Custom Parts Manufacturing Solutions

Power Generation Parts Manufacturing Service

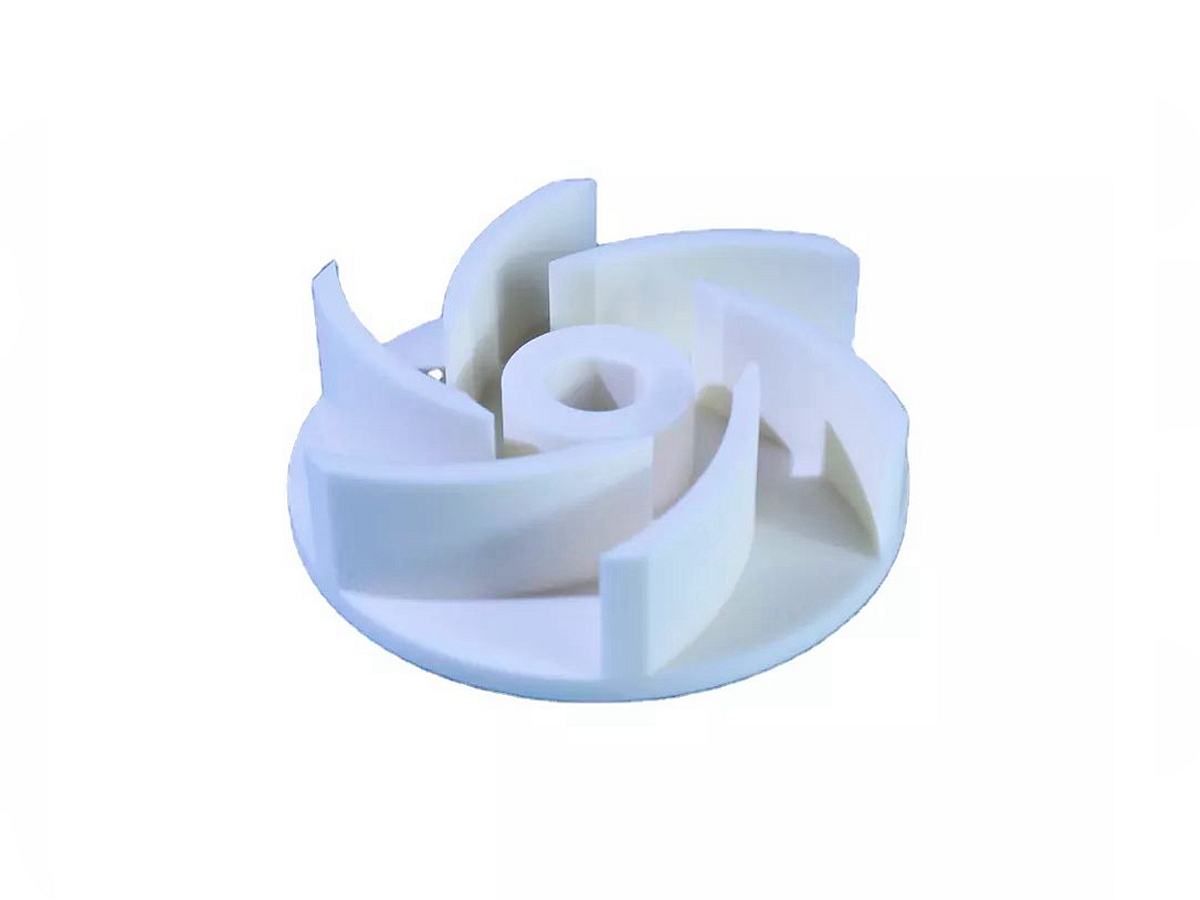

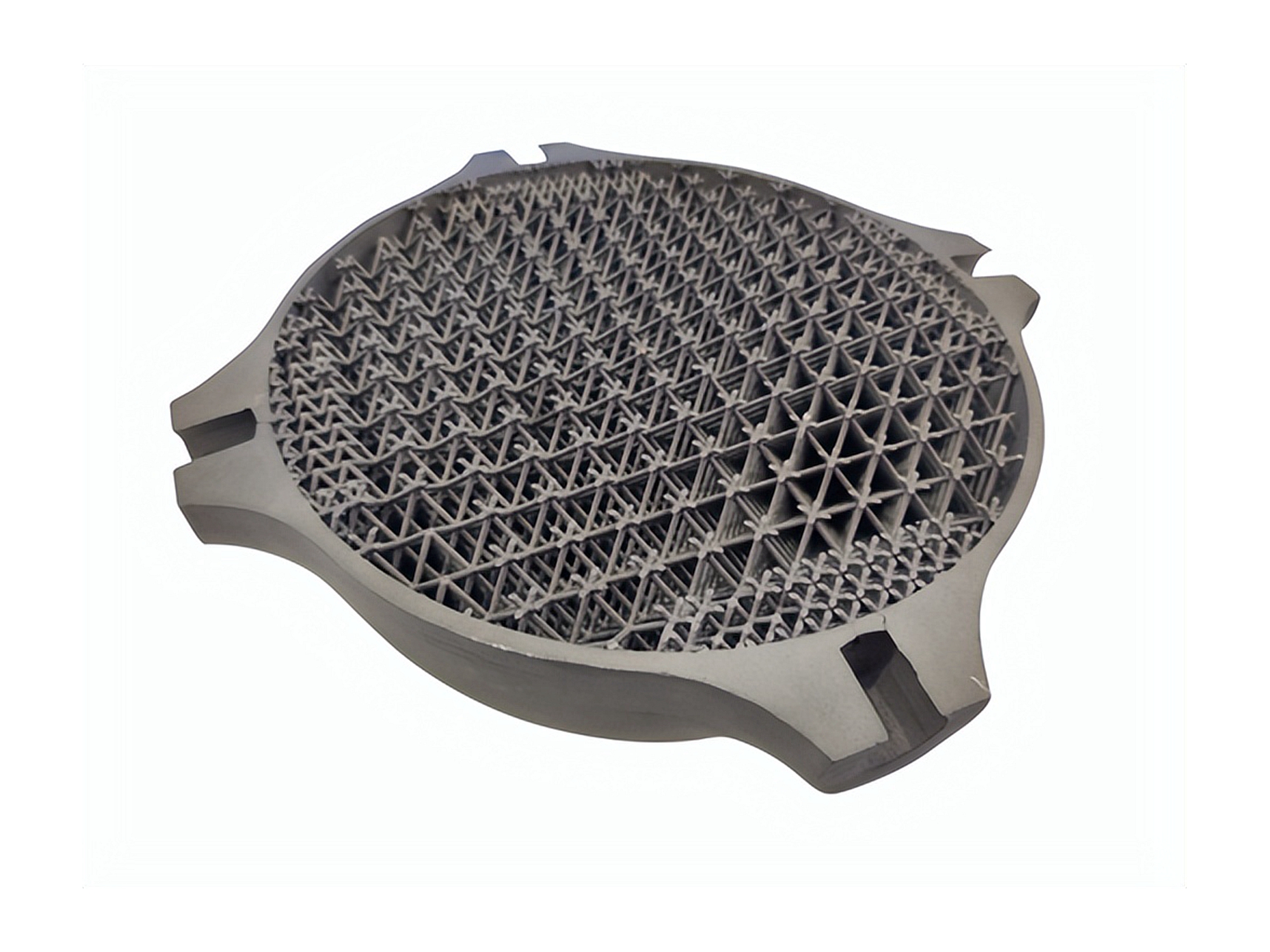

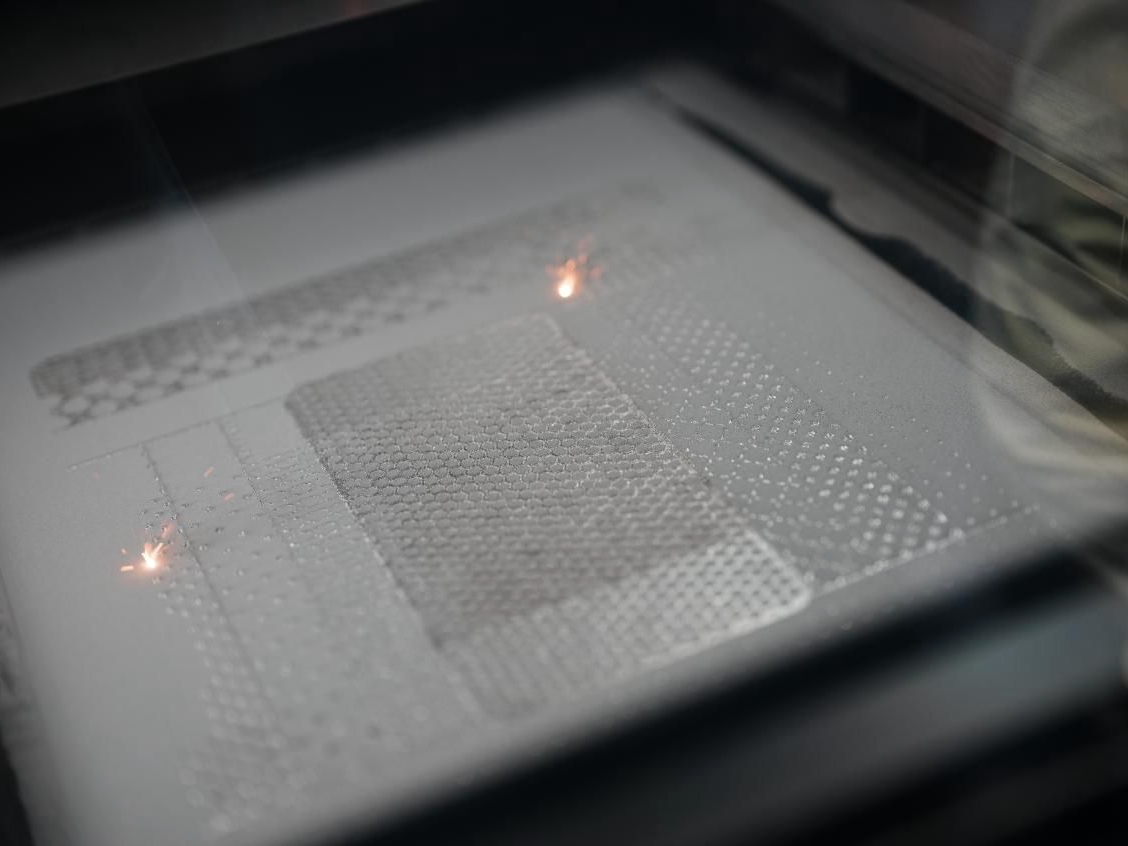

Neway provides specialized Power Generation Parts Manufacturing services, including precise CNC Machining, advanced 3D Printing, and high-quality Investment Casting. Our solutions are tailored for turbines, heat exchangers, and other critical components, ensuring optimal performance and durability. We deliver high-performance parts to meet the stringent demands of the power generation industry.

