Custom Parts Manufacturing Solutions

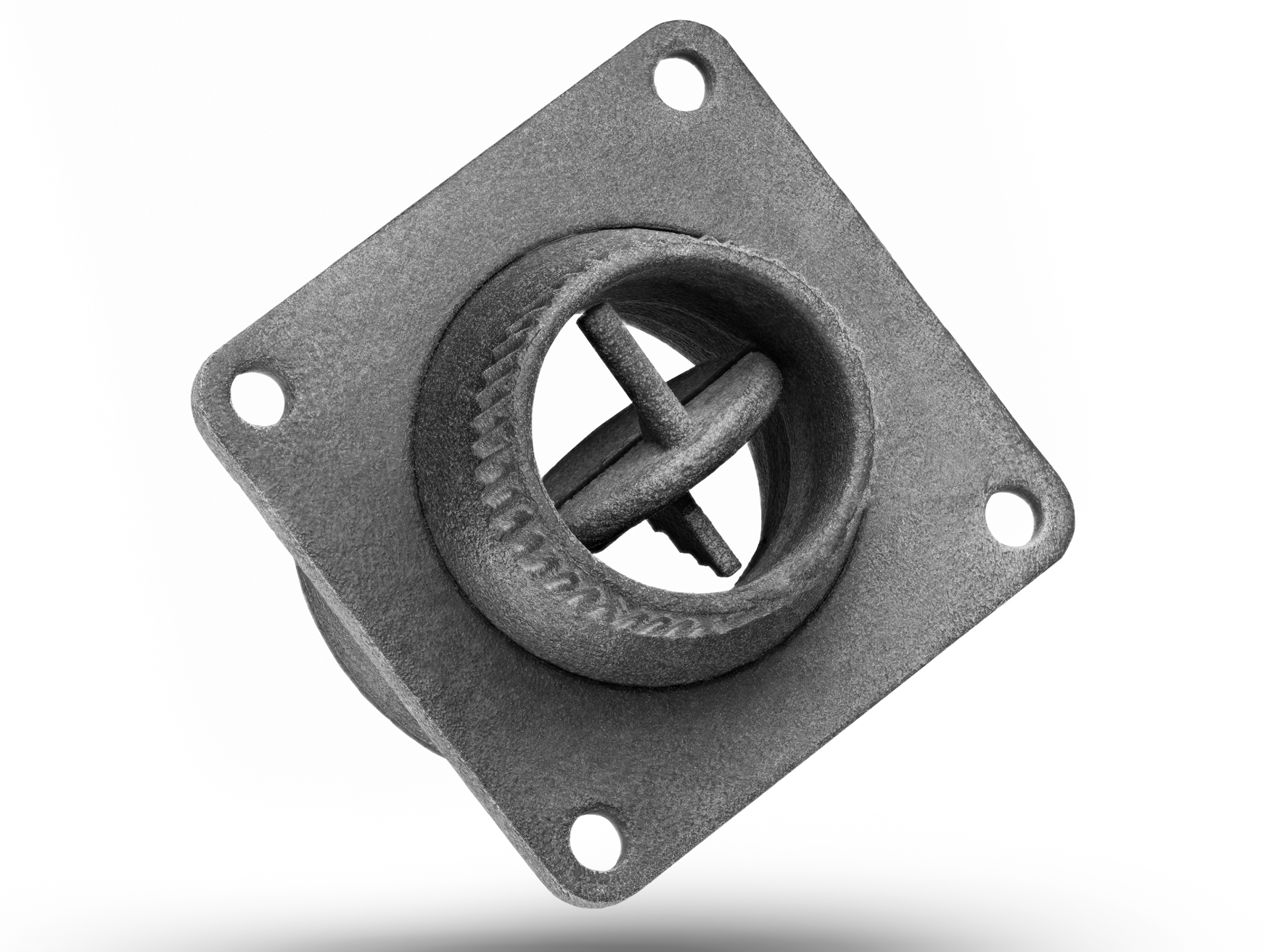

Oil and Gas Parts Manufacturing Service

Neway provides expert Oil and Gas Parts Manufacturing services, including CNC Machining, 3D Printing, Vacuum Casting, and Investment Casting. We specialize in high-performance components for drilling, refining, and extraction applications, delivering superior precision, durability, and reliability. Our advanced manufacturing processes meet the rigorous standards of the oil and gas industry.

