Custom Parts Manufacturing Solutions

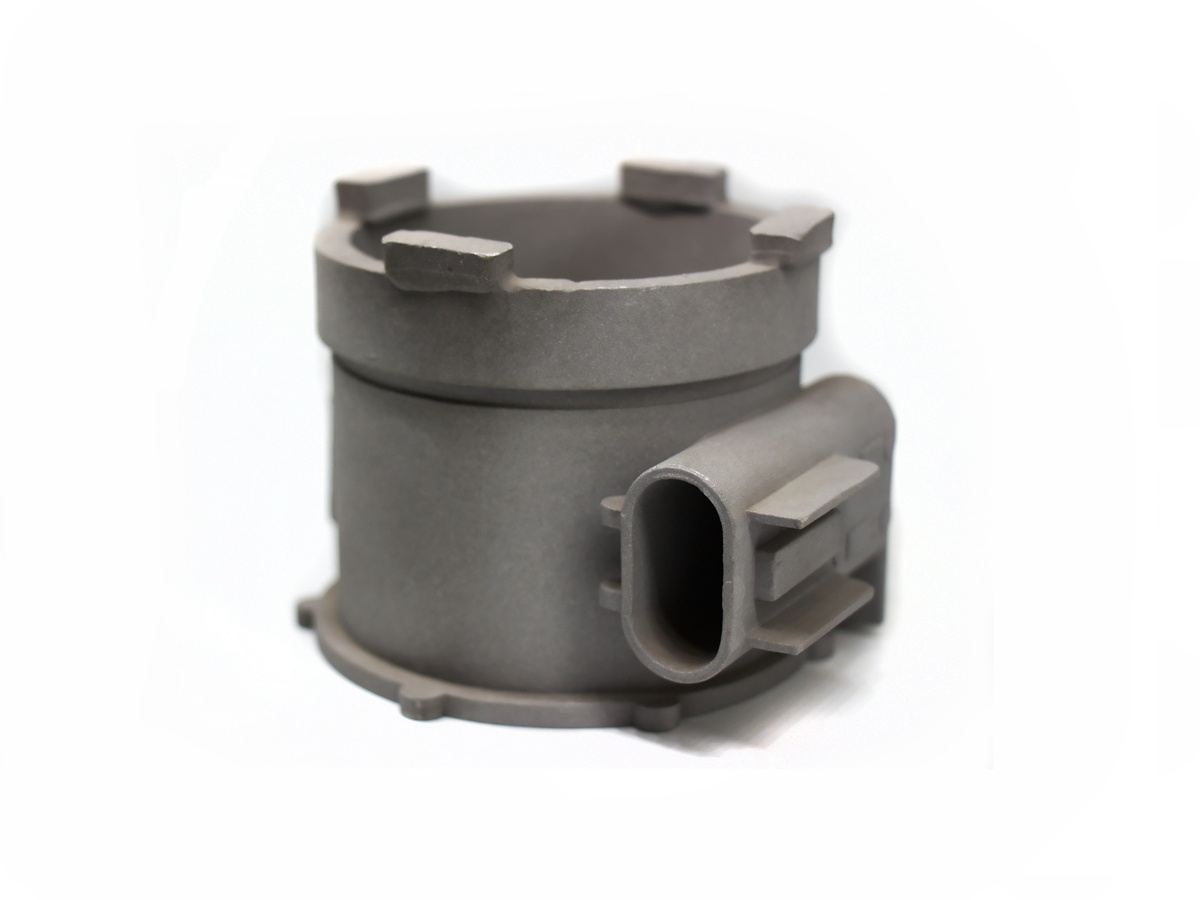

Nuclear Components Manufacturing Service

Neway specializes in Nuclear Components Manufacturing, offering CNC Machining, 3D Printing, Vacuum Casting, and Investment Casting services. We provide high-precision, durable components designed to meet the stringent requirements of the nuclear industry.

