Precision Electrical Discharge Machining (EDM) Service

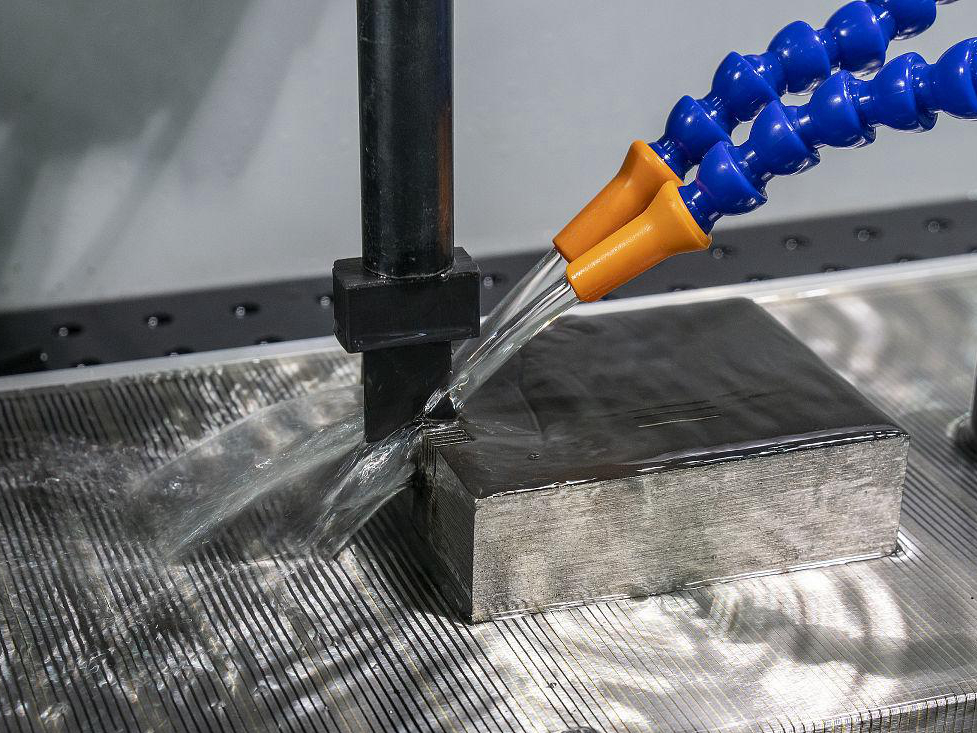

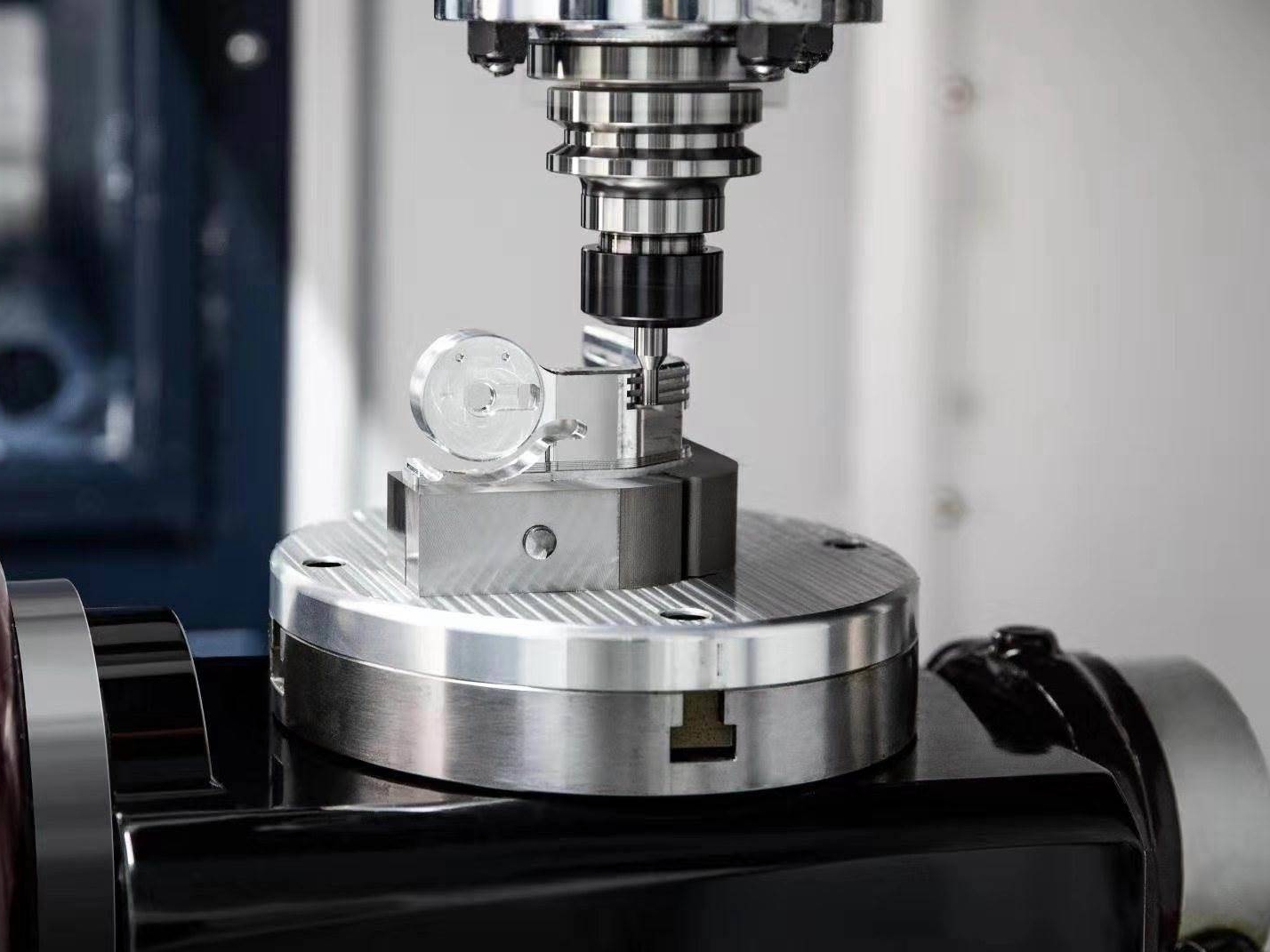

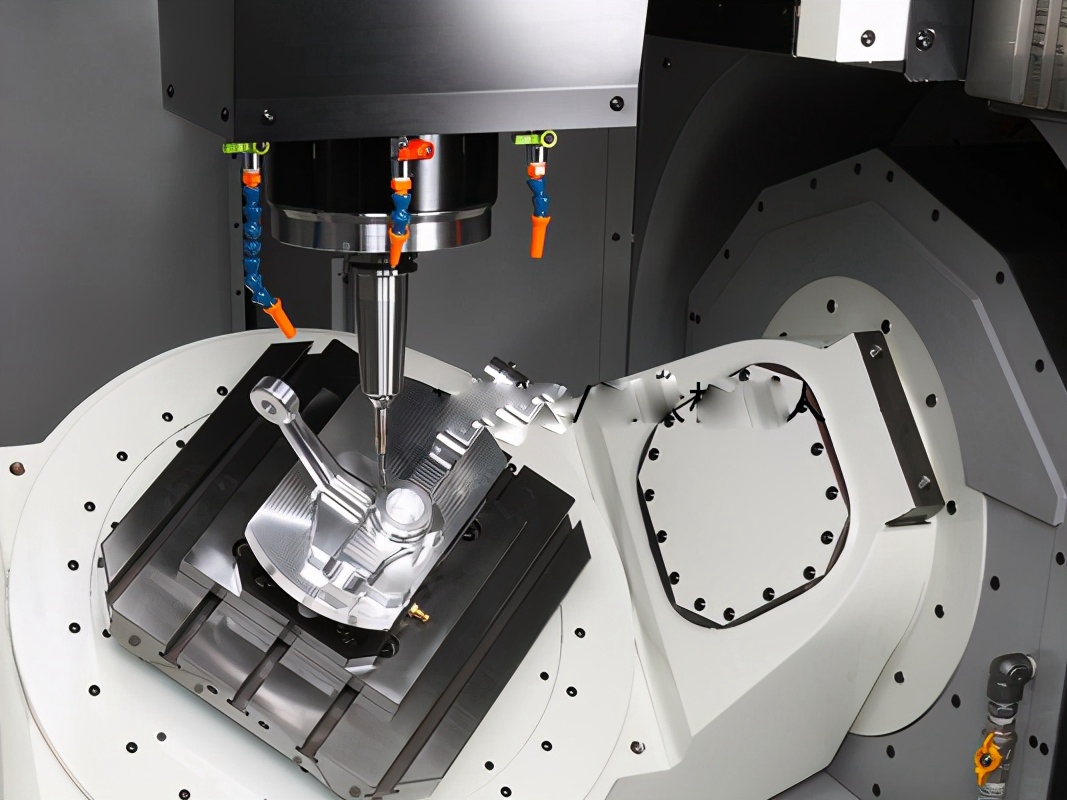

