Custom Online CNC Boring Manufacturing Service

Our Custom Online CNC Boring Manufacturing Service offers precision boring for complex parts, with tight tolerances and smooth finishes. We provide online ordering, fast turnaround, and customization options, ensuring high-quality, cost-effective solutions for various industrial applications.

- Rapid Boring Prototyping Service

- Low Volume CNC Boring Service

- CNC Boring Mass Production Service

- One Stop CNC Boring Service

Send us your designs and specifications for a free quotation

All uploaded files are secure and confidential

What Is CNC Boring Manufacturing

CNC Boring Manufacturing involves precision enlarging and shaping existing holes using CNC machinery. This process ensures tight tolerances, smooth finishes, and enhanced hole accuracy, making it ideal for creating cylindrical parts, improving dimensional accuracy, and achieving high-quality results.

Key Materials for Precision CNC Boring

CNC boring is commonly performed on a variety of materials, each offering unique properties. Superalloys and titanium are used for high-temperature applications, while aluminum, copper, brass, and bronze provide excellent machinability and corrosion resistance. Carbon and stainless steel offer strength and durability, while plastics and ceramics are ideal for lightweight and precise components in specialized industries.

Surface Finishings for CNC Boring Parts

Surface Finishings for CNC Boring Parts enhance the functionality and aesthetics of machined components. Options include polished, ground, and smooth finishes, ensuring tight tolerances, reduced friction, and optimal performance. These finishes are essential for precision parts across various industries.

learn more

Thermal Coating

learn more

As Machined

learn more

Painting

learn more

PVD (Physical Vapor Deposition)

learn more

Sandblasting

learn more

Electroplating

learn more

Polishing

learn more

Anodizing

learn more

Powder Coating

learn more

Electropolishing

learn more

Passivation

learn more

Brushing

learn more

Black Oxide

learn more

Heat Treatment

learn more

Thermal Barrier Coating (TBC)

