Precision Online Multi-Axis Machining Service

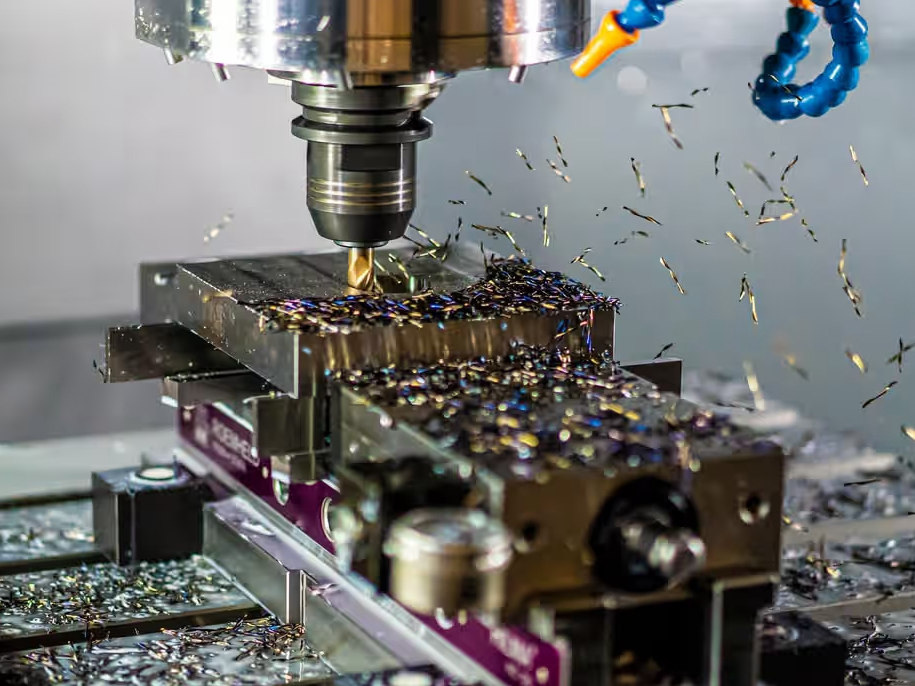

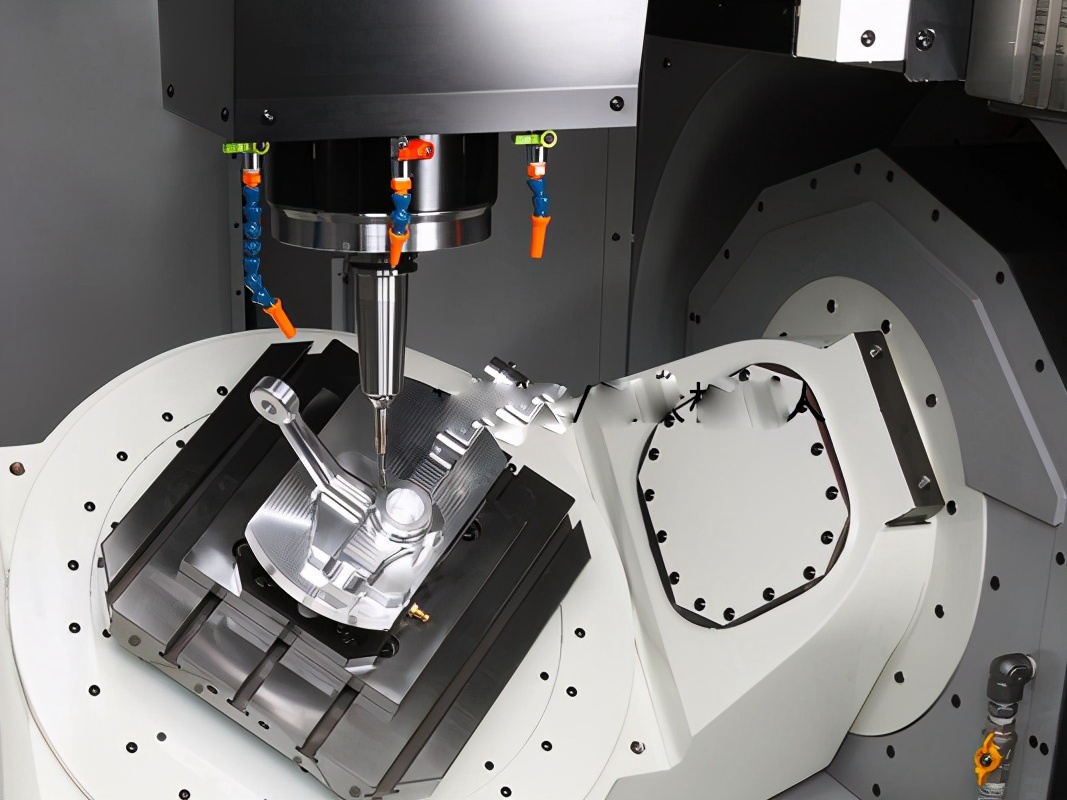

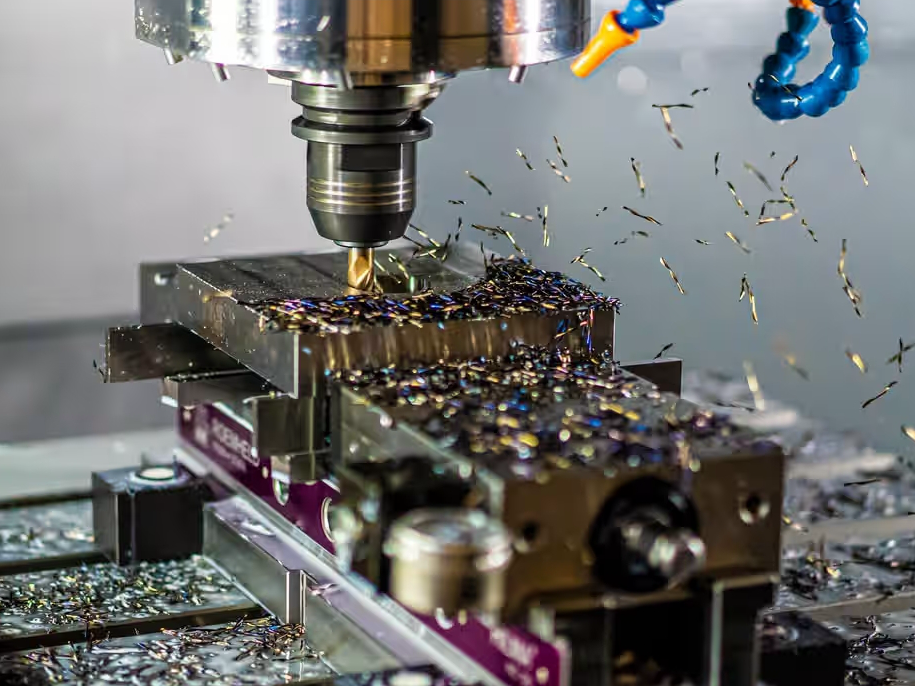

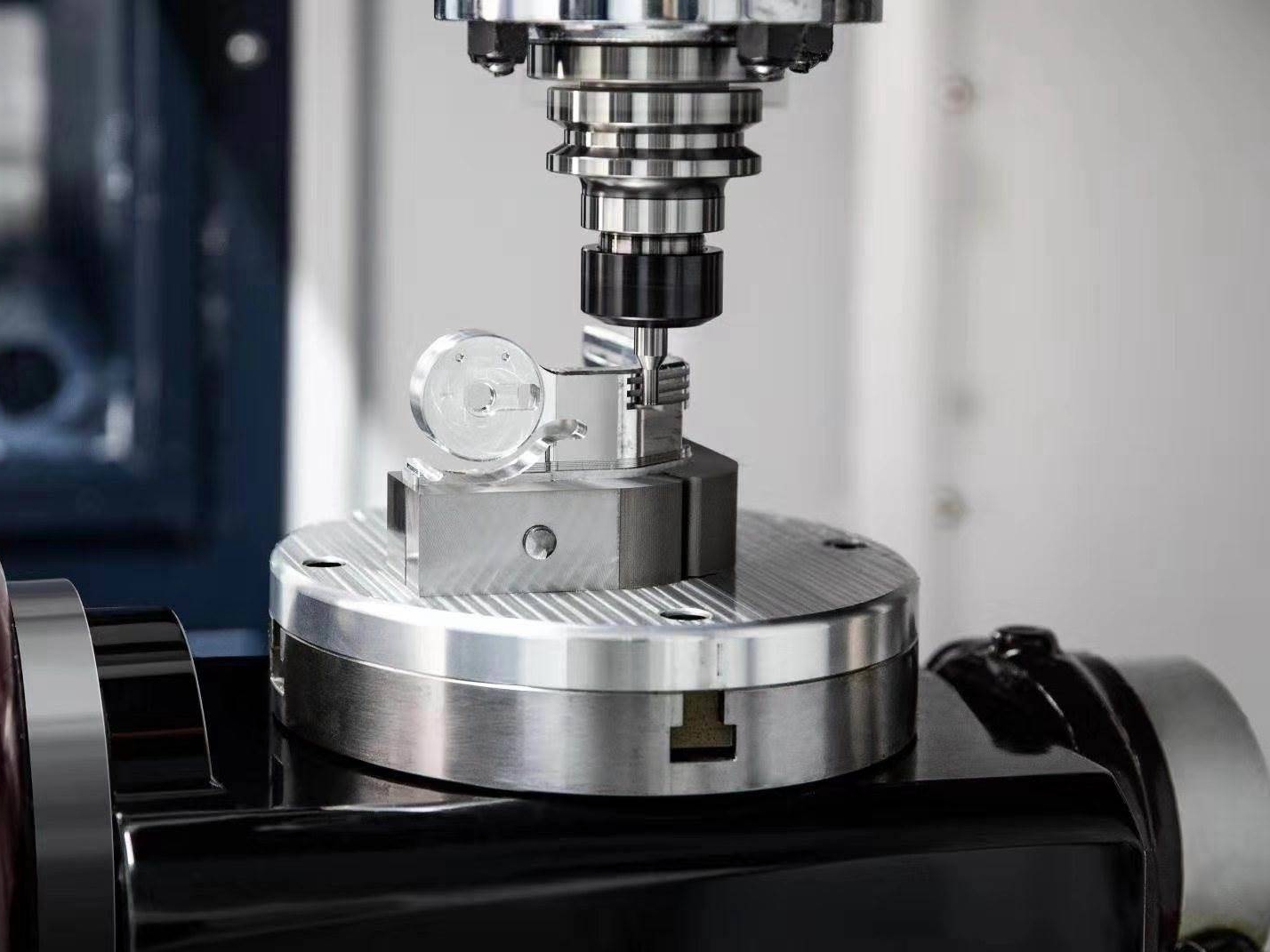

Precision Online Multi-Axis Machining Service offers advanced 3, 4, and 5-axis machining for complex parts with high precision. This service enables intricate geometries, tight tolerances, and smooth finishes, ideal for aerospace, automotive, medical, and other high-precision applications.

