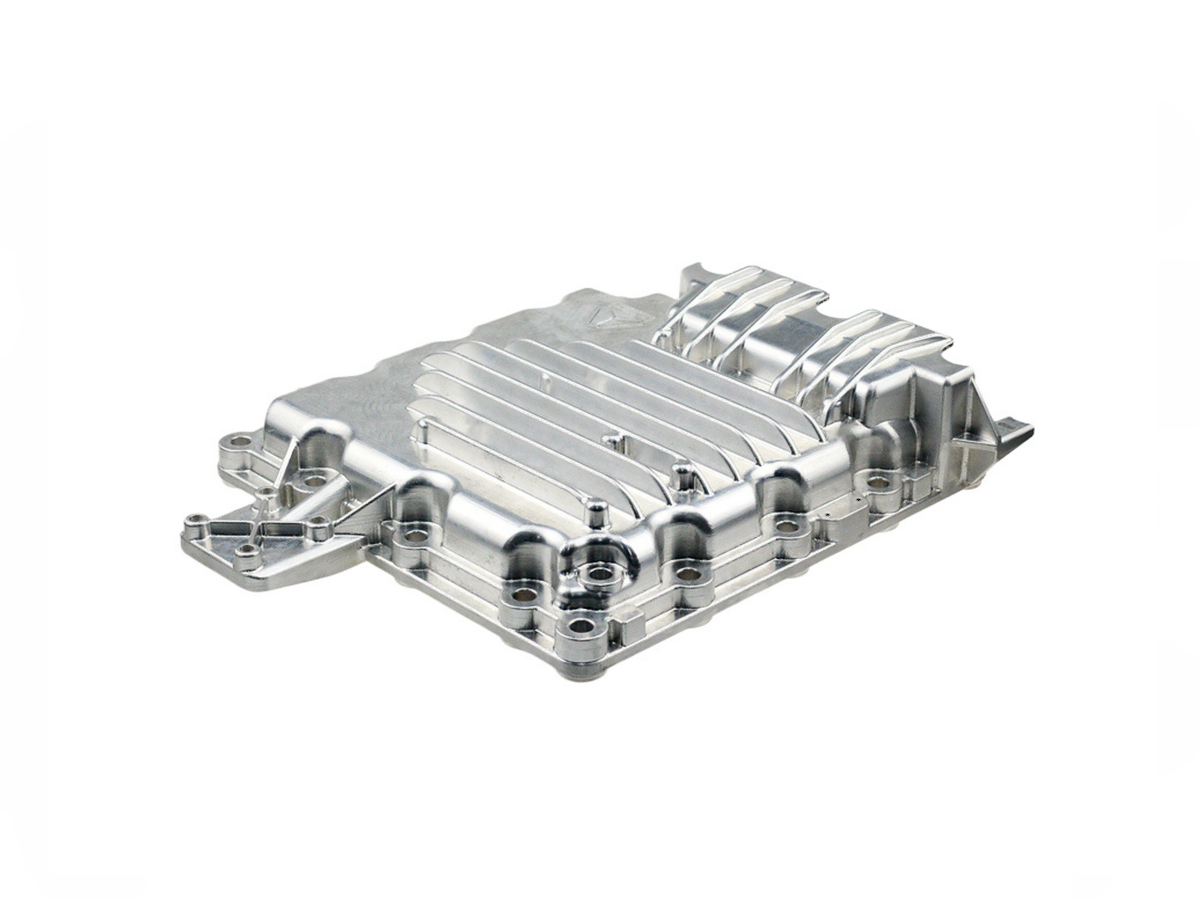

Automotive CNC Machining Components

CNC machining provides precision parts for the automotive industry, from engine components to suspension systems, ensuring high performance, reliability, and safety in every vehicle.

Let's Start A New Project Today

Automotive Components Manufacturing Methods Suggestions

Selecting the right manufacturing methods for automotive components is crucial for ensuring safety, performance, and durability. Precision methods like CNC machining, injection molding, and die casting enable the production of high-strength, lightweight, and reliable parts, contributing to fuel efficiency, safety, and overall vehicle performance.