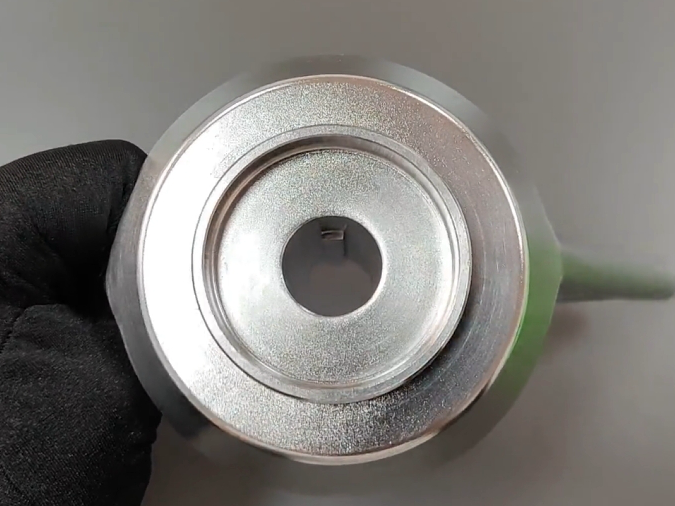

Precision Electrical Discharge Machining (EDM) service utilizes controlled electrical sparks to precisely machine hard materials and complex shapes. Ideal for intricate designs, tight tolerances, and difficult-to-machine materials, EDM ensures high accuracy, smooth finishes, and minimal material deformation in manufacturing.