- Rapid Multi-Axis Machining Prototyping Service

- Low Volume Multi-Axis Machining Service

- Multi-Axis Machining Mass Production Service

- One Stop Multi-Axis Machining Service

Send us your designs and specifications for a free quotation

All uploaded files are secure and confidential

Precision Custom Multi-Axis Machining Manufacturing

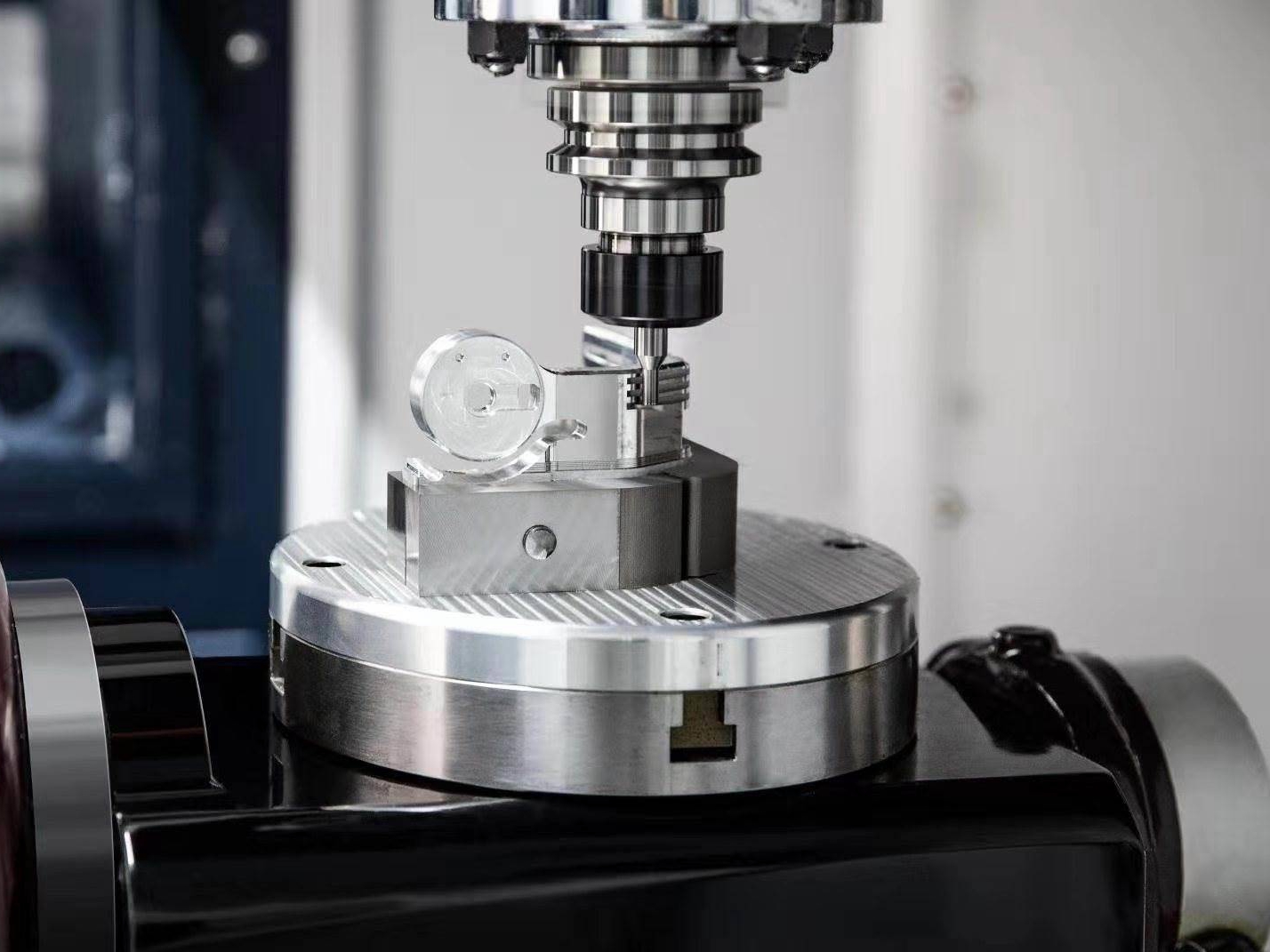

Precision Custom Multi-Axis Machining Manufacturing provides tailored solutions for complex components using 3, 4, and 5-axis CNC machines. This advanced machining process ensures high precision, tight tolerances, and intricate geometries, making it ideal for aerospace, medical, and automotive industries.

