Precision Online Custom_ CNC Grinding Service

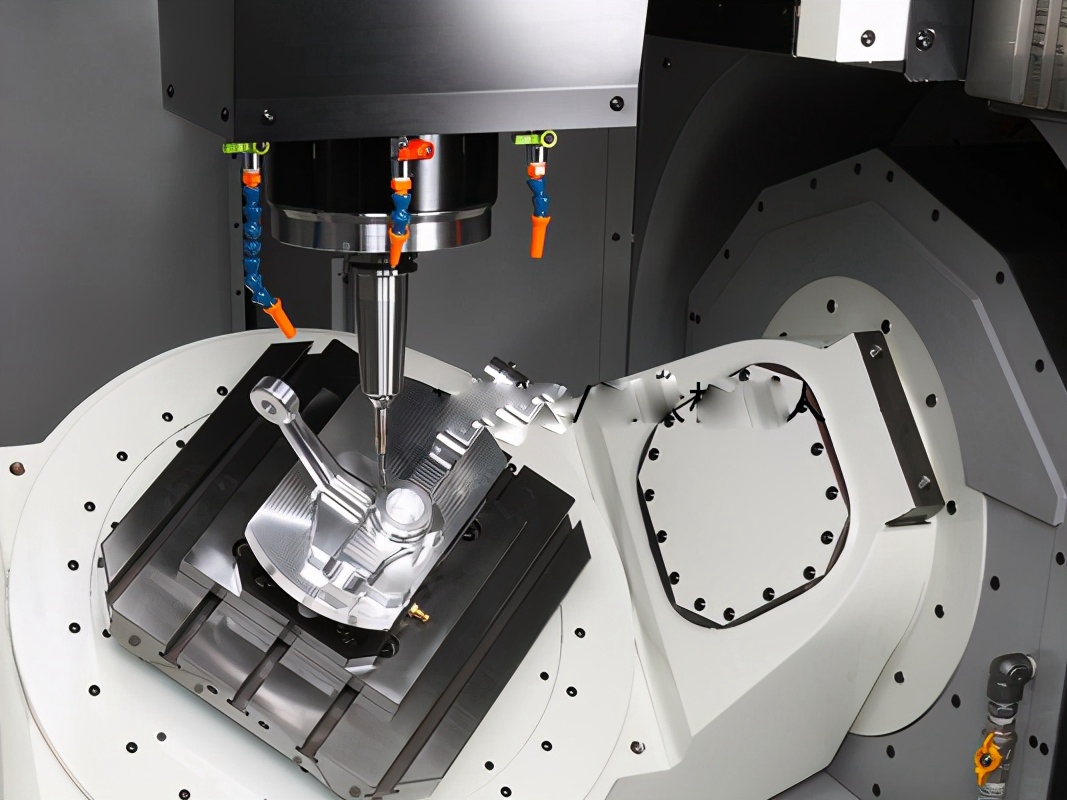

Our On-Demand Precision CNC Milling Service is tailored to meet the most exacting standards for industries requiring high-quality, reliable, and efficient superalloys, ceramic, stainless steel, aluminum, and titanium parts CNC milling solutions.