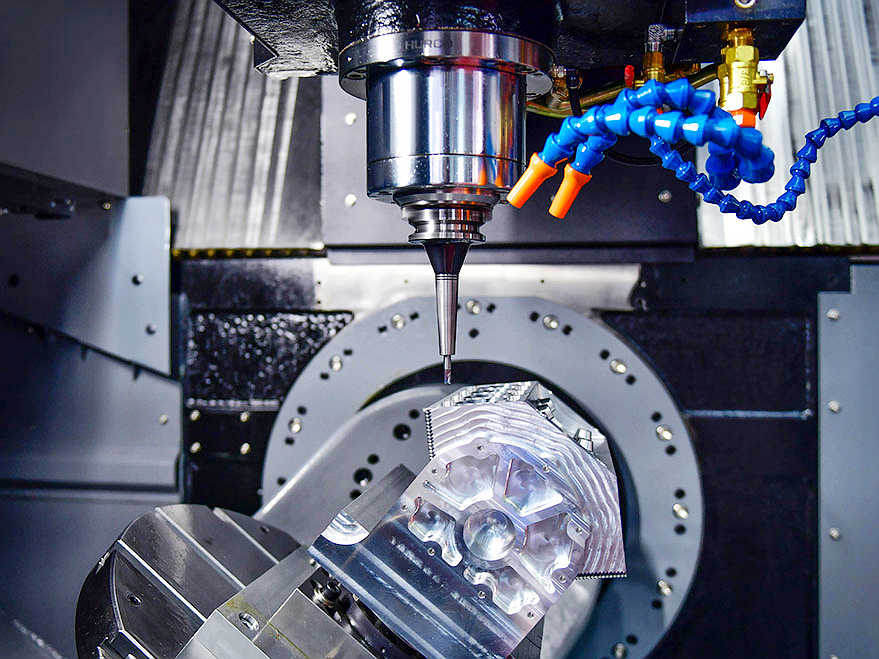

Custom Oil and Gas Parts Machining

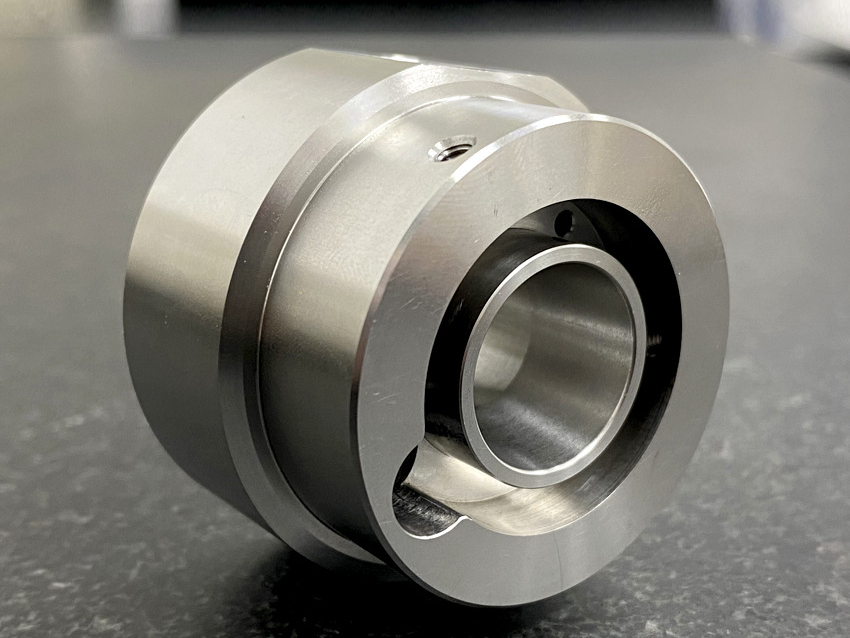

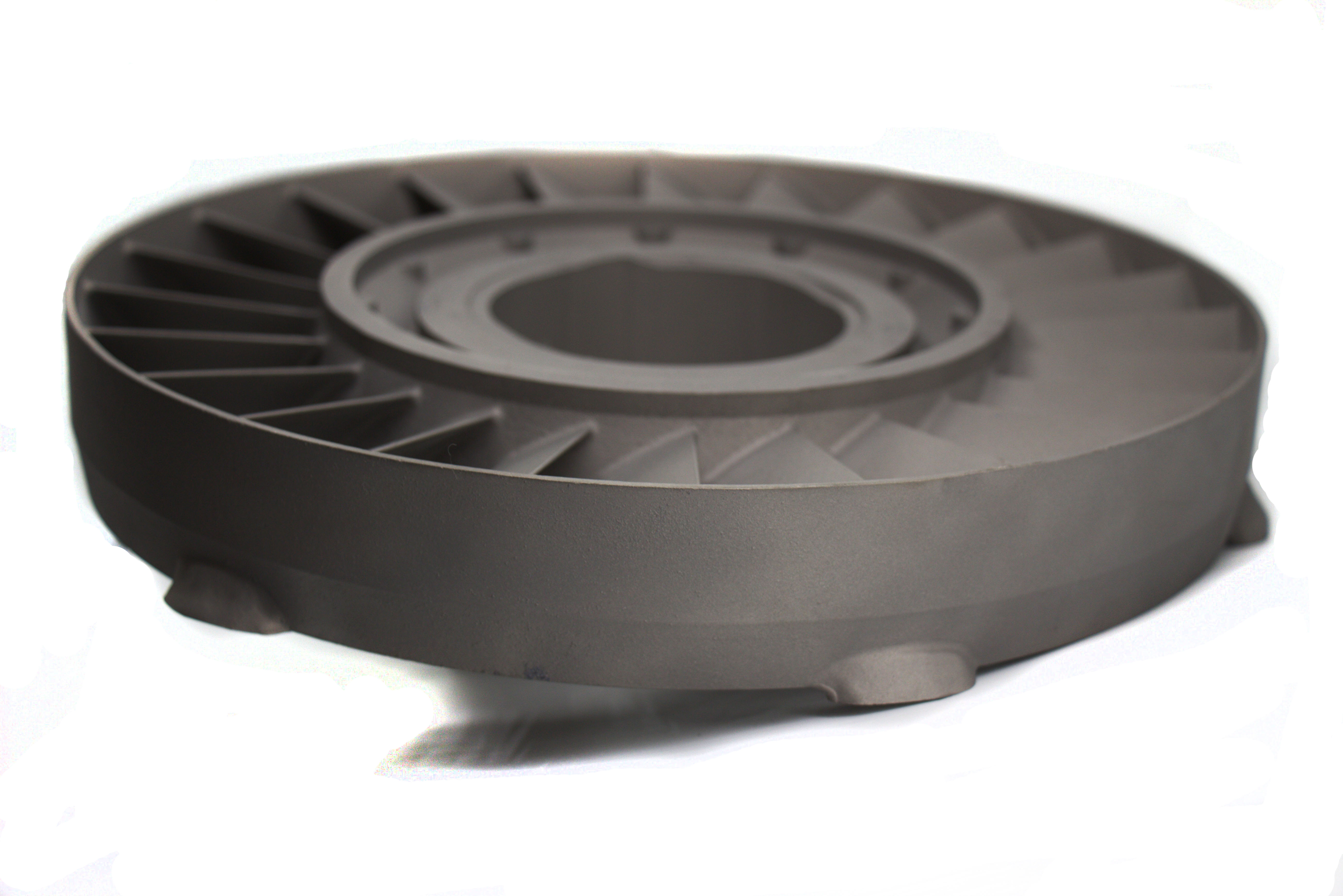