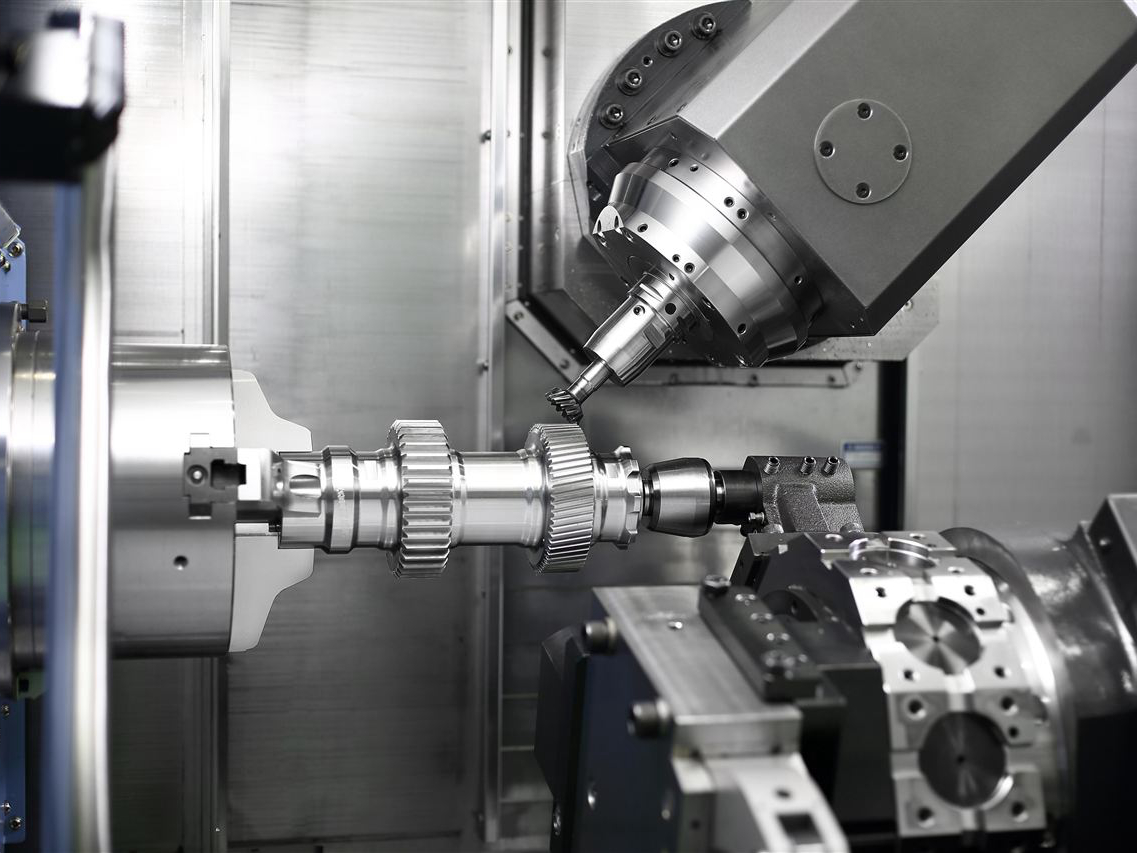

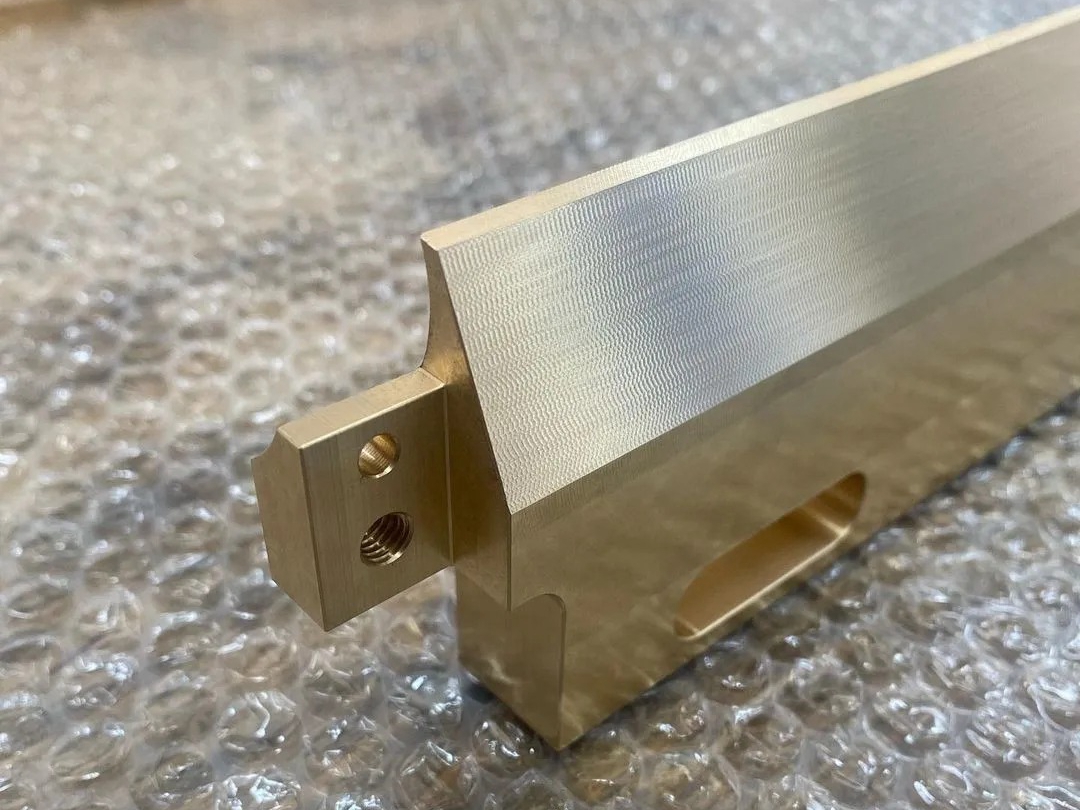

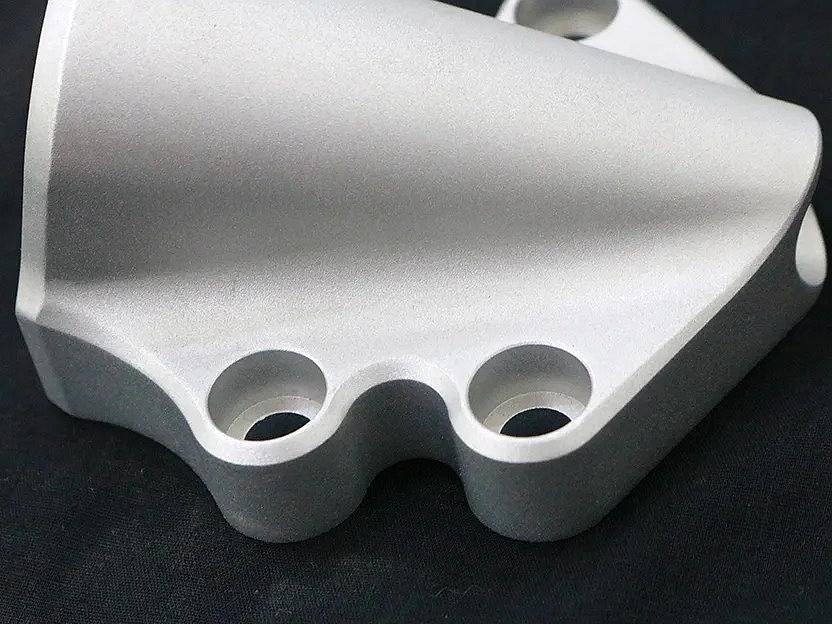

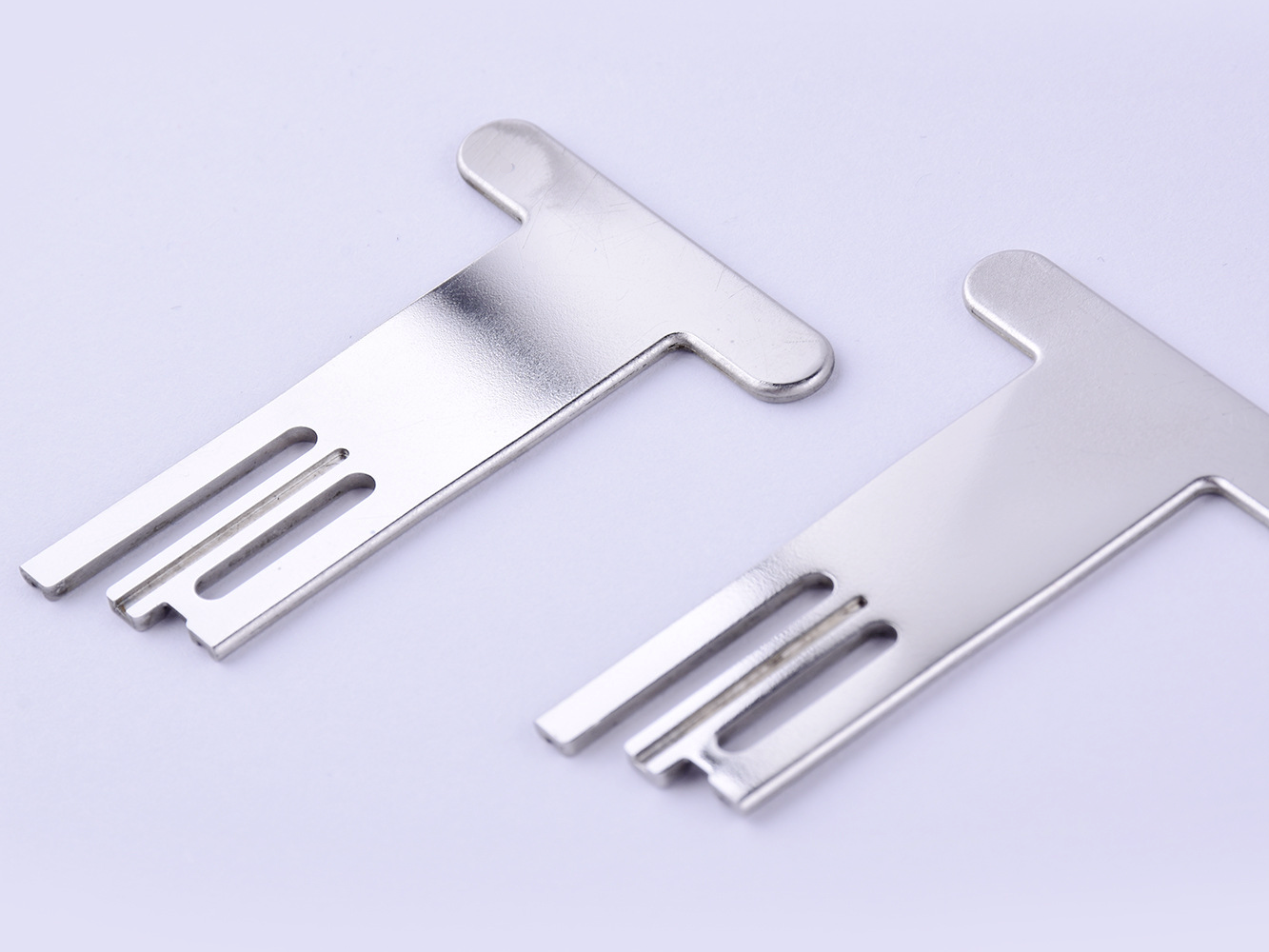

Custom Nuclear Components Machining

Custom nuclear components machining involves the precision fabrication of parts used in nuclear reactors and related systems. Utilizing advanced CNC techniques like milling, turning, and EDM, these components are produced with high accuracy and reliability. Ensuring strict adherence to safety and quality standards, this machining process guarantees performance and durability in critical nuclear applications.