Send us your designs and specifications for a free quotation

All uploaded files are secure and confidential

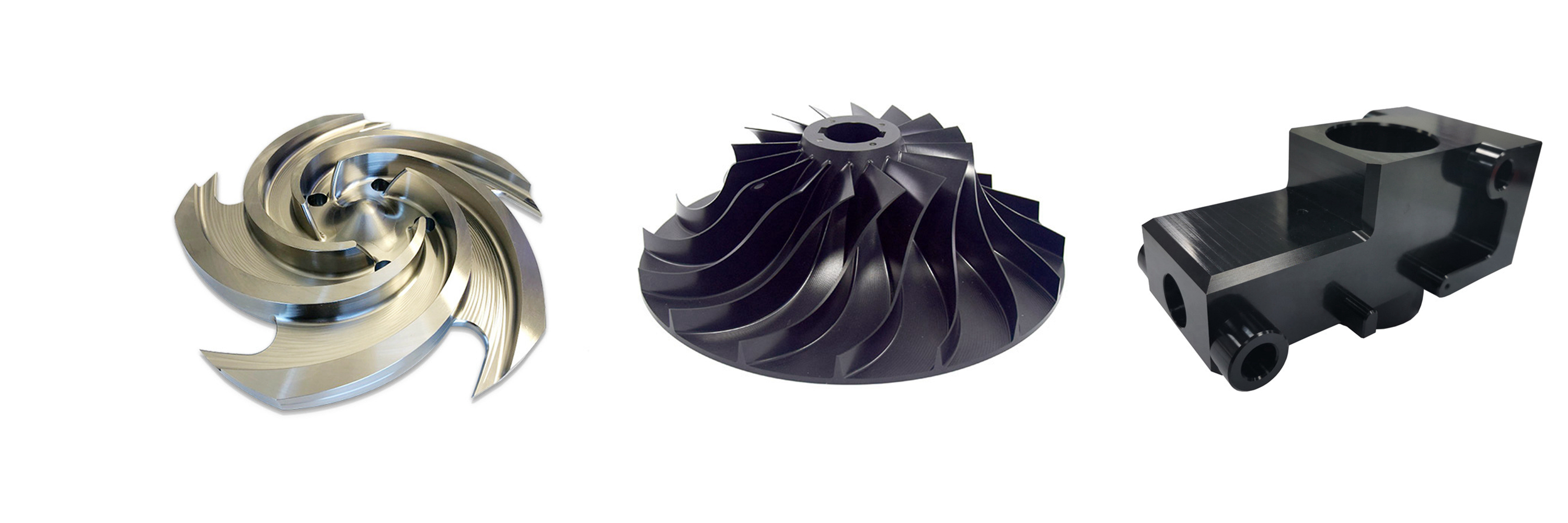

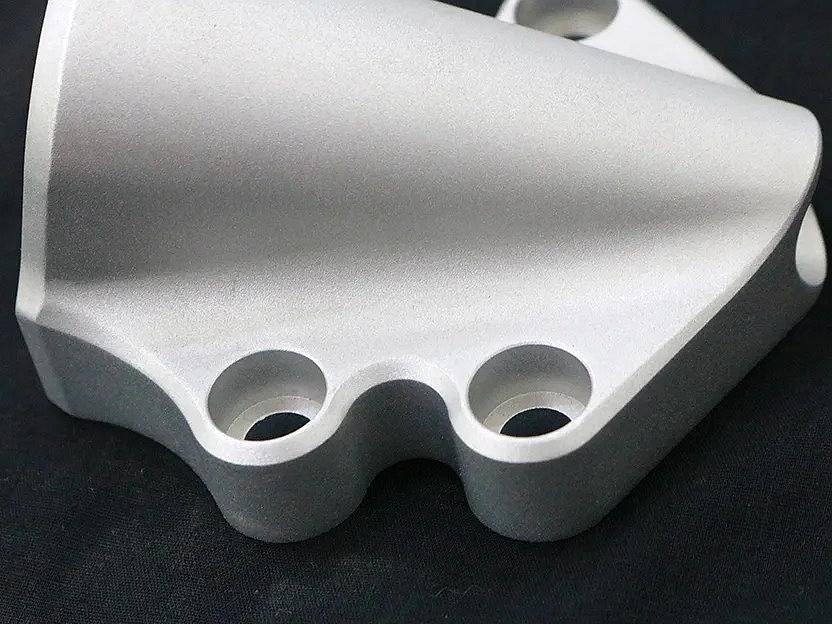

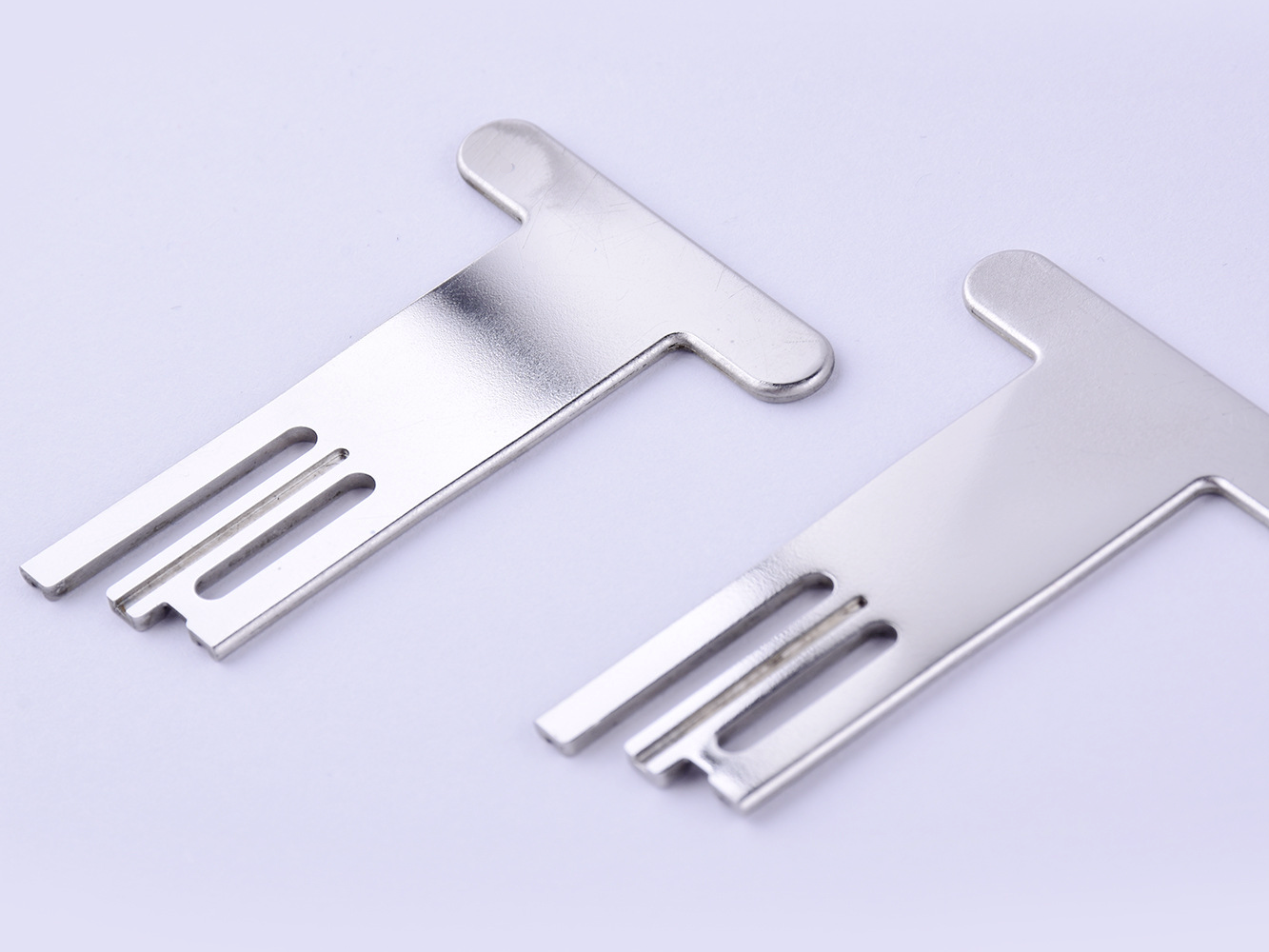

Electrical Discharge Machining (EDM) Applications

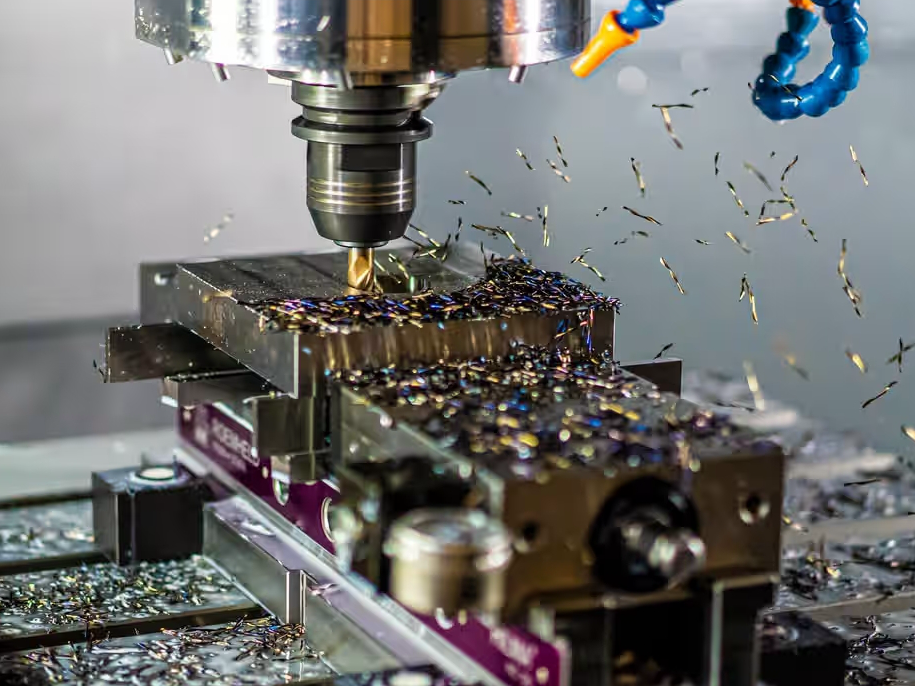