- Rapid CNC Grinding Prototyping Service

- Low Volume CNC Grinding Service

- CNC Grinding Mass Production Service

- One Stop CNC Grinding Service

Send us your designs and specifications for a free quotation

All uploaded files are secure and confidential

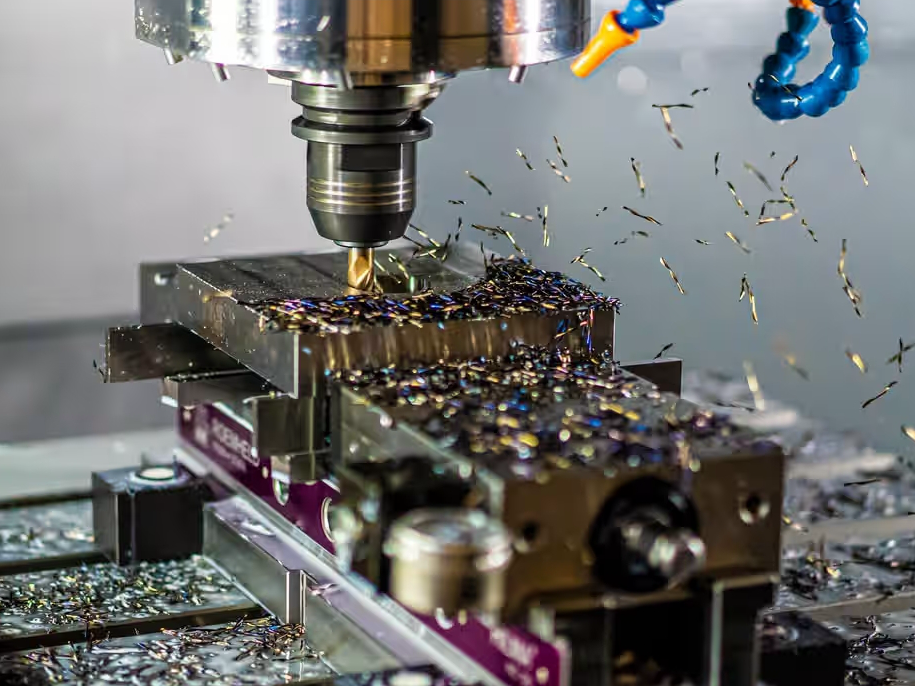

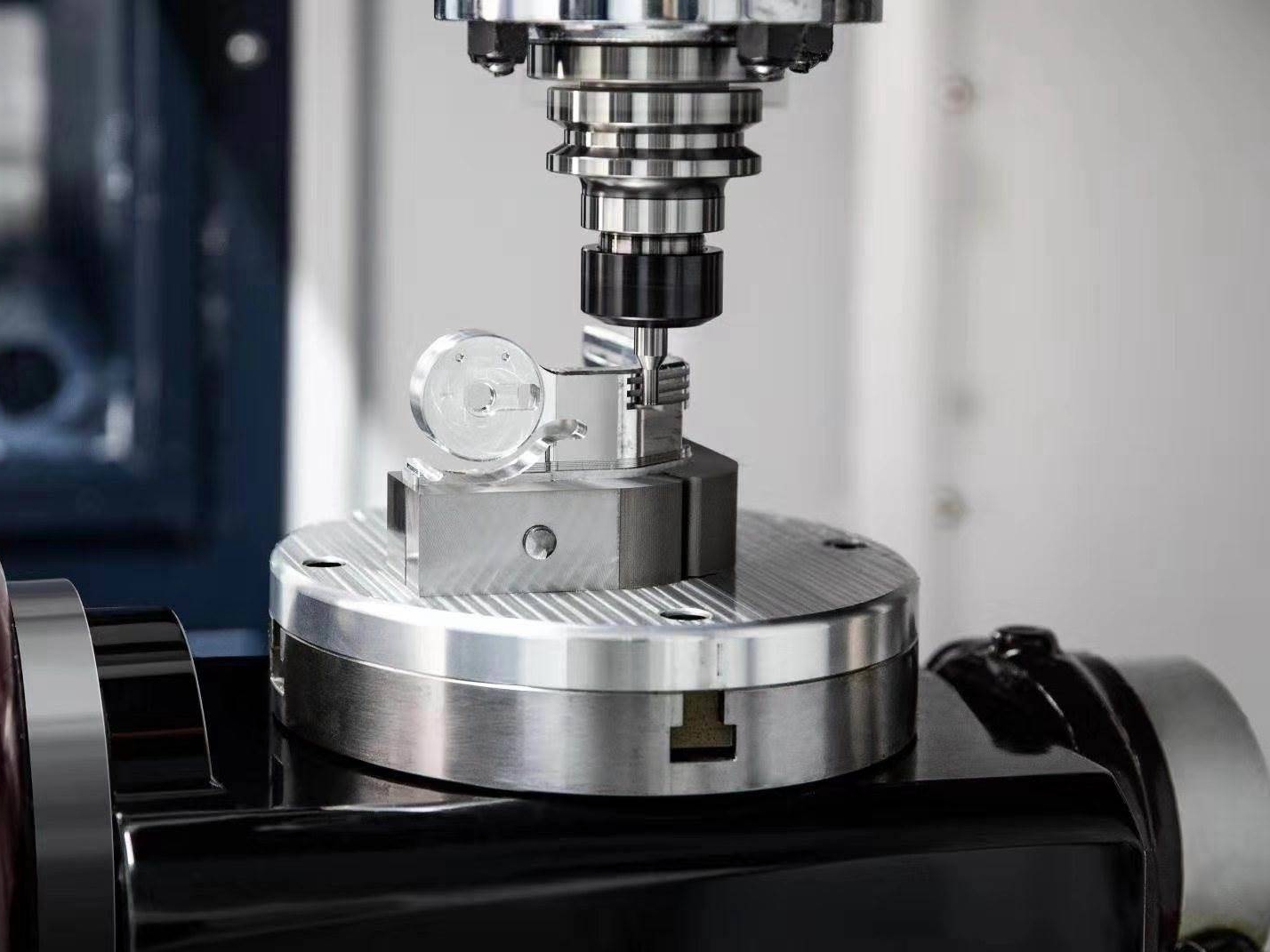

Precision CNC Grinding Applications

Precision CNC Grinding Applications involve high-accuracy machining for parts requiring tight tolerances and smooth finishes. Common applications include gears, shafts, and aerospace components, ensuring optimal performance in industries like aerospace, automotive, medical, and industrial equipment with exceptional precision and surface quality.