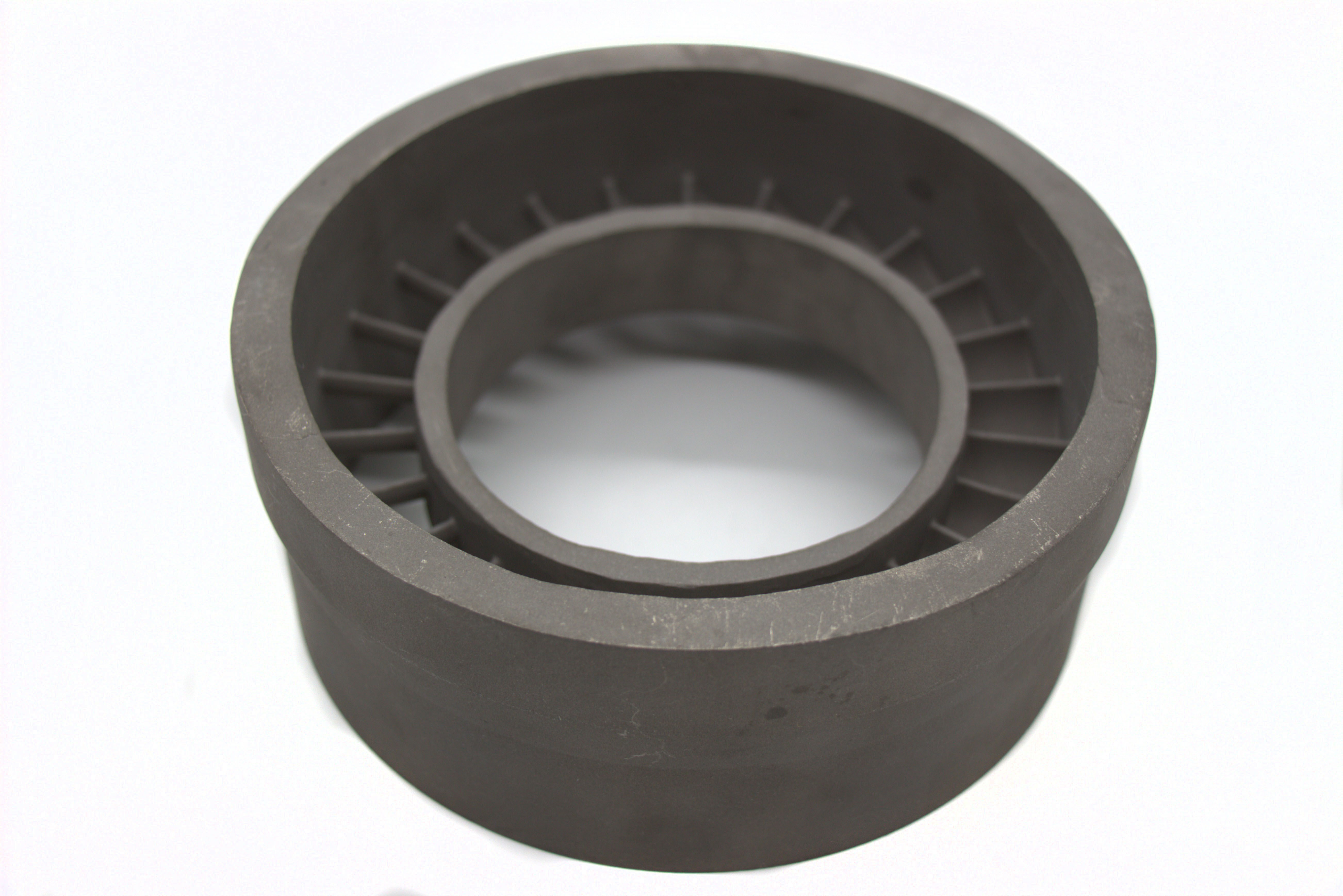

Nuclear Material Selection

Nuclear parts manufacturing requires materials that can withstand extreme temperatures, radiation, and corrosion. Superalloys, titanium, stainless steel, and ceramics are commonly used for reactor components, heat exchangers, and shielding. Materials must also offer structural integrity and durability for long-term, safe operation in nuclear environments.