Precision Electrical Discharge Machining (EDM) applications involve creating intricate, high-precision components by eroding hard materials with electrical sparks. Ideal for complex shapes, tight tolerances, and tough materials, EDM is widely used in aerospace, medical, automotive, and tooling industries.

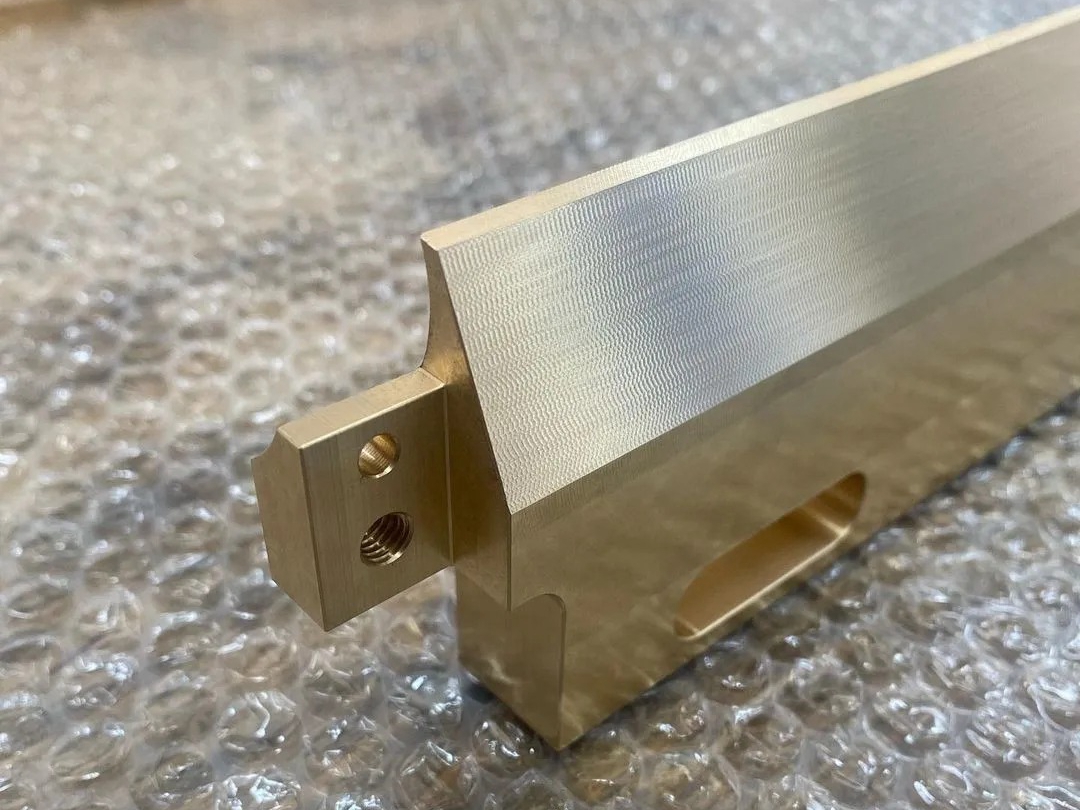

Electrical Discharge Machining Materials

Electrical Discharge Machining (EDM) is used to precisely shape hard materials like superalloys, titanium, and stainless steel. It’s also effective for machining conductive metals such as aluminum, copper, brass, and bronze. EDM can process a variety of materials, including carbon steel, plastics, and ceramics, offering versatility in manufacturing complex components with high precision and minimal material stress.

