Custom Parts Manufacturing Solutions

Consumer Products Parts Manufacturing Service

Neway provides comprehensive Consumer Products Components Manufacturing services, offering CNC Machining, 3D Printing, Vacuum Casting, Die Casting, and Injection Molding. We deliver high-quality, durable components tailored to the consumer goods industry, ensuring precision, performance, and cost-efficiency in every product.

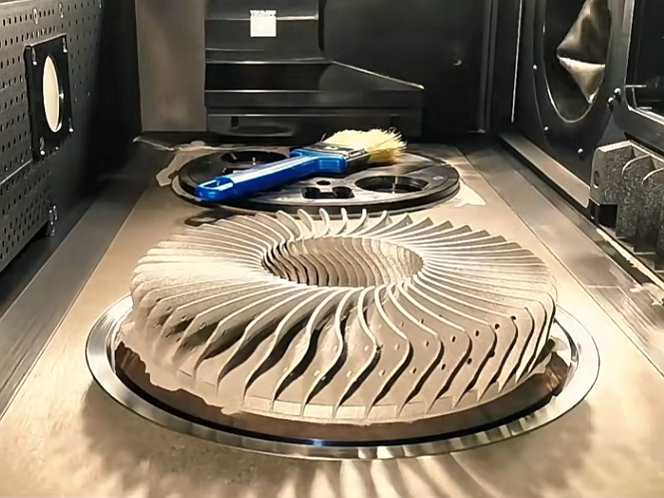

Consumer Products Parts Machining

Consumer products parts machining involves the precise fabrication of components using various CNC processes, such as milling, turning, drilling, and grinding. These advanced techniques ensure high accuracy and quality for products like electronics, appliances, and personal devices. Multi-axis machining and EDM provide enhanced precision for complex shapes, meeting the demands of modern consumer goods.

