Online Rapid CNC Machining Prototyping Service

Online Rapid CNC Machining Prototyping services offer fast, precise production of custom parts using 3,4,5 axis CNC machining. These services provide quick turnaround times, high accuracy, and cost-effective solutions for prototypes and low-volume production across various materials and industries.

- CNC Rapid Prototyping Service

- Low Volume CNC Machining Service

- CNC Machining Mass Production

- One Stop Machining Service

Send us your designs and specifications for a free quotation

All uploaded files are secure and confidential

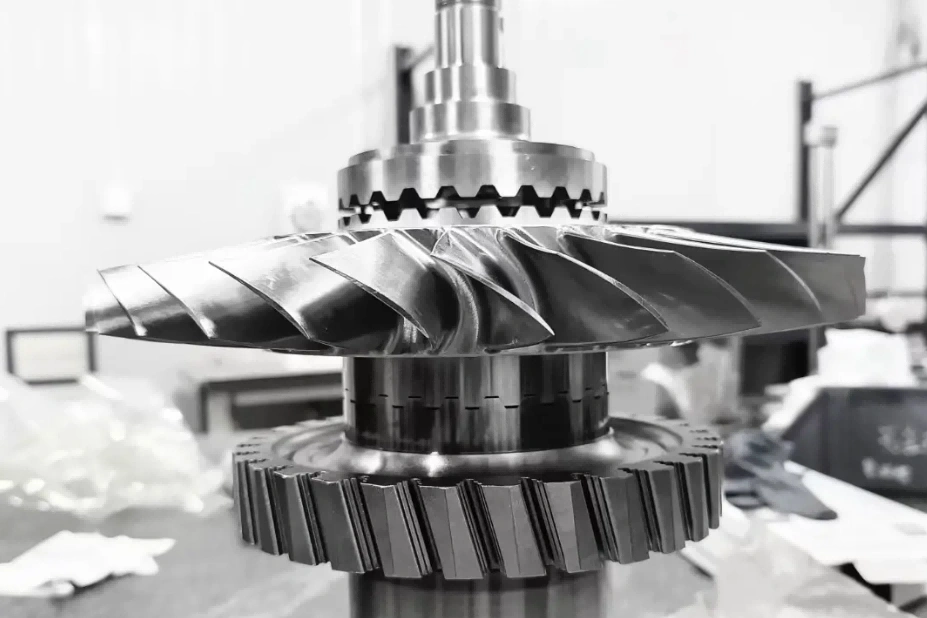

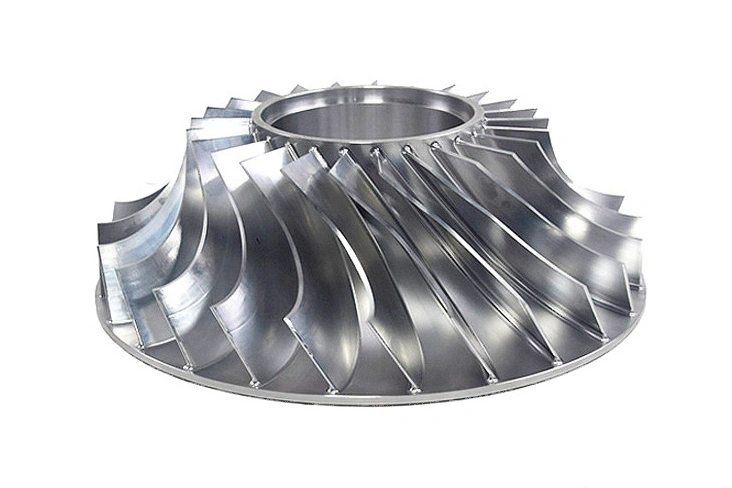

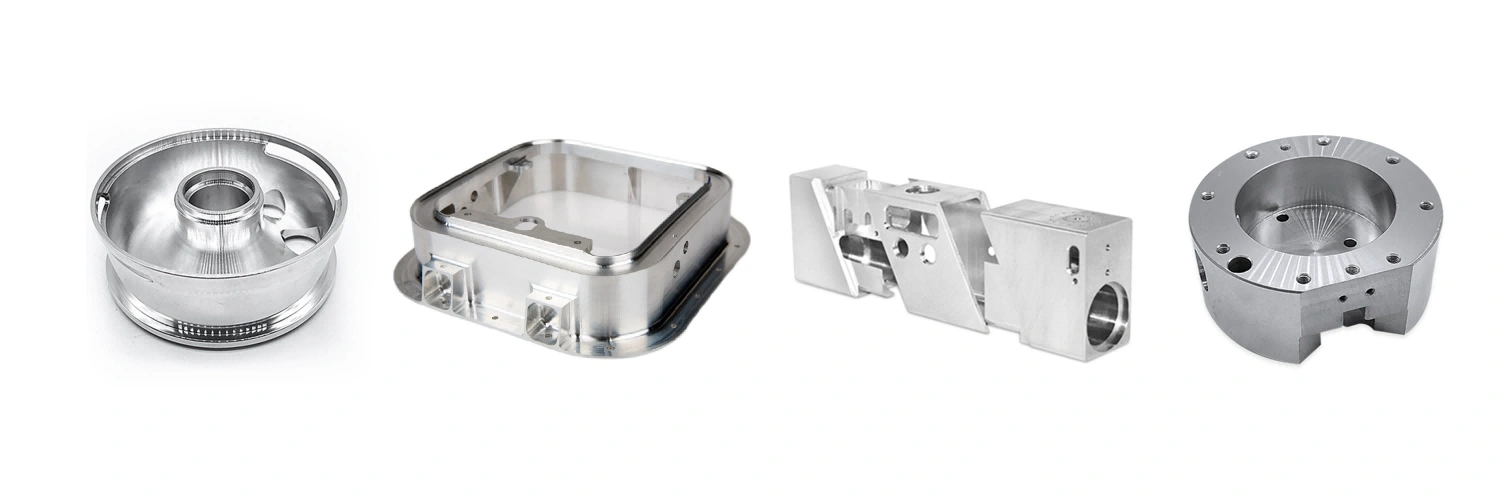

Custom Parts CNC Machining Service

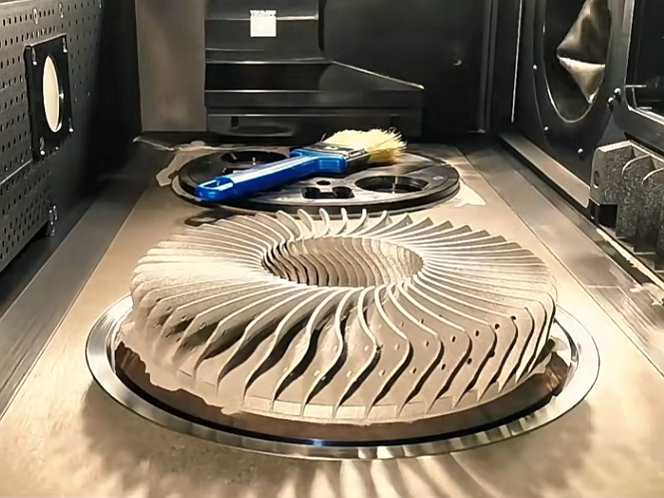

Our CNC prototyping methods include precision milling, turning, and drilling, utilizing advanced machinery for high-quality, custom parts. These methods ensure rapid turnaround, tight tolerances, and versatility across materials, supporting prototypes, functional testing, and low-volume production across industries.

