Online CNC Turning Manufacturing Service

Our Custom CNC Turning Manufacturing Service offers precision machining of complex parts using advanced turning technology. We produce high-quality components from various materials, including metals and plastics, with tight tolerances and fast turnaround to meet specific customer requirements.

- Rapid CNC Turning Prototyping Service

- Low Volume CNC Turning Service

- CNC Turning Mass Production Service

- One Stop CNC Turning Service

Send us your designs and specifications for a free quotation

All uploaded files are secure and confidential

CNC Turning Applications

Custom CNC Turning Applications include manufacturing precision components for industries like aerospace, automotive, medical, and electronics. Our services cover parts such as shafts, bushings, and fittings, tailored to meet exact specifications with high accuracy and efficiency.

CNC Turning Materials

CNC turning is widely used for machining various materials like superalloy, titanium, aluminum, copper, brass, bronze, carbon steel, stainless steel, plastic, and ceramic. These materials are essential in industries such as aerospace, automotive, medical, oil and gas, and consumer products. CNC turning ensures precision, durability, and high-quality finishes for complex, high-performance components across diverse applications.

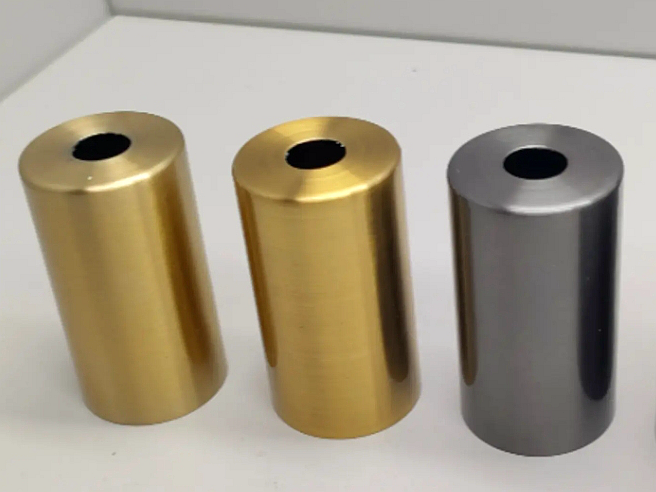

Surface Treatment for CNC Turning Parts

Surface Treatment for CNC Turning Parts enhances durability, corrosion resistance, and surface finish. We offer various treatments, including anodizing, electroplating, powder coating, and polishing, tailored to meet specific industry requirements for high-performance and long-lasting components.

learn more

Thermal Coating

learn more

As Machined

learn more

Painting

learn more

PVD (Physical Vapor Deposition)

learn more

Sandblasting

learn more

Electroplating

learn more

Polishing

learn more

Anodizing

learn more

Powder Coating

learn more

Electropolishing

learn more

Passivation

learn more

Brushing

learn more

Black Oxide

learn more

Heat Treatment

learn more

Thermal Barrier Coating (TBC)