Key Materials for Precision CNC Grinding

CNC grinding is widely used for precision machining of materials like superalloy, titanium, aluminum, copper, brass, bronze, carbon steel, stainless steel, plastic, and ceramic. These materials are selected for their durability, strength, and versatility in various industries. CNC grinding ensures high accuracy, smooth finishes, and tight tolerances, making it ideal for complex and high-performance applications.

Surface Treatment for CNC Grinding Parts

Surface Treatment for CNC Grinding Parts enhances durability, performance, and appearance. Options include polishing, plating, and coating to improve wear resistance, reduce friction, and protect against corrosion, ensuring high-quality finishes for precision components across various industrial applications.

learn more

Thermal Coating

learn more

As Machined

learn more

Painting

learn more

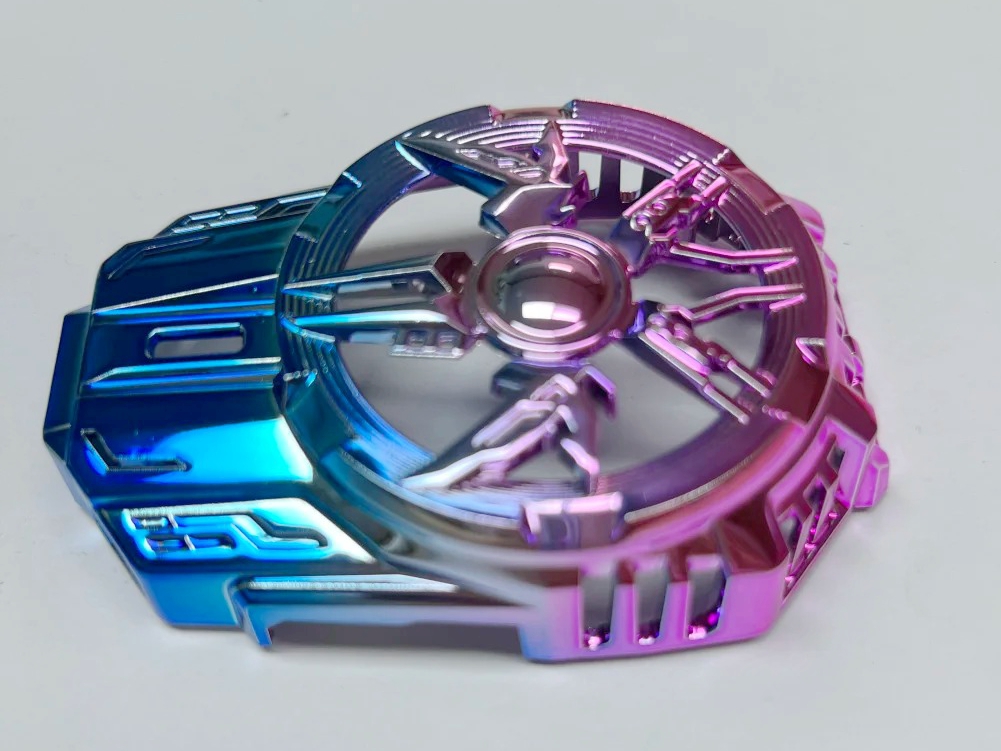

PVD (Physical Vapor Deposition)

learn more

Sandblasting

learn more

Electroplating

learn more

Polishing

learn more

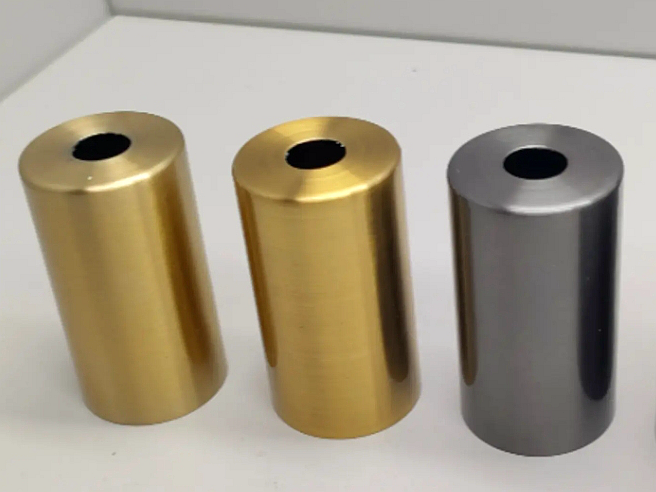

Anodizing

learn more

Powder Coating

learn more

Electropolishing

learn more

Passivation

learn more

Brushing

learn more

Black Oxide

learn more

Heat Treatment

learn more

Thermal Barrier Coating (TBC)