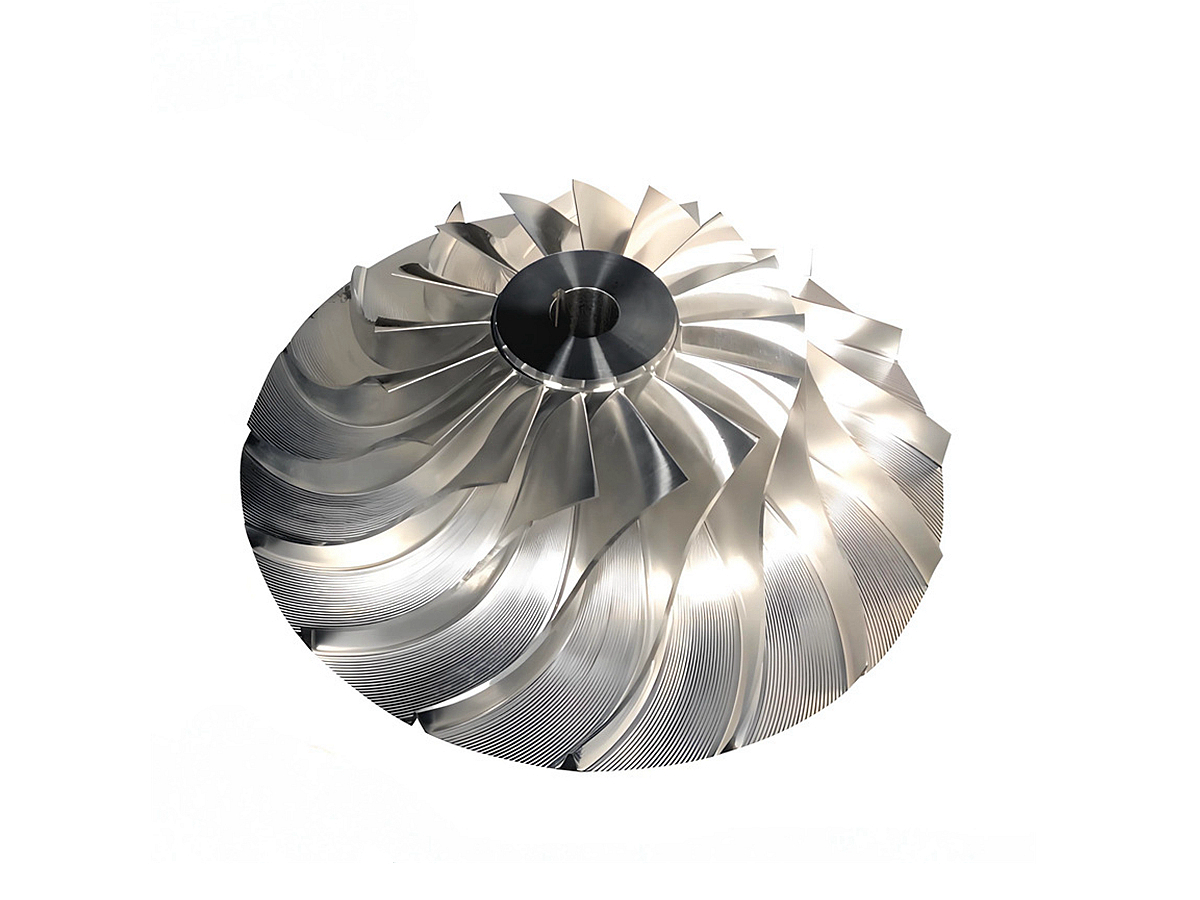

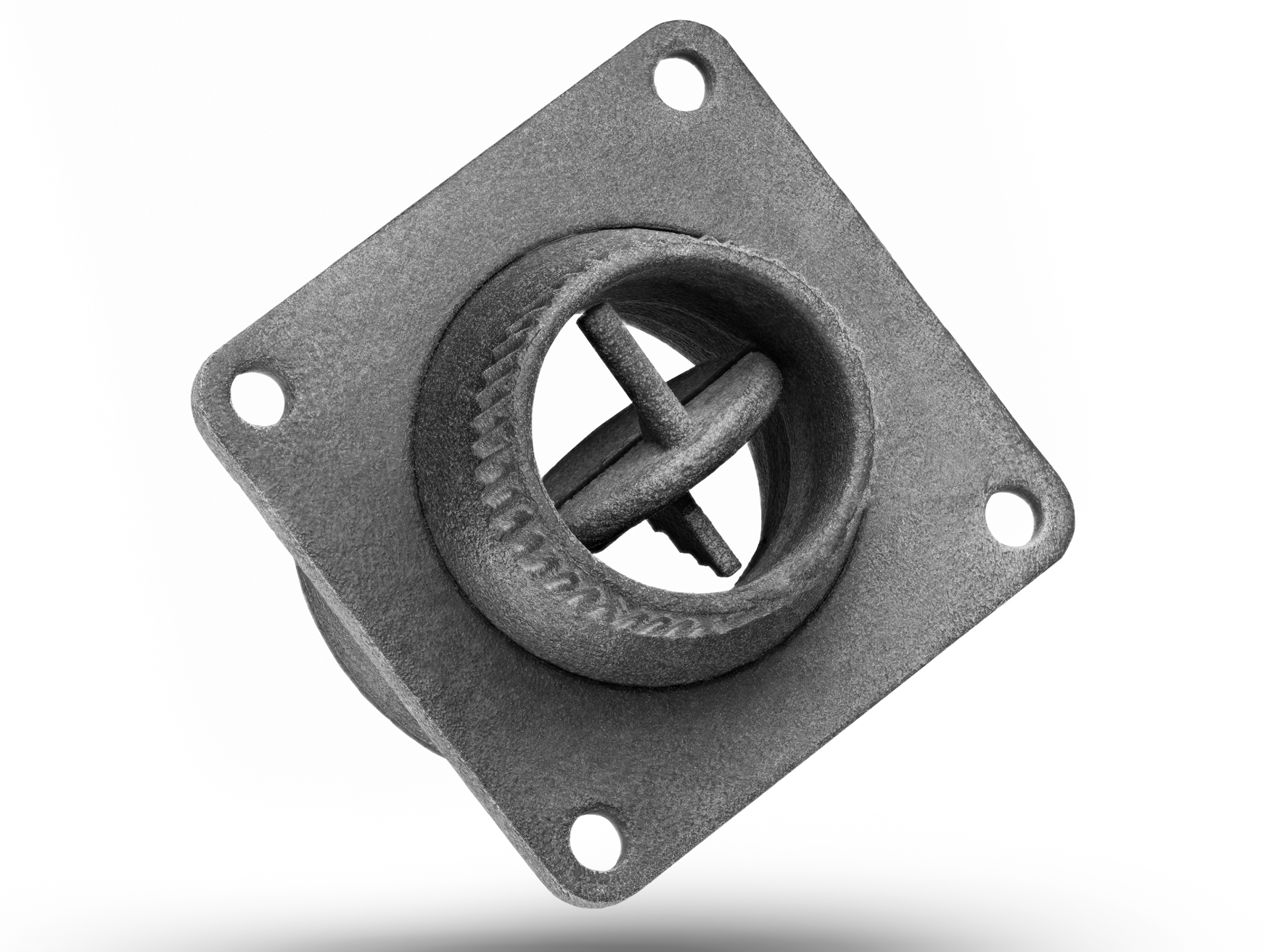

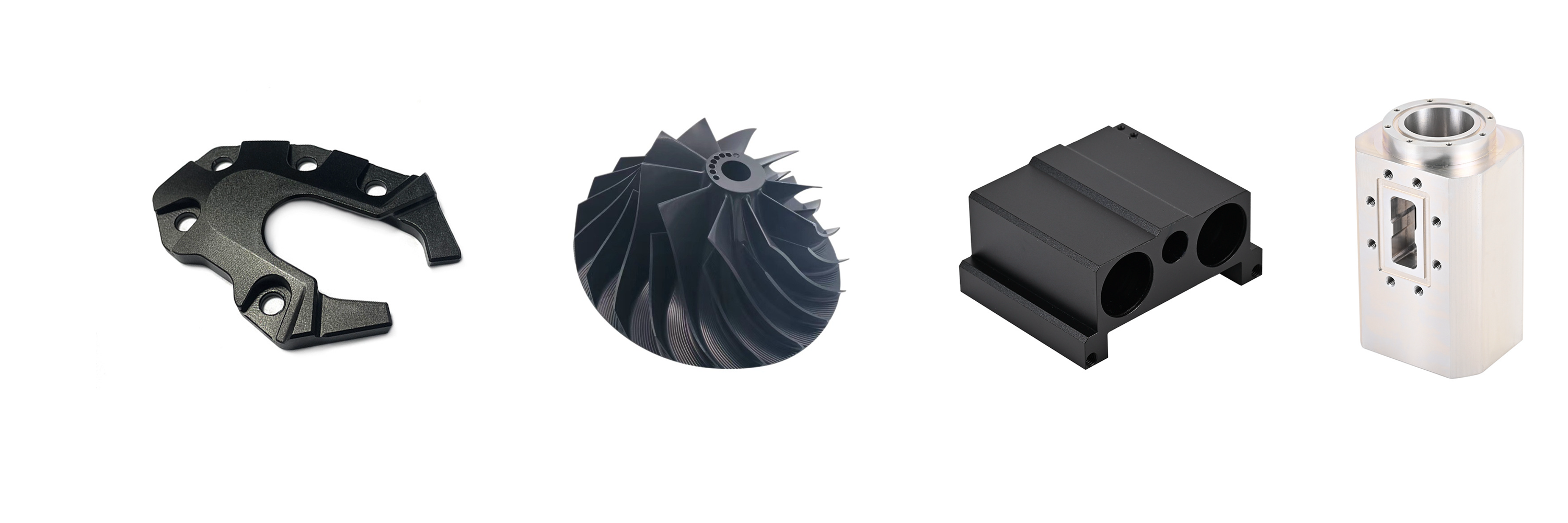

Custom Multi Axis CNC Machining Applications

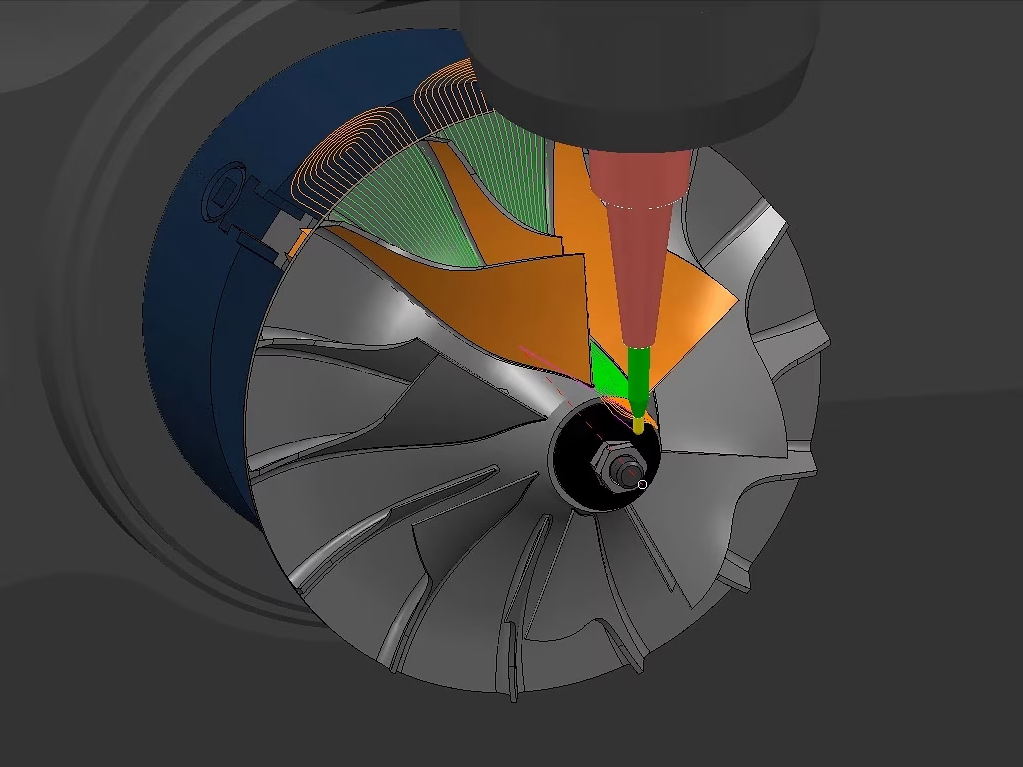

Custom Multi-Axis CNC Machining Applications enable precise manufacturing of complex components across industries like aerospace, medical, and automotive. Typical applications include turbine blades, surgical instruments, and transmission components, ensuring tight tolerances, intricate geometries, and superior performance for demanding projects.