learn more

Tumbling

learn more

Alodine

learn more

Chrome Plating

learn more

Phosphating

learn more

Nitriding

learn more

Galvanizing

learn more

UV Coating

learn more

Lacquer Coating

learn more

Teflon Coating

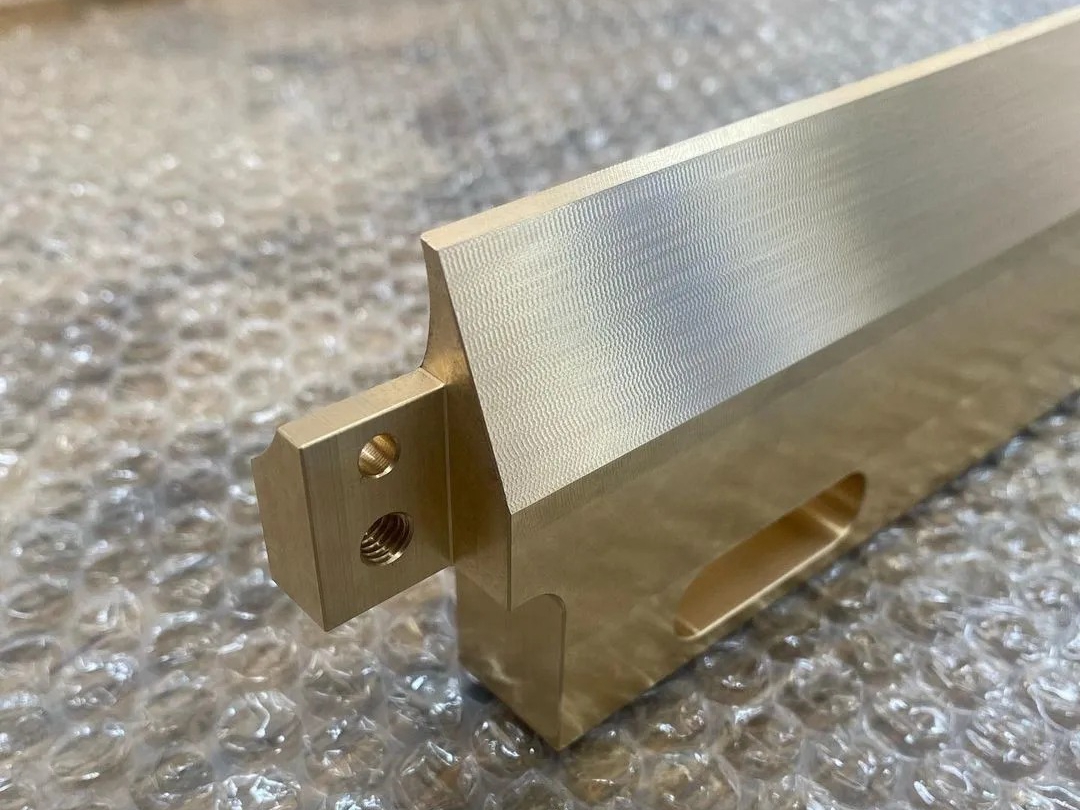

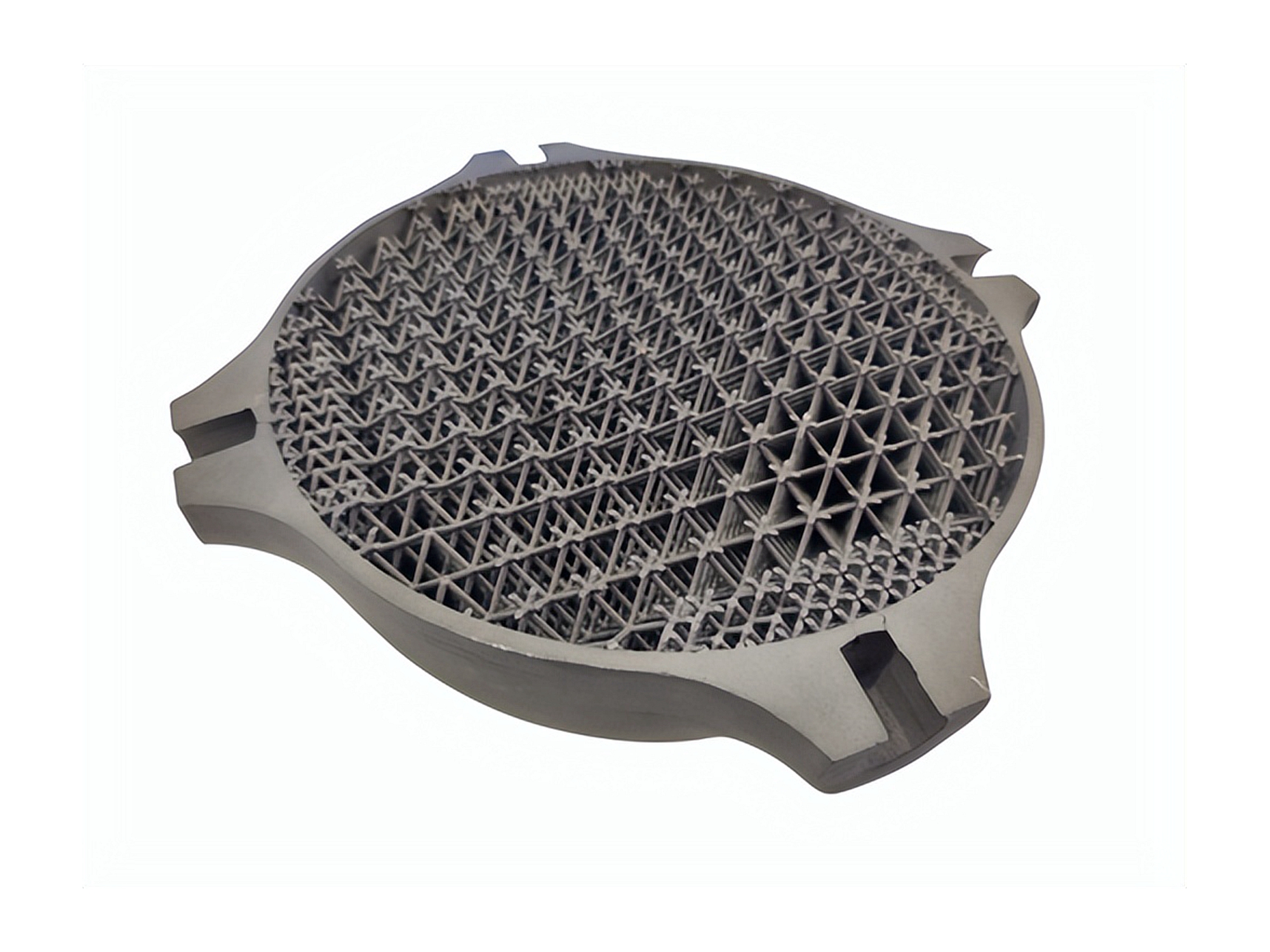

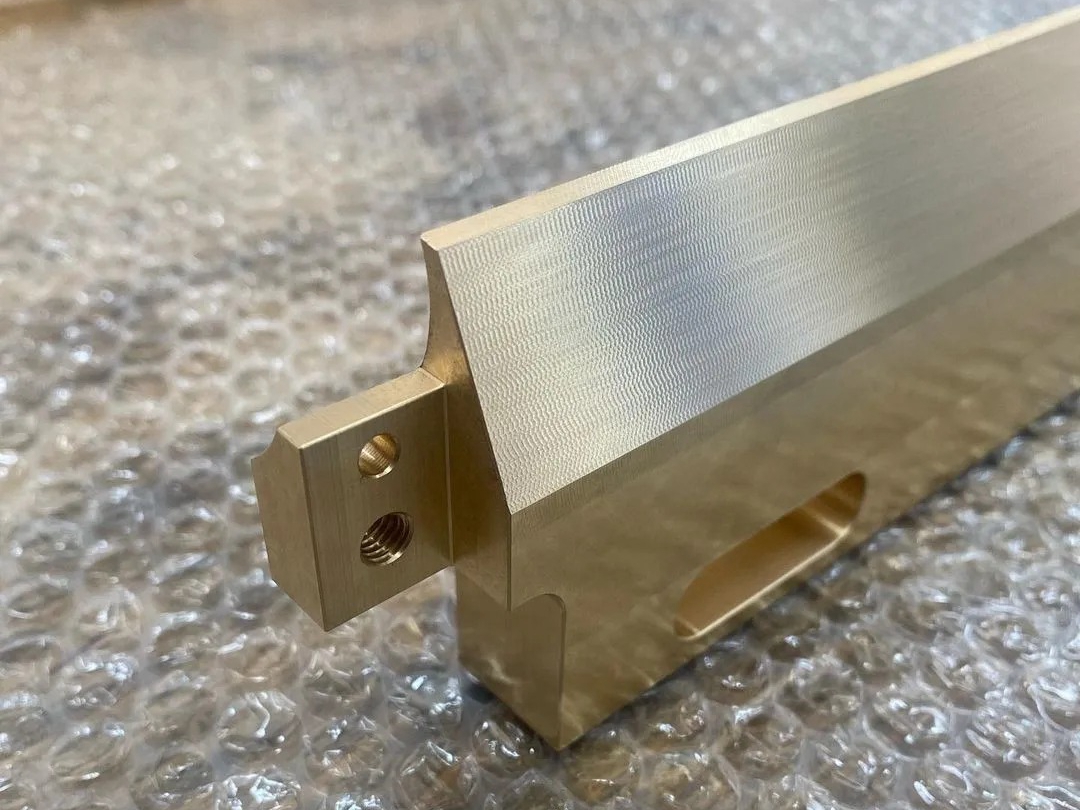