learn more

Tumbling

learn more

Alodine

learn more

Chrome Plating

learn more

Phosphating

learn more

Nitriding

learn more

Galvanizing

learn more

UV Coating

learn more

Lacquer Coating

learn more

Teflon Coating

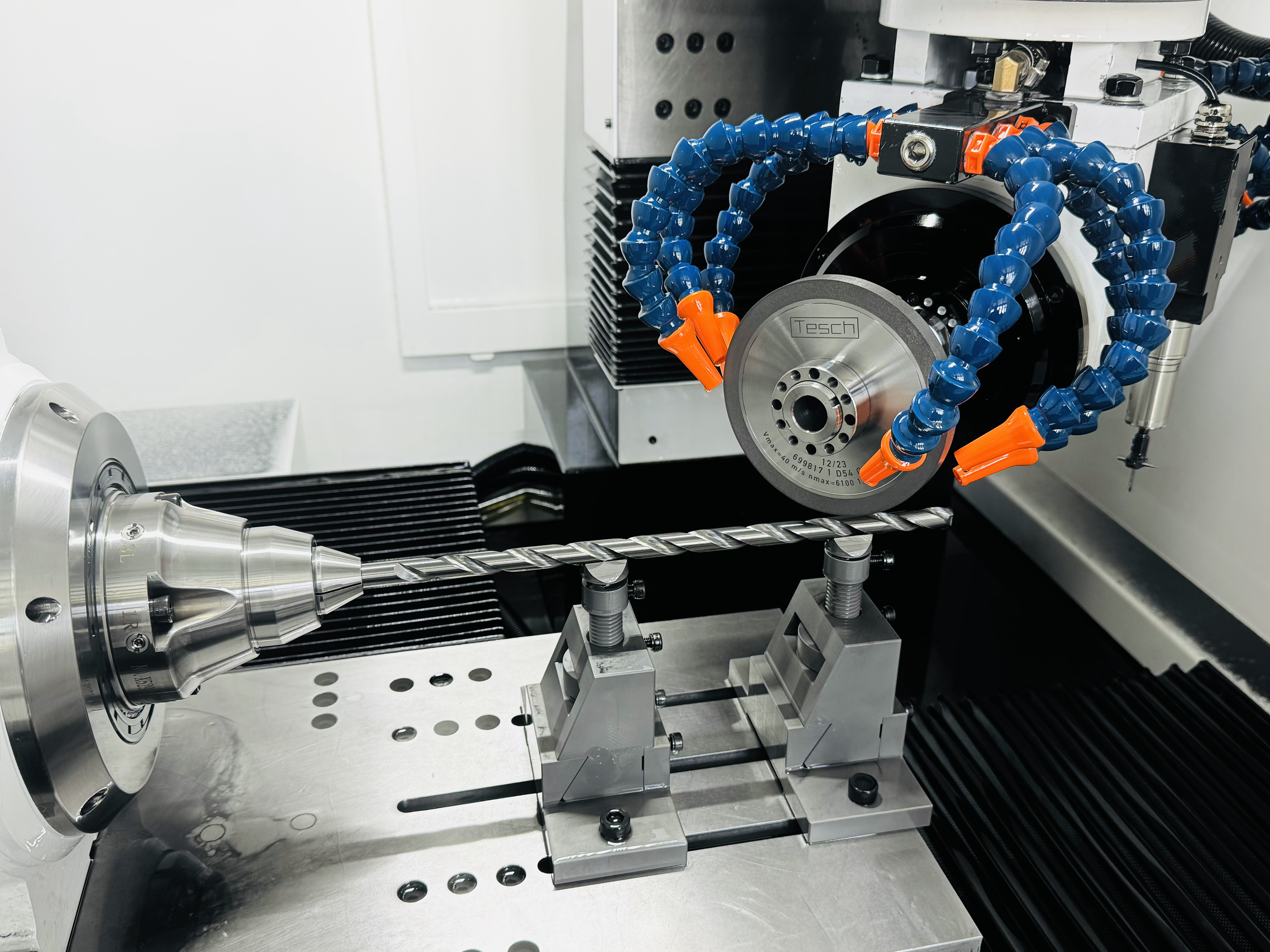

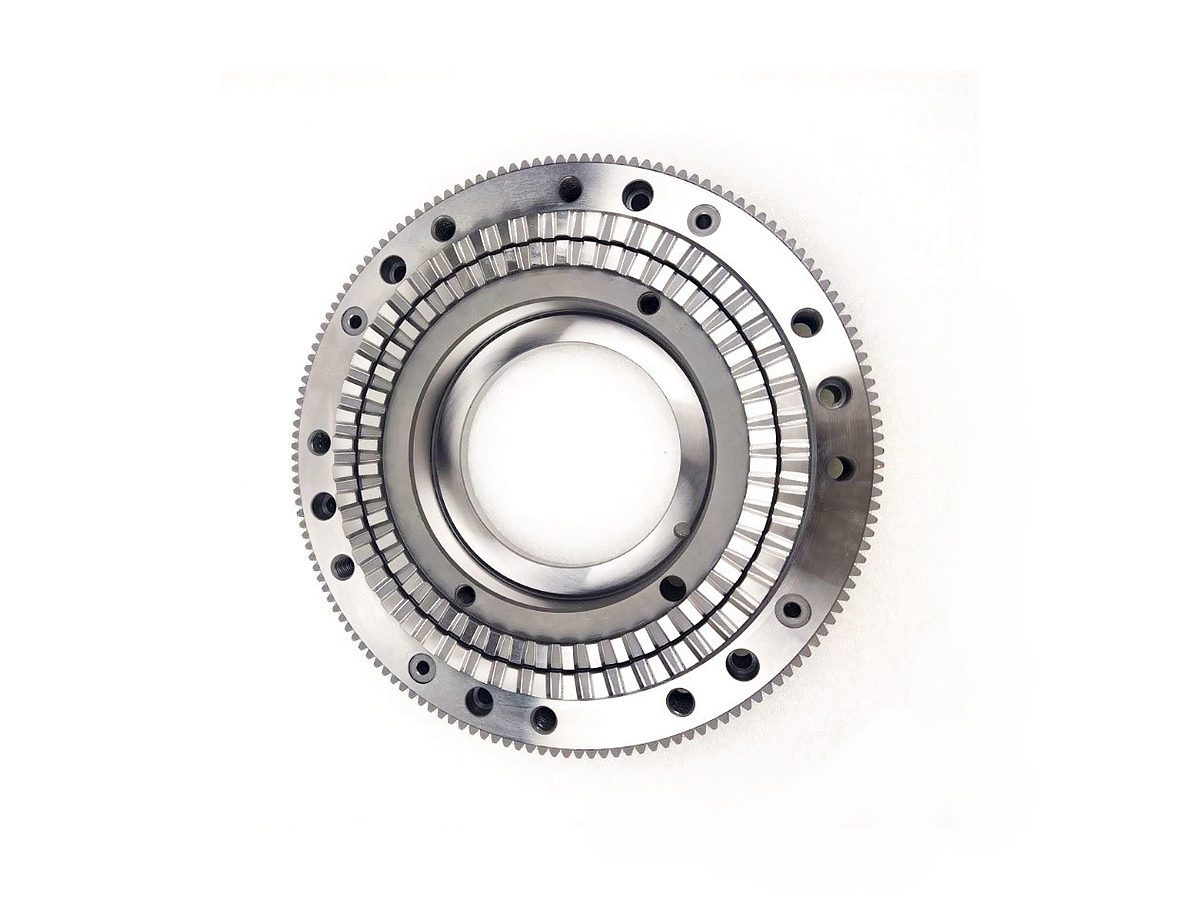