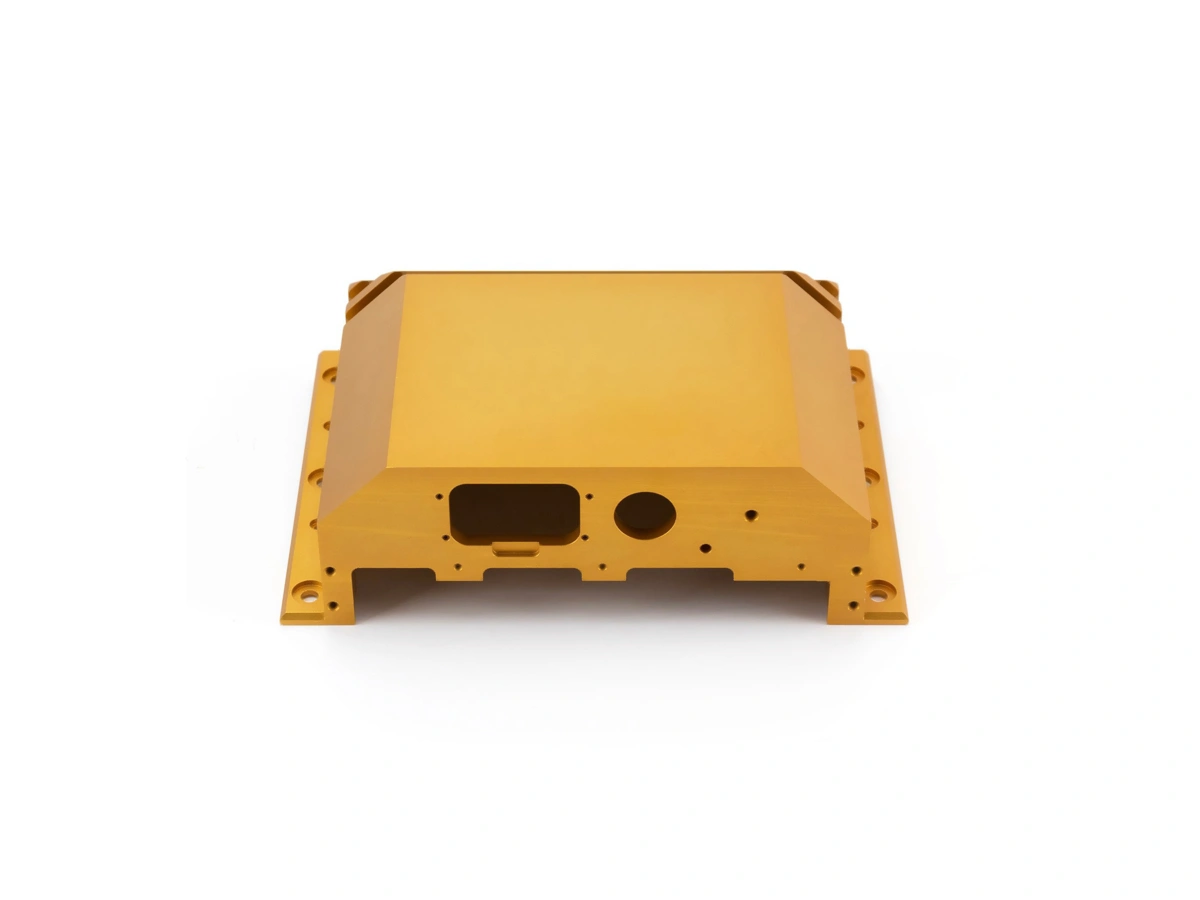

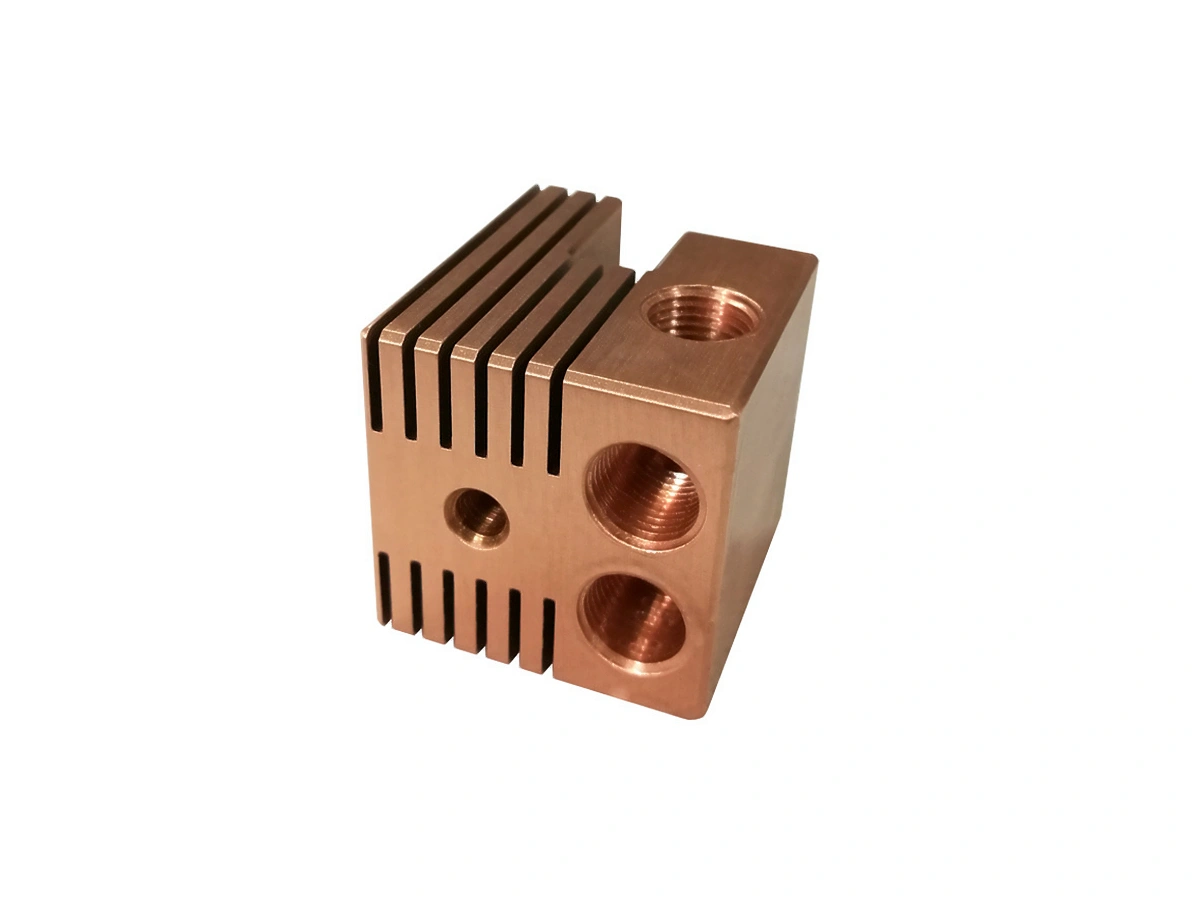

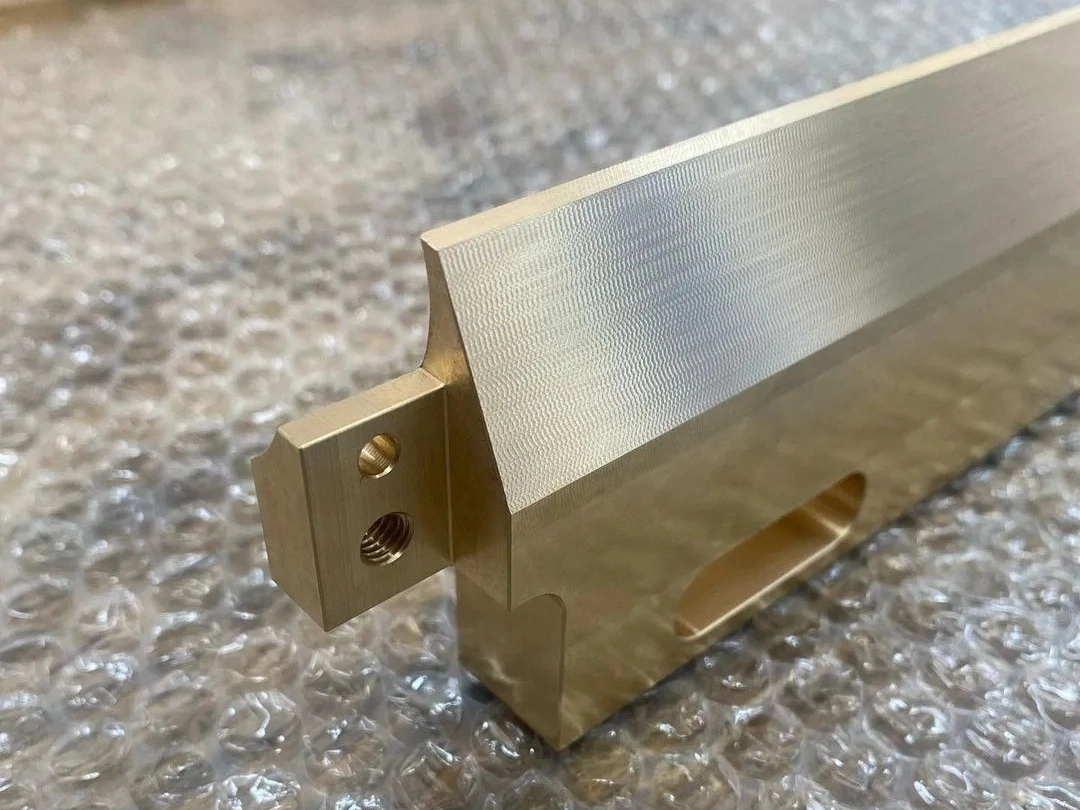

CNC Prototyping Materials At Neway

At Neway, we offer CNC prototyping using a wide range of materials, including superalloys, titanium, aluminum, copper, stainless steel, and plastics. These materials provide excellent strength, precision, and durability, suitable for industries like aerospace, automotive, and manufacturing.