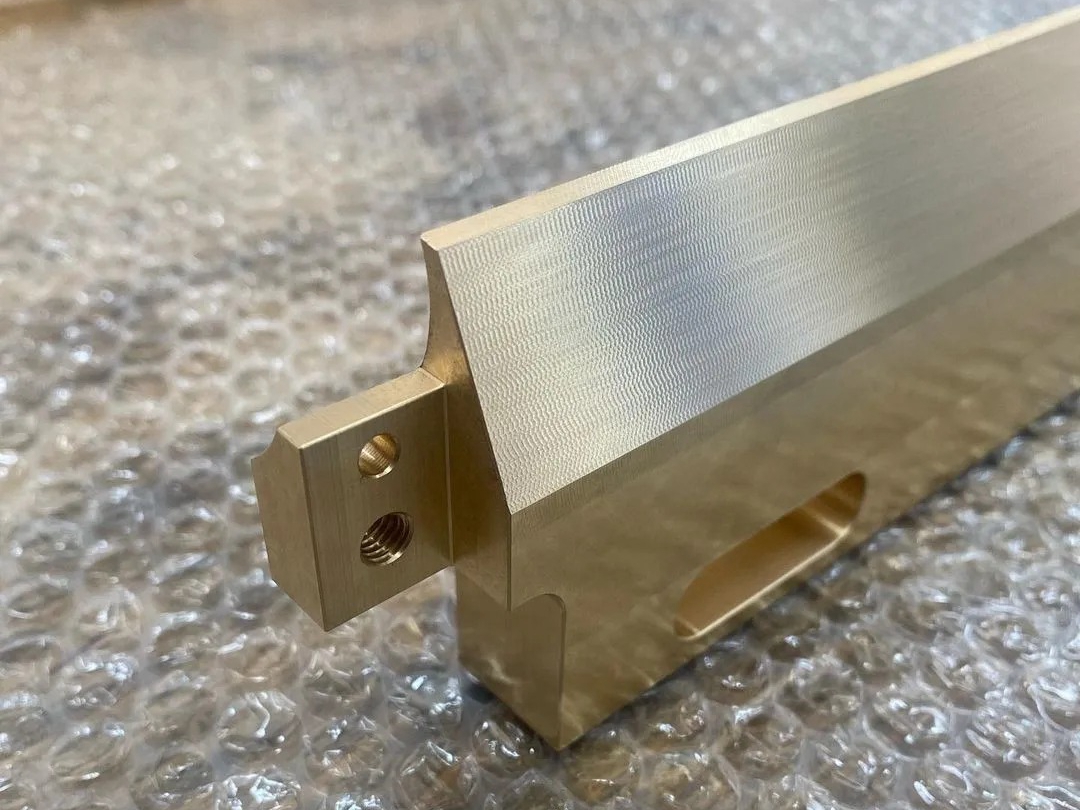

Multi Axis CNC Machining Materials

Multi-axis CNC machining is versatile, accommodating a wide range of materials, including superalloys, titanium, aluminum, copper, brass, bronze, carbon steel, stainless steel, plastic, and ceramics. These materials are chosen for their unique properties, such as strength, corrosion resistance, and precision, making them ideal for industries like aerospace, automotive, medical, and manufacturing where high-performance components are essential.