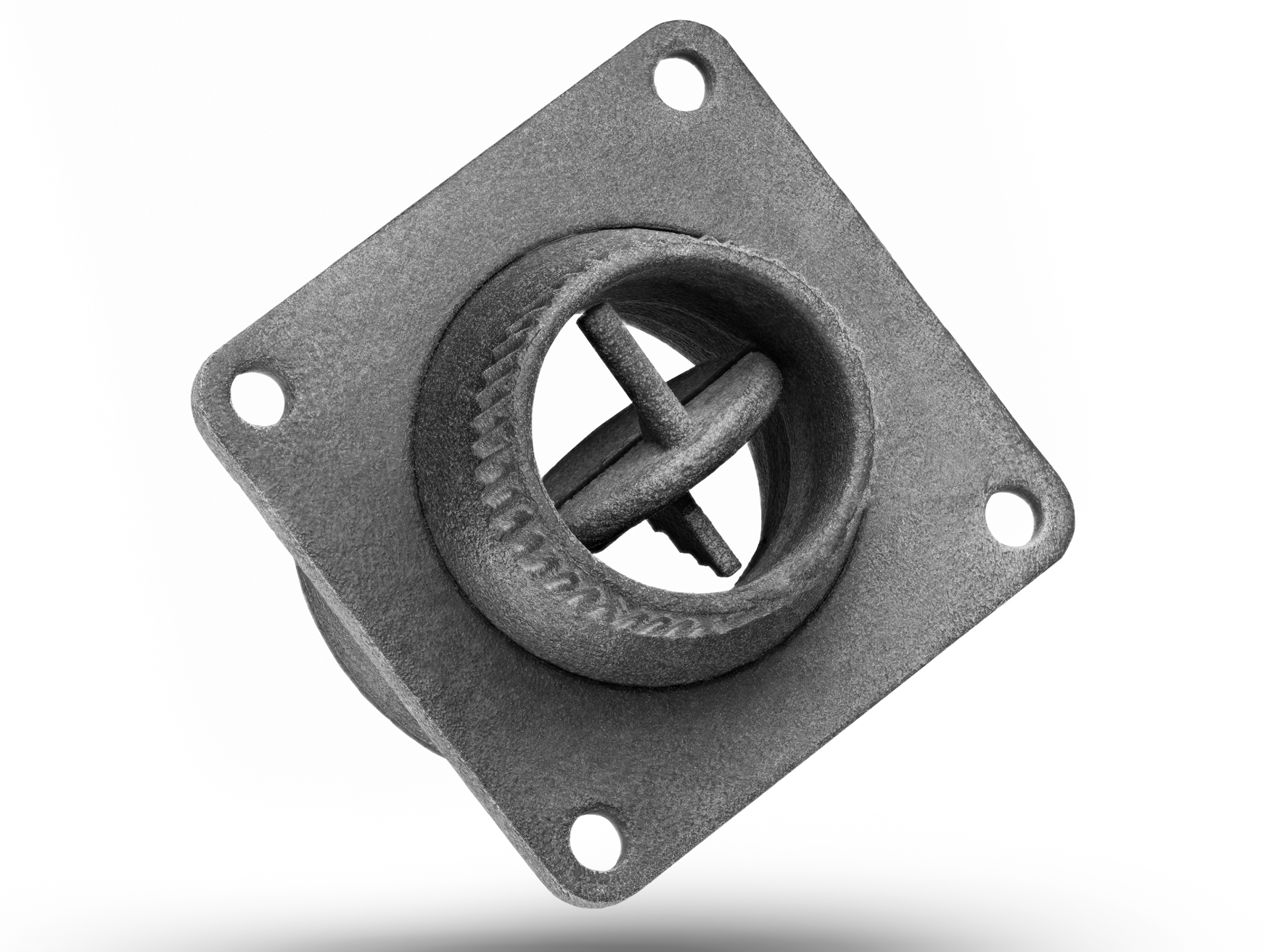

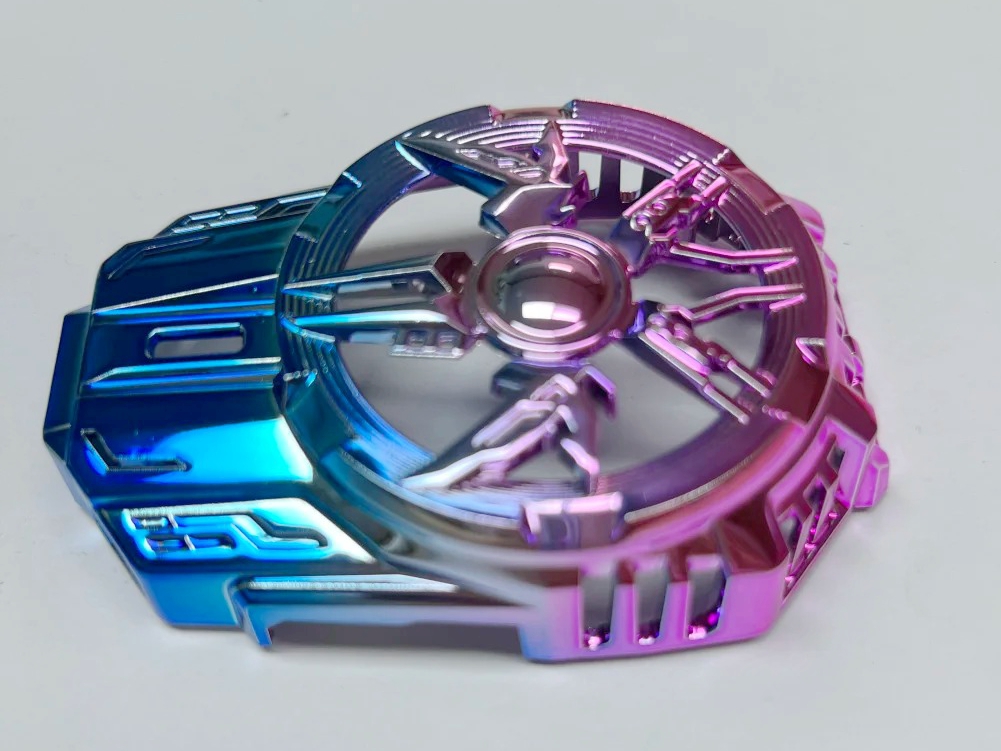

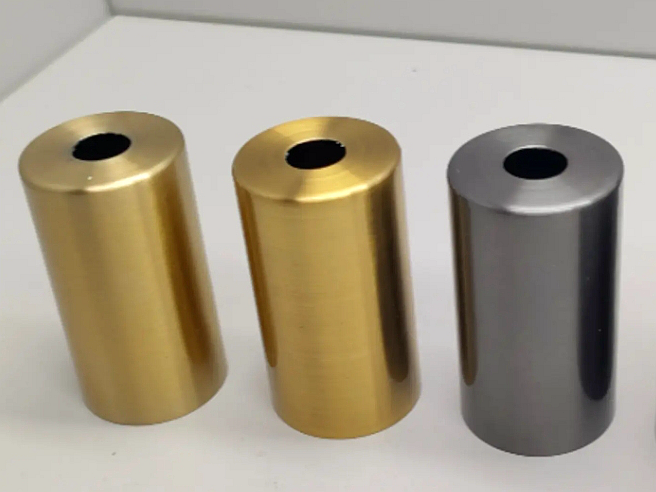

Typical Surface Treatment for Nuclear Parts

Typical surface treatments for nuclear parts include coatings and processes like anodizing, PVD, passivation, electroplating, and thermal barrier coatings (TBC). These treatments enhance corrosion resistance, improve wear properties, and ensure safety under extreme conditions. Techniques such as nitriding, phosphating, and black oxide are used for durability, while UV, lacquer, and Teflon coatings provide additional protection in radiation environments.

learn more

Thermal Coating

learn more

As Machined

learn more

Painting

learn more

PVD (Physical Vapor Deposition)

learn more

Sandblasting

learn more

Electroplating

learn more

Polishing

learn more

Anodizing

learn more

Powder Coating

learn more

Electropolishing

learn more

Passivation

learn more

Brushing

learn more

Black Oxide

learn more

Heat Treatment

learn more

Thermal Barrier Coating (TBC)

learn more

Tumbling

learn more

Alodine

learn more

Chrome Plating

learn more

Phosphating

learn more

Nitriding

learn more

Galvanizing

learn more

UV Coating

learn more

Lacquer Coating

learn more

Teflon Coating

CNC Machining in Nuclear Industry Components

CNC machining plays a vital role in manufacturing nuclear power plant components, such as reactor cores, shielding systems, and control systems, ensuring critical safety and operational efficiency.

Let's Start A New Project Today

Nuclear Components Manufacturing Methods Suggestions

Selecting the correct manufacturing method for nuclear components is essential to meet stringent safety, durability, and regulatory standards. Methods like precision casting, welding, and heat treatment ensure components can withstand extreme conditions and radiation exposure. The right choice enhances reliability, minimizes risks, and ensures the integrity of critical nuclear systems.