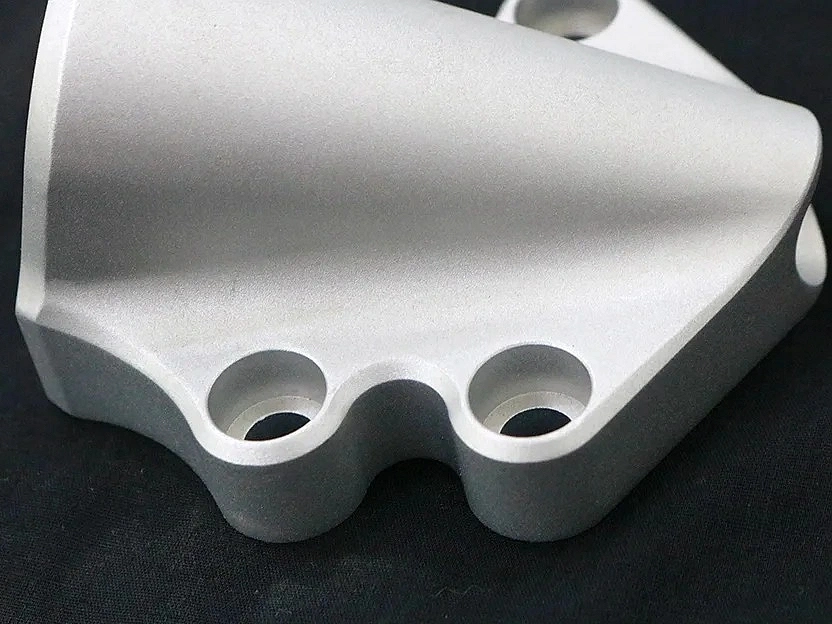

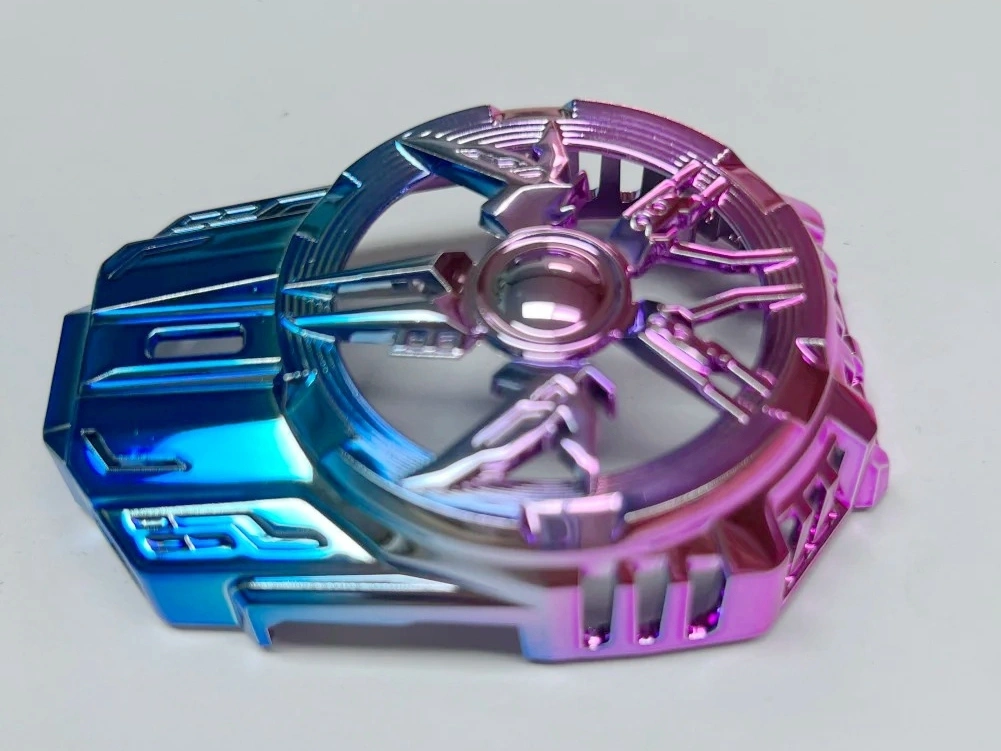

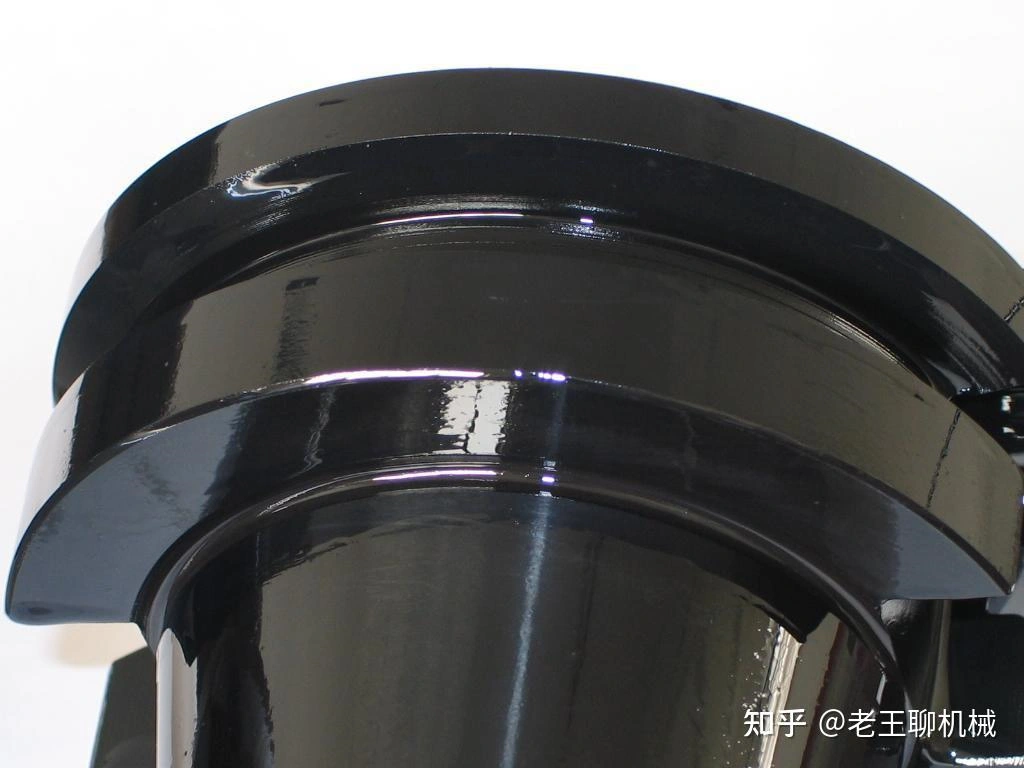

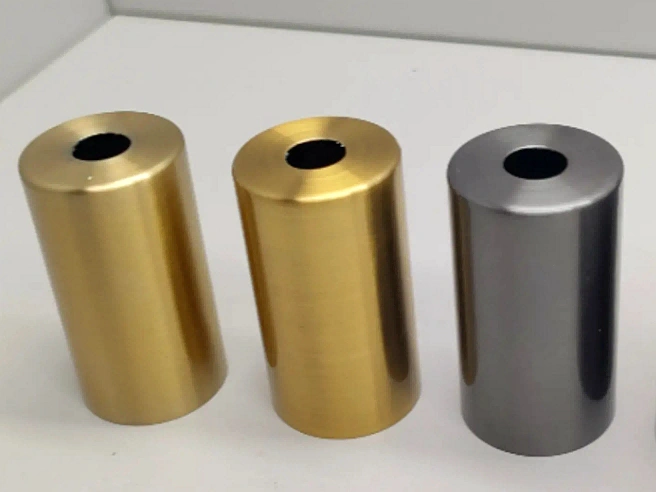

Surface Treatment for CNC Prototyping Parts

Neway provides various surface treatments for CNC prototyping parts, including anodizing, coating, polishing, and heat treatment. These processes enhance durability, corrosion resistance, and aesthetics, ensuring high-quality, long-lasting components for industries such as aerospace, automotive, and medical.

Learn More

Thermal Coating

Learn More

As Machined

Learn More

Painting

Learn More

PVD (Physical Vapor Deposition)

Learn More

Sandblasting

Learn More

Electroplating

Learn More

Polishing

Learn More

Anodizing

Learn More

Powder Coating

Learn More

Electropolishing

Learn More

Passivation

Learn More

Brushing

Learn More

Black Oxide

Learn More

Heat Treatment

Learn More

Thermal Barrier Coating (TBC)

Learn More

Tumbling

Learn More

Alodine

Learn More

Chrome Plating

Learn More

Phosphating

Learn More

Nitriding

Learn More

Galvanizing

Learn More

UV Coating

Learn More

Lacquer Coating

Learn More

Teflon Coating

Custom Rapid CNC Prototyping Case Study

This case study highlights Neway's custom rapid CNC prototyping services, showcasing our ability to deliver high-precision parts quickly for diverse industries. We optimized design, reduced lead times, and ensured high quality, helping clients achieve faster time-to-market and cost savings.

Let's Start A New Project Today

CNC Prototypes Design Guidelines

CNC prototype design guidelines emphasize material selection, uniform wall thickness, achievable tolerances, and accessible features. Key principles include avoiding sharp corners, minimizing material removal, and ensuring proper hole design and symmetry to optimize machining efficiency, cost, and part quality.

Frequently Asked Questions

Explore Related Resources

Solutions

Copyright © 2025 Machining Precision Works Ltd.All Rights Reserved.