Multi-Axis CNC Machined Parts Surface Treatment

Multi-Axis CNC Machined Parts Surface Treatment enhances the durability, appearance, and performance of complex components. Common treatments include anodizing, plating, polishing, coating, and heat treatment, ensuring parts meet industry standards for corrosion resistance, hardness, and surface finish.

learn more

Thermal Coating

learn more

As Machined

learn more

Painting

learn more

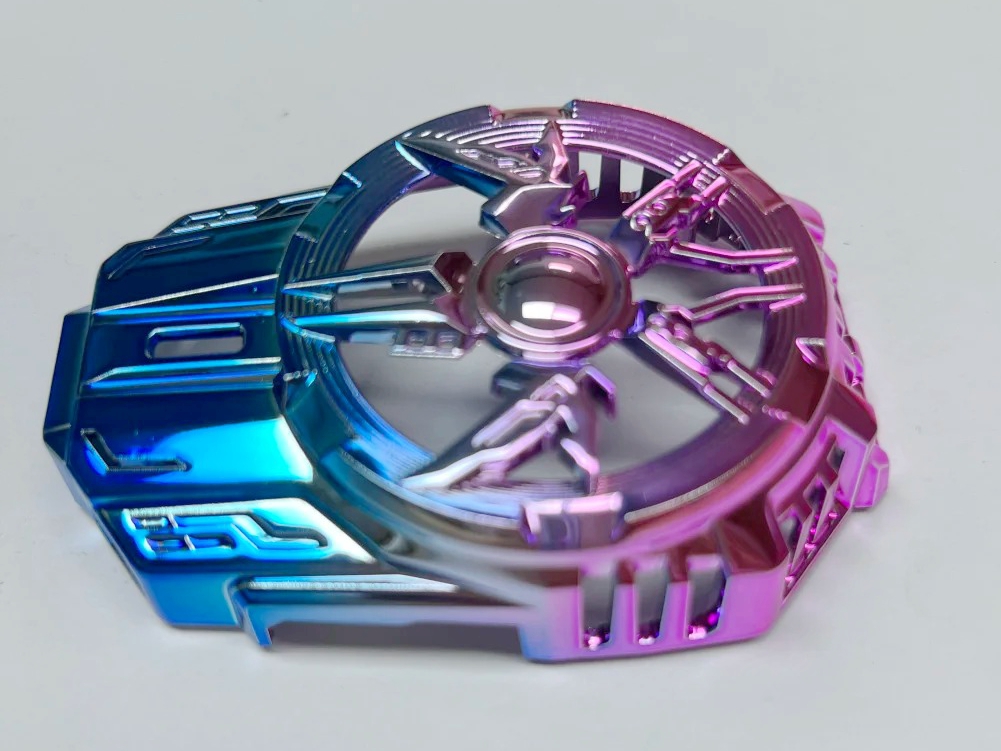

PVD (Physical Vapor Deposition)

learn more

Sandblasting

learn more

Electroplating

learn more

Polishing

learn more

Anodizing

learn more

Powder Coating

learn more

Electropolishing

learn more

Passivation

learn more

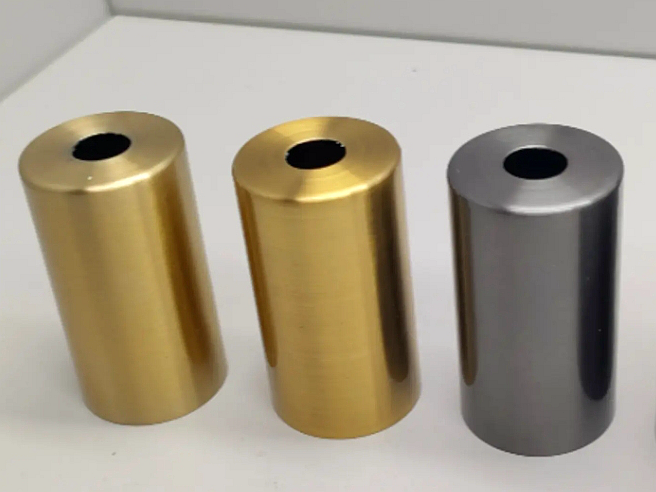

Brushing

learn more

Black Oxide

learn more

Heat Treatment

learn more

Thermal Barrier Coating (TBC)