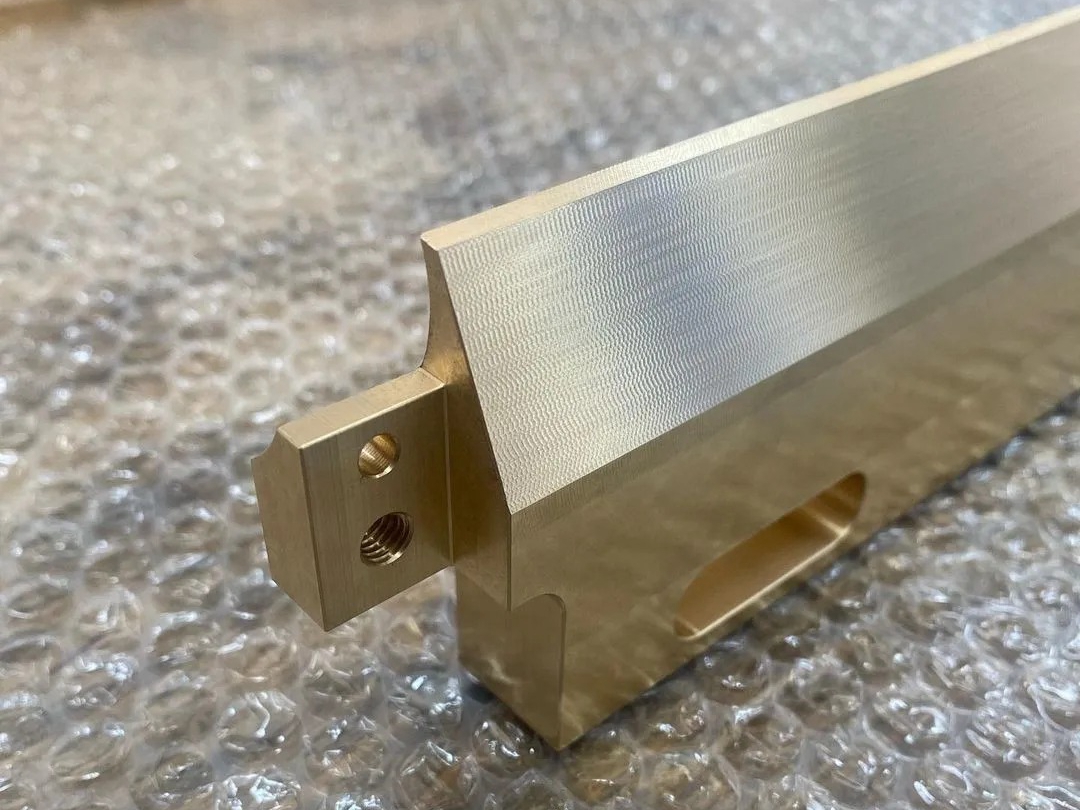

Consumer Products Material Selection

In consumer products manufacturing, materials like superalloys, titanium, aluminum, copper, brass, bronze, carbon steel, stainless steel, plastic, and ceramic are essential for producing durable, functional, and aesthetically appealing items such as kitchenware, electronics, toys, and decorative goods.

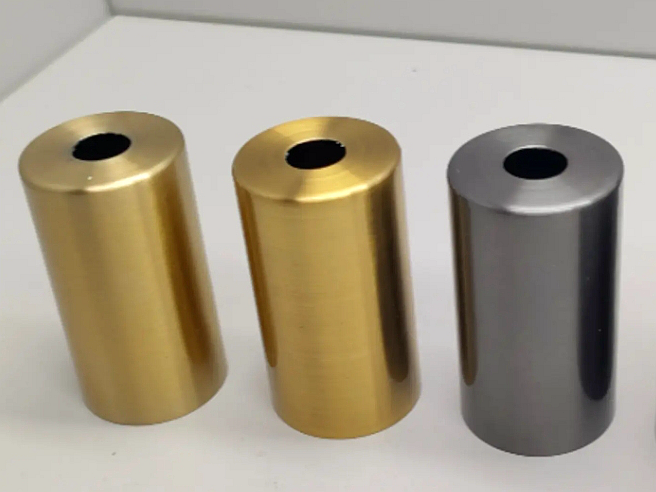

Typical Surface Treatment for Consumer Products

Typical surface treatments for consumer products include techniques like painting, electroplating, anodizing, and powder coating, which enhance aesthetics and durability. Additional processes such as polishing, passivation, and UV coating improve finish and resistance to wear. For specialized needs, options like PVD, sandblasting, and Teflon coating offer enhanced performance, while heat treatments strengthen materials for longer-lasting use.