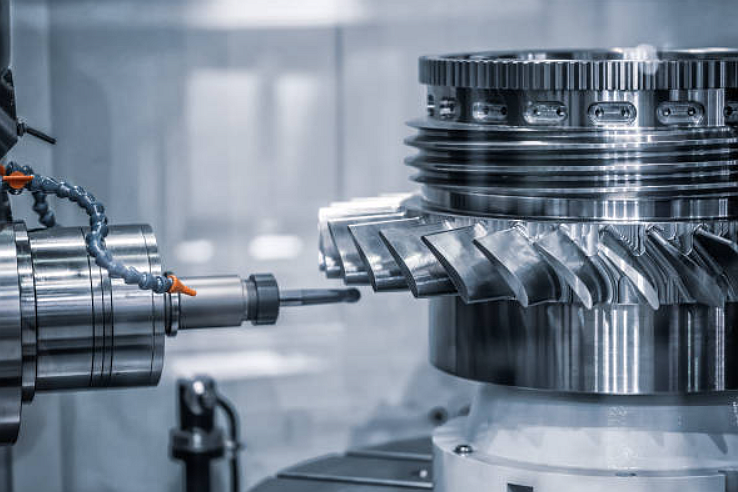

Power Generation Parts Machining

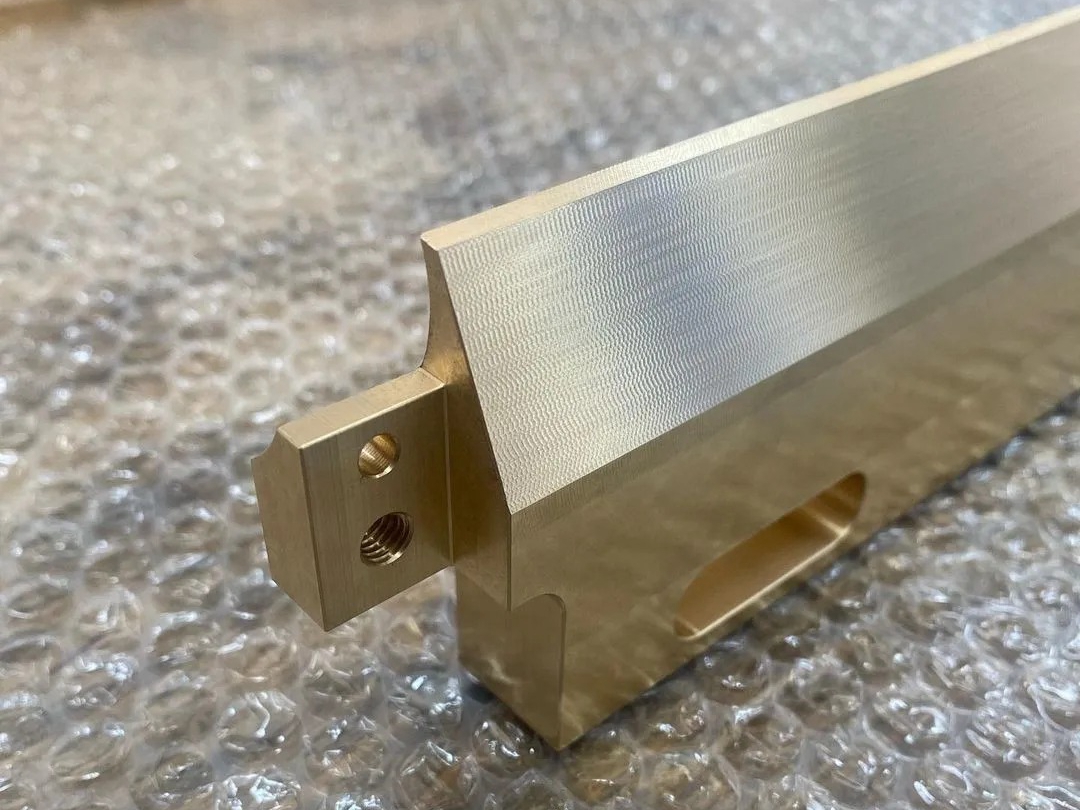

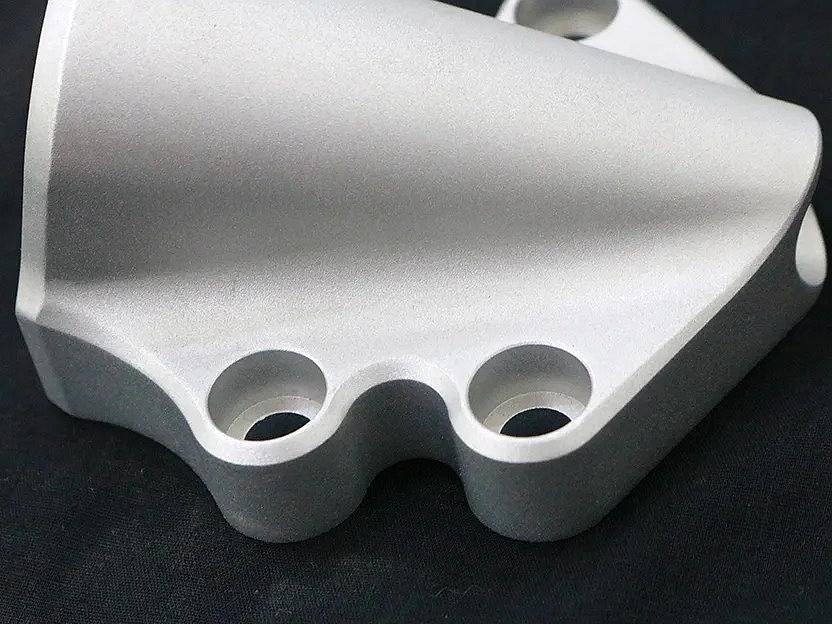

Our Power Generation Parts Machining services deliver precision-engineered components for power plants, utilizing advanced CNC processes such as Milling, Turning, Drilling, Boring, Grinding, and Multi-Axis Machining. With Electrical Discharge Machining (EDM) for intricate designs, we ensure high-quality, durable parts that meet the demanding performance and safety standards of the power generation industry for reliable, efficient operations.

Power Generation Material Selection

In power generation, high-performance materials like superalloys, titanium, aluminum, copper, brass, bronze, carbon steel, stainless steel, plastic, and ceramic are essential for manufacturing durable, heat-resistant, and corrosion-resistant components in turbines, generators, heat exchangers, and electrical systems.