learn more

Tumbling

learn more

Alodine

learn more

Chrome Plating

learn more

Phosphating

learn more

Nitriding

learn more

Galvanizing

learn more

UV Coating

learn more

Lacquer Coating

learn more

Teflon Coating

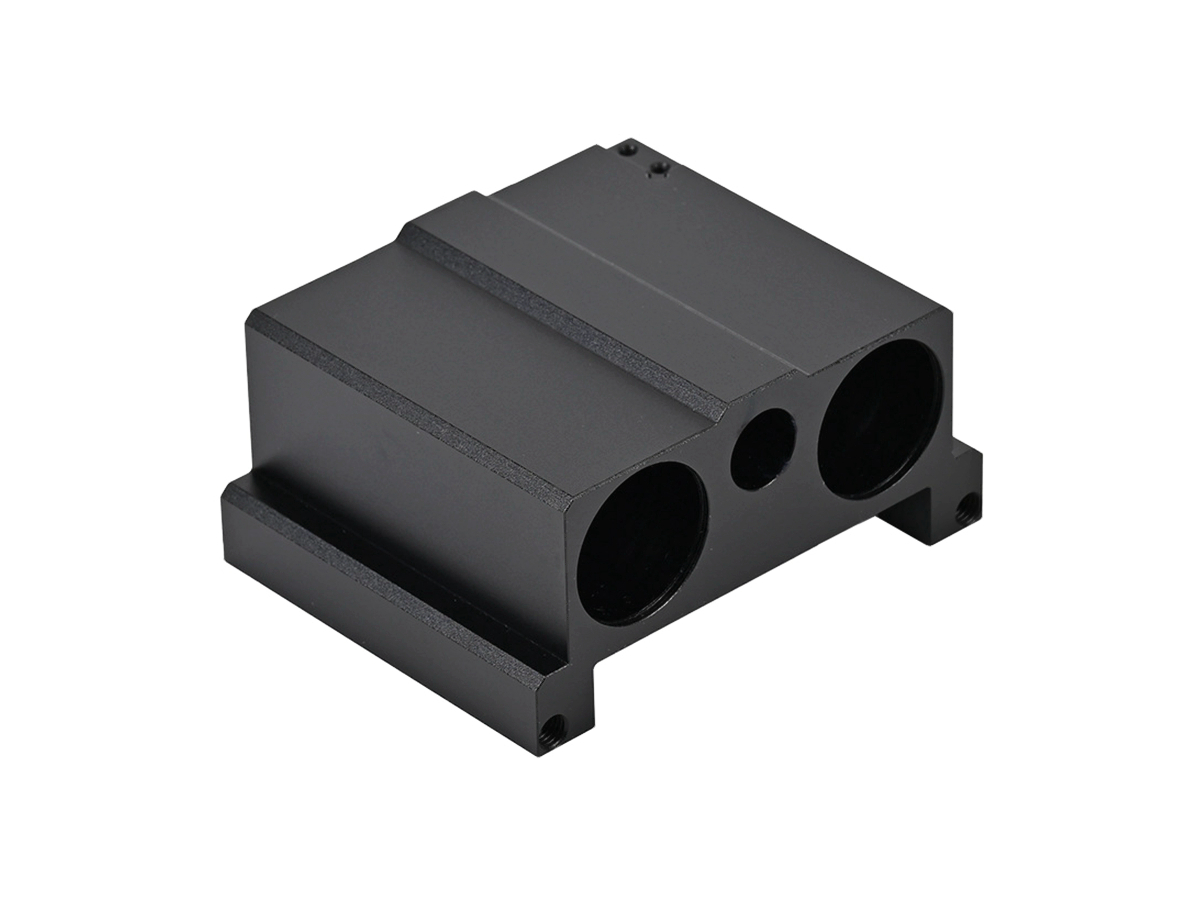

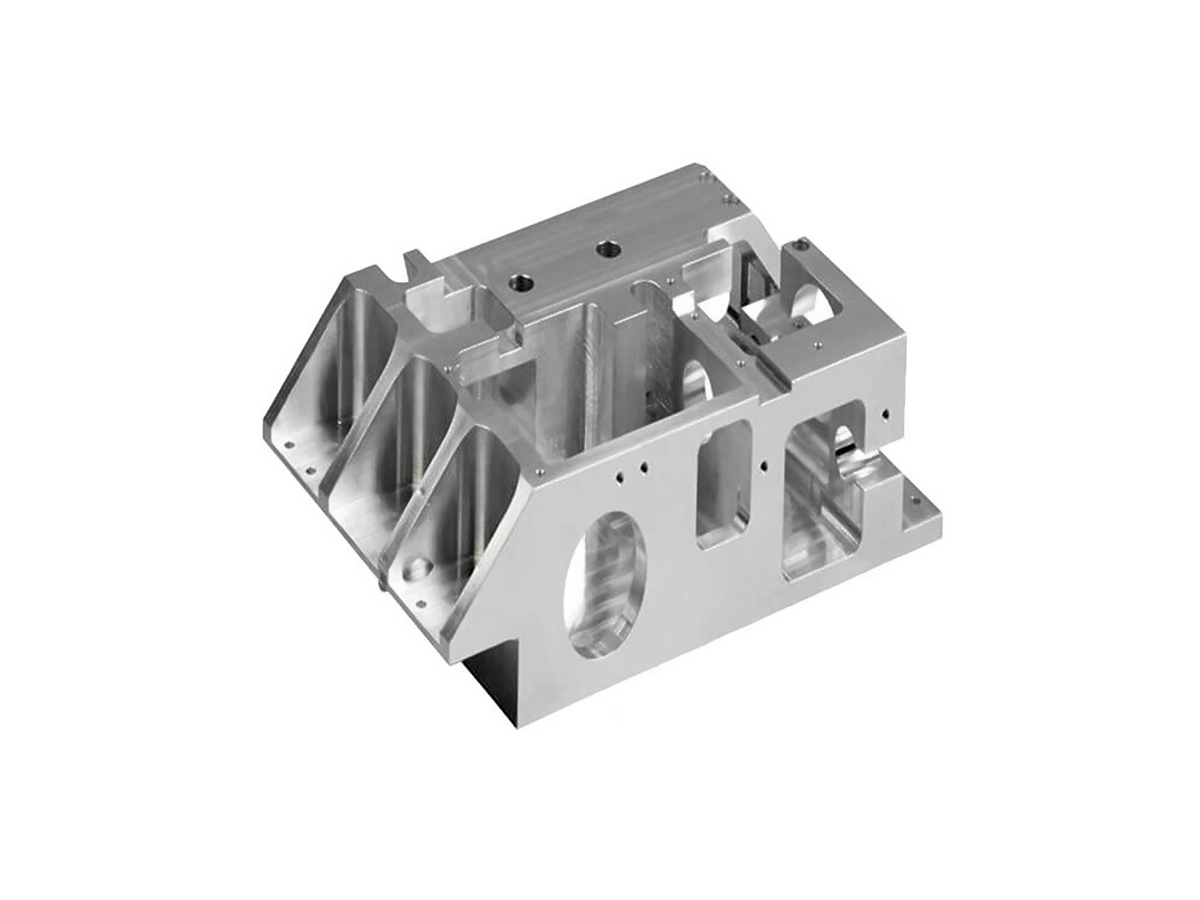

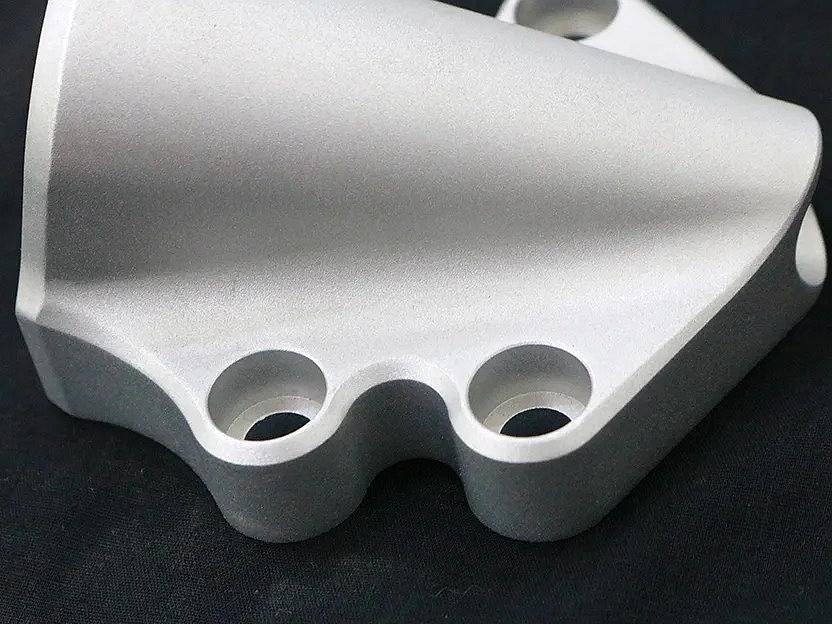

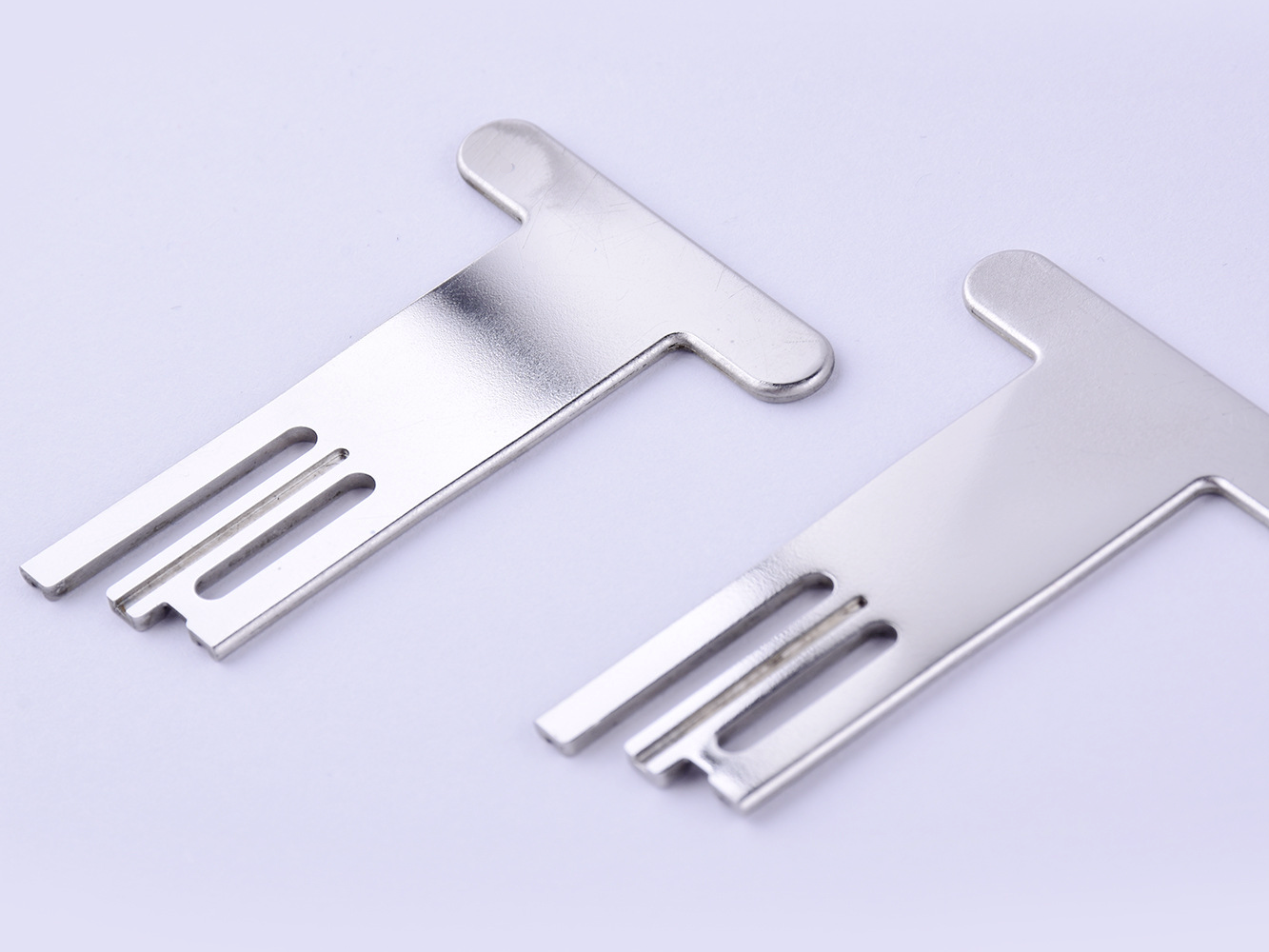

Multi-Axis CNC Machined Parts Case Study

Multi-Axis CNC Machined Parts Case Study showcases the precision and efficiency of complex part manufacturing across industries. The study highlights real-world applications, demonstrating how multi-axis machining enhances performance, reduces production time, and achieves tight tolerances for critical components.

Let's Start A New Project Today

Multi-Axis CNC Machining Tolerance Suggestions

Multi-Axis CNC Machining Tolerance Suggestions provide guidance on achieving precise dimensional accuracy in complex parts. Recommended tolerances depend on material, geometry, and machining process, ensuring optimal fit and function while minimizing errors and improving overall part performance and quality.

Multi-Axis CNC Machining Design Guideline

Multi-Axis CNC Machining Design Guideline offers best practices for creating complex parts with precision and efficiency. It includes recommendations for tool accessibility, part orientation, tolerance considerations, and material selection, ensuring optimal machining results and high-quality, cost-effective manufacturing.