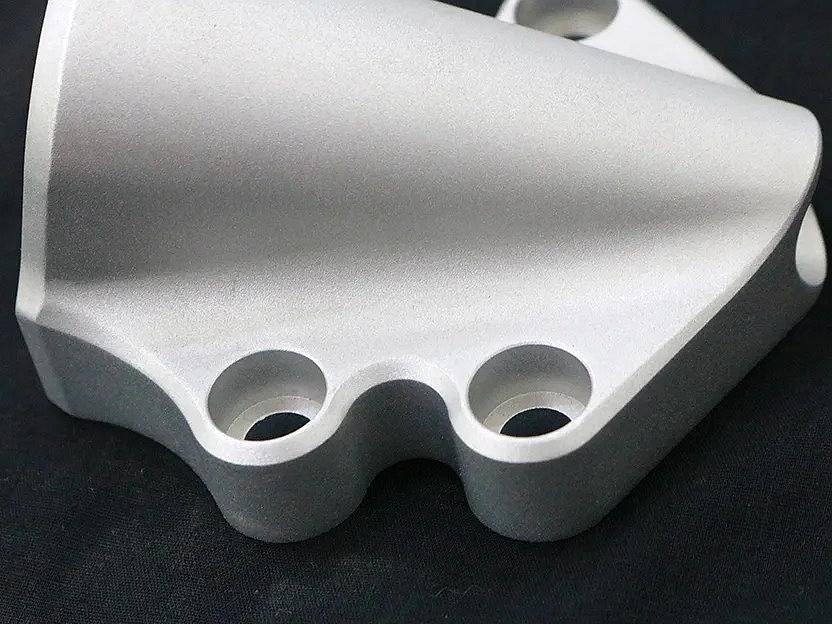

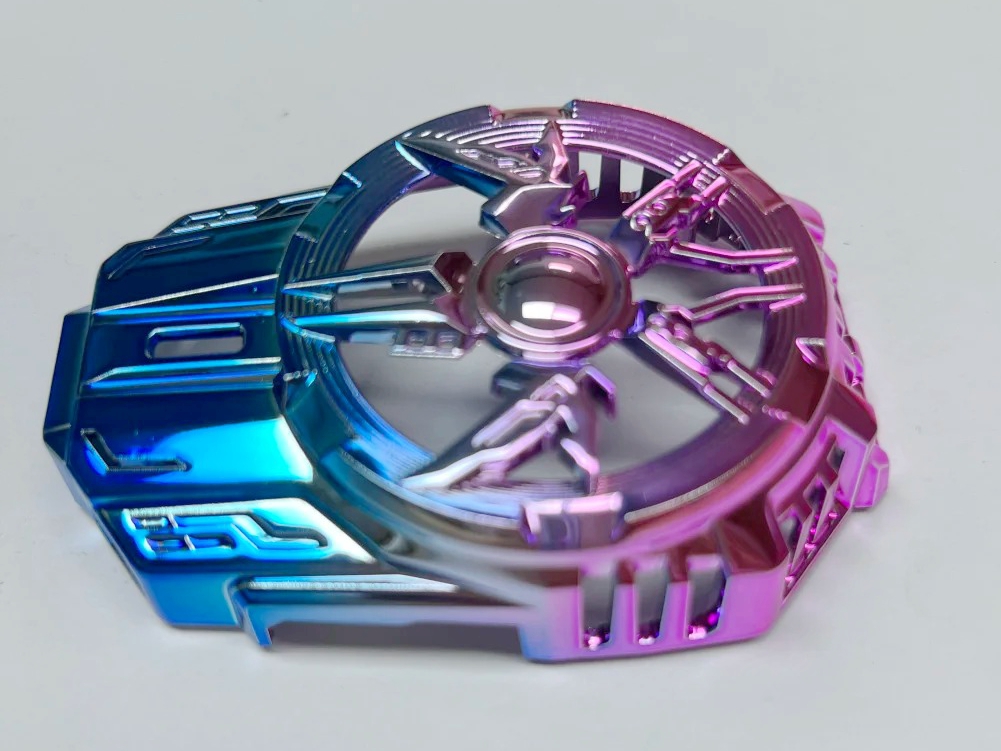

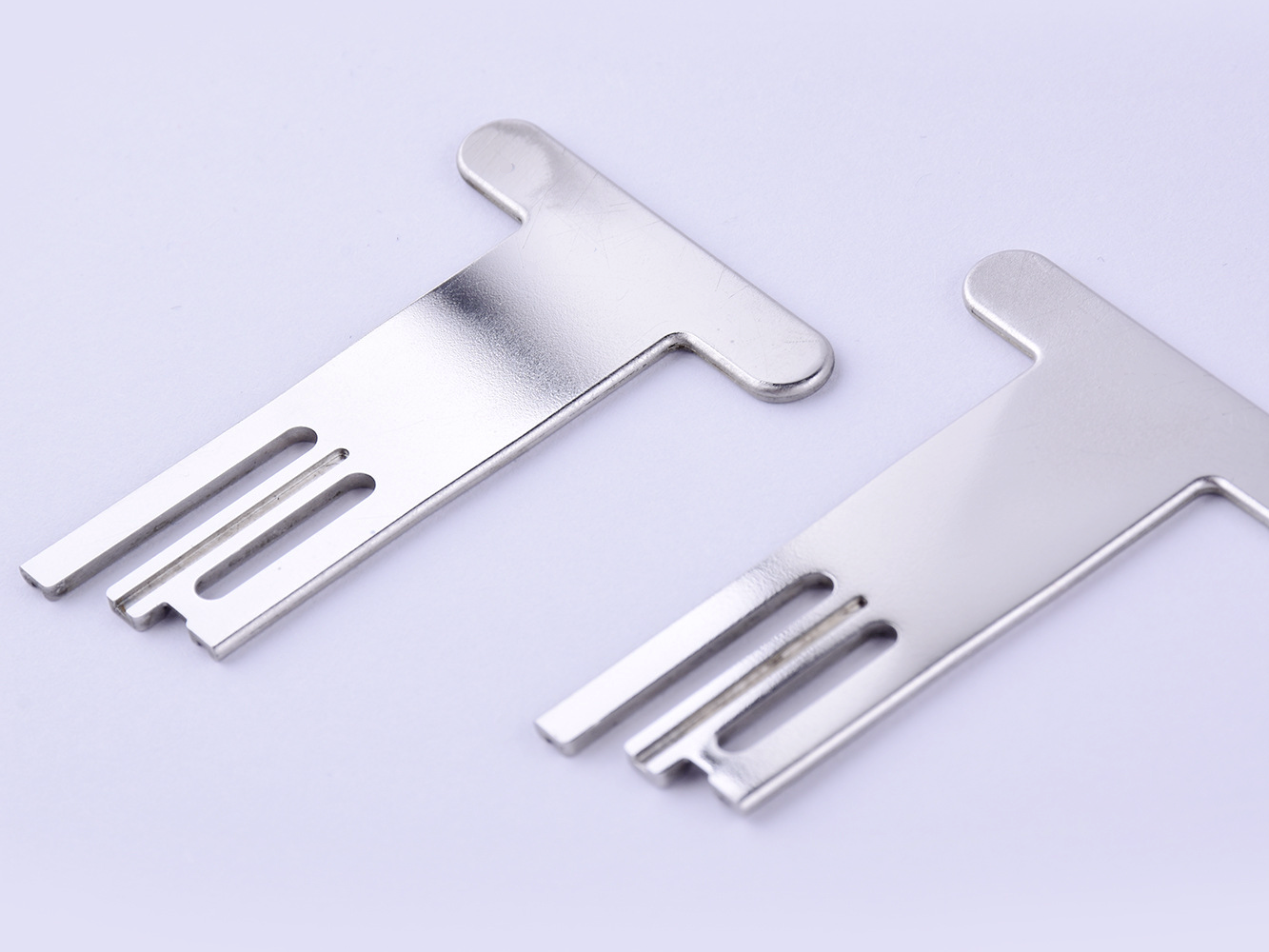

Custom CNC Turning Parts Gallery

Our Custom CNC Turning Parts Gallery showcases a wide range of precision-machined components, including shafts, bushings, and fittings, tailored to meet diverse industry needs. Each part is crafted with high accuracy and attention to detail for optimal performance.

Let's Start A New Project Today

CNC Turning Tolerance Suggestions

CNC Turning Tolerance Suggestions provide guidelines for achieving precise and reliable parts. For general applications, a tolerance of ±0.1 mm is standard, while precision parts can achieve tolerances as tight as ±0.02 mm, depending on design complexity and material choice.

CNC Turning Design Guideline

CNC Turning Design Guideline offers best practices for creating parts with optimal performance and precision. It includes recommendations on tolerances, hole design, radii, thread specifications, wall thickness, tool clearance, and surface finishes to ensure efficient and high-quality machining outcomes.