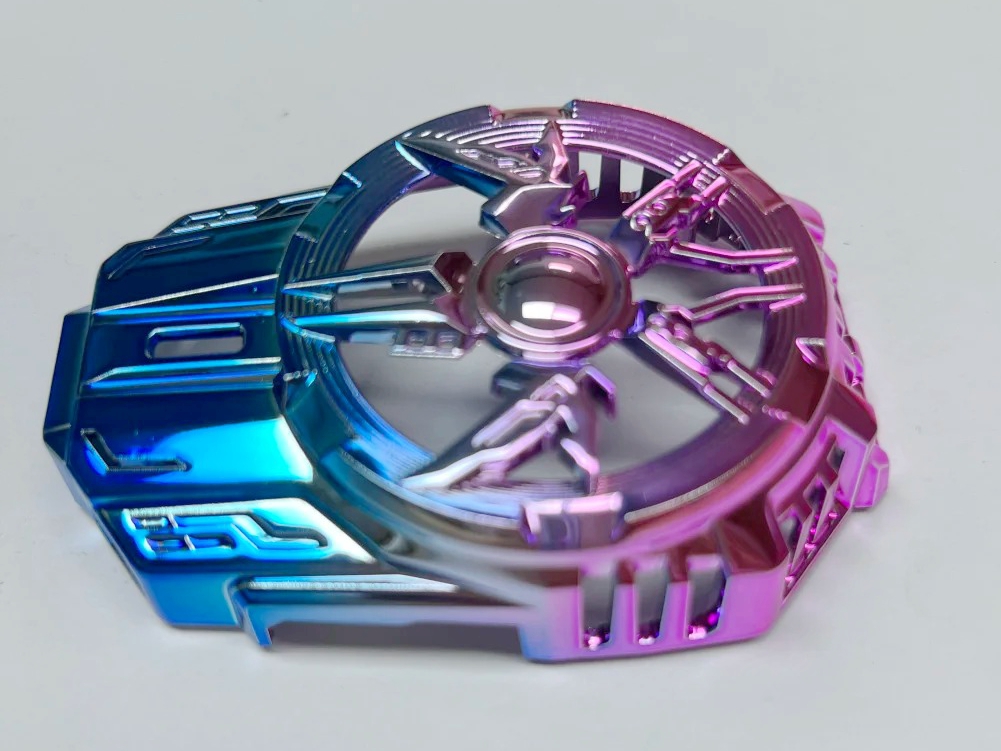

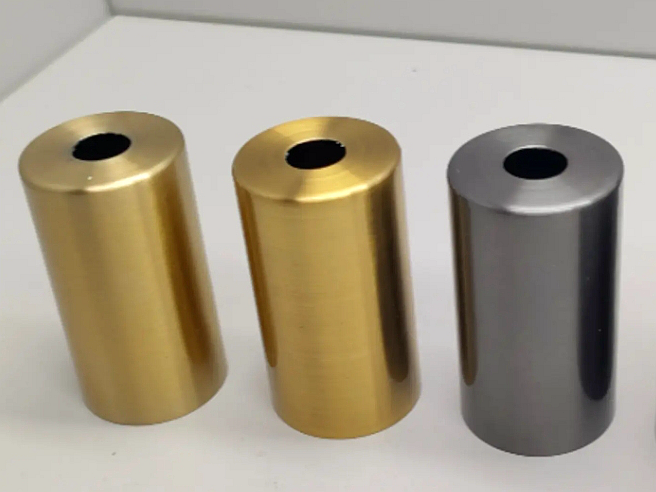

Surface Treatment for Power Generation Industry

Surface treatments in the power generation industry enhance the durability, corrosion resistance, and performance of components exposed to extreme conditions. Techniques like thermal coating, anodizing, electroplating, and PVD protect parts from wear, heat, and oxidation. These processes ensure reliability, reduce maintenance costs, and extend the lifespan of critical equipment, such as turbines, heat exchangers, and valves.