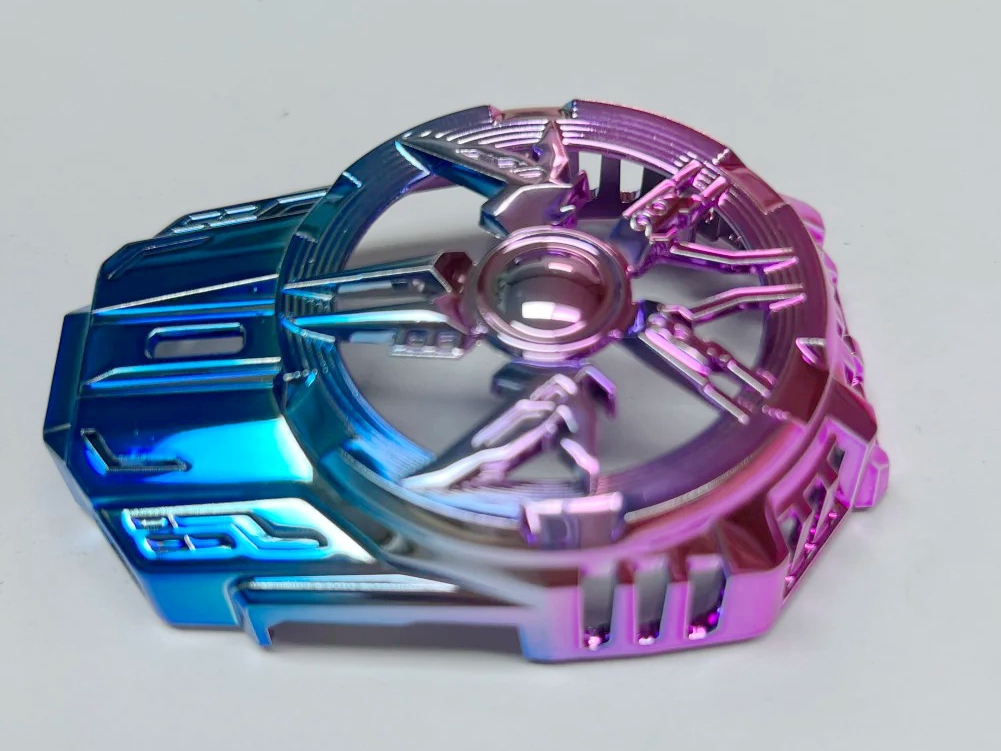

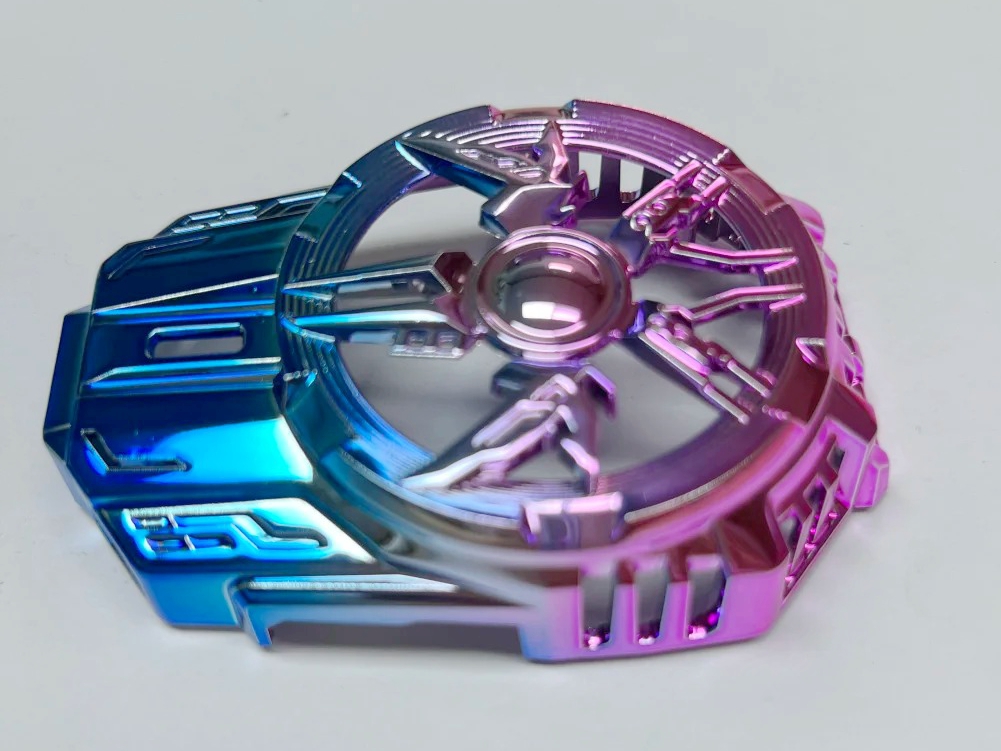

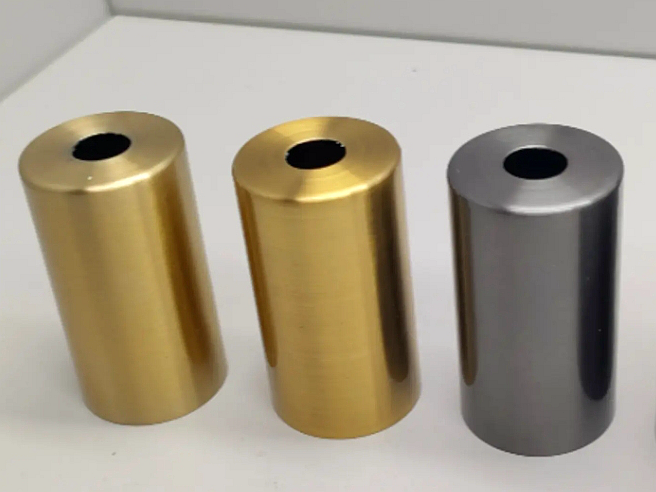

Surface Treatment for EDM Parts

Surface treatment for EDM parts enhances durability, corrosion resistance, and appearance. Techniques like polishing, coating, and nitriding improve the surface integrity, reduce wear, and extend the lifespan of EDM-manufactured components, ensuring optimal performance in demanding industrial applications.

learn more

Thermal Coating

learn more

As Machined

learn more

Painting

learn more

PVD (Physical Vapor Deposition)

learn more

Sandblasting

learn more

Electroplating

learn more

Polishing

learn more

Anodizing

learn more

Powder Coating

learn more

Electropolishing

learn more

Passivation

learn more

Brushing

learn more

Black Oxide

learn more

Heat Treatment

learn more

Thermal Barrier Coating (TBC)

learn more

Tumbling

learn more

Alodine

learn more

Chrome Plating

learn more

Phosphating

learn more

Nitriding

learn more

Galvanizing

learn more

UV Coating

learn more

Lacquer Coating

learn more

Teflon Coating

Let's Start A New Project Today

EDM Machining Tolerance Suggestions

EDM machining tolerance suggestions provide guidance for achieving high precision in complex components. By selecting appropriate tolerances—such as ±0.1 mm for general use and ±0.005 mm for high-precision parts—manufacturers can optimize performance, minimize errors, and meet stringent design requirements.

EDM Machining Design Guideline

EDM machining design guidelines ensure efficient and accurate production of complex parts. By considering factors like electrode design, radii, hole placement, surface finish, and tolerance, manufacturers can achieve optimal results, reduce tool wear, and meet high-precision requirements effectively.