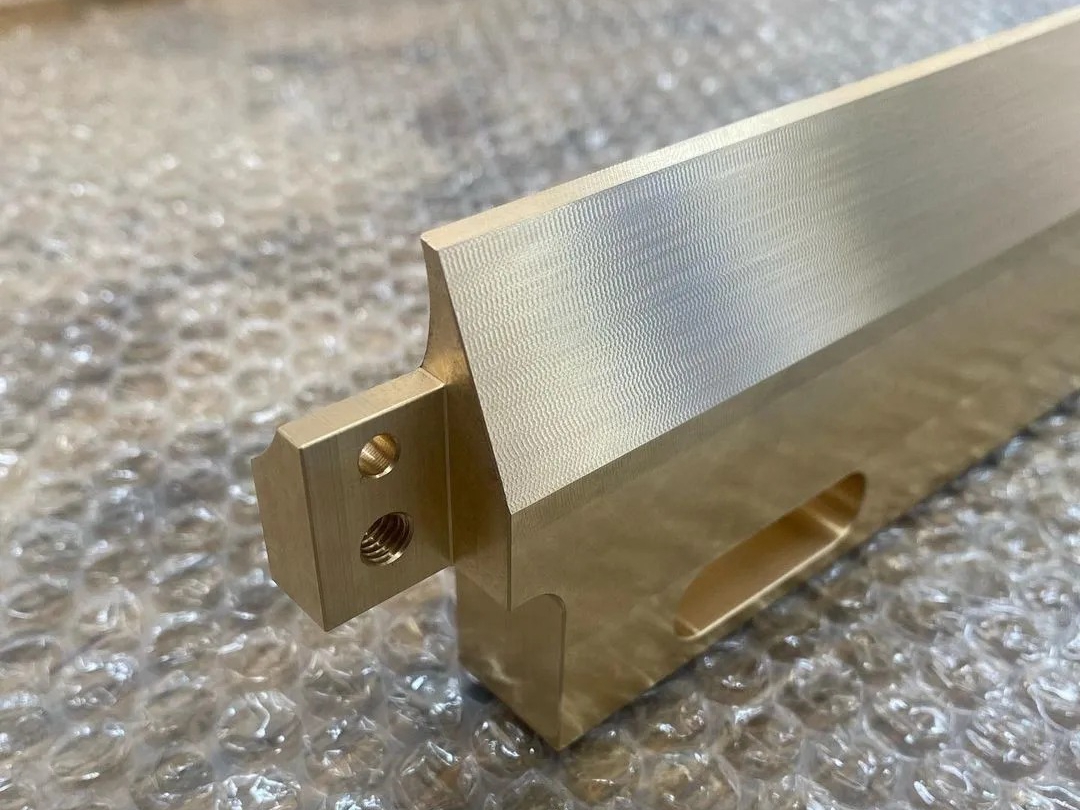

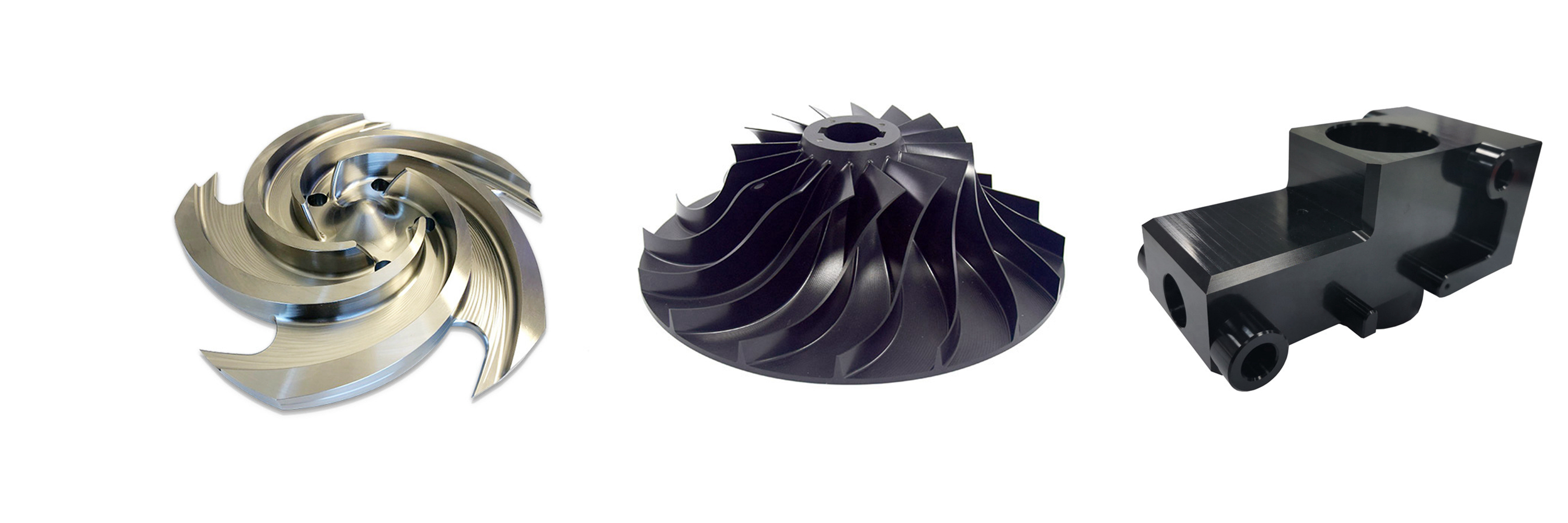

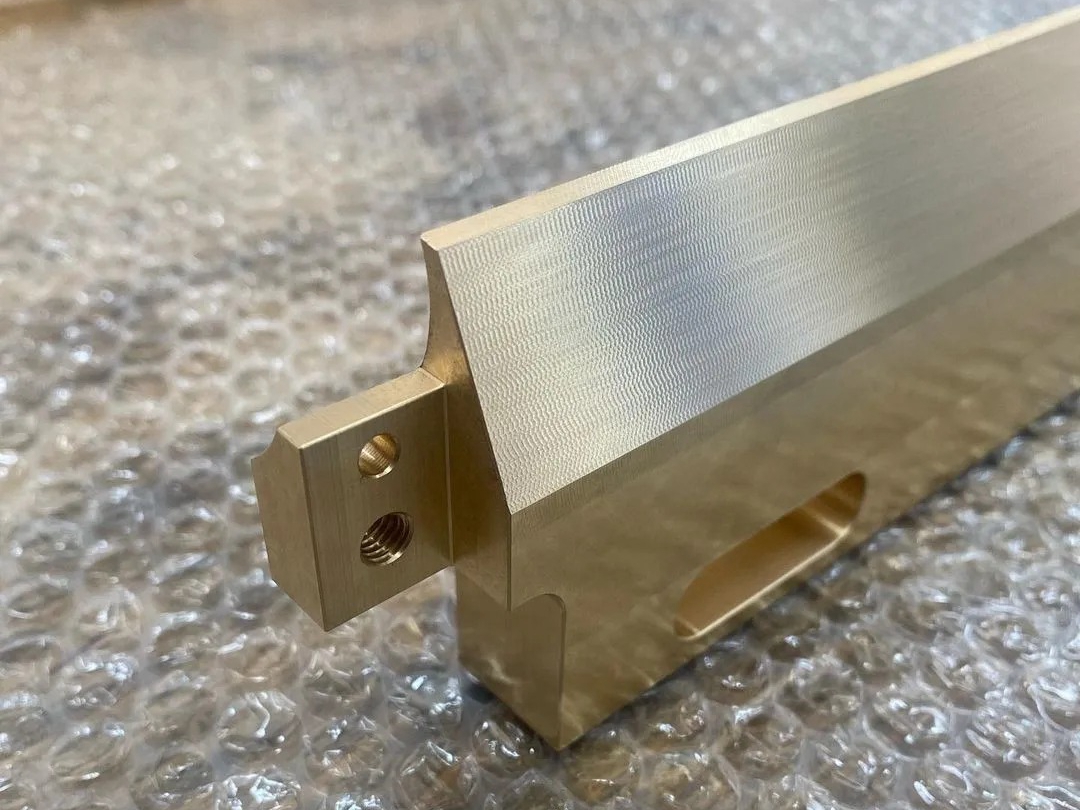

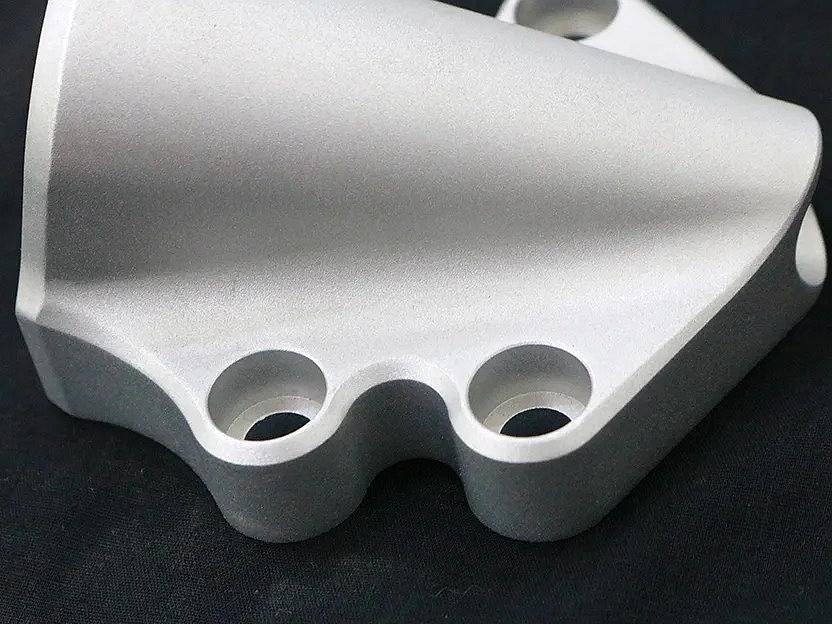

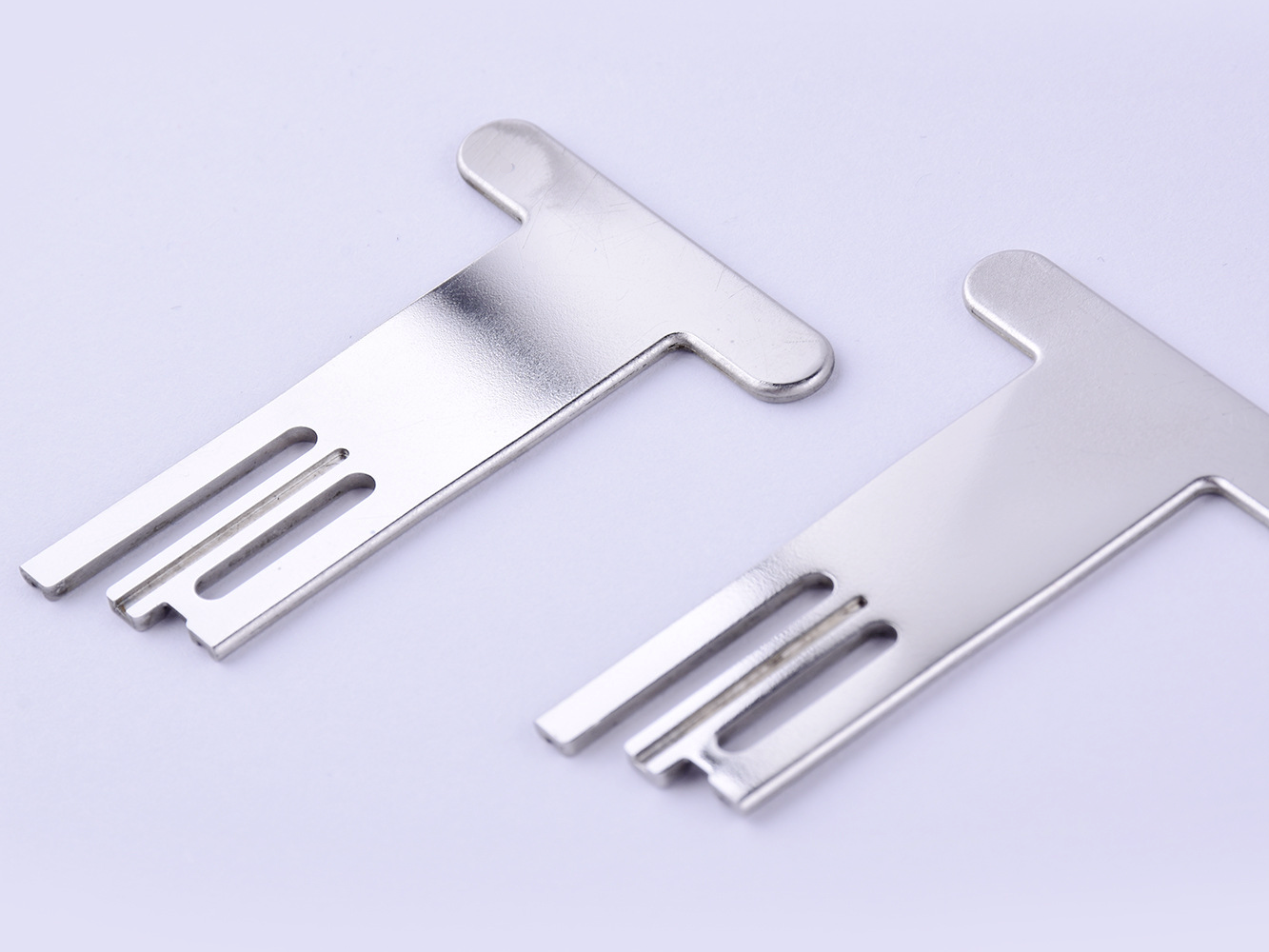

Custom CNC Grinding Components Gallery

Our Custom CNC Grinding Components Gallery showcases precision-engineered parts, including gears, shafts, and bearings, crafted with exceptional accuracy and smooth finishes. Each component demonstrates our expertise in meeting tight tolerances and complex specifications for diverse industrial applications.

Let's Start A New Project Today

CNC Grinding Tolerance

CNC Grinding Tolerance ensures precise dimensions and high-quality finishes for critical components. General tolerances range from ±0.1 mm, while precision grinding achieves ±0.005 mm to ±0.02 mm, meeting the exacting demands of industries like aerospace, automotive, and medical.

CNC Grinding Design Guideline

CNC Grinding Design Guideline ensures optimal machining efficiency and high-precision results. Key considerations include radii, hole design, surface finish, tolerances, and wall thickness, enabling precise component production for industries like aerospace, automotive, and medical with superior surface quality.