learn more

Thermal Coating

learn more

As Machined

learn more

Painting

learn more

PVD (Physical Vapor Deposition)

learn more

Sandblasting

learn more

Electroplating

learn more

Polishing

learn more

Anodizing

learn more

Powder Coating

learn more

Electropolishing

learn more

Passivation

learn more

Brushing

learn more

Black Oxide

learn more

Heat Treatment

learn more

Thermal Barrier Coating (TBC)

learn more

Tumbling

learn more

Alodine

learn more

Chrome Plating

learn more

Phosphating

learn more

Nitriding

learn more

Galvanizing

learn more

UV Coating

learn more

Lacquer Coating

learn more

Teflon Coating

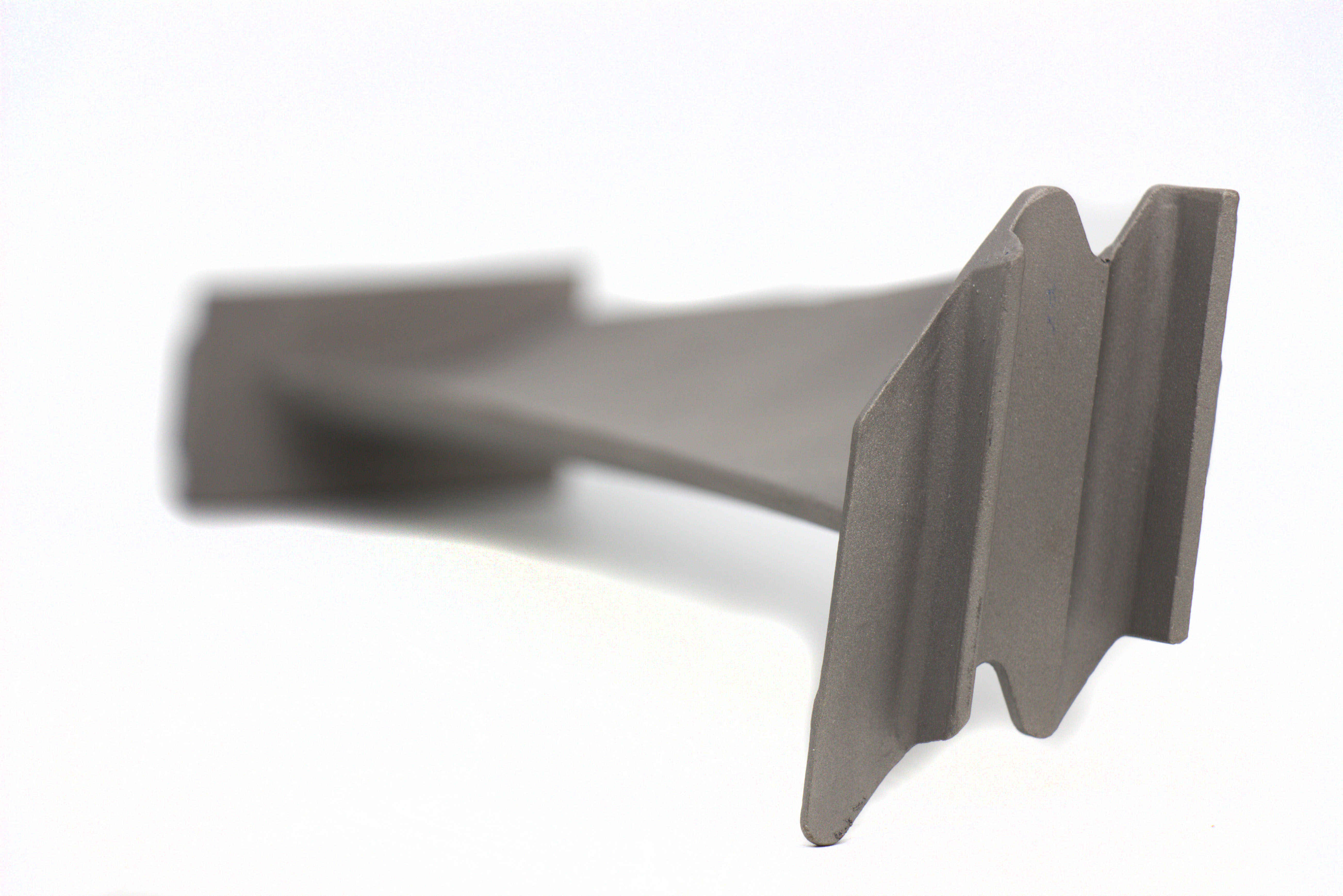

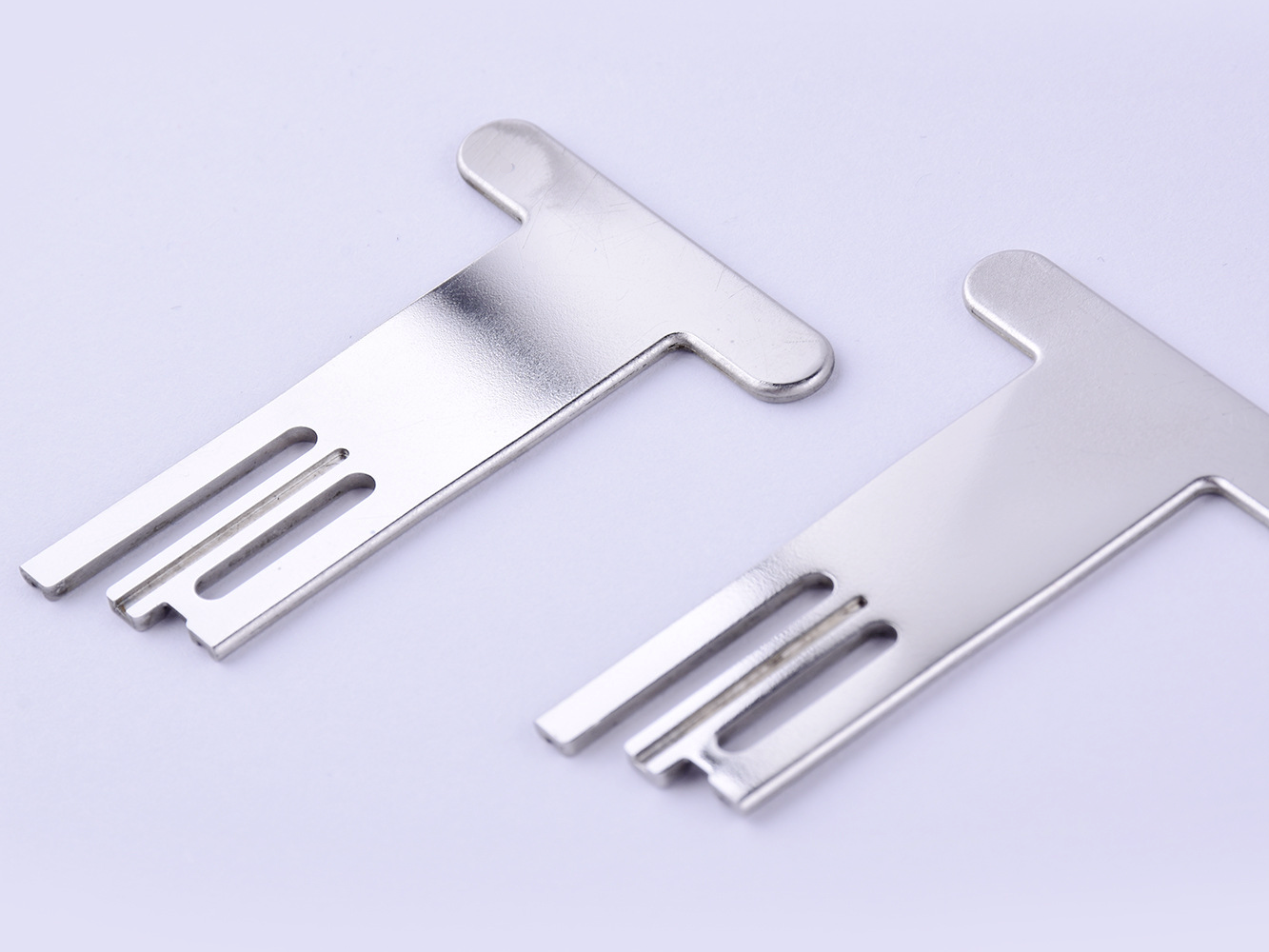

CNC Machined Parts for Power Generation Systems

CNC machining is essential in power generation, producing parts like turbine blades, generator components, and heat exchangers, which are designed for reliability and efficiency in energy production.

Let's Start A New Project Today

Aviation Parts Manufacturing Methods Suggestions

Consider part complexity, material choice, and required precision when selecting manufacturing methods. For high-performance parts, choose Superalloy, Metal, or Ceramic for 3D printing, CNC machining, or precision casting. Injection molding is ideal for high-volume plastic or metal components. Rapid prototyping, laser cutting, and sheet metal fabrication ensure efficient development and precision in critical applications.