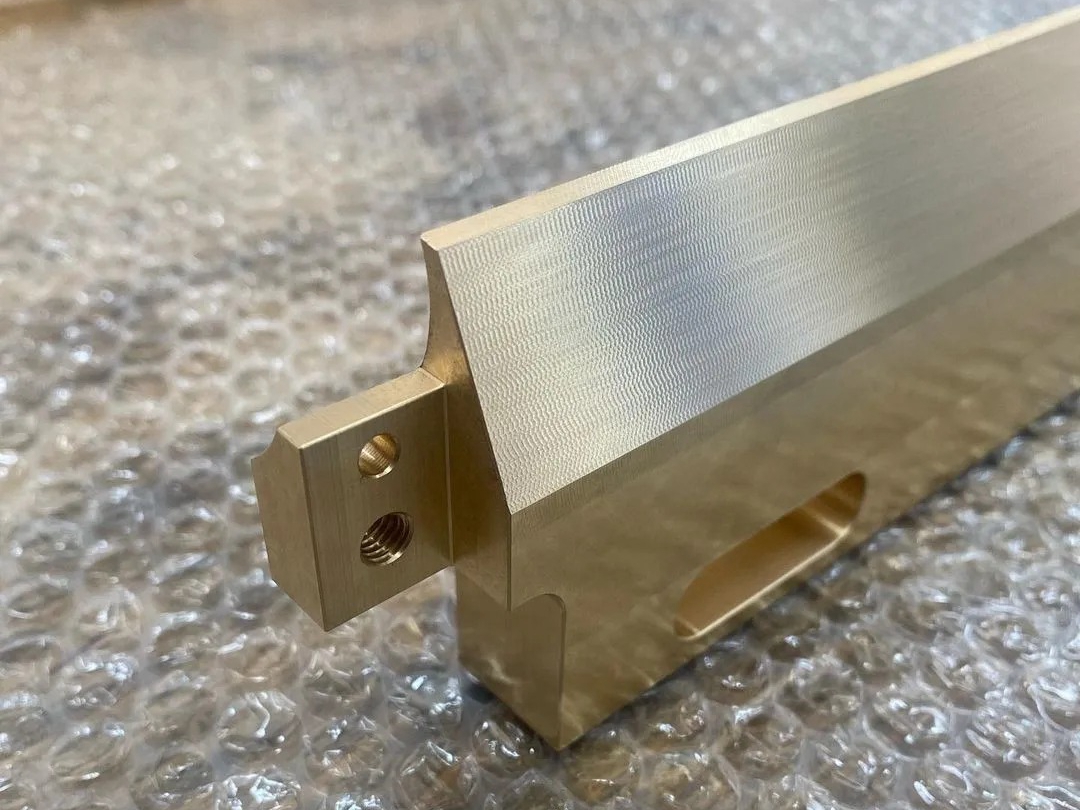

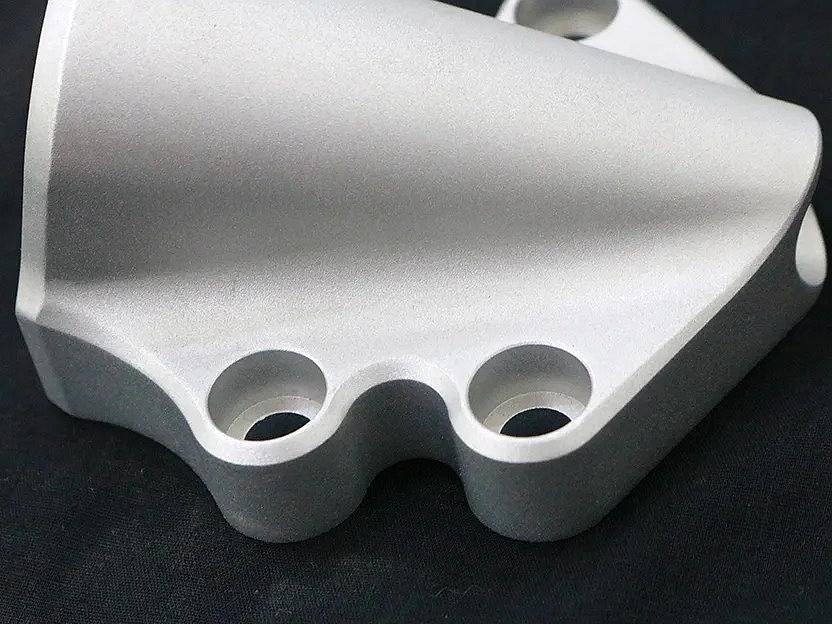

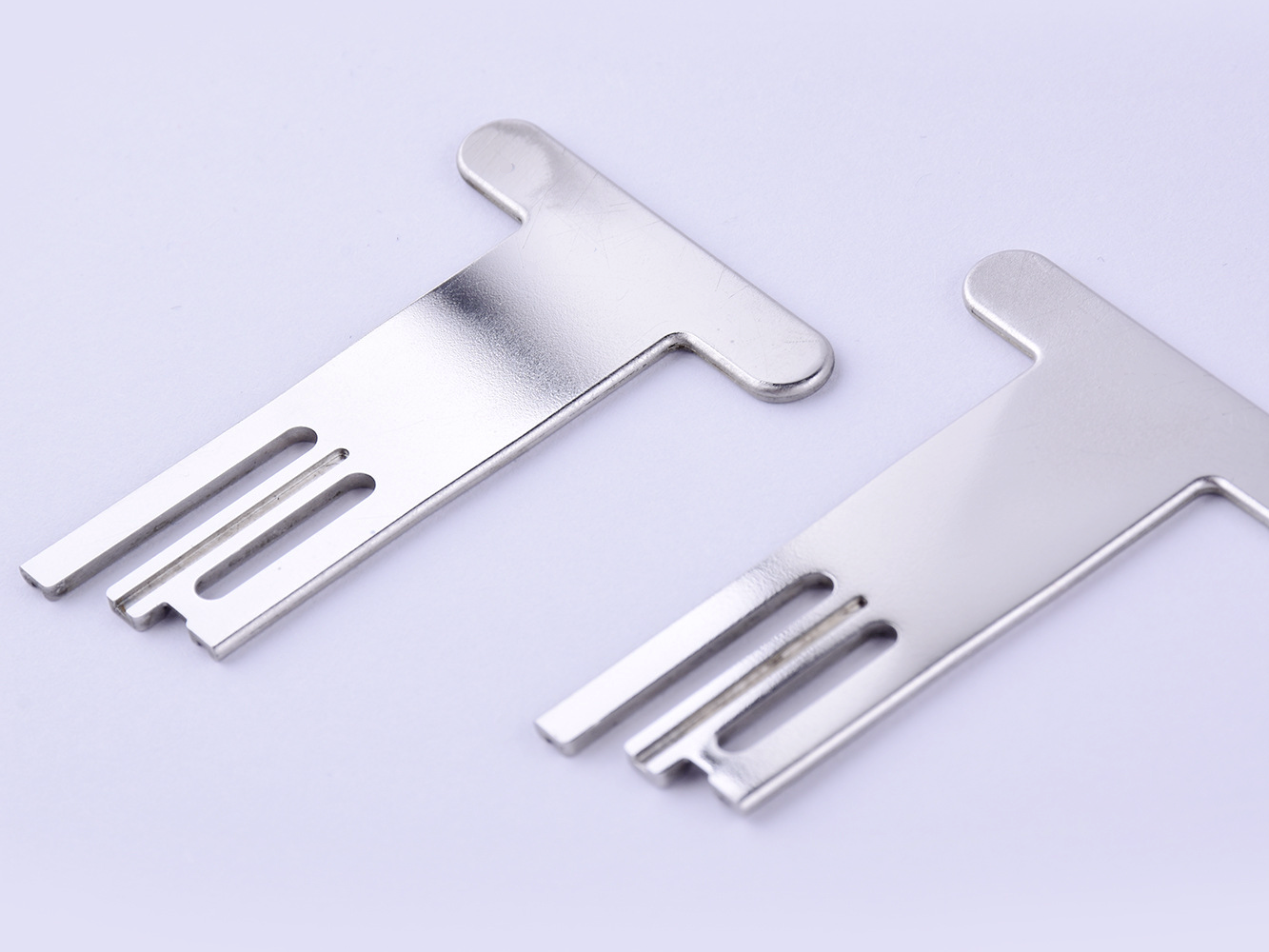

Our custom oil and gas parts machining services utilize advanced CNC technologies, including milling, turning, drilling, boring, grinding, and EDM, to produce high-precision components for the industry. We specialize in manufacturing durable, high-quality parts that meet stringent performance standards, ensuring reliability in demanding environments. Multi-axis machining capabilities allow for intricate designs and tight tolerances.