learn more

Tumbling

learn more

Alodine

learn more

Chrome Plating

learn more

Phosphating

learn more

Nitriding

learn more

Galvanizing

learn more

UV Coating

learn more

Lacquer Coating

learn more

Teflon Coating

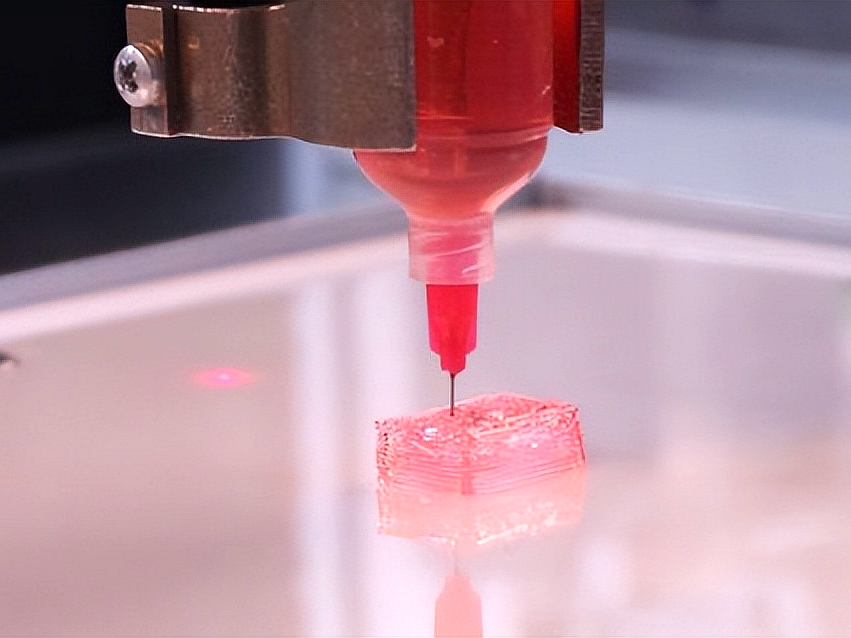

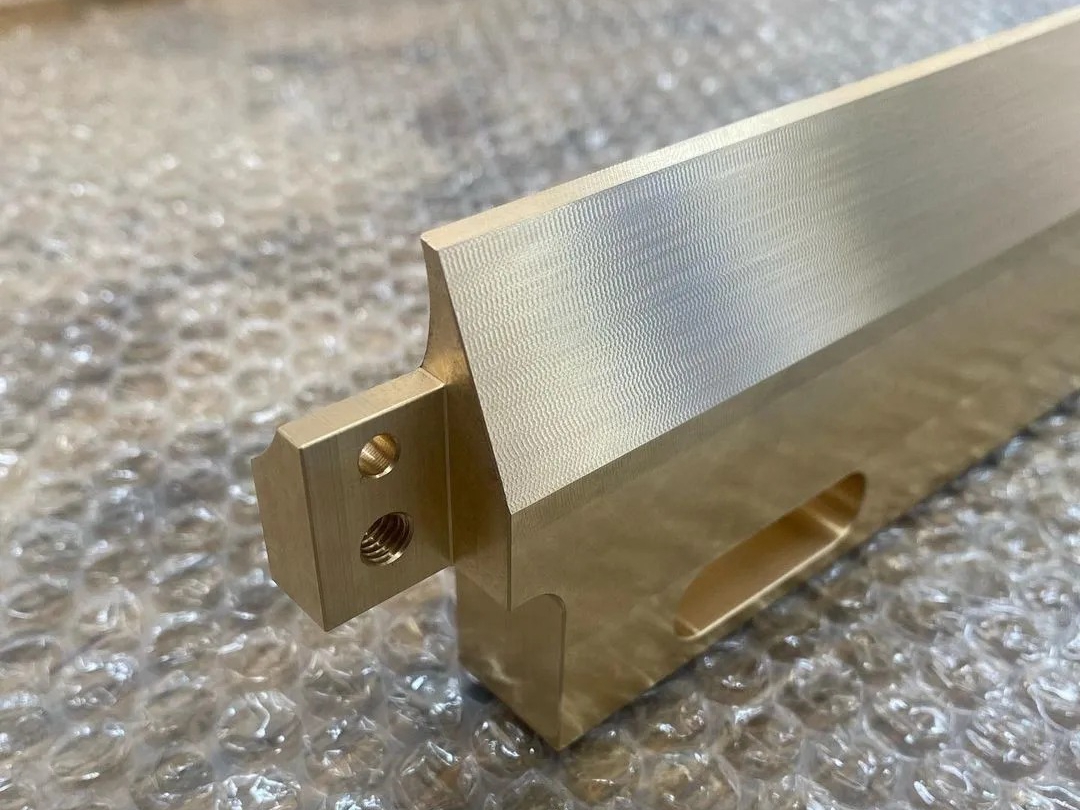

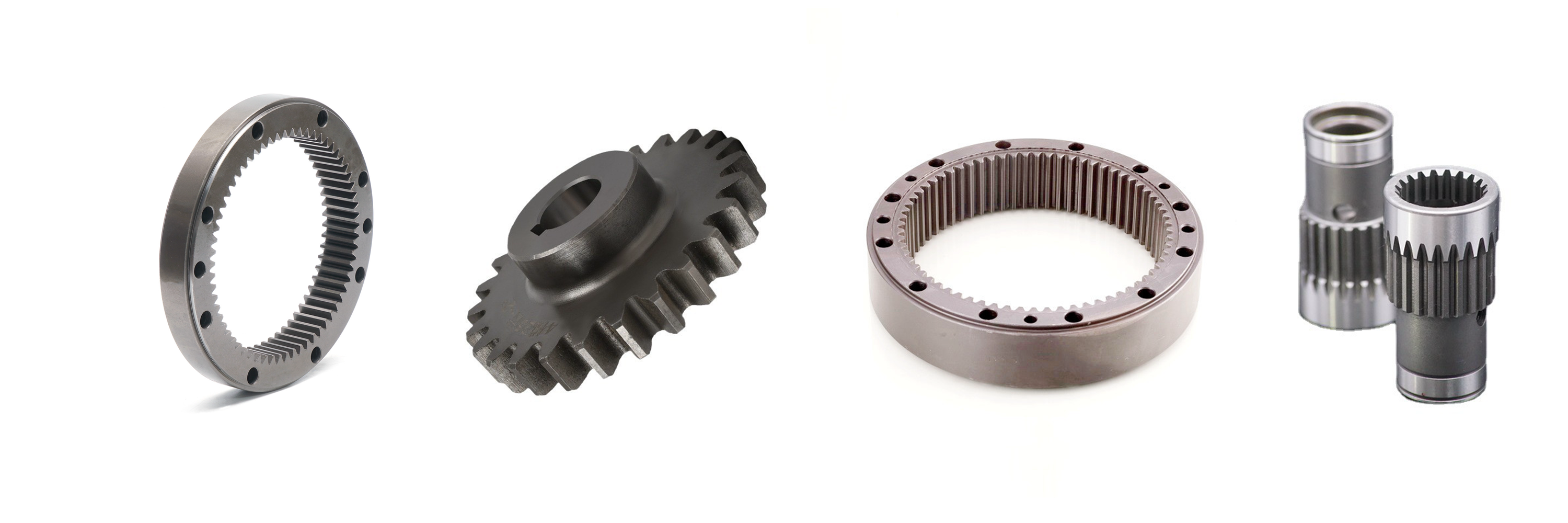

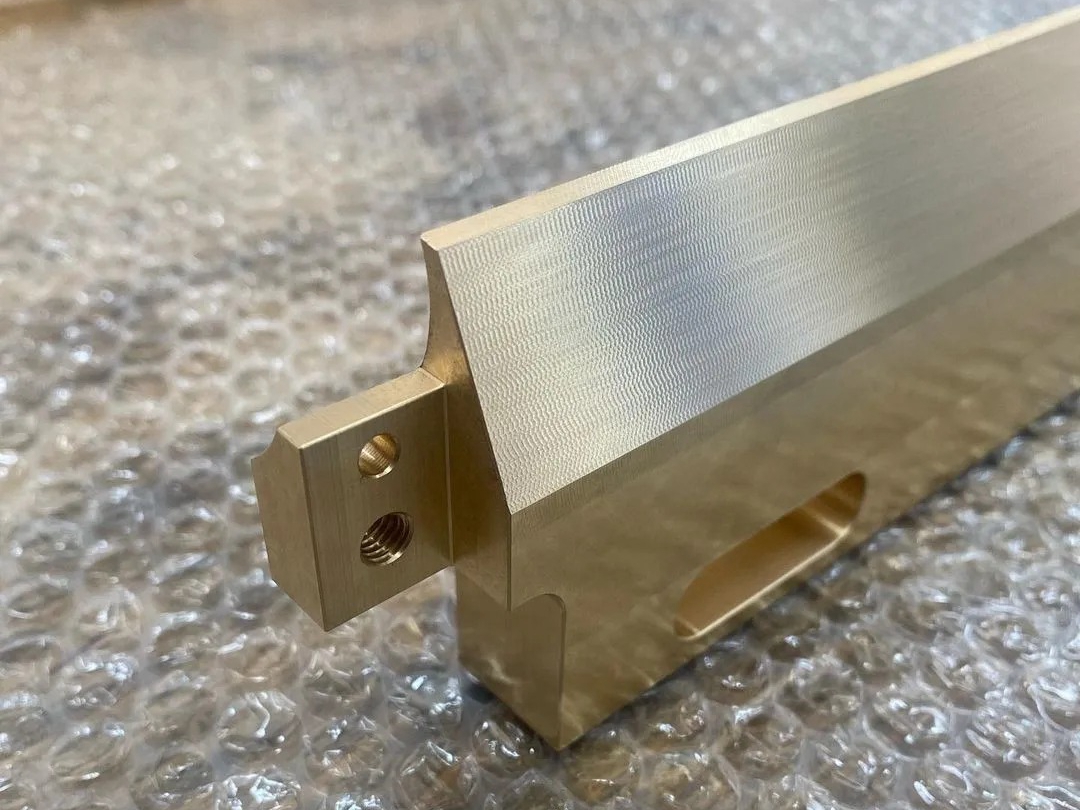