learn more

Thermal Coating

learn more

As Machined

learn more

Painting

learn more

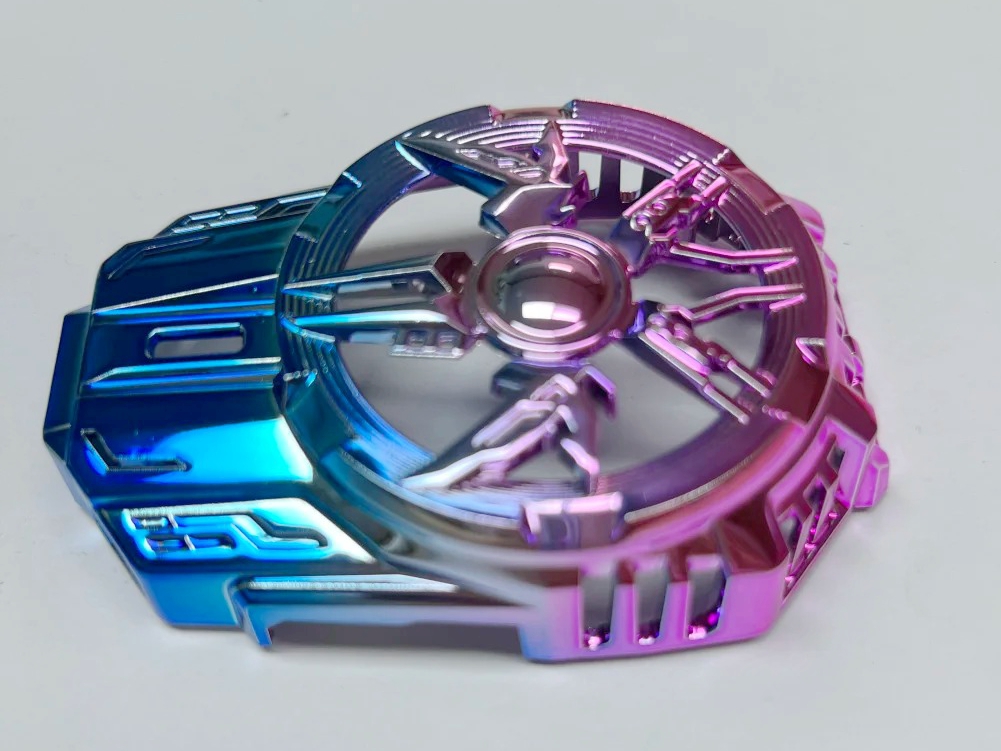

PVD (Physical Vapor Deposition)

learn more

Sandblasting

learn more

Electroplating

learn more

Polishing

learn more

Anodizing

learn more

Powder Coating

learn more

Electropolishing

learn more

Passivation

learn more

Brushing

learn more

Black Oxide

learn more

Heat Treatment

learn more

Thermal Barrier Coating (TBC)