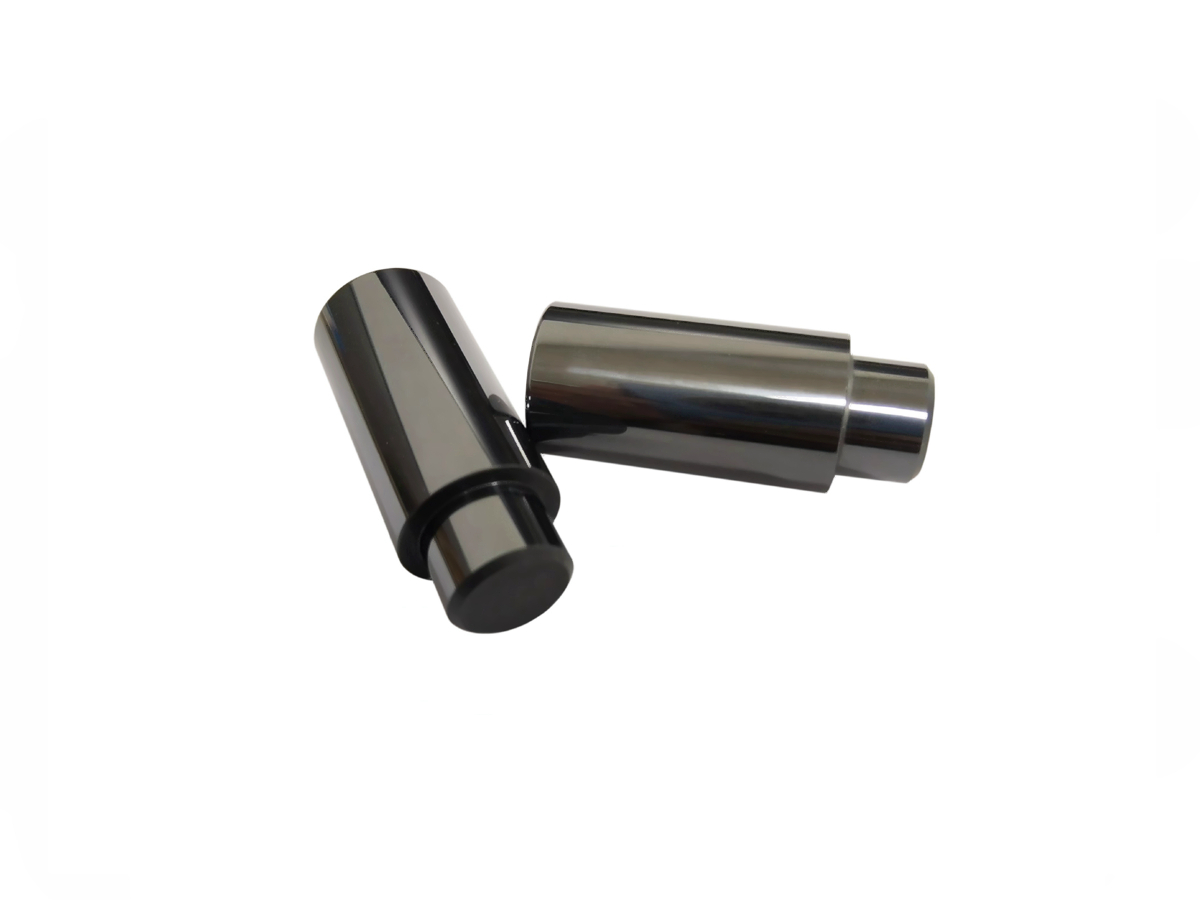

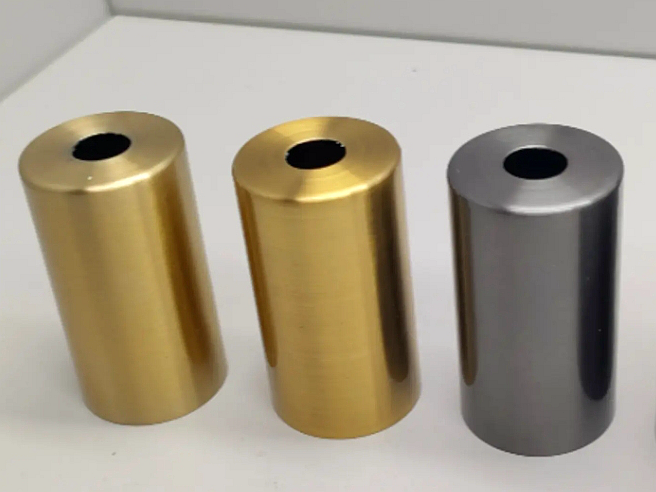

Oil and Gas Material Selection

For oil and gas applications, high-performance materials such as superalloys, titanium, aluminum, copper, brass, bronze, carbon steel, stainless steel, plastic, and ceramic are crucial for manufacturing durable, corrosion-resistant, and heat-resistant components used in drilling, valves, pipelines, and offshore equipment.

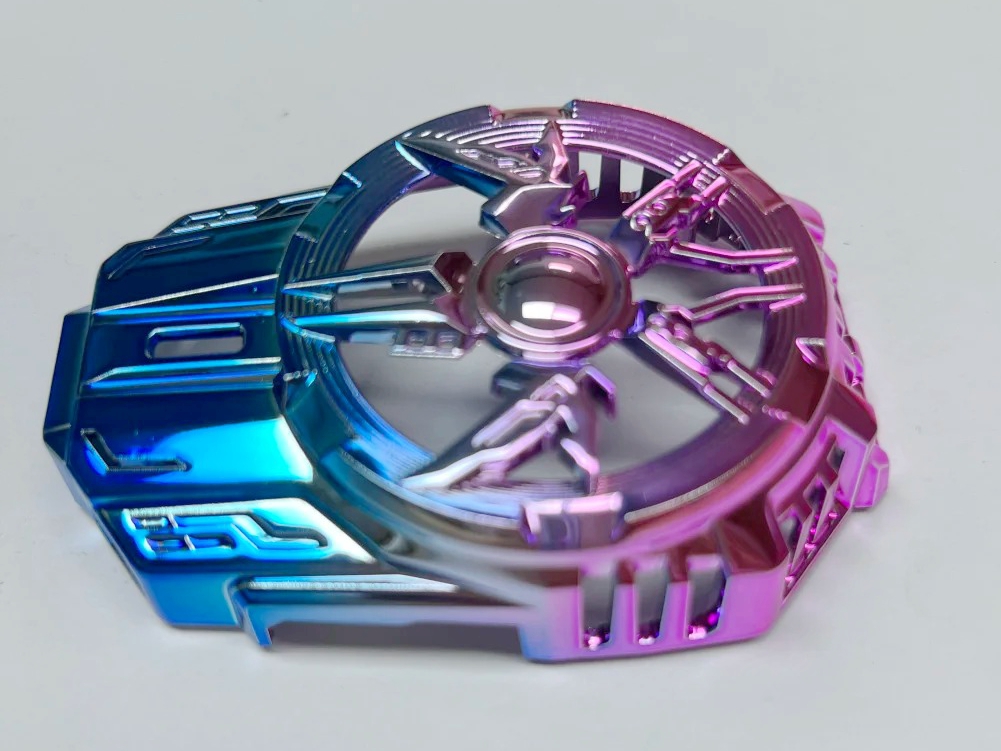

Surface Treatment for Oil and Gas Industry

Surface treatment in the oil and gas industry enhances durability and resistance of components exposed to harsh environments. Techniques like thermal coating, PVD, electroplating, anodizing, and heat treatment improve corrosion resistance, wear protection, and heat tolerance. These processes extend the lifespan of parts, ensuring reliability and safety in high-pressure, high-temperature, and chemically aggressive conditions.

learn more

Thermal Coating

learn more

As Machined

learn more

Painting

learn more

PVD (Physical Vapor Deposition)

learn more

Sandblasting

learn more

Electroplating

learn more

Polishing

learn more

Anodizing

learn more

Powder Coating

learn more

Electropolishing

learn more

Passivation

learn more

Brushing

learn more

Black Oxide

learn more

Heat Treatment

learn more

Thermal Barrier Coating (TBC)

learn more

Tumbling

learn more

Alodine

learn more

Chrome Plating

learn more

Phosphating

learn more

Nitriding

learn more

Galvanizing

learn more

UV Coating

learn more

Lacquer Coating

learn more

Teflon Coating

CNC Machining for Oil and Gas Equipment

CNC machining is used to create robust parts for the oil and gas industry, including valves, pipes, and drill bits, ensuring precision and resilience under extreme pressure and harsh conditions.