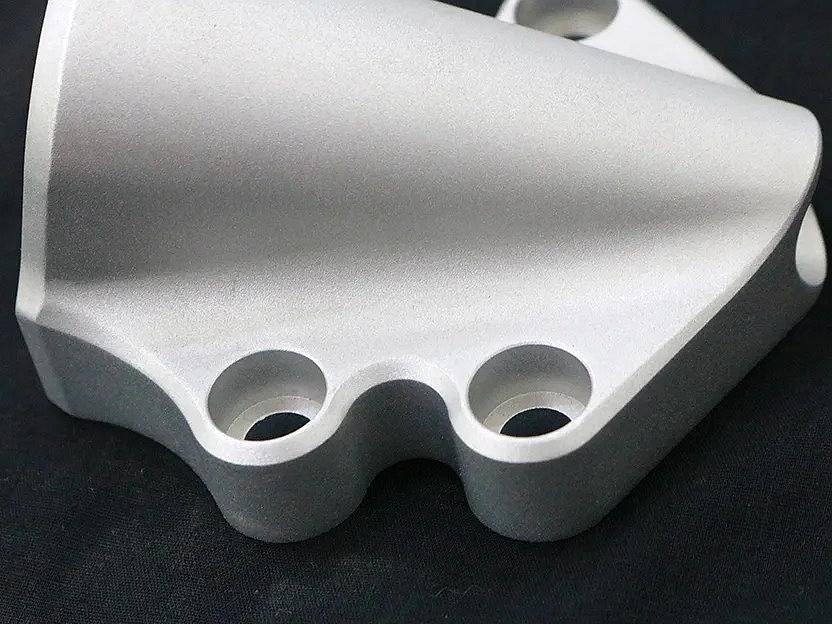

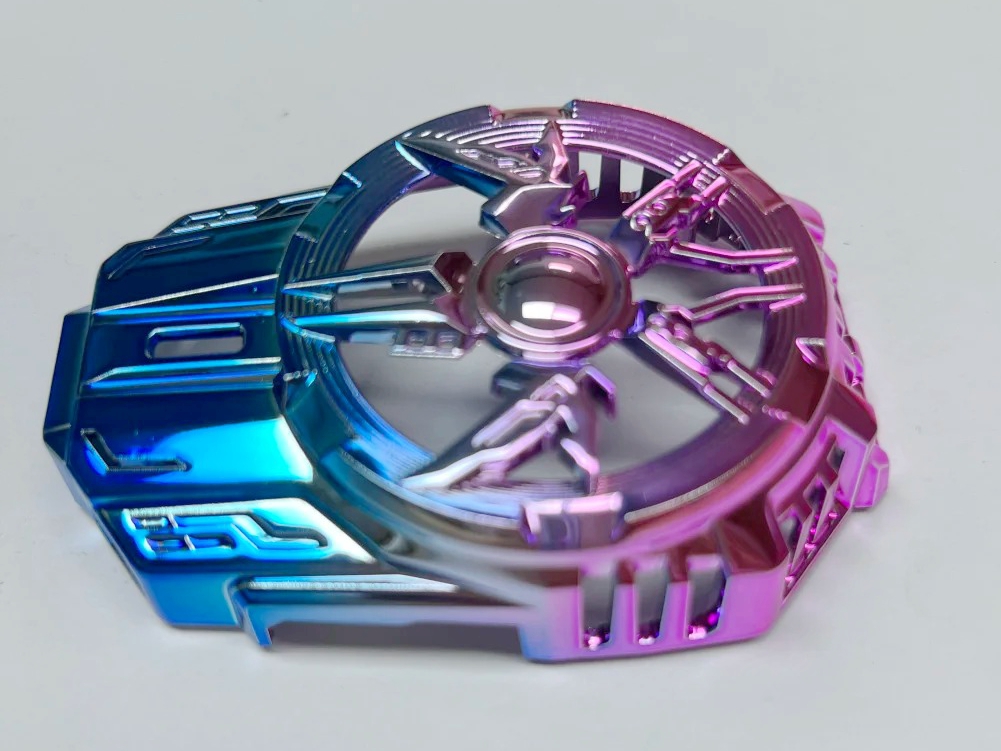

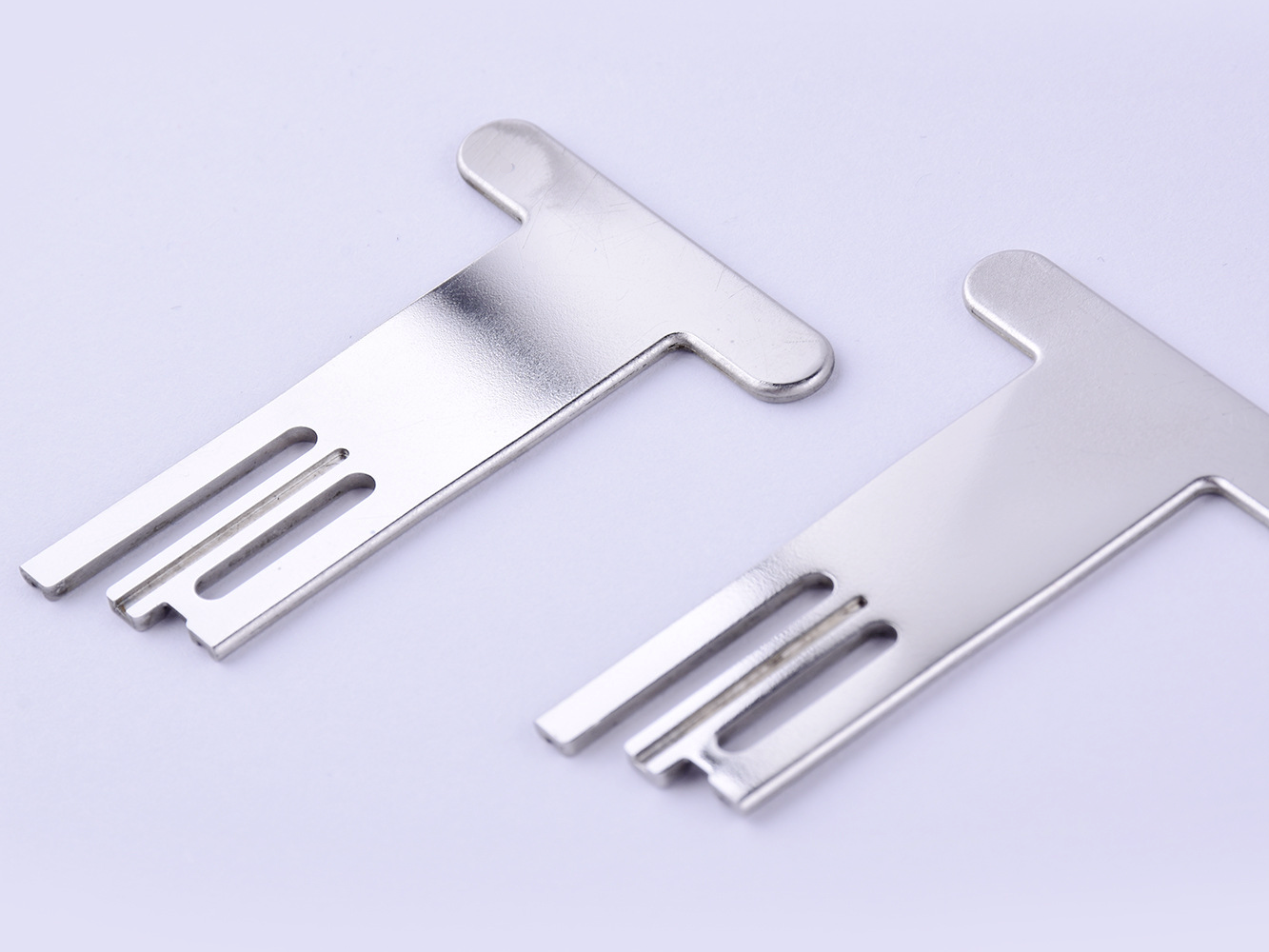

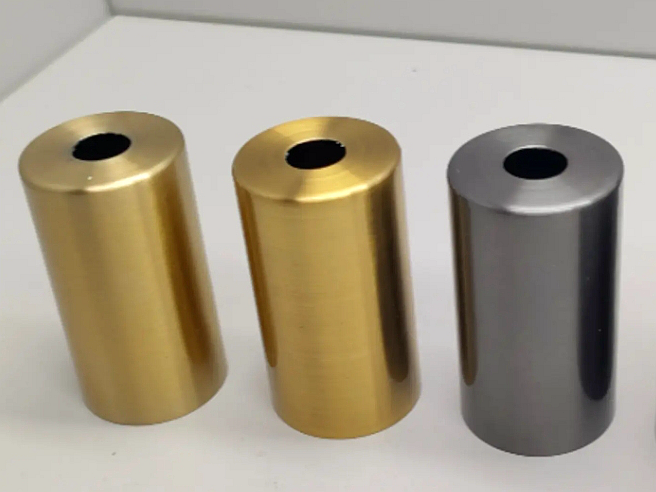

Custom CNC Boring Parts Gallery

Our Custom CNC Boring Parts Gallery showcases precision-engineered components, including cylinders, housings, and shafts, tailored for various industries. Each part highlights tight tolerances, smooth finishes, and exceptional quality, demonstrating our expertise in advanced CNC boring manufacturing solutions.

Let's Start A New Project Today

CNC Boring Tolerance Suggestions

CNC Boring Tolerance Suggestions ensure precision and consistency in machining. For general applications, ±0.1 mm tolerance is standard, while high-precision parts require ±0.02 mm to ±0.05 mm. These guidelines guarantee complex components' optimal fit, performance, and surface quality.

CNC Boring Design Guideline

CNC Boring Design Guidelines outline essential best practices for achieving precise and functional components. Key considerations include optimal radii, hole dimensions, wall thickness, surface finishes, and tool access, ensuring accuracy, efficiency, and quality in CNC boring operations.