learn more

Tumbling

learn more

Alodine

learn more

Chrome Plating

learn more

Phosphating

learn more

Nitriding

learn more

Galvanizing

learn more

UV Coating

learn more

Lacquer Coating

learn more

Teflon Coating

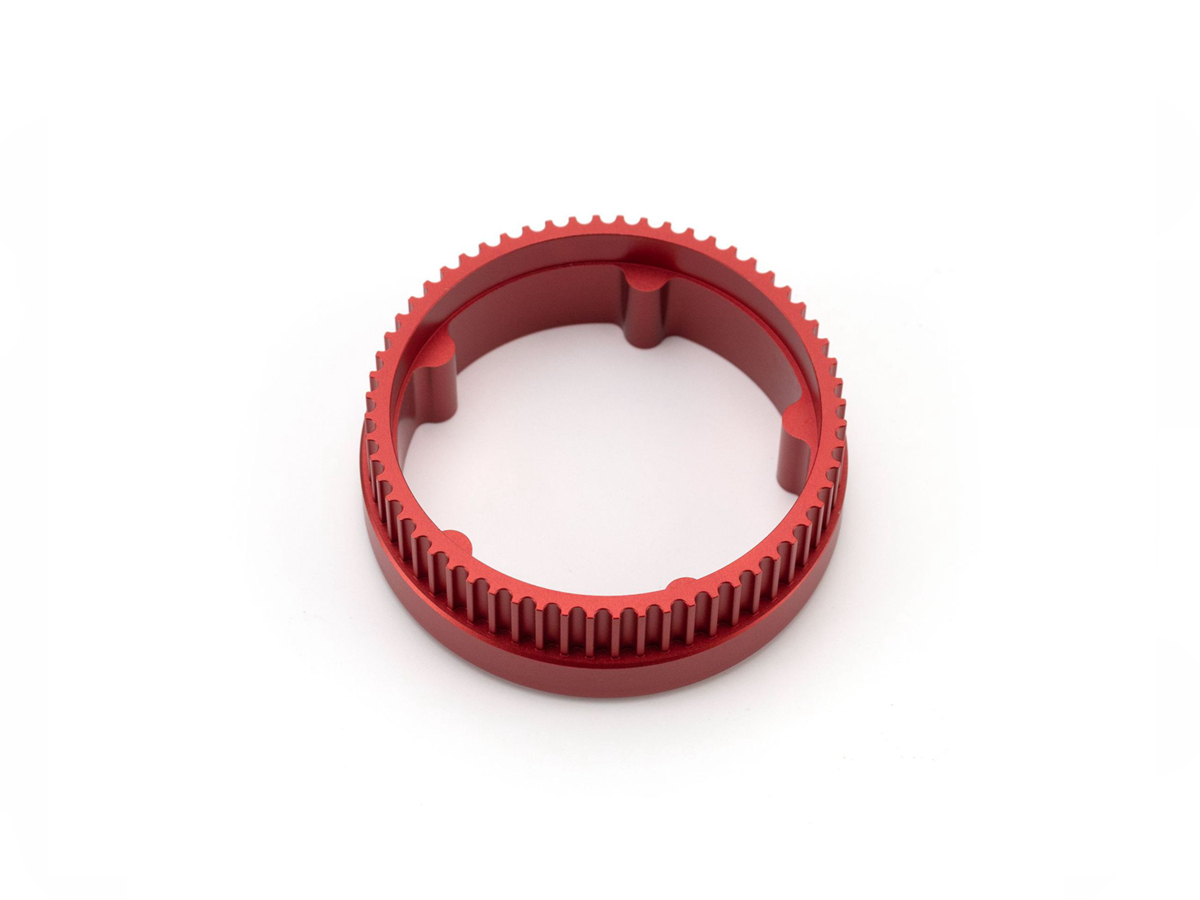

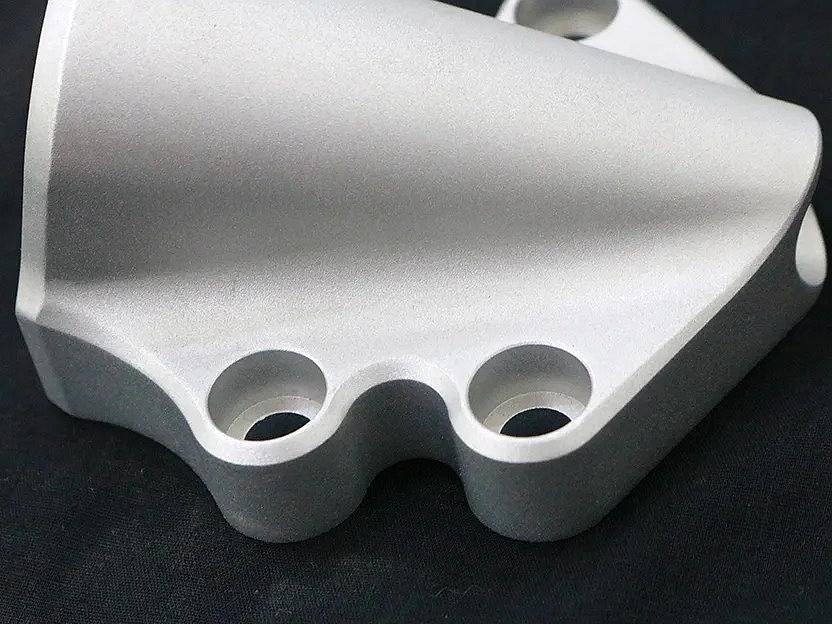

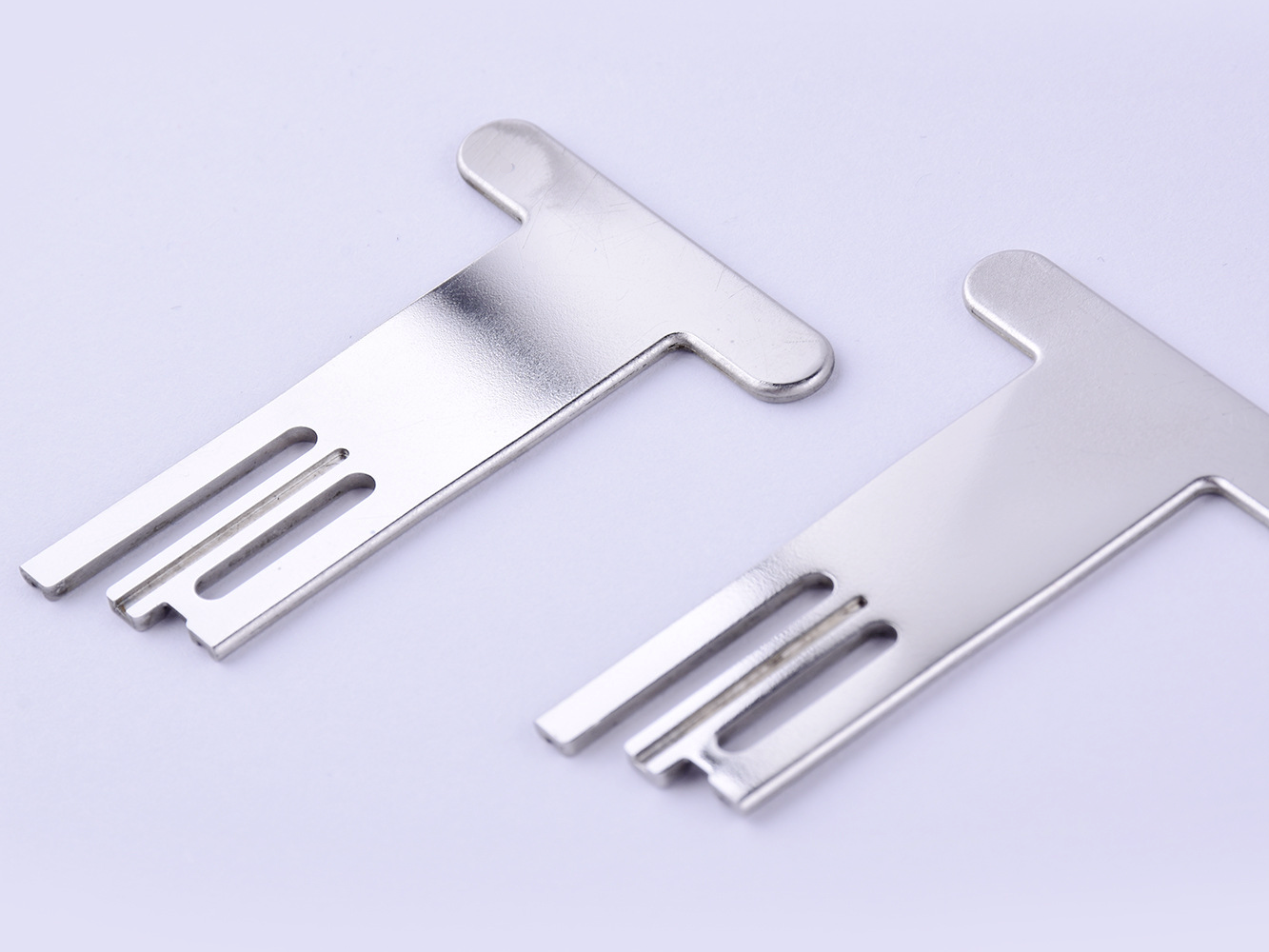

CNC Machined Components for Consumer Products

In consumer products, CNC machining manufactures parts such as housings, brackets, and enclosures, delivering high-quality finishes and precise tolerances for everyday electronic devices, appliances, and accessories.

Let's Start A New Project Today

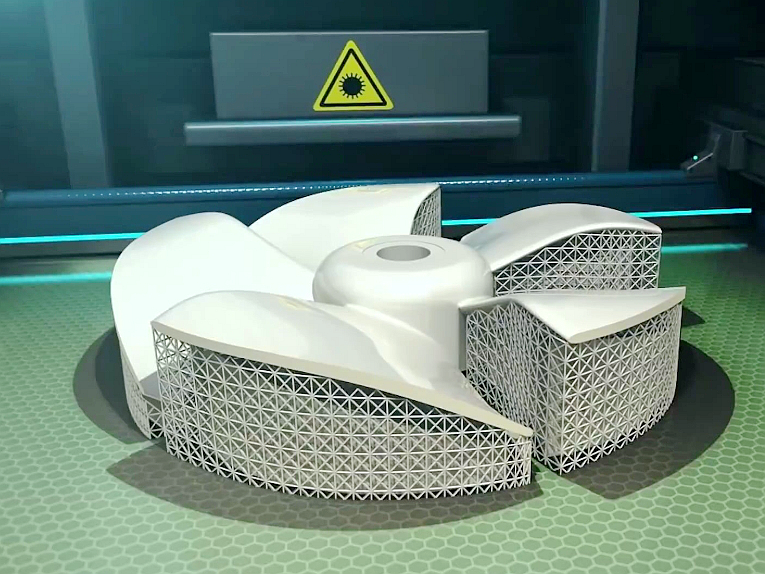

Custom Consumer Products Parts Manufacturing Methods Suggestions

Selecting the right manufacturing method ensures high-quality, cost-effective production of consumer products. Techniques like injection molding, CNC machining, and rapid prototyping deliver precise, durable components, enabling fast market entry, design flexibility, and scalability for mass production while maintaining performance and aesthetics.