Let's Start A New Project Today

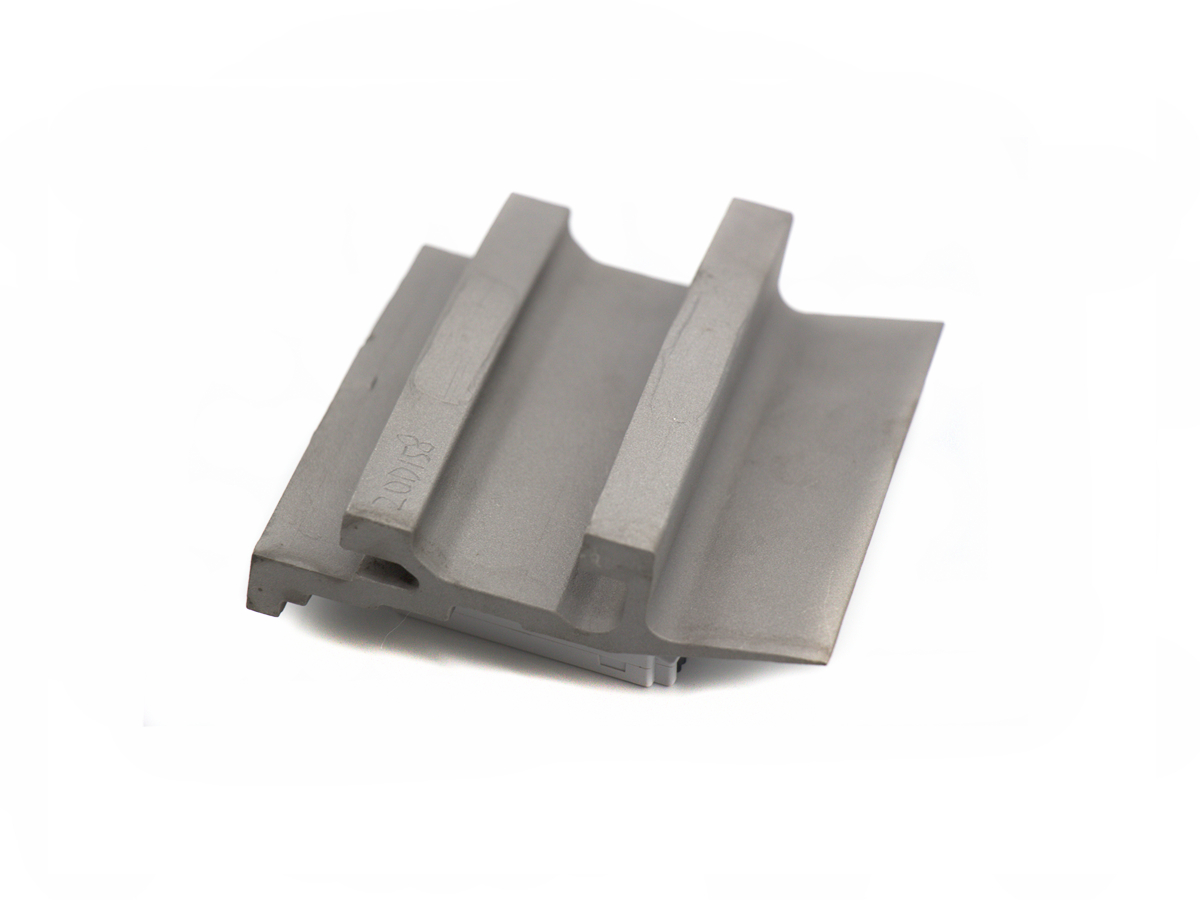

Oil and Gas Parts Manufacturing Methods Suggestions

Selecting the appropriate manufacturing method ensures durability, performance, and cost-effectiveness for oil and gas components. Accurate methods like precision casting, CNC machining, and injection molding provide strength, corrosion resistance, and reliability, essential for harsh environments and